Page 32: of Maritime Reporter Magazine (March 1974)

Read this page in Pdf, Flash or Html5 edition of March 1974 Maritime Reporter Magazine

B&W To Supply

Six Marine Boilers For

Three Merchant Ships

National Steel & Shipbuilding

Company (NASSCO) of San Diego,

Calif., has ordered six two-drum Bab- cock & Wilcox marine boilers valued at approximately $1.4 million.

According to a NASSCO spokes- man, the boilers will be installed aboard three 38,000-ton oil/gasoline/ kerosene tankers being built at a cost of over $65 million for the Moore &

McCormack Co.

Each of the boilers is designed to generate 57,030 pounds of steam per hour, with a superheater outlet pres- sure of 615 pounds per square inch, and temperature of 905 .degrees Fah- renheit when firing at the normal load rate of 4,035 pounds of No. 6 oil per hour.

All of the units will be equipped with a superheater, extended surface economizer, steam air heater and two

B&W Saratoga-type oil burners with racer steam atomizers.

The vessels, scheduled for delivery in October 1975, June 1976 and Janu- ary 1977, will have a shallow draft of 35 feet, a service speed of 16 knots, automated engine rooms, and semi-automated cargo control sys- tems.

B&W's Bailey Meter Company of

Wickliffe, Ohio, will provide bridge- controlled combustion and turbine throttle controls. The combustion controls feature fluidic burner man- agement for reduced manning re- quirements. The Bailey systems will be designed for future unmanned en- gine room use. B&W's Diamond

Power Specialty Corporation of Lan- caster, Ohio, will provide boiler clean- ing equipment.

The boilers will be designed at

B&W's Coventry, Ohio, detail engi- neering offices near Akron, Ohio.

Component manufacturing has been assigned to B&W Power Generation

Group facilities located in Paris, Tex- as, West Point, Miss., and Wilming- ton, N.C.

Boiler shipsets are scheduled for shipment in September, November and December 1974.

C.J. Hendry Co.

Appoints John Iamarino

John Iamarino

Fred Barg, vice president of C.J.

Hendry Co., San Francisco, Calif.- based ship chandlery firm since 1865, has announced the appoint- ment of John Iamarino as manager of their San Pedro branch. He re- places Dan Baldwin, who has re- tired after serving C.J. Hendry for 38 years in the southern California area.

For the past 10 years, Mr. Iama- rino has worked very closely with and around the maritime industry.

From 1963 to 1967, he worked at

Litton Industries while attending

San Diego College, graduating in 1967 with a business management degree. For the next six years, he was northern California sales repre- sentative for the Macwhyte Wire

Rope Co., a division of Amsted.

The San Pedro branch services accounts in the marine industry from San Diego to Santa Barbara, from their stock warehoused in their facility at 761 Channel Street.

C.J. Hendry Co. is considered to be one of the finest, if not the oldest, complete chandlery firms on the

West Coast. They are one of the few firms operating today who manufacture their own line of products. Among the most well- known are the Sea Jay Elliot USCG approved life raft, the Raftgo® Hy- drostatic Release used on most

US'OG approved life rafts, the Sea

Jay YFC life raft, the Sea Jay Anti-

Exposure Covers to USCG specifi- cations and custom canvas/synthet- ic hatch and boat covers, nets, lad- ders and slings.

Manufacturers represented in- clude Cleco Air Tools, MSA (Mine

Safety Appliances), Samson Cor- dage, Baltimore Copper Paint, Co- lumbian Rope, Kilgore Safety

Equipment, Dupont Freon and

General Electric lamps.

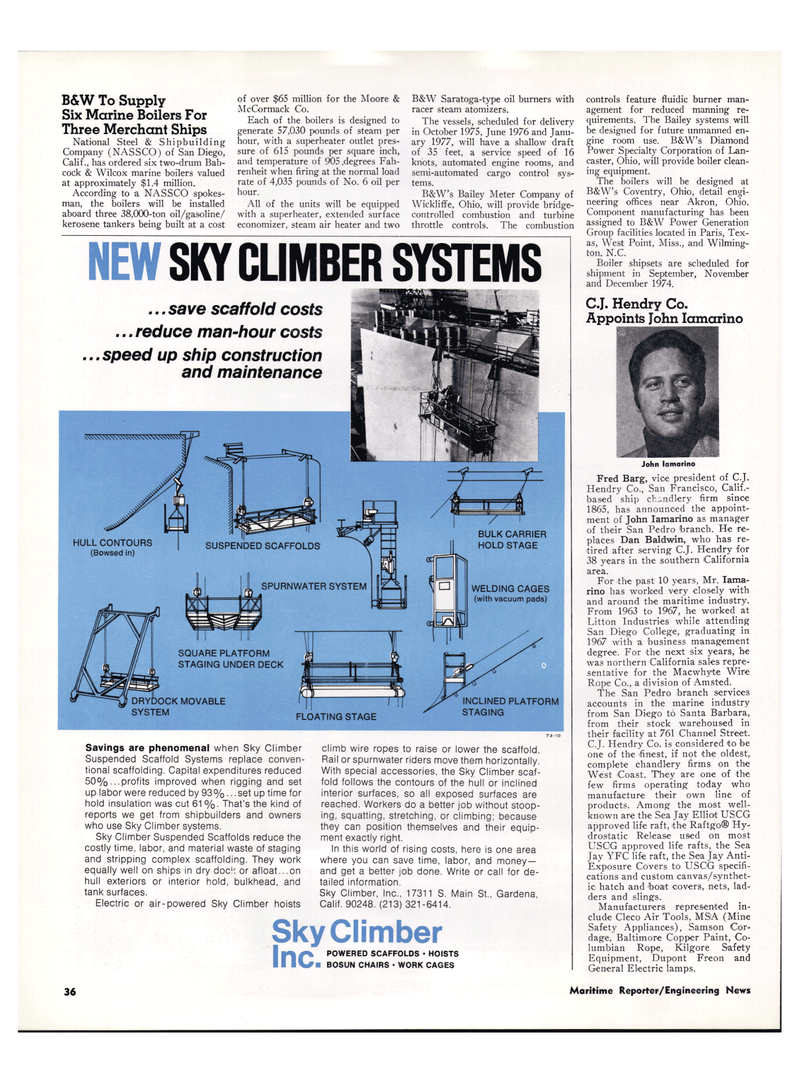

NEW SKY CUMBER SYSTEMS ... save scaffold costs ... reduce man-hour costs speed up ship construction and maintenance

HULL CONTOURS (Bowsed in)

SUSPENDED SCAFFOLDS

SPURNWATER SYSTEM

BULK CARRIER

HOLD STAGE

WELDING CAGES (with vacuum pads)

SQUARE PLATFORM

STAGING UNDER DECK

OCK MOVABLE

SYSTEM FLOATING STAGE

INCLINED PLATFORM

STAGING

Savings are phenomenal when Sky Climber

Suspended Scaffold Systems replace conven- tional scaffolding. Capital expenditures reduced 50%...profits improved when rigging and set up labor were reduced by 93%.. .set up time for hold insulation was cut 61 %. That's the kind of reports we get from shipbuilders and owners who use Sky Climber systems.

Sky Climber Suspended Scaffolds reduce the costly time, labor, and material waste of staging and stripping complex scaffolding. They work equally well on ships in dry doc!- or afloat...on hull exteriors or interior hold, bulkhead, and tank surfaces.

Electric or air-powered Sky Climber hoists climb wire ropes to raise or lower the scaffold.

Rail or spurnwater riders move them horizontally.

With special accessories, the Sky Climber scaf- fold follows the contours of the hull or inclined interior surfaces, so all exposed surfaces are reached. Workers do a better job without stoop- ing, squatting, stretching, or climbing; because they can position themselves and their equip- ment exactly right.

In this world of rising costs, here is one area where you can save time, labor, and money— and get a better job done. Write or call for de- tailed information.

Sky Climber, Inc., 17311 S. Main St., Gardena,

Calif. 90248. (213) 321-6414.

Sky Climber Inc.

POWERED SCAFFOLDS • HOISTS

BOSUN CHAIRS • WORK CAGES 36 Maritime Reporter/Engineering News

31

31

33

33