Page 3rd Cover: of Maritime Reporter Magazine (July 15, 1977)

Read this page in Pdf, Flash or Html5 edition of July 15, 1977 Maritime Reporter Magazine

R.J. Reynolds Industries

Elects McEvoy To Board

Michael R. McEvoy

Michael R. McEvoy, executive vice president of R.J. Reynolds

Industries, Inc., Winston-Salem,

N.C., has been elected to the board of directors of the company.

Mr. McEvoy moved to the exec- utive vice presidency last Septem- ber from his position as chairman and chief executive officer of Sea-

Land Service, Inc., RJR's con- tainerized shipping business. As executive vice president, Mr.

McEvoy sits on the RJR manage- ment committee as the corporate executive responsible for the com- pany's transportation business.

Mr. McEvoy joined Sea-Land in 1956 as sales promotion manager.

He later served as vice president and general sales manager, assist- ant to the president, and president and general manager before be- coming chairman and chief exec- utive officer in 1970.

A native of Alabama, Mr.

McEvoy attended Auburn Univer- sity and worked as a newspaper reporter, editor and columnist for the Mobile Press Register before joining Sea-Land.

In addition to Sea-Land Serv- ice, Inc., R.J. Reynolds Industries,

Inc., a diversified worldwide cor- poration, is the parent company of R.J. Reynolds Tobacco Co.;

R.J. Reynolds Tobacco Inter- national, Inc.; Aminoil Interna- tional, Inc. (petroleum) ; RJR

Foods, Inc. (foods and bever- ages) ; and RJR Archer, Inc. (alu- minum products and packaging).

American Abrasive Metals

Announces New Non-Slip

Roll-On Safety Coating

A new non-slip coating, proven in use by the U.S. Navy, is now available as original safety equip- ment for new or existing ships and offshore rigs, regardless of age. The safety coating is manu- factured and marketed by Amer- ican Abrasive Metals Co.

Called Epoxo, the low-cost coat- ing simply rolls on in minutes to help stop slips and falls at sea.

Epoxo's unique high-traction sur- face protects personnel and equip- ment, as well as providing vital non-skid safety for helicopter land- ing pads on offshore rigs. The coating is easily applied by ship- yard or shipboard personnel. Sim- ply roll, trowel or spray on. A two-man team can roll on up to 1,000 square feet in only 60 min- utes.

Originally developed to meet critical requirements of the U.S.

Navy, Epoxo Non-Skid Coating has been installed on the entire flight deck of every aircraft car- rier constructed since 1960. Epoxo protects personnel, rolling equip- ment and aircraft under the rig- orous conditions of carrier flight deck operations.

For the first time, this profes- sional non-slip coating is offered to the commercial marine and off- shore industry. With Epoxo, na- val architects and everyone con- cerned with marine safety can now specify professional non-slip safety as an integral part of de- sign for ships and offshore rigs.

Because of its special blend of resins, Epoxo is unaffected by seawater, oil, gasoline, grease, most chemicals, hydraulic fluids, acids, alkalines, solvents and de- tergents.

Long-lasting, economical Epoxo can be applied to any properly prepared, clean, sound surface.

For a free sample and literature, write to Sheldon Rovener, Amer- ican Abrasive Metals Co., 460 Coit

Street, Irvington, N.J. 07111.

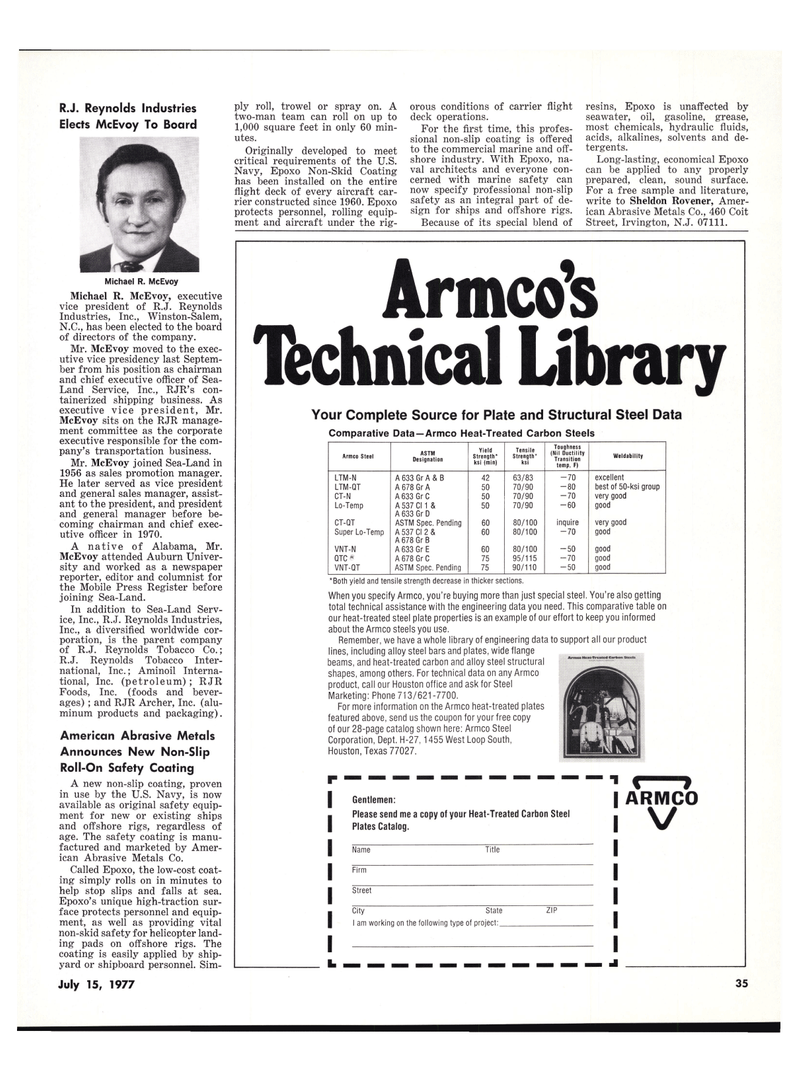

Armco's Technical Library

Your Complete Source for Plate and Structural Steel Data

Comparative Data —Armco Heat-Treated Carbon Steels

Armco Steel flSTM Designation

Yield

Strength" ksi (min)

Tensile

Strength* ksi

Toughness (Nil Ductility

Transition temp, F)

Weldability

LTM-N A 633 Gr A & B 42 63/83 -70 excellent

LTM-QT A 678 Gr A 50 70/90 -80 best of 50-ksi group

CT-N A 633 Gr C 50 70/90 -70 very good

Lo-Temp A 537 C11 & 50 70/90 -60 good

A 633 Gr D

CT-QT ASTM Spec. Pending 60 80/100 inquire very good

Super Lo-Temp A 537 CI 2 & 60 80/100 -70 good

A 678 Gr B

VNT-N A 633 Gr E 60 80/100 -50 good

QTC " A 678 Gr C 75 95/115 -70 good

VNT-QT ASTM Spec. Pending 75 90/110 -50 good *Both yield and tensile strength decrease in thicker sections.

When you specify Armco, you're buying more than just special steel. You're also getting total technical assistance with the engineering data you need. This comparative table on our heat-treated steel plate properties is an example of our effort to keep you informed about the Armco steels you use.

Remember, we have a whole library of engineering data to support all our product lines, including alloy steel bars and plates, wide flange beams, and heat-treated carbon and alloy steel structural shapes, among others. For technical data on any Armco product, call our Houston office and ask for Steel

Marketing: Phone 713/621 -7700.

For more information on the Armco heat-treated plates featured above, send us the coupon for your free copy of our 28-page catalog shown here: Armco Steel

Corporation, Dept. H-27,1455 West Loop South,

Houston, Texas 77027.

Gentlemen:

Please send me a copy of your Heat-Treated Carbon Steel

Plates Catalog.

Name Title

Firm

Street

City State ZIP

I am working on the following type of project:

ARMCO

V

July 15, 1977 35

32

32

4th Cover

4th Cover