Marystown Shipyard Reports On Progress Of $23-Million Norwegian Tugboat Contract

Marystown Shipyard Limited, Marystown, Newfoundland, Canada, now currently working on a $23-million Norwegian order to build five of the heaviest class of tugboats used in offshore oil operations, is now establishing a vessel production control system, extending its production facility and building a new plumber's shop.

Anthony Barclay, Marystown's general manager, said this expansion program is on top of a recent building program which included a new 200-foot-long fitting-out dock, a 7,600-square-foot sheet metal shop for light fabrication, and a 1,200-square-foot assembly bay for specialized custom-built contracts.

Commenting on Marystown's expansion program, Mr. Barclay said: "Thanks to our expansion, Marystown is emerging as one of North America's most efficient and well-equipped shipbuilding and ship repair facilities of its size." Easily accessible to the North Atlantic shipping lanes, the 10- year-old Canadian shipyard is owned by the Newfoundland Government.

Commenting on future sales possibilities, John Lundrigan, the province's Minister of Industrial Development, said: "We are pleased with our performance to date on the tugboat order for Norway, and we are currently bidding on orders from the Middle East, Europe, the Far East, and Southeast Asia. Marystown's expansion should put us in a good position to win some of these new contracts, as well as construction of trawlers resulting from Canada's new 200-mile fishing limit." Helping Marystown Shipyard secure new international orders are its agents located in Norway, West Germany, the Netherlands, and Singapore.

The current $23-million order for five super tugboats is for K-S Normand Tugs A.S. of Skudenshaven, Norway, which will use them in North Sea oil work. The Norwegian company already has nine supply boats operating there, but the 140-foot-long anchorhandling tugboats being built in Newfoundland will feature an 80- ton bollard pull, and each will be equipped with 6,000-horsepower twin-screw controllable-pitch propellers.

According to Mr. Barclay, the first tug for Normand will be completed this fall by the work force of 350. Two of the vessels are on the berth, with steel work almost complete. The first units of the third were erected in July.

One reason why Marystown Shipyard Ltd. is highly regarded is its "under cover" facilities, where construction can go on day and night and during inclement weather. Another unusual feature is a side transfer carriage enabling ships under construction to be moved laterally from one berth to another, giving the yard an exceptional degree of operational flexibility and mobility.

The new Marystown publication also describes the yard's preparation shop, assembly and erection unit, engineering facility, joiner's shop, .repair berths and wharves, and its Syncrolift marine elevator which can drydock vessels up to 280 feet long.

This unit has a maximum lifting capacity of 3,000 tons.

The new 16-page report on Marystown Shipyard Ltd. can be obtained at no charge by writing Anthony Barclay, Marystown Shipyard Limited, P.O. Box 262, Marystown, Newfoundland, Canada.

Read Marystown Shipyard Reports On Progress Of $23-Million Norwegian Tugboat Contract in Pdf, Flash or Html5 edition of September 1977 Maritime Reporter

Other stories from September 1977 issue

Content

- Lloyd's To Class Two Large Crane Barges To Be Built By Mitsui page: 4

- Estimated Foreign Cost Of Two LNG Carriers $115.5 Million Each page: 6

- McAllister Brothers Name Robert Lounsbery Chief Operating Officer page: 7

- Lockheed Wins Contract To Evaluate Ocean Platform Candidates page: 7

- Bethlehem Steel Names G.Y. Marriner Manager San Francisco Yard page: 7

- AMPAC To Build Four Container Feeder Ships At Cost Of $92 Million page: 7

- MarAd Approves Title XI For Five Moran Tugboats page: 8

- SNAME New York Section Announces Program For 1977/1978 Season page: 8

- Willamette Awarded $15 Million To Modernize Alaska State Ferry page: 9

- Marathon Manufacturing Adds $61 Million To Drilling Rig Backlog page: 9

- NASSCO Building 188,500-DWT Tankers For Alaskan Oil Trade page: 10

- Exxon Begins Operating Remote Sea-Floor Production System page: 10

- Propeller Club Convention Includes Shipyard Panel page: 11

- MacMillctn Bloedel Orders Log Carrier At Cost Of $14 Million page: 12

- C-E Names Matthews Manager Of Contracts, Marine Power Systems page: 12

- Role Of Ro/Ro Shipping In Dry Cargo Trade page: 12

- Port Of New Orleans Presents Key To City To Egyptian Official page: 13

- Representatives Meet For First Time In Bahrain page: 14

- Marystown Shipyard Reports On Progress Of $23-Million Norwegian Tugboat Contract page: 14

- Dravo Awarded Two Contracts Totaling $7 Million page: 14

- Morris Guralnick Associates, Inc. Name Hubert E. Russell page: 14

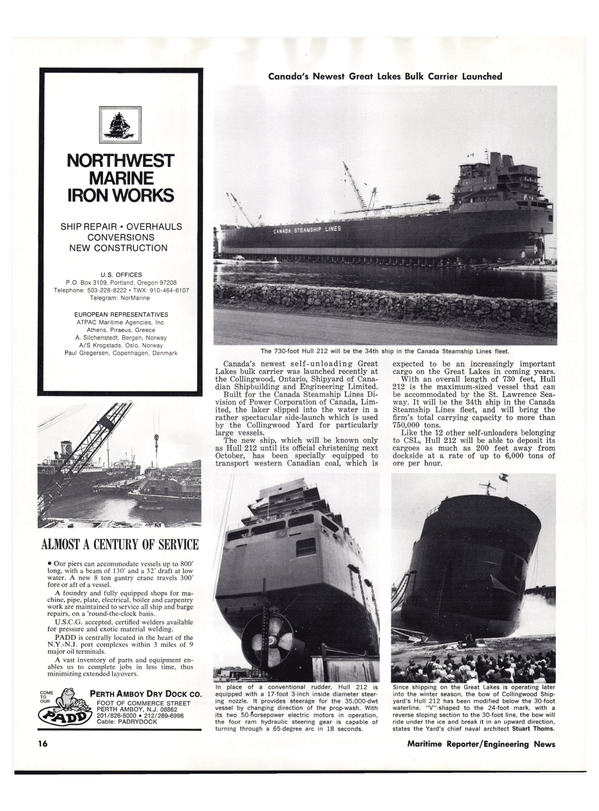

- Canada's Newest Great Lakes Bulk Carrier Launched page: 16

- Todd Seattle Division Lays Keel For Royal Australian Navy Frigate page: 18

- Title XI Approval For Two IOT Subsidiaries page: 18

- Jerry D. Icenhower Named President Glitsch Cryogenics page: 18

- Hillman-Designed New Class Towboat Delivered To Exxon At Baton Rouge page: 19

- BP Invests $50 Million In Stolt-Nielsen page: 20

- Speakers Named For Weather Conference September 14-15-16 page: 22

- $45-Million Subsidy Repayment Approved page: 23

- Study Shows Worldwide LNG Production Increase —60 Carriers Needed page: 24

- Bethlehem Steel Subsidiaries Name Collins And Coulahan page: 25

- Gotaverken Converts Cargo Ship To Carry 32,000 Live Sheep page: 25

- Halter Marine Delivers Large Supply Boat To George Engine Co. page: 26

- Bethlehem Steel Shipbuilding Names Roland V. Danielson —Hollinshead De Luce Retires page: 26

- Perspectives On Third World Port Development page: 30

- APL Names Hubbard Senior VP Operations page: 31

- New National Supply Anchoring Windlass page: 31

- Shallow Water Maneuvering Trials Completed In Gulf page: 32

- Farrell Sale And Leaseback Agreement Approved By MarAd page: 32

- Delta Steamship Names Badger And Collins page: 32

- Gross Tonnage In ABS Classification Exceeds 100-Million Mark page: 33

- Airfilco Appoints Kevin McPherson page: 33

- CCN Of Brazil Launches New Type Bulk Carrier page: 33

- 51st Annual Propeller Club Convention And 1977 American Merchant Marine Conference Set For Galveston, Texas, Oct. 10, 11, 12, 13 And 14 page: 34

- Bulletin Describes Heavy-Duty Oil Filtration Systems page: 35

- Eight-Page Brochure Describes National's Fully Hydraulic Cranes page: 35

- Joseph Hurley Named President ITT Decca Marine page: 36

- Oceangoing Split Hull Self-Propelled Dredge Completes Trials In Gulf page: 37

- ITT Decca Marine Introduces 'Clearscan' New Radar Technique To Reduce Interference page: 38

- Todd Shipyards Los Angeles Division Lays Keel For First Of Six U.S. Navy Frigates page: 38

- MacGregor Slewing Ramps Successfully Tested page: 39

- Skagit Corporation Announces European Dealership Agreement page: 40

- FMC Marine & Rail Lays Keel For Ro/Ro Barge To Carry 374 Forty-Foot Truck Trailers page: 40

- Egyptian Shipyard Receives License To Build Willard Boats page: 42

- Bergeron Industries Names Captain Tatman page: 42

- Port Authorities (AAPA) 66th Annual Convention Set For Mexico City page: 43

- Lloyd's Register Completely Revises Rules For Marine Refrigerated Cargo Installations page: 44

- Tanker Design Change Approved By MSB page: 44

- Navy Contracts For Additional Years Of MARISAT Satellite Service page: 46

- Mitsubishi Receives Tug Barge Systems' License To Build page: 46

- Petro-Marine Names Murray Burns Manager Process Engineering page: 47

- Norshipco Dedicates New $5-Million Repair Pier page: 47

- COMSAT General Expands MARISAT Services To Entire Indian Ocean page: 48

- U.S. Lines Names Three In Operations page: 48

- Fetzner Named President Sun Trading & Marine page: 48

- Philippine Center Exhibit Highlights Filipino Seaman page: 49

- Henschel Announces New Steering-Failure Alarm page: 49

- Tulsa Port Of Catoosa Sets Tonnage Record page: 49

- Jane's Fighting Ships 1977-78 Revised Edition page: 49

- Stanford Research Awarded $271,000 For Firefighting Study page: 50

- Gulf Oil Trading & Transportation Announces Management Changes page: 51

- Renegotiation Board Erred In Computing Lockheed Steel Usage page: 51

- Pott Industries Names Miller VP Offshore Marine Services Div. page: 54

- Joseph R. Burgess To Head Central Pacific Shipping Agency page: 56

- Capt. James F. McNulty New Dean At Maine Maritime Academy page: 56

- Richard Daschbach Named Federal Maritime Commission Chairman page: 57

- Keene Brochure Describes Marine Discharge Control System page: 57

- Heavy Weather Ship Operation Subject Of Webb Seminar page: 58