Page 30: of Maritime Reporter Magazine (August 15, 1981)

Read this page in Pdf, Flash or Html5 edition of August 15, 1981 Maritime Reporter Magazine

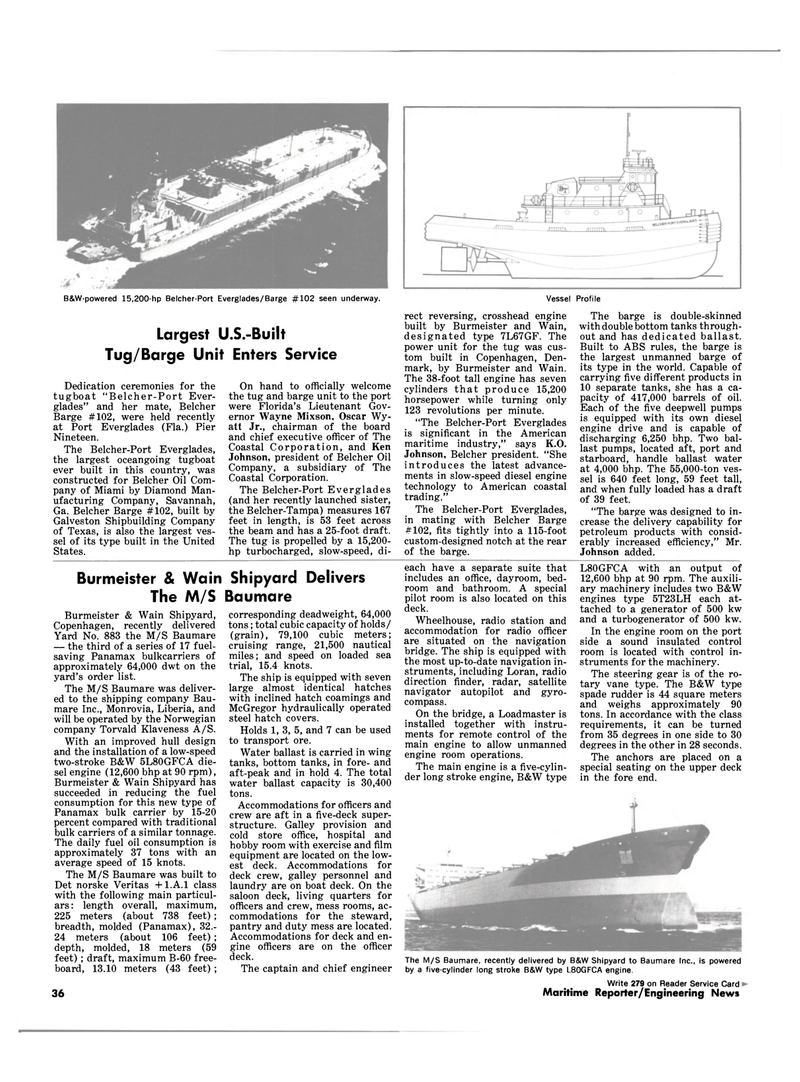

B&W-powered 15,200-hp Belcher-Port Everglades/Barge #102 seen underway. Vessel Profile

Largest U.S.-Built

Tug/Barge Unit Enters Service

Dedication ceremonies for the tugboat "Belcher-Port Ever- glades" and her mate, Belcher

Barge #102, were held recently at Port Everglades (Fla.) Pier

Nineteen.

The Belcher-Port Everglades, the largest oceangoing tugboat ever built in this country, was constructed for Belcher Oil Com- pany of Miami by Diamond Man- ufacturing Company, Savannah,

Ga. Belcher Barge #102, built by

Galveston Shipbuilding Company of Texas, is also the largest ves- sel of its type built in the United

States.

Burmeister & Wain Shipyard,

Copenhagen, recently delivered

Yard No. 883 the M/S Baumare — the third of a series of 17 fuel- saving Panamax bulkcarriers of approximately 64,000 dwt on the yard's order list.

The M/S Baumare was deliver- ed to the shipping company Bau- mare Inc., Monrovia, Liberia, and will be operated by the Norwegian company Torvald Klaveness A/S.

With an improved hull design and the installation of a low-speed two-stroke B&W 5L80GFCA die- sel engine (12,600 bhp at 90 rpm),

Burmeister & Wain Shipyard has succeeded in reducing the fuel consumption for this new type of

Panamax bulk carrier by 15-20 percent compared with traditional bulk carriers of a similar tonnage.

The daily fuel oil consumption is approximately 37 tons with an average speed of 15 knots.

The M/S Baumare was built to

Det norske Veritas +1.A.1 class with the following main particul- ars: length overall, maximum, 225 meters (about 738 feet) ; breadth, molded (Panamax), 32.- 24 meters (about 106 feet) ; depth, molded, 18 meters (59 feet) ; draft, maximum B-60 free- board, 13.10 meters (43 feet) ;

On hand to officially welcome the tug and barge unit to the port were Florida's Lieutenant Gov- ernor Wayne Mixson, Oscar Wy- att Jr., chairman of the board and chief executive officer of The

Coastal Corporation, and Ken

Johnson, president of Belcher Oil

Company, a subsidiary of The

Coastal Corporation.

The Belcher-Port Everglades (and her recently launched sister, the Belcher-Tampa) measures 167 feet in length, is 53 feet across the beam and has a 25-foot draft.

The tug is propelled by a 15,200- hp turbocharged, slow-speed, di- corresponding deadweight, 64,000 tons; total cubic capacity of holds/ (grain), 79,100 cubic meters; cruising range, 21,500 nautical miles; and speed on loaded sea trial, 15.4 knots.

The ship is equipped with seven large almost identical hatches with inclined hatch coamings and

McGregor hydraulically operated steel hatch covers.

Holds 1, 3, 5, and 7 can be used to transport ore.

Water ballast is carried in wing tanks, bottom tanks, in fore- and aft-peak and in hold 4. The total water ballast capacity is 30,400 tons.

Accommodations for officers and crew are aft in a five-deck super- structure. Galley provision and cold store office, hospital and hobby room with exercise and film equipment are located on the low- est deck. Accommodations for deck crew, galley personnel and laundry are on boat deck. On the saloon deck, living quarters for officers and crew, mess rooms, ac- commodations for the steward, pantry and duty mess are located.

Accommodations for deck and en- gine officers are on the officer deck.

The captain and chief engineer rect reversing, crosshead engine built by Burmeister and Wain, designated type 7L67GF. The power unit for the tug was cus- tom built in Copenhagen, Den- mark, by Burmeister and Wain.

The 38-foot tall engine has seven cylinders that produce 15,200 horsepower while turning only 123 revolutions per minute. "The Belcher-Port Everglades is significant in the American maritime industry," says K.O.

Johnson, Belcher president. "She introduces the latest advance- ments in slow-speed diesel engine technology to American coastal trading."

The Belcher-Port Everglades, in mating with Belcher Barge #102, fits tightly into a 115-foot custom-designed notch at the rear of the barge. each have a separate suite that includes an office, dayroom, bed- room and bathroom. A special pilot room is also located on this deck.

Wheelhouse, radio station and accommodation for radio officer are situated on the navigation bridge. The ship is equipped with the most up-to-date navigation in- struments, including Loran, radio direction finder, radar, satellite navigator autopilot and gyro- compass.

On the bridge, a Loadmaster is installed together with instru- ments for remote control of the main engine to allow unmanned engine room operations.

The main engine is a five-cylin- der long stroke engine, B&W type

The barge is double-skinned with double bottom tanks through- out and has dedicated ballast.

Built to ABS rules, the barge is the largest unmanned barge of its type in the world. Capable of carrying five different products in 10 separate tanks, she has a ca- pacity of 417,000 barrels of oil.

Each of the five deepwell pumps is equipped with its own diesel engine drive and is capable of discharging 6,250 bhp. Two bal- last pumps, located aft, port and starboard, handle ballast water at 4,000 bhp. The 55,000-ton ves- sel is 640 feet long, 59 feet tall, and when fully loaded has a draft of 39 feet. "The barge was designed to in- crease the delivery capability for petroleum products with consid- erably increased efficiency," Mr.

Johnson added.

L80GFCA with an output of 12,600 bhp at 90 rpm. The auxili- ary machinery includes two B&W engines type 5T23LH each at- tached to a generator of 500 kw and a turbogenerator of 500 kw.

In the engine room on the port side a sound insulated control room is located with control in- struments for the machinery.

The steering gear is of the ro- tary vane type. The B&W type spade rudder is 44 square meters and weighs approximately 90 tons. In accordance with the class requirements, it can be turned from 35 degrees in one side to 30 degrees in the other in 28 seconds.

The anchors are placed on a special seating on the upper deck in the fore end.

The M/S Baumare, recently delivered by B&W Shipyard to Baumare Inc., is powered by a five-cylinder long stroke B&W type L80GFCA engine.

Burmeister & Wain Shipyard Delivers

The M/S Baumare 36

Write 279 on Reader Service Card

Maritime Reporter/Engineering News

29

29

31

31