Page 3: of Maritime Reporter Magazine (August 15, 1981)

Read this page in Pdf, Flash or Html5 edition of August 15, 1981 Maritime Reporter Magazine

commodations for up to six per- sons in three staterooms.

The Shawn and Craig were built by Halter's Chalmette, La.,

Division, one of a group of ship- yards owned and operated by

Halter in the Southeastern Unit- ed States.

Racal-Decca Marine

Expands U.S. Operations

Racal-Decca Marine, Inc., a sub- sidiary of Racal Electronics Ltd., has announced the expansion of two facilities in the U.S.

The company has relocated its

Port of New York Service Center to a new and larger facility lo- cated at 70 Jackson Drive (2nd floor), Cranford, N.J. 07016. An enlarged technical staff will be based there to maintain and serv- ice marine electronic equipment.

A sales and service support of- fice has been established in the

New Orleans area to provide greater assistance to the existing dealer network which services the offshore, fishing, and inland wa- terway industries. In addition,

Racal-Decca Marine is expanding its existing warehouse facility at

New Orleans Airport.

The new offices will provide support for all of the Racal-Decca

Marine equipment which includes radar, loran, satellite navigation equipment, track plotters, auto- pilots, integrated ship's instru- mentation systems, fuel economy systems and Decca Navigator Re- ceivers. In addition, Racal-Decca

Marine, Inc., will provide support for other European manufactured electronics, acting as the exclu- sive U.S. distributor. These prod- uct lines include Sailor Radio of

Denmark; Honeywell Elac of West

Germany; Microtecnica of Italy; and Walker Logs of England.

For additional information on

Racal-Decca Marine, Inc. products and services,

Write 17 on Reader Service Card

Ramseyer Promoted At

Consolidated Grain

Phoenix Management Rig

To Be Built By

Bethlehem Sparrows Point

Phoenix Management Corpora- tion of Houston has awarded

Bethlehem Steel Corporation's shipyard at Sparrows Point, Md., a contract for construction of a mobile offshore oil drilling rig.

Announcement of the contract was made by William R. Har- grove, president of Phoenix Man- agement, and George S. Hamilton, general manager of the Sparrows

Point yard.

The jackup rig will be capable of drilling in water depths up to 100 feet.

The unit's mat will be 180 feet long by 140 feet wide by 9.6 inches deep, and the drilling plat- form will be 140 feet long by 100 feet wide by 13.5 inches deep.

Work on the rig is scheduled to begin immediately, with a keel- laying set for December. Delivery is scheduled for July 1982.

This is the fifth oil drilling rig the yard has on order, Mr. Ham- ilton said. The first complete rig to be built by the yard, the

Sabine III, was delivered to Hou- ston Offshore International in

June. It was the first such rig built in the United States outside the Gulf of Mexico.

Rob Ramseyer

Consolidated Grain and Barge

Company, St. Louis, Mo., has an- nounced the promotion of Rob

Ramseyer to the position of sales manager of Freight Merchandis- ing. Mr. Ramseyer joined Consol- idated in 1978 as a grain mer- chant at Consolidated's Terminal at Hennepin, 111. In 1979, Mr.

Ramseyer became a merchandiser of barge transportation, the po- sition he held prior to his recent promotion.

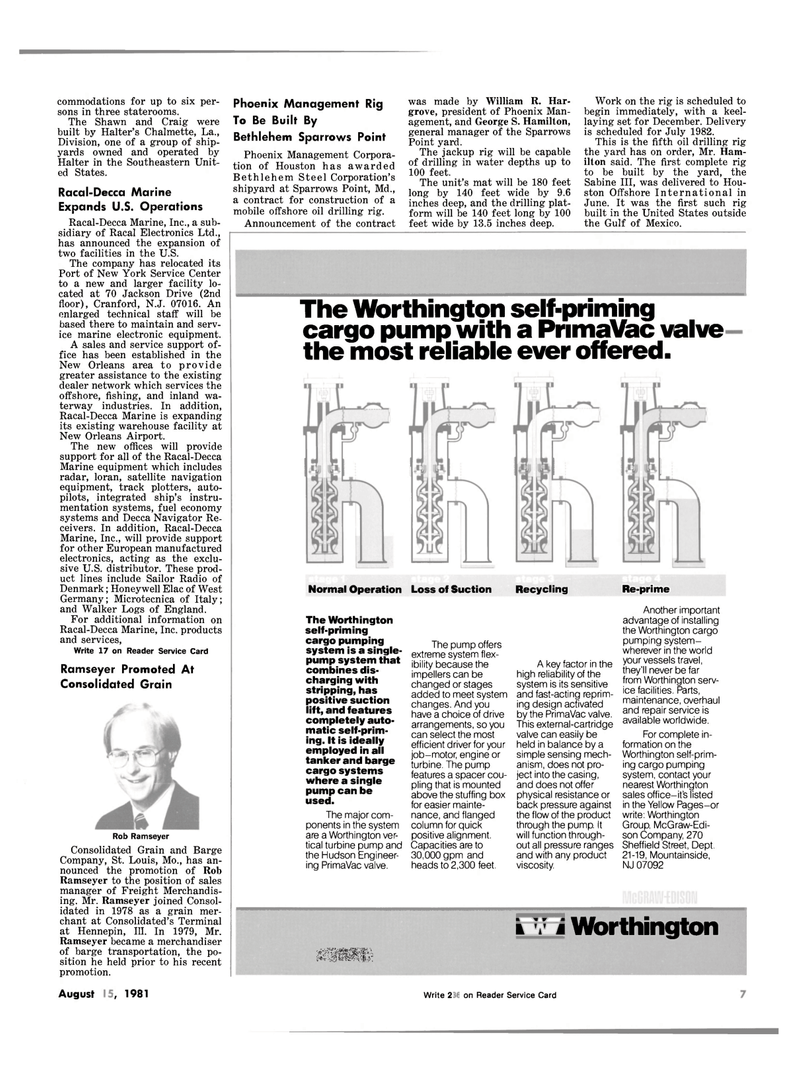

The Worthington self-priming cargo pump with a PrimaVac valve the most reliable ever offered.

Normal Operation Loss of Suction Recycling

The Worthington self-priming cargo pumping system is a single- pump system that combines dis- charging with stripping, has positive suction lift, and features completely auto- matic self-prim- ing. It is ideally employed in all tanker and barge cargo systems where a single pump can be used.

The major com- ponents in the system are a Worthington ver- tical turbine pump and the Hudson Engineer- ing PrimaVac valve.

The pump offers extreme system flex- ibility because the impellers can be changed or stages added to meet system changes. And you have a choice of drive arrangements, so you can select the most efficient driver for your job-motor, engine or turbine. The pump features a spacer cou- pling that is mounted above the stuffing box for easier mainte- nance, and flanged column for quick positive alignment.

Capacities are to 30,000 gpm and heads to 2,300 feet.

A key factor in the high reliability of the system is its sensitive and fast-acting reprim- ing design activated by the PrimaVac valve.

This external-cartridge valve can easily be held in balance by a simple sensing mech- anism, does not pro- ject into the casing, and does not offer physical resistance or back pressure against the flow of the product through the pump. It will function through- out all pressure ranges and with any product viscosity.

Re-prime

Another important advantage of installing the Worthington cargo pumping system- wherever in the world your vessels travel, they'll never be far from Worthington serv- ice facilities. Parts, maintenance, overhaul and repair service is available worldwide.

For complete in- formation on the

Worthington self-prim- ing cargo pumping system, contact your nearest Worthington sales office-it's listed in the Yellow Pages-or write: Worthington

Group, McGraw-Edi- son Company, 270

Sheffield Street, Dept. 21-19, Mountainside,

NJ 07092 iiW® m Worthington

August 7, 1981 Write 324 on Reader Service Card 13

2

2

4

4