Page 50: of Maritime Reporter Magazine (August 1983)

Read this page in Pdf, Flash or Html5 edition of August 1983 Maritime Reporter Magazine

First Guyed Tower Platform

Installed In Gulf of Mexico

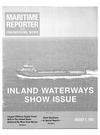

The Ben Candies, powered by two EMD 16-645-E6 main diesel engines, shown towing the first guyed tower platform installed in Gulf of Mexico.

Swiftships Delivers Second 117-Foot Tug To Otto Candies

Swiftships, Inc. of Morgan City, tug assisted in the towing of a

La., recently delivered the second unique new unloading platform of a two-tug boat order, the 117- for Exxon Co. U.S.A. The 1,078- foot Ben Candies to Otto Candies foot-tall offshore drilling platform,

Inc. of Des Allemandes, La. is designed with guylines that al-

The vessel measures 117 feet low it to move slightly in hurri- long, by 34 feet wide, and is 17 cane force winds, 70-foot high feet deep. The tug is powered by waves or strong currents. It is lo- two EMD-16-645-E6 main diesel cated in the Gulf of Mexico in engines, with two Reintjes model 1,000 feet of water about 110 miles 2650 gears having a ratio of 5:1, south of New Orleans. (See story at driving two Coolidge 117 by 86.1- right.) inch propellers.

Built to ABS classification, Ice

Class C, the Ben Candies capaci- ties include 129,000 gallons of fuel oil; 8,500 gallons of ballast; 11,800 gallons of potable water, 3,500 gallons of lube oil; 700 gallons of hvdranlic nil' and has arrnmmn-

BEN CANDIES

Major Suppliers

Main Propulsion (2) EMD

Reduction Gears Reintjes

Propellers Coolidge

Chiftr CL-J

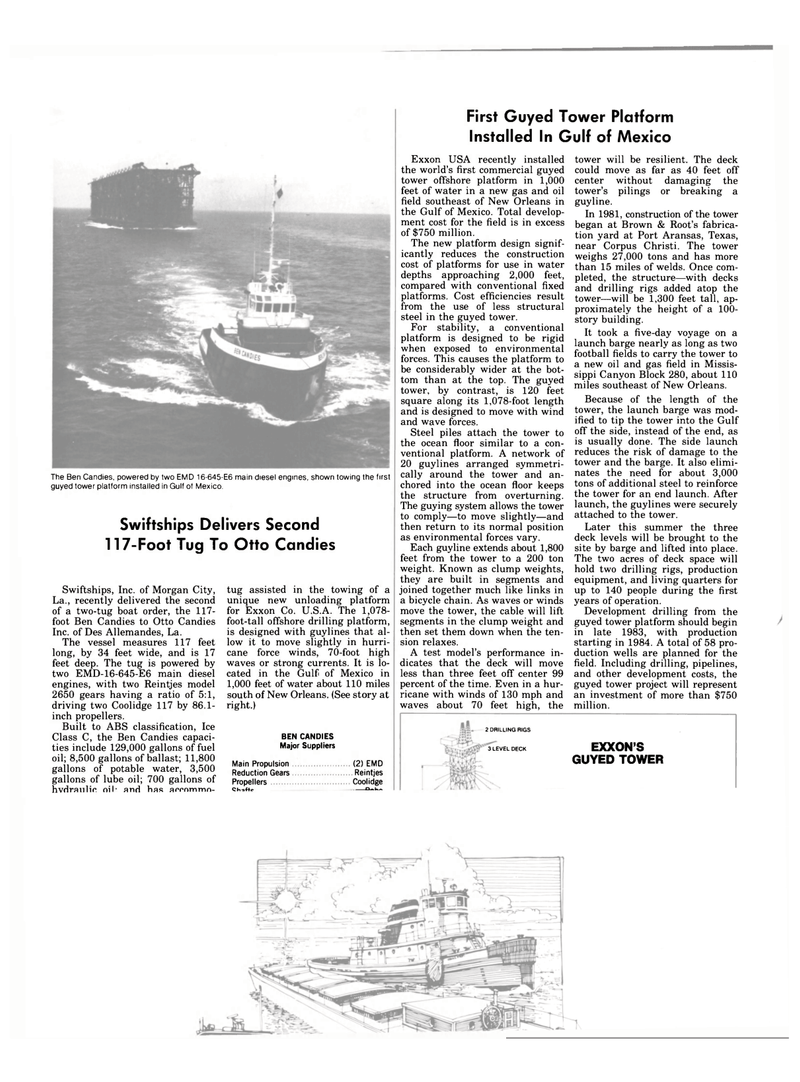

Exxon USA recently installed the world's first commercial guyed tower offshore platform in 1,000 feet of water in a new gas and oil field southeast of New Orleans in the Gulf of Mexico. Total develop- ment cost for the field is in excess of $750 million.

The new platform design signif- icantly reduces the construction cost of platforms for use in water depths approaching 2,000 feet, compared with conventional fixed platforms. Cost efficiencies result from the use of less structural steel in the guyed tower.

For stability, a conventional platform is designed to be rigid when exposed to environmental forces. This causes the platform to be considerably wider at the bot- tom than at the top. The guyed tower, by contrast, is 120 feet square along its 1,078-foot length and is designed to move with wind and wave forces.

Steel piles attach the tower to the ocean floor similar to a con- ventional platform. A network of 20 guylines arranged symmetri- cally around the tower and an- chored into the ocean floor keeps the structure from overturning.

The guying system allows the tower to comply—to move slightly—and then return to its normal position as environmental forces vary.

Each guyline extends about 1,800 feet from the tower to a 200 ton weight. Known as clump weights, they are built in segments and joined together much like links in a bicycle chain. As waves or winds move the tower, the cable will lift segments in the clump weight and then set them down when the ten- sion relaxes.

A test model's performance in- dicates that the deck will move less than three feet off center 99 percent of the time. Even in a hur- ricane with winds of 130 mph and waves about 70 feet high, the tower will be resilient. The deck could move as far as 40 feet off center without damaging the tower's pilings or breaking a guyline.

In 1981, construction of the tower began at Brown & Root's fabrica- tion yard at Port Aransas, Texas, near Corpus Christi. The tower weighs 27,000 tons and has more than 15 miles of welds. Once com- pleted, the structure—with decks and drilling rigs added atop the tower—will be 1,300 feet tall, ap- proximately the height of a 100- story building.

It took a five-day voyage on a launch barge nearly as long as two football fields to carry the tower to a new oil and gas field in Missis- sippi Canyon Block 280, about 110 miles southeast of New Orleans.

Because of the length of the tower, the launch barge was mod- ified to tip the tower into the Gulf off the side, instead of the end, as is usually done. The side launch reduces the risk of damage to the tower and the barge. It also elimi- nates the need for about 3,000 tons of additional steel to reinforce the tower for an end launch. After launch, the guylines were securely attached to the tower.

Later this summer the three deck levels will be brought to the site by barge and lifted into place.

The two acres of deck space will hold two drilling rigs, production equipment, and living quarters for up to 140 people during the first years of operation.

Development drilling from the guyed tower platform should begin in late 1983, with production starting in 1984. A total of 58 pro- duction wells are planned for the field. Including drilling, pipelines, and other development costs, the guyed tower project will represent an investment of more than $750 million.

EXXON'S

GUYED TOWER 2 DRILLING RIGS 3 LEVEL DECK

49

49

51

51