Page 31: of Maritime Reporter Magazine (November 1984)

Read this page in Pdf, Flash or Html5 edition of November 1984 Maritime Reporter Magazine

Witness a study done by the re- nowned accounting firm of Arthur

Andersen & Co. They gathered fi- nancial data from 15 of the largest inland barge companies. In 1980, these companies earned an aggre- gate profit of $130 million on $1.1 billion in revenue. In 1982, these same companies lost $30 million. In 1983, they lost over $40 million.

Mind you, these are among the larg- est companies. You can imagine how the little fellows have fared. Bank- ruptcies abound. The downward spiral is unmistakably clear.

What happened?

The industry is dependent upon bulk products, largely petroleum, coal and grain. All three commodi- ties are depressed.

President Carter's disastrous grain embargo savaged this indus- try. We carried 46 percent of all U.S. grain for export. In 1980, before the embargo was imposed, the U.S. shipped 20 million metric tons of grain to the USSR. That went to zero until last year when this admin- istration signed a new agreement with the Soviets for 8-12 million metric tons. It will be very difficult to recapture the market share we once had. The Soviet government, to protect its own interests, has diversified its purchases to include

Australia, Canada and Argentina.

The economies of western Europe and Japan have lagged the robust recovery of the American economy.

As a result of that and fissures in the

OPEC cartel, the world is awash in petroleum. Demand is slack and transportation of the black gold is down.

What has been good for the

United States has hurt the barge industry: energy conservation has taken hold. Last year, demand for electricity actually went down for the first time in our history. And, with it, domestic coal consumption slowed. Barge traffic suffered.

Overhanging all this is a vast sur- feit of equipment in the industry.

New tax laws brought hordes of investors ... physicians, dentists, attorneys . . . into barge owning partnerships used to shelter their income. We are about 15 percent overbuilt.

Understanding its importance and its troubles, I have been asked to address, "What is the role of the federal government in the water- ways industry?" That depends on who you talk to.

My old friend Dave Stockman, director of the Office of Manage- ment and Budget, says the federal government should recover between 70-100 percent of all federal expen- ditures on the waterways and the ports.

Senator Abdnor and Senator

Stafford believe the federal gov- ernment should recover 100 percent of federal capital outlays for inland projects and 30-100 percent of port development.

The Interstate Commerce Com- mission believes that the Panama

Canal Act is outmoded and rail- roads can own barge lines.

Bob Roe, Congressman from the 8th District of New Jersey, believes that the industry should pay a third of the cost of inland capital projects, no inland operation and mainte- nance costs, 50 percent of superport development and no port operation and maintenance costs.

President Reagan believes that the maritime industry is "important in peacetime and critical in times of conflict," but has done so little as to consign that statement to an empty rhetoric bin.

So, you see what the federal gov- ernment's role is depends entirely on who is talking. Let me tell you what I believe.

I want first to persuade you that we have every reason to be proud of and pleased with our nation's over- all transportation system. Indeed, our domestic transportation system is one of the most highly develop- ed—and envied—in the world, pro- viding the foundation upon which

American economic growth pro- gresses—or declines. Our prosperity as a nation is due in large part to the success of that system, and to the two hundred years of ever advanc- ing technology, combined with old- fashioned know-how which has en- abled us to build such a formidable network of highways, railroads, air- ways, pipelines, and last, but not (continued on page 36)

More work in fewer hours with new super-clean Copper Blast

Approximate Profile-

Coarse

Copper Blast

Abrasive

Performance on Steel

Copper Blast Cutting

Rate Comparison Chart 3/8 Venturi Nozzle 80 PSI Air Pressure 1/4 ASTM A36 Steel Plate 200100 40 30 20 1

Average Particle Size—U S. Mesh

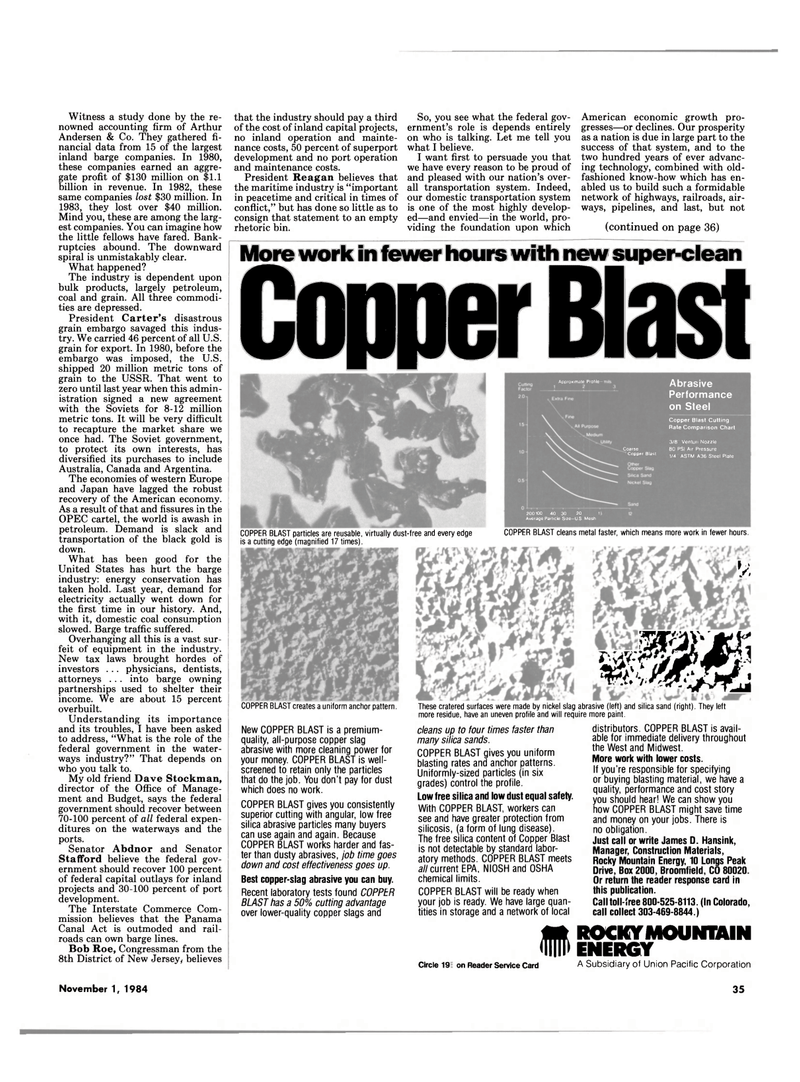

COPPER BLAST particles are reusable, virtually dust-free and every edge is a cutting edge (magnified 17 times).

COPPER BLAST cleans metal faster, which means more work in fewer hours. 1 • t y,

COPPER BLAST creates a uniform anchor pattern.

New COPPER BLAST is a premium- quality, all-purpose copper slag abrasive with more cleaning power for your money. COPPER BLAST is well- screened to retain only the particles that do the job. You don't pay for dust which does no work.

COPPER BLAST gives you consistently superior cutting with angular, low free silica abrasive particles many buyers can use again and again. Because

COPPER BLAST works harder and fas- ter than dusty abrasives, job time goes down and cost effectiveness goes up.

Best copper-slag abrasive you can buy.

Recent laboratory tests found COPPER

BLAST has a 50% cutting advantage over lower-quality copper slags and wMM,

These cratered surfaces were made by nickel slag abrasive (left) and silica sand (right). They left more residue, have an uneven profile and will require more paint. cleans up to four times faster than many silica sands.

COPPER BLAST gives you uniform blasting rates and anchor patterns.

Uniformly-sized particles (in six grades) control the profile.

Low free silica and low dust equal safety.

With COPPER BLAST, workers can see and have greater protection from silicosis, (a form of lung disease).

The free silica content of Copper Blast is not detectable by standard labor- atory methods. COPPER BLAST meets all current EPA, NIOSH and OSHA chemical limits.

COPPER BLAST will be ready when your job is ready. We have large quan- tities in storage and a network of local ®

Circle 319 on Reader Service Card distributors. COPPER BLAST is avail- able for immediate delivery throughout the West and Midwest.

More work with lower costs.

If you're responsible for specifying or buying blasting material, we have a quality, performance and cost story you should hear! We can show you how COPPER BLAST might save time and money on your jobs. There is no obligation.

Just call or write James D. Hansink,

Manager, Construction Materials,

Rocky Mountain Energy, 10 Longs Peak

Drive, Box 2000, Broomfield, CO 80020.

Or return the reader response card in this publication.

Call toll-tree 800-525-8113. (In Colorado, call collect 303-469-8844.)

ROCKY MOUNTAIN ENERGY

A Subsidiary of Union Pacific Corporation

November 1, 1984 35

30

30

32

32