Page 15: of Maritime Reporter Magazine (September 1985)

Read this page in Pdf, Flash or Html5 edition of September 1985 Maritime Reporter Magazine

BIW-PORTLAND

Circle 82 on Reader Service Card

Bath Iron Works opened its Port- land, Maine, overhaul and repair facility in late 1983. Since then, four

U.S. Navy ships have been accom- modated in the huge floating dry- dock, the largest of its type on the

East Coast.

With a certified lifting capacity of 81,000 tons, this drydock could ac- commodate 80 percent of the ships now operating throughout the world. The dock measures 844 feet in length, 256 in width, and has a clear docking width between wing- walls of 142 feet. Crane service is provided by two 25-ton wingwall units.

As originally designed during

World War II, the drydock utilized independent machinery spaces within the hull of each of the nine dock sections. Each of these spaces contained the pumps, diesel genera- tors, electrical switchgear, and con- trols required to operate that dock section.

The BIW overhaul of the electri- cal systems included three major objectives: the power distribution system needed to be converted to operate on commercial mains in lieu of the 18 installed generators; facili- ties had to be added to provide for the greatly increased shore power requirements of modern ships; and a centralized control and monitor- ing system was necessary to elimi- nate the need for nine machinery space operating crews.

Commercial power was brought aboard at 12,740 volts using two independent feeders. These supply a new 480-volt distribution switch- board via two new 2,500-kva trans- formers. Independent shore power for ships within the dock is distrib- uted from the dock feeders via 2,000-kva transformers and a sec- ond new 480/450-volt switchboard.

A 560-kw emergency generator was added to permit limited operation in the event commercial power is lost.

A new centralized control station was provided by construction of a control house above the inboard wingwall. The centralized control and monitoring features added in- clude monitoring of tank levels, con- trol of the ballast pumps, monitor- ing and limited control of the power distribution and lighting systems, and control of the tank, pump, and flooding valves.

Approximately 900 existing ma- chinery control circuits are inter- faced with the control system and multiplexed for transmission back to the central control station by a remote electronics panel installed in each of the machinery spaces. Auto- matic control and alarm features are provided by a central computer within the control console.

BETHLEHEM STEEL

Circle 83 on Reader Service Card

Bethlehem Steel Corporation's floating drydock at the new Sabine

Yard in Port Arthur, Texas, consists of eight identical sections. They each measure 240-feet long, 101-feet wide, and 23^-feet deep. The eight sections, when fastened together, have a lifting capacity of 64,000 tons, making it one of the largest drydocks in the country.

Each drydock section is a 4,200- ton, all-welded steel structure con- sisting of a ship-shaped hull (pon- toon) that supports two rectangular box-shaped wing (side) walls. The midship portion of the pontoon con- tains a non-floodable compartment, or buoyancy chamber. The greater part of the mechanical and electrical equipment required for operation of the dock section is located in the various compartments of this cham- ber.

During normal operation of the dock, access to the buoyancy cham- ber is gained from the wing walls through two watertight passageways extending through the pontoon, one passageway to each wing wall. The passageways continue upward through the wing walls in the form of circular stairways and terminate at the safety decks.

The remainder of the pontoon is subdivided by two longitudinal and two transverse bulkheads into eight ballast compartments, four on each side of the buoyancy chamber. Each ballast compartment can be flooded or pumped out through a lateral pipe that is connected to the flood- continued on page 18)

TOMORROW'S SHIPBUILDING

TECHNOLOGY TODAY

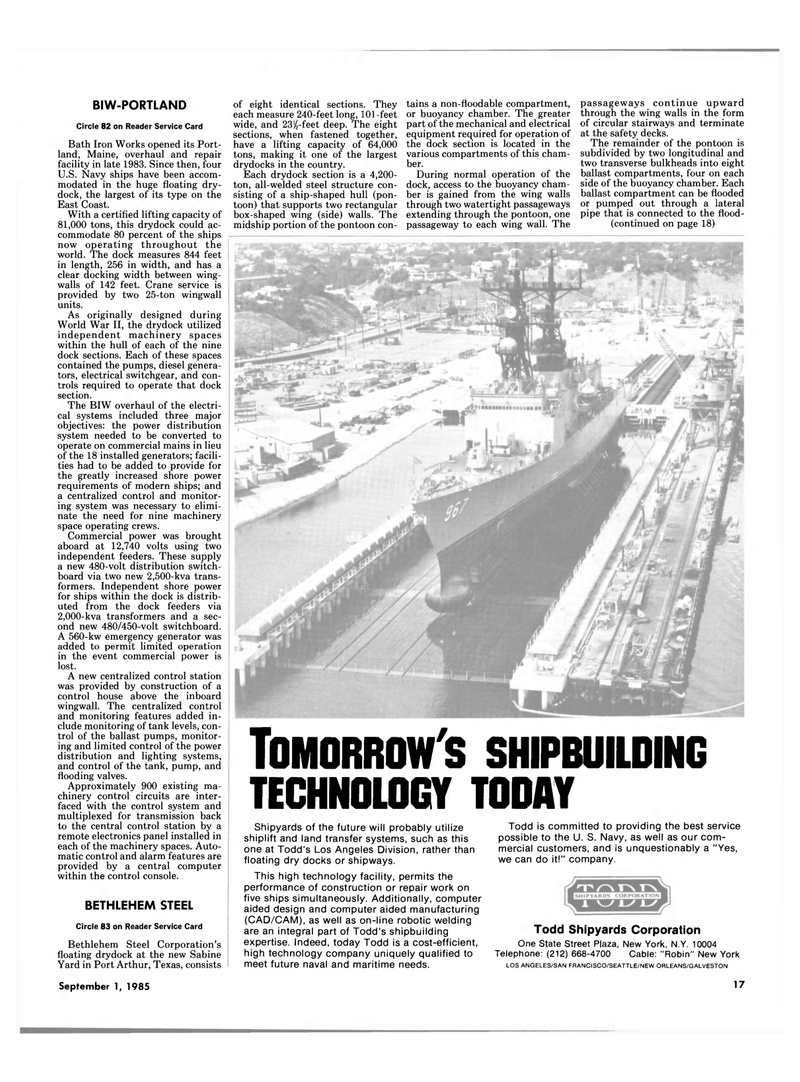

Shipyards of the future will probably utilize shiplift and land transfer systems, such as this one at Todd's Los Angeles Division, rather than floating dry docks or shipways.

This high technology facility, permits the performance of construction or repair work on five ships simultaneously. Additionally, computer aided design and computer aided manufacturing (CAD/CAM), as well as on-line robotic welding are an integral part of Todd's shipbuilding expertise. Indeed, today Todd is a cost-efficient, high technology company uniquely qualified to meet future naval and maritime needs.

Todd is committed to providing the best service possible to the U. S. Navy, as well as our com- mercial customers, and is unquestionably a "Yes, we can do it!" company.

Todd Shipyards Corporation

One State Street Plaza, New York, N.Y. 10004

Telephone: (212) 668-4700 Cable: "Robin" New York

LOS ANGELES/SAN FRANCISCO/SEATTLE/NEW ORLEANS/GALVESTON

September 1, 1985 17

14

14

16

16