Page 40: of Maritime Reporter Magazine (September 2000)

Read this page in Pdf, Flash or Html5 edition of September 2000 Maritime Reporter Magazine

COVER STORY: Maritime 2050

Barring the ability to transport mass amounts of cargo in a Star Trek-esque manner, it's reasonable to assume that ships and boats will continue to be the globes' hauler of goods for the foreseeable future. In the quest to make water transportation safer and more efficient, designers are constantly pushing the limits, and has led the editors of Maritime Reporter & Engineering News to ask such questions as ...

Hinge-Ship is a patented concept designed to com- bine the advantages of both deep draft and shallow draft shipping within the confines of a single vessel.

The concept, if proven viable, could help to further the mandate of shaving valuable time from the transporta- tion of goods from "point A to point B," as it would lit- erally eliminate the need for storage at transshipment points and the transfer of cargo to other vessels, and all of the time and cost inherent in both.

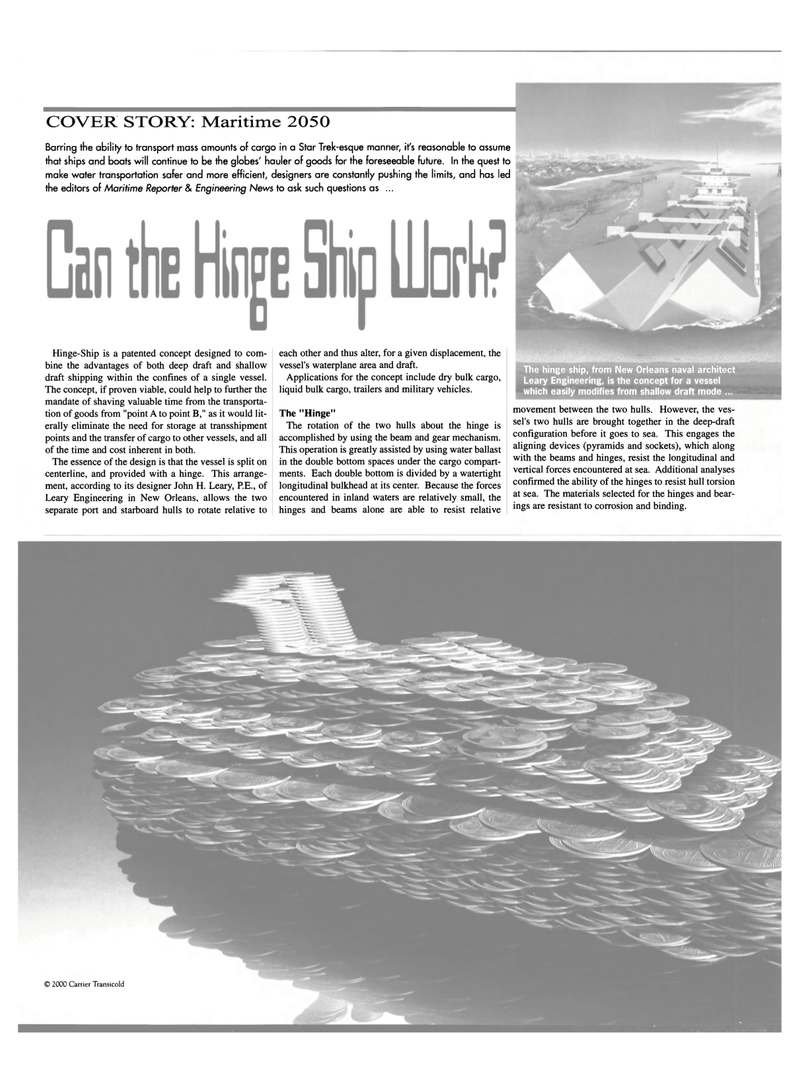

The essence of the design is that the vessel is split on centerline, and provided with a hinge. This arrange- ment, according to its designer John H. Leary, P.E., of

Leary Engineering in New Orleans, allows the two separate port and starboard hulls to rotate relative to each other and thus alter, for a given displacement, the vessel's waterplane area and draft.

Applications for the concept include dry bulk cargo, liquid bulk cargo, trailers and military vehicles.

The "Hinge"

The rotation of the two hulls about the hinge is accomplished by using the beam and gear mechanism.

This operation is greatly assisted by using water ballast in the double bottom spaces under the cargo compart- ments. Each double bottom is divided by a watertight longitudinal bulkhead at its center. Because the forces encountered in inland waters are relatively small, the hinges and beams alone are able to resist relative movement between the two hulls. However, the ves- sel's two hulls are brought together in the deep-draft configuration before it goes to sea. This engages the aligning devices (pyramids and sockets), which along with the beams and hinges, resist the longitudinal and vertical forces encountered at sea. Additional analyses confirmed the ability of the hinges to resist hull torsion at sea. The materials selected for the hinges and bear- ings are resistant to corrosion and binding.

The hinge ship, from New Orleans naval architect

Leary Engineering, is the concept for a vessel which easily modifies from shallow draft mode ... © 2000 Carrier Transicold

39

39

41

41