Page 71: of Maritime Reporter Magazine (June 2014)

Annual World Yearbook

Read this page in Pdf, Flash or Html5 edition of June 2014 Maritime Reporter Magazine

www.marinelink.com 71

Rio Controls & Hydraulics

Rio Controls & Hydraulics’ steering system modi? es exist- ing inductive sensors used in the oil and gas industry and designs a steering system that utilizes this technology to provide accurate, longer lasting sensor command and feedback signals. This technology revolution- izes the marine industry by replacing conventional devices with cutting edge technology. The system eliminates up to 62 hookup points and three junc- tion boxes. www.riomarineinc.com

John Deere’s Engines for

Marine Auxiliaries

John Deere Pow- er Systems’ full line of radiator- cooled, dry-ex- haust-manifold

PowerTech aux- iliary engines are ideal for power- ing deck auxil- iaries, including pumps, winches, cranes, hydraulics and generators.

The lineup meets EPA Marine Tier 3 emissions regulations for U.S. waterways, and offers reliable, cost-effective power to customers for their auxiliary applications. Marine Tier 3 auxiliary drive engines will be available in summer 2014. www.JohnDeere.com/jdpower

Laborde Repower Provides

Long Tug Endurance

Smith Maritime depends on Laborde. For its third repower with Smith, Laborde supplied three Mit- subishi S12R-Y2MPTK Tier II engines rated at 5,000 hp for the tug Rhea. For its maiden voyage,

Rhea towed a huge piece of oil-? eld equipment for seven weeks. Rhea is a small, powerful, agile, sea- going tug capable of withstanding the rigors of any service in all weather conditions. www.labordeproducts.com

Applied Membranes’ Line of Watermakers

Applied Membranes, Inc. manufactures reverse os- mosis systems, membranes and equipment. Backed by a large manufacturing facility, serving the entire range of commercial applications, and with instal- lations in over 100 countries worldwide, Applied

Membranes stocks a substantial inventory of wa- termaker parts, consumables, yacht-sized media ? lters, UV sterilizers, to cleaning, storage and min- eralization cartridge ? lters and accessories. www.appliedmembranes.com

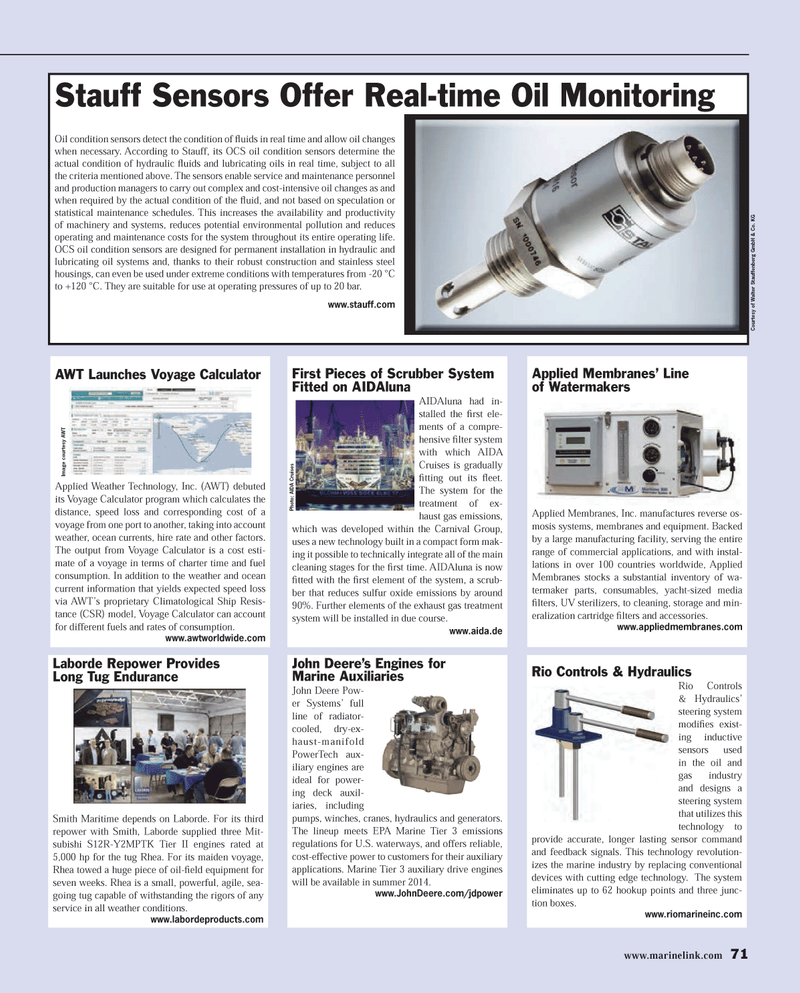

Stauff Sensors Offer Real-time Oil Monitoring

Oil condition sensors detect the condition of ? uids in real time and allow oil changes when necessary. According to Stauff, its OCS oil condition sensors determine the actual condition of hydraulic ? uids and lubricating oils in real time, subject to all the criteria mentioned above. The sensors enable service and maintenance personnel and production managers to carry out complex and cost-intensive oil changes as and when required by the actual condition of the ? uid, and not based on speculation or statistical maintenance schedules. This increases the availability and productivity of machinery and systems, reduces potential environmental pollution and reduces operating and maintenance costs for the system throughout its entire operating life.

OCS oil condition sensors are designed for permanent installation in hydraulic and lubricating oil systems and, thanks to their robust construction and stainless steel housings, can even be used under extreme conditions with temperatures from -20 °C to +120 °C. They are suitable for use at operating pressures of up to 20 bar. www.stauff.com

Cour tesy of W alter Stauf fenber g GmbH & Co. KG

AWT Launches Voyage Calculator

Applied Weather Technology, Inc. (AWT) debuted its Voyage Calculator program which calculates the distance, speed loss and corresponding cost of a voyage from one port to another, taking into account weather, ocean currents, hire rate and other factors.

The output from Voyage Calculator is a cost esti- mate of a voyage in terms of charter time and fuel consumption. In addition to the weather and ocean current information that yields expected speed loss via AWT’s proprietary Climatological Ship Resis- tance (CSR) model, Voyage Calculator can account for different fuels and rates of consumption. www.awtworldwide.com

First Pieces of Scrubber System

Fitted on AIDAluna

AIDAluna had in- stalled the ? rst ele- ments of a compre- hensive ? lter system with which AIDA

Cruises is gradually ? tting out its ? eet.

The system for the treatment of ex- haust gas emissions, which was developed within the Carnival Group, uses a new technology built in a compact form mak- ing it possible to technically integrate all of the main cleaning stages for the ? rst time. AIDAluna is now ? tted with the ? rst element of the system, a scrub- ber that reduces sulfur oxide emissions by around 90%. Further elements of the exhaust gas treatment system will be installed in due course. www.aida.de

Image cour tesy AWT

Photo: AIDA Cruises

MR #6 (66-74).indd 71 6/9/2014 11:35:54 AM

70

70

72

72