Page 51: of Maritime Reporter Magazine (July 2016)

Marine Communications Edition

Read this page in Pdf, Flash or Html5 edition of July 2016 Maritime Reporter Magazine

PPG gets EU Funding for project aiming to produce a new fouling protection system for commercial vessels.

Industry Group Developing New Hull Coating System

A project development group including PPG,

MACtac, Meyer Werft/ND Coatings, VertiDrive and Hamburg Ship Model Basin HSVA are work- ing to establish an automatic application process for allowing a self-adhesive/fouling release ? lm to be used on commercial seagoing vessels. The process would allow shipowners and operators to enjoy fouling release properties and drag reduc- tion capabilities of the PPG SIGMAGLIDE self- adhesive ? lm.

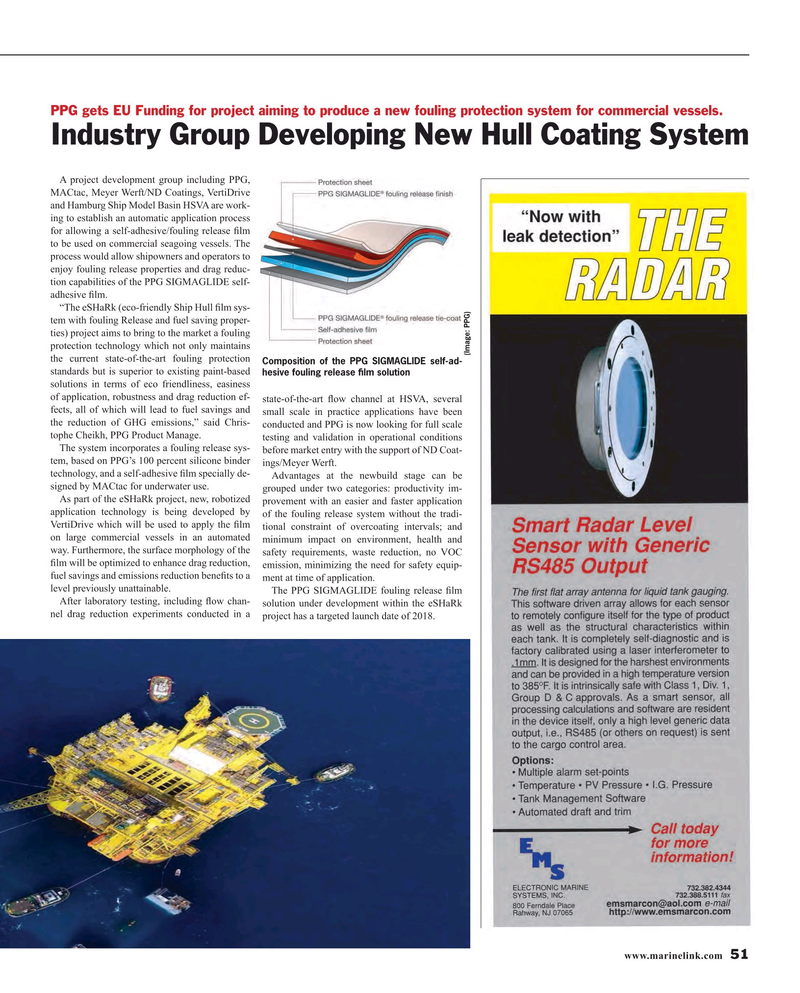

“The eSHaRk (eco-friendly Ship Hull ? lm sys- tem with fouling Release and fuel saving proper- ties) project aims to bring to the market a fouling protection technology which not only maintains (Image: PPG) the current state-of-the-art fouling protection

Composition of the PPG SIGMAGLIDE self-ad- standards but is superior to existing paint-based hesive fouling release ? lm solution solutions in terms of eco friendliness, easiness of application, robustness and drag reduction ef- state-of-the-art ? ow channel at HSVA, several fects, all of which will lead to fuel savings and small scale in practice applications have been the reduction of GHG emissions,” said Chris- conducted and PPG is now looking for full scale tophe Cheikh, PPG Product Manage.

testing and validation in operational conditions

The system incorporates a fouling release sys- before market entry with the support of ND Coat- tem, based on PPG’s 100 percent silicone binder ings/Meyer Werft.

technology, and a self-adhesive ? lm specially de-

Advantages at the newbuild stage can be signed by MACtac for underwater use.

grouped under two categories: productivity im-

As part of the eSHaRk project, new, robotized provement with an easier and faster application application technology is being developed by of the fouling release system without the tradi-

VertiDrive which will be used to apply the ? lm tional constraint of overcoating intervals; and on large commercial vessels in an automated minimum impact on environment, health and way. Furthermore, the surface morphology of the safety requirements, waste reduction, no VOC ? lm will be optimized to enhance drag reduction, emission, minimizing the need for safety equip- fuel savings and emissions reduction bene? ts to a ment at time of application.

level previously unattainable.

The PPG SIGMAGLIDE fouling release ? lm

After laboratory testing, including ? ow chan- solution under development within the eSHaRk nel drag reduction experiments conducted in a project has a targeted launch date of 2018.

www.marinelink.com 51

MR #7 (50-57).indd 51 7/6/2016 11:20:57 AM

50

50

52

52