Page 90: of Maritime Reporter Magazine (November 2016)

Workboat Edition

Read this page in Pdf, Flash or Html5 edition of November 2016 Maritime Reporter Magazine

US NAVY REPORT

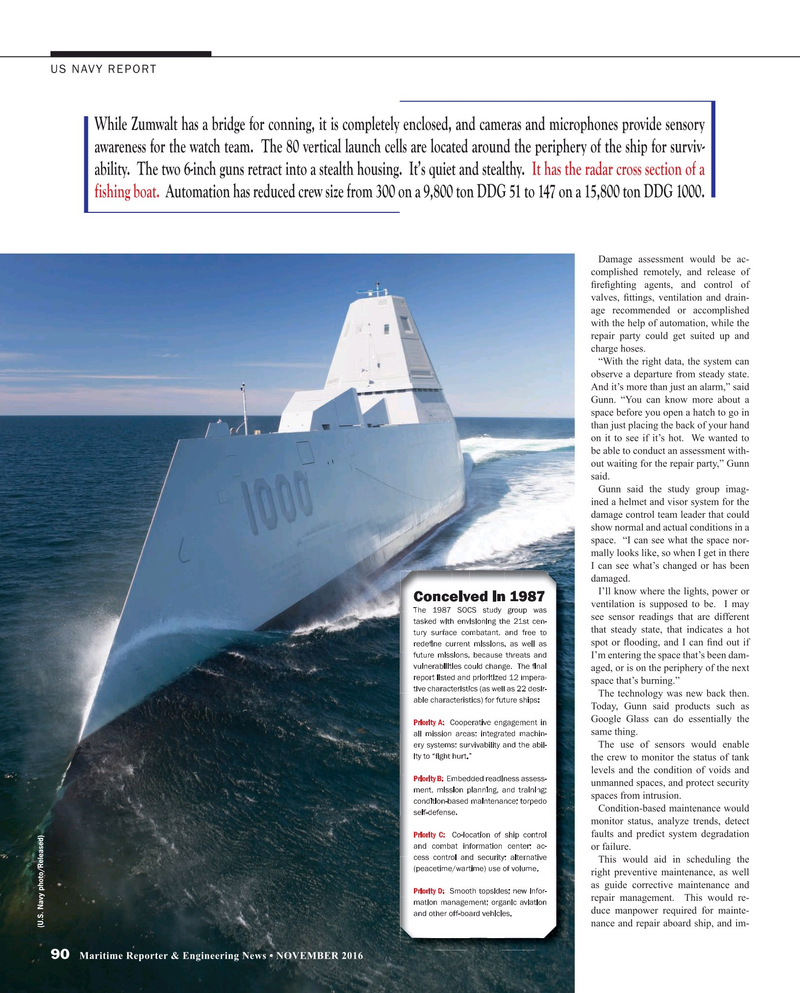

While Zumwalt has a bridge for conning, it is completely enclosed, and cameras and microphones provide sensory awareness for the watch team. The 80 vertical launch cells are located around the periphery of the ship for surviv- ability. The two 6-inch guns retract into a stealth housing. It’s quiet and stealthy. It has the radar cross section of a fishing boat. Automation has reduced crew size from 300 on a 9,800 ton DDG 51 to 147 on a 15,800 ton DDG 1000.

Damage assessment would be ac- complished remotely, and release of ? re? ghting agents, and control of valves, ? ttings, ventilation and drain- age recommended or accomplished with the help of automation, while the repair party could get suited up and charge hoses. “With the right data, the system can observe a departure from steady state.

And it’s more than just an alarm,” said

Gunn. “You can know more about a space before you open a hatch to go in than just placing the back of your hand on it to see if it’s hot. We wanted to be able to conduct an assessment with- out waiting for the repair party,” Gunn said.

Gunn said the study group imag- ined a helmet and visor system for the damage control team leader that could show normal and actual conditions in a space. “I can see what the space nor- mally looks like, so when I get in there

I can see what’s changed or has been damaged.

I’ll know where the lights, power or ventilation is supposed to be. I may see sensor readings that are different that steady state, that indicates a hot spot or ? ooding, and I can ? nd out if

I’m entering the space that’s been dam- aged, or is on the periphery of the next space that’s burning.”

The technology was new back then.

Today, Gunn said products such as

Google Glass can do essentially the same thing.

The use of sensors would enable the crew to monitor the status of tank levels and the condition of voids and unmanned spaces, and protect security spaces from intrusion.

Condition-based maintenance would monitor status, analyze trends, detect faults and predict system degradation or failure.

This would aid in scheduling the right preventive maintenance, as well as guide corrective maintenance and repair management. This would re- duce manpower required for mainte- nance and repair aboard ship, and im- (U.S. Navy photo/Released) 90 Maritime Reporter & Engineering News • NOVEMBER 2016

MR #11 (90-97).indd 90 11/4/2016 1:21:46 PM

89

89

91

91