Page 32: of Maritime Reporter Magazine (December 2020)

Great Ships of 2020

Read this page in Pdf, Flash or Html5 edition of December 2020 Maritime Reporter Magazine

Great

Ships of 2020

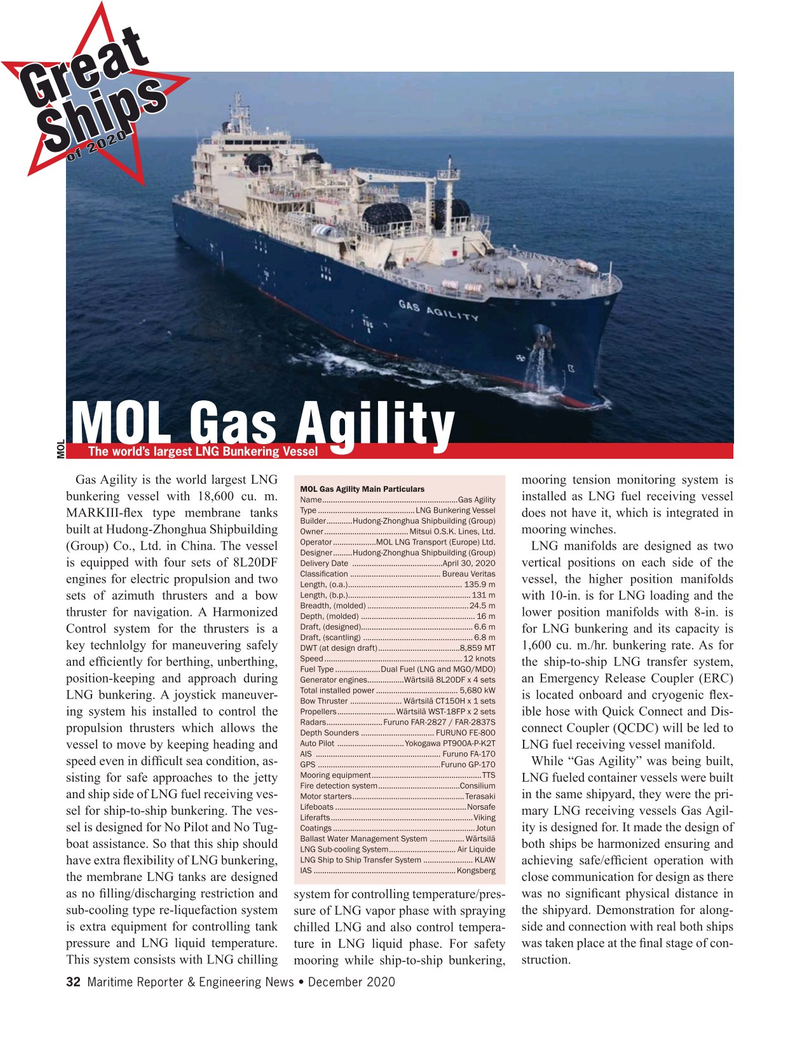

MOL Gas Agility

The world’s largest LNG Bunkering Vessel

MOL

Gas Agility is the world largest LNG mooring tension monitoring system is

MOL Gas Agility Main Particulars bunkering vessel with 18,600 cu. m. installed as LNG fuel receiving vessel

Name ...............................................................Gas Agility

Type .............................................LNG Bunkering Vessel

MARKIII-? ex type membrane tanks does not have it, which is integrated in

Builder ............Hudong-Zhonghua Shipbuilding (Group) built at Hudong-Zhonghua Shipbuilding mooring winches.

Owner .......................................Mitsui O.S.K. Lines, Ltd.

Operator ....................MOL LNG Transport (Europe) Ltd.

(Group) Co., Ltd. in China. The vessel LNG manifolds are designed as two

Designer .........Hudong-Zhonghua Shipbuilding (Group)

Delivery Date ..........................................April 30, 2020 is equipped with four sets of 8L20DF vertical positions on each side of the

Classi? cation ..........................................Bureau Veritas engines for electric propulsion and two vessel, the higher position manifolds

Length, (o.a.) .....................................................135.9 m

Length, (b.p.) .........................................................131 m sets of azimuth thrusters and a bow with 10-in. is for LNG loading and the

Breadth, (molded) ...............................................24.5 m thruster for navigation. A Harmonized lower position manifolds with 8-in. is

Depth, (molded) .....................................................16 m

Draft, (designed)....................................................6.6 m

Control system for the thrusters is a for LNG bunkering and its capacity is

Draft, (scantling) ...................................................6.8 m key technlolgy for maneuvering safely 1,600 cu. m./hr. bunkering rate. As for

DWT (at design draft) ......................................8,859 MT

Speed ................................................................12 knots and ef? ciently for berthing, unberthing, the ship-to-ship LNG transfer system,

Fuel Type .....................Dual Fuel (LNG and MGO/MDO) position-keeping and approach during an Emergency Release Coupler (ERC)

Generator engines .................Wärtsilä 8L20DF x 4 sets

Total installed power ......................................5,680 kW

LNG bunkering. A joystick maneuver- is located onboard and cryogenic ? ex-

Bow Thruster ........................Wärtsilä CT150H x 1 sets

Propellers ...........................Wärtsilä WST-18FP x 2 sets ing system his installed to control the ible hose with Quick Connect and Dis-

Radars ..........................Furuno FAR-2827 / FAR-2837S propulsion thrusters which allows the connect Coupler (QCDC) will be led to

Depth Sounders ..................................FURUNO FE-800

Auto Pilot ...............................Yokogawa PT900A-P-K2T vessel to move by keeping heading and LNG fuel receiving vessel manifold.

AIS ..........................................................Furuno FA-170 speed even in dif? cult sea condition, as- While “Gas Agility” was being built,

GPS .........................................................Furuno GP-170

Mooring equipment ...................................................TTS sisting for safe approaches to the jetty LNG fueled container vessels were built

Fire detection system ......................................Consilium and ship side of LNG fuel receiving ves- in the same shipyard, they were the pri-

Motor starters ....................................................Terasaki

Lifeboats .............................................................Norsafe sel for ship-to-ship bunkering. The ves- mary LNG receiving vessels Gas Agil-

Liferafts ..................................................................Viking

Coatings ..................................................................Jotun sel is designed for No Pilot and No Tug- ity is designed for. It made the design of

Ballast Water Management System ................Wärtsilä boat assistance. So that this ship should both ships be harmonized ensuring and

LNG Sub-cooling System ...............................Air Liquide

LNG Ship to Ship Transfer System .......................KLAW have extra ? exibility of LNG bunkering, achieving safe/ef? cient operation with

IAS ..................................................................Kongsberg the membrane LNG tanks are designed close communication for design as there as no ? lling/discharging restriction and system for controlling temperature/pres- was no signi? cant physical distance in sub-cooling type re-liquefaction system sure of LNG vapor phase with spraying the shipyard. Demonstration for along- is extra equipment for controlling tank chilled LNG and also control tempera- side and connection with real both ships pressure and LNG liquid temperature. ture in LNG liquid phase. For safety was taken place at the ? nal stage of con-

This system consists with LNG chilling mooring while ship-to-ship bunkering, struction. 32 Maritime Reporter & Engineering News • December 2020

MR #12 (18-33).indd 32 12/4/2020 10:43:15 AM

31

31

33

33