Page 39: of Maritime Reporter Magazine (January 2021)

The Ship Repair & Conversion Edition

Read this page in Pdf, Flash or Html5 edition of January 2021 Maritime Reporter Magazine

REPAIR & CONVERSION cost, as well as reliability and adequate redundancy for a number

The Bowthruster of con? guration options. The con? gurations included • Replacing propulsion alternators • ZF Marine model AT 5011 RT TT-FP. o Azimuthing thruster capable of tunnel operation • New engines when retracted.

• New gensets o 1600 mm diameter ? xed pitch propeller, 5 bladed, • Integrated bus within a nozzle.

• Integrated bus with new alternators o L-drive con? guration, with a variable-speed 825 kW • Repower jacket-water-cooled AC motor.

• Repower with variable speed o Electric steering motors.

The goal was to ? nd the best value, including reduction in risk o Active front end motor drive, water cooled.

of failures impacting missions, lifecycle cost, and reduction in emissions. The chosen con? guration of four generators, two large and two small, on an integrated bus provided the best over- all reliability and fuel economy.

Insights on the BWMS

An Optimarin Ballast System (OBS) rated to 100 cu. m./hr. ballasting and 167 cu. m./hr. deballasting was chosen for the job. A study of available ballast water treatment systems was completed. It was found that, at the time, the Optimarin Ballast

System was the only appropriately sized ballast water treatment system (BWTS) which was United States Coast Guard (USCG) type-approved. While others may have obtained approval by the time of construction, Glosten recommended to design around and install a USCG type-approved system to reduce project risk and ensure a path to approval.

Images courtesy Glosten

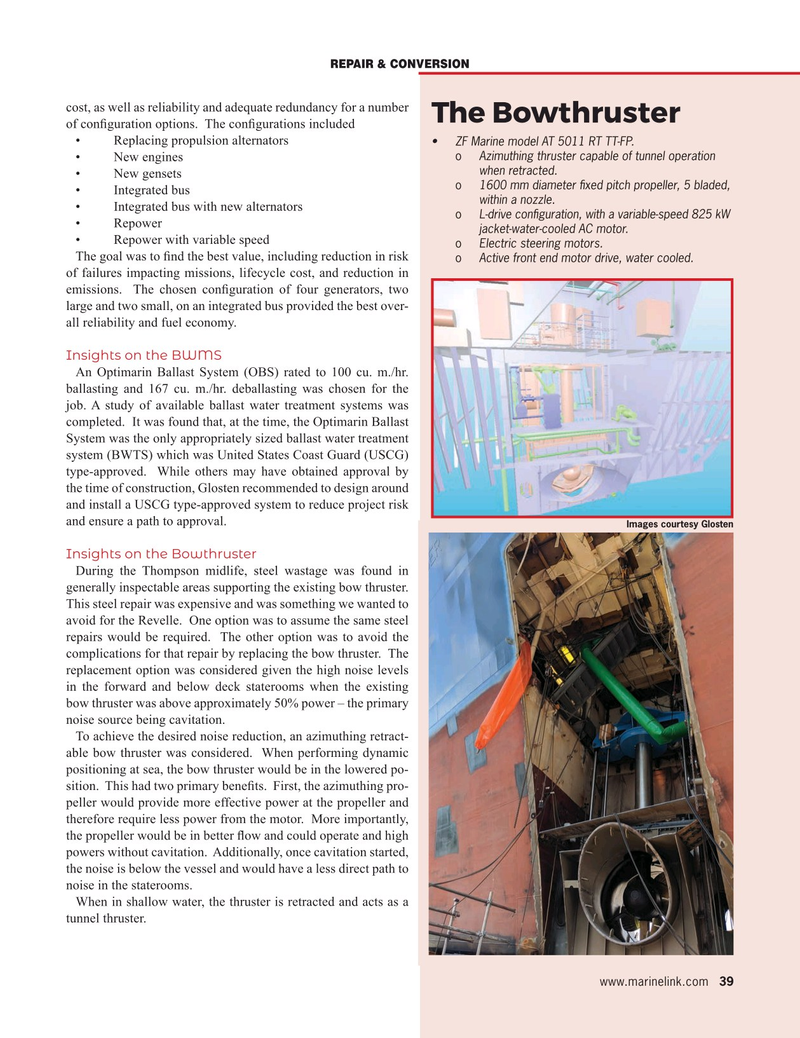

Insights on the Bowthruster

During the Thompson midlife, steel wastage was found in generally inspectable areas supporting the existing bow thruster.

This steel repair was expensive and was something we wanted to avoid for the Revelle. One option was to assume the same steel repairs would be required. The other option was to avoid the complications for that repair by replacing the bow thruster. The replacement option was considered given the high noise levels in the forward and below deck staterooms when the existing bow thruster was above approximately 50% power – the primary noise source being cavitation.

To achieve the desired noise reduction, an azimuthing retract- able bow thruster was considered. When performing dynamic positioning at sea, the bow thruster would be in the lowered po- sition. This had two primary bene? ts. First, the azimuthing pro- peller would provide more effective power at the propeller and therefore require less power from the motor. More importantly, the propeller would be in better ? ow and could operate and high powers without cavitation. Additionally, once cavitation started, the noise is below the vessel and would have a less direct path to noise in the staterooms.

When in shallow water, the thruster is retracted and acts as a tunnel thruster.

www.marinelink.com 39

MR #1 (34-49).indd 39 1/7/2021 5:09:10 PM

38

38

40

40