Page 28: of Offshore Engineer Magazine (Jul/Aug 2021)

The Robotics Revolution

Read this page in Pdf, Flash or Html5 edition of Jul/Aug 2021 Offshore Engineer Magazine

FEATURE ROBOTICS operating them. There, they’re doing rounds autonomously in a

MEG (gas dehydration) treatment unit. This is a big step, says

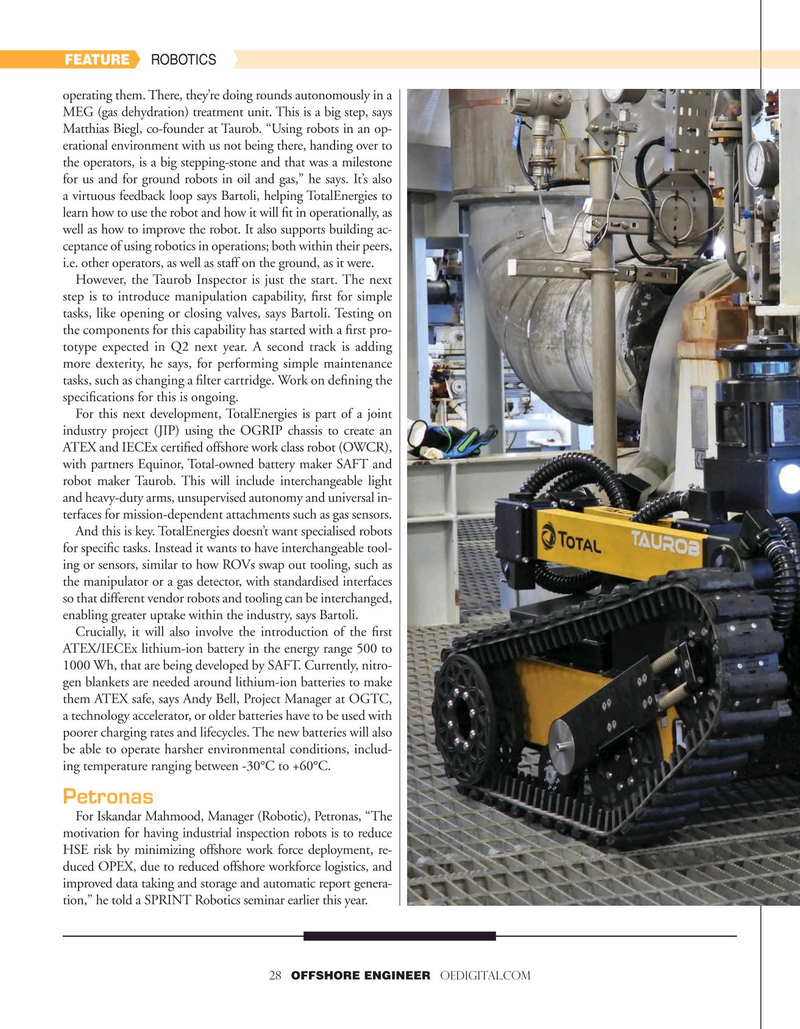

Matthias Biegl, co-founder at Taurob. “Using robots in an op- erational environment with us not being there, handing over to the operators, is a big stepping-stone and that was a milestone for us and for ground robots in oil and gas,” he says. It’s also a virtuous feedback loop says Bartoli, helping TotalEnergies to learn how to use the robot and how it will ft in operationally, as well as how to improve the robot. It also supports building ac- ceptance of using robotics in operations; both within their peers, i.e. other operators, as well as staff on the ground, as it were.

However, the Taurob Inspector is just the start. The next step is to introduce manipulation capability, frst for simple tasks, like opening or closing valves, says Bartoli. Testing on the components for this capability has started with a frst pro- totype expected in Q2 next year. A second track is adding more dexterity, he says, for performing simple maintenance tasks, such as changing a flter cartridge. Work on defning the specifcations for this is ongoing.

For this next development, TotalEnergies is part of a joint industry project (JIP) using the OGRIP chassis to create an

ATEX and IECEx certifed offshore work class robot (OWCR), with partners Equinor, Total-owned battery maker SAFT and robot maker Taurob. This will include interchangeable light and heavy-duty arms, unsupervised autonomy and universal in- terfaces for mission-dependent attachments such as gas sensors.

And this is key. TotalEnergies doesn’t want specialised robots for specifc tasks. Instead it wants to have interchangeable tool- ing or sensors, similar to how ROVs swap out tooling, such as the manipulator or a gas detector, with standardised interfaces so that different vendor robots and tooling can be interchanged, enabling greater uptake within the industry, says Bartoli.

Crucially, it will also involve the introduction of the frst

ATEX/IECEx lithium-ion battery in the energy range 500 to 1000 Wh, that are being developed by SAFT. Currently, nitro- gen blankets are needed around lithium-ion batteries to make them ATEX safe, says Andy Bell, Project Manager at OGTC, a technology accelerator, or older batteries have to be used with poorer charging rates and lifecycles. The new batteries will also be able to operate harsher environmental conditions, includ- ing temperature ranging between -30°C to +60°C.

Petronas

For Iskandar Mahmood, Manager (Robotic), Petronas, “The motivation for having industrial inspection robots is to reduce

HSE risk by minimizing offshore work force deployment, re- duced OPEX, due to reduced offshore workforce logistics, and improved data taking and storage and automatic report genera- tion,” he told a SPRINT Robotics seminar earlier this year. 28 OFFSHORE ENGINEER OEDIGITAL.COM

27

27

29

29