Paint

-

- Strategic Value Adding Purchasing Maritime Reporter, Apr 2000 #28

An effective purchasing strategy is at the core of successful purchasing departments. Strategies that offer total value to an organization should be the goal of all purchasing organizations.

Purchasing professionals around the world are always in search of new strategies that creatively reduce costs and add previously unrealized value to an organization.

Since motivating multi-company groups is difficult, the purchasing department must offer a clear strategy that offers value to all involved. Hence.

Purchasing Programs, procuring products plus services, is a strategy that can be employed successfully to bring value to all involved.

The theory of Purchasing Programs is to leverage vendors to offer products and services — whereas previously — vendors were only offering products. The approach is to challenge vendors to offer significant value in areas not previously realized. This shift requires that the purchasing department refuse to purchase products based solely on the acquisition cost of the product. The evaluation of the total purpose of the product and services within an enterprise is the key.

Purchasing Programs utilize the vendor's services to enhance the value of commodity purchases. Purchasing Programs focus on buying service plus products, not simply products. This concept is simple, however the application of such a methodology of purchasing within an organization is difficult.

Unlike purchasing to simply reduce the purchase price of a product, Purchasing Programs need careful planning prior to the solicitation of requests from vendors.

Effective Purchasing Programs must have clearly defined objectives, a process to review these objectives, and a method to evaluate the objectives of the process.

American Classic Voyages (AMCV) had been struggling with coating technologies, and had diversified their vendor and product base in the hopes of finding the most effective mix of products and vendors. AMCV also spent considerable time and effort in the research and testing products that companies offered in hopes of finding the correct items to meet their needs. After research and review, purchasing determined that concentrating purchases with one particular vendor would be more effective in gaining the commitment of one qualified company to assist in handling the company's paint requirements. After careful study of the company's total purchases, and vendor base, International Paint was determined to be the best fit - its size, reputation, and ability further supported this decision. In addition, the company was awarded significant projects in AMCV's future expansion.

Once International Paint was identified as a potential partner to create a Purchasing Program for AMCV, International Paint was approached by Ocean Development, a wholly owned subsidiary of American Classic Voyages, with the lure of additional business. A three-element program was created by Ocean Development (ODC) to offer incentives to all parties involved. Beginning with a rebate program, which was created to lower overall costs, it was also designed to offer the operating divisions incentives to concentrate their purchases with this supplier. Secondly, there was up front allowance granting paint to AMCV that would be used to support their upcoming projects. Third, there would be a quantifiable process to allow the vendor to address all coatings issues in an attempt to offer coating solutions to existing problems.

Upon implementation of this plan, there would be then be a multi-division meeting to address all of the coatings challenges. A meeting was set where all individuals involved with paint were to participate in a feedback session with a senior vice president of International Paint. The purpose of the meeting was to clarify requirements on both sides in order to establish an action plan.

With favorable intentions in mind, the initial meeting opened with all participants venting their dissatisfaction with the previous level of service of International Paint. There were several outstanding issues with the company, such as incorrect invoices, lack of a consis- tent customer service representative, and lack of product, which matched existing paint. The International Paint representative listened attentively to each complaint and took copious notes regarding each concern. Once all of the concerns had been raised, the International Paint representative apologized for all the problems previously encountered and assured that these issues would be corrected.

He then launched into his presentation explaining what his company could offer and discussed what steps the two companies should take in the future.

This presentation included considerable data regarding International Paint and its many different offerings. It was clear that International Paint had the resources to offer all of the needed coatings services. The challenge then became to determine in what priority should these offerings be implemented.

A few days following the meeting, International Paint had already distrib- uted a task listing complete with responsible parties and due dates, which in turn became the vehicle for the Purchasing Program. Each issue, concern, support and training requirement was included on this list, thus mobilizing International Paint resources in ports around the U.S. This program also included the full time services of International Paint inspectors in three key ports in support of various projects, as well as a paint application and use training program for end users. International Paint was also called upon to provide coatings handbooks for new projects, the creation of a color matching program for existing coatings, a custom blend on demand program, and a paint identification program.

Through the diligence of ODC and International Paint, the program was ultimately labeled a success. International Paint has been diligently delivering the desired results along with correcting previous omissions in their service.

After six months all participants were asked to rate International Paint; the company was rated 3.59 on a scale of 1 to 4. Although there is some room for improvement it is very clear that the overall satisfaction level is favorable.

In addition to this improvement in service, AMCV has received custom training and the services of paint inspectors in three key ports. If AMCV were to fund additional full time paint inspectors and training at these sites the cost to the company would amount to approximately $100,000. Clearly there is considerable benefit by bundling these services within the cost of the product rather than purchasing these services independently. Labor savings, costs savings, expertise and training are all tangible benefits of the program. International Paint has benefited from its early involvement in the process of color selections. This has allowed them to offer critical input regarding past experience with other owners, as well as giving them input early into the upcoming projects. International Paint also learned how to mobilize its offerings in a manner to increase customer satisfaction and to better understand the unique needs of the cruise industry. In what could be dubbed as a win-win situation, AMCV has received a valuable partner with regards to coatings technology, and International Paint has been rewarded with a loyal client.

Robert Lee Gordon is currently the director of purchasing for Ocean Development Company. Mr. Gordon is responsible for all project related purchasing of hotel, nautical, and engineering products for Project America, M/S Patriot, Columbia Queen, and the coastal vessels.

-

- Antifouling Paint Helps USCG Sink Maintenance Costs Maritime Reporter, Mar 2002 #36

The United States Coast Guard (USCG) has reduced maintenance costs by minimizing the time spent on ship bottom refurbishing, with the help of E Paint Company of East Falmouth, Mass. E Paint SN-I coating provides USCG vessels with well-balanced control over a wide array of common soft and hard fouling

-

- International Paint Enters Commercial Agreement With Nippon Paint Co. Maritime Reporter, Feb 15, 1977 #33

International Paint Company, New York, N.Y., has announced that the International Paint Group, the world's largest marine coatings manufacturers, has entered into a technical and commercial agreement for marine paint with the Nippon Paint Company of Osaka, Japan, the largest paint manufacturer

-

- Nippon Paint Restructures Maritime Reporter, Mar 2004 #69

Nippon Paint is restructuring its marine coatings subsidiary to increase its presence in the global marine paint market for newbuildings, shiprepair and maintenance. As part of a strategy to build up its marine coatings business worldwide, Nippon Paint Co Ltd is restructuring its specialized subsidiary

-

- Optimizing Blast and Paint Processes in New Construction Shipbuilding Marine News, Apr 2024 #38

approach. This intricate process, essential for achieving top-tier corrosion control, is methodically segmented into five crucial stages:Raw material entryPainting the modulesSmall partsPainting of erection joints at the module levelFinal paint and ship's completion. Each stage is crucial in its own

-

- International Paint Enters Korean Coatings Market Maritime Reporter, Aug 1981 #13

International Paint Company, with U.S. headquarters in Union, N.J., and manufacturing centers in New Orleans and San Francisco, recently entered a joint venture with the Seoul, Koreabased Daihan Ink & Paint Company. The merger is now registered as International Paint (Korea) Ltd. The venture was

-

- Marine coatings & corrosion control Maritime Reporter, May 1984 #26

, preventing them from being loosened or kicked out. Epoxo is said to maintain its highly effective non-slip properties five times longer than sand and paint. It is unaffected by seawater, oil, gasoline, grease, and chemicals, and can be rolled, troweled, or sprayed on. A two-man team can roll up to

-

- Shipyard Coatings: Green is the Best Color Marine News, Apr 2019 #40

its facility is ready for whatever harsh conditions come next. That’s because, in April of 2018, VT Halter Marine unveiled a state-of-the-art blast and paint facility that today allow ship sections to be prepared, blasted and painted in a controlled environment. The new facility incorporates cutting-edge

-

- The Perfect Anchor for Paint Marine News, Jul 2014 #51

Barge manufacturer doubles production and reduces paint waste with new blast line. When the 600th barge launch was celebrated at Brownsville Marine Products (BMP) just south of Pittsburgh in November 2012, it marked the company’s success at reviving a site with over 75 years of history. At the same time

-

- International Paint Appoints Two Specialists In Coatings Maritime Reporter, Feb 1977 #52

John M. Wise, general manager of the Protective Coatings Division of International Paint Co., Inc., has announced the appointment of Jack Voyles and Al Ellis as engineering specialists. Formerly chief engineer of coatings sales for AMF Tuboscope, Mr. Voyles joined the International Paint Group in

-

- The NewiIMdlTreaty to Ban TBT Maritime Reporter, Dec 2002 #21

of Harmful Anti-fouling Systems for Ships." The Convention has been developed to immediately ban the use of Tributyltin (TBT) globally in antifouling paints to "protect the marine environment". The ban on TBT has come about because TBT has detrimental effects on non-target marine organisms. In November

-

- Better Blasting: Send in the Robots Marine News, Feb 2020 #50

When designing and constructing a new blast and paint facility at its yard in Belle Chasse, La., C&C Marine and Repair set out to create a safe, efficient and environmentally friendly worksite that would deliver a high-quality product.Fifteen months and 131 barges later, C&C Marine has nearly

-

)

April 2024 - Marine News page: 39

)

April 2024 - Marine News page: 39There are ? ve major paint catego- lenges in shipyards is managing small building is a multifaceted endeavor ries in new construction shipbuilding: parts, which are prone to surface rust that demands integrative systems before installation. Optimizing the planning, as well as adoption of new 1.

-

)

April 2024 - Marine News page: 38

)

April 2024 - Marine News page: 38Tech File Optimizing Blast and Paint Processes in New Construction Shipbuilding By Colin Gallagher, Director of Shipyard Optimization, BlastOne International The ef? cacy of surface preparation and coating appli- 1. Raw material entry cation in the new construction shipbuilding industry is 2. Painting

-

)

April 2024 - Marine News page: 2

)

April 2024 - Marine News page: 2Challenges By Joe Nicastro, Legit Security Inland Waterways Impact 46 Classi? ed Advertising 10 Insights: 38 Tech File: Blast & Paint 48 Advertisers Index By Colin Gallagher, BlastOne International Jennifer Carpenter, American Waterways Operators By Eric Haun On

-

)

November 2023 - Marine News page: 33

)

November 2023 - Marine News page: 33the U.S. offshore wind market and keeping a close and 25% of the country’s energy demand by 2050. eye on hybrid solutions for its ? eet. While that may paint a rosy picture of a cleaner, greener fu- “There is currently a ? urry of new construction happen- ture, achieving that level of energy production

-

)

August 2023 - Maritime Reporter and Engineering News page: 20

)

August 2023 - Maritime Reporter and Engineering News page: 20are performed by mechanized de- the certi? cation framework for a shipyard to integrate innova- vices (blasting, cutting, grinding processing, coating/paint- tive smart technologies into their operational processes and ing procedure, welding of subassembly, etc.). But the start demonstrate their commitment

-

)

August 2023 - Marine News page: 42

)

August 2023 - Marine News page: 42Tech File Shipyard Tools jects of rust, paint and contaminants to bare metal. lando, Fla.-based Laser Photonics, a provider of patented However, for operators, exposure to corrosive acids and industrial grade CleanTech laser systems for cleaning and noxious chemical fumes is inherently dangerous.

-

)

August 2023 - Marine News page: 40

)

August 2023 - Marine News page: 40and scale with a high-energy laser beam that leaves the substrate unaffected. The technology can also be used for selective cleaning and even de-painting on access points and service latches when required. Prepara- tion and cleanup time are minimal, and the low-mainte- nance equipment can last decades

-

)

August 2023 - Marine News page: 9

)

August 2023 - Marine News page: 9will receive $704,206 to purchase a 176-ton hydraulic self- Mississippi River, will receive $1.2 million for blasting and propelled vessel transporter. painting equipment upgrades. Main Industries, Inc., of North Charleston, S.C., will Sterling Shipyard LLC, of Port Neches, Texas, on the receive $527,173

-

)

June 2023 - Maritime Reporter and Engineering News page: 39

)

June 2023 - Maritime Reporter and Engineering News page: 39to Garry Noonan, Director, Innovation, Ardmore Shipping, an essential fuel and emissions reduction tool is coatings. “When we look at hull coatings, paint is expensive; but when you compare it to the life cycle of the paint, it's relatively cheap,” said Noonan. With that, Ardmore opts for the highest

-

)

June 2023 - Maritime Reporter and Engineering News page: 6

)

June 2023 - Maritime Reporter and Engineering News page: 6Ardmore invited Terry Breese [email protected]; +1 561-732-1185 training practices, surveying vessel owners, two coatings companies to each paint one Lucia Annunziata maritime education and training institu- half of an Ardmore ship to really deter- [email protected]; +1 212-477-6700

-

)

May 2023 - Maritime Reporter and Engineering News page: 54

)

May 2023 - Maritime Reporter and Engineering News page: 54fouling spe- ing to replace biocidal hull coatings overnight. There will cies such as molluscs, simply cannot attach, unless slime is still be a need to paint hulls under the waterline in something already present. Yet, as any small boat owner who owns a that is unappealing to marine life. The difference

-

)

May 2023 - Maritime Reporter and Engineering News page: 40

)

May 2023 - Maritime Reporter and Engineering News page: 40GREEN MARINE We are no longer a coating supplier that applies paint and waits for the next maintenance event. We are there all the time. We look at [our customer's] ships on our screens every day, and we partner with them on managing operations as well, from our lens.” Alexander Enström, EVP

-

)

May 2023 - Maritime Reporter and Engineering News page: 28

)

May 2023 - Maritime Reporter and Engineering News page: 28, rubbers, clothes, medical equipment, detergents, better access to markets, better ? scal terms, and lower risks. adhesives, pesticides, and paints and coatings. Also, how much of this resource might be available given a Asked recently what she would say to a ‘Just Stop Oil’ pro- certain price

-

)

May 2023 - Maritime Reporter and Engineering News page: 16

)

May 2023 - Maritime Reporter and Engineering News page: 16. by periodic signi? cant advancements (e.g. copper sheathing, Through a series of collaborative partnerships, with both anti-fouling & fouling release paints). We are now in the midst the US Navy and commercial companies, the CCBC team has of another advancement: hull grooming. Research funded by the

-

)

April 2023 - Maritime Reporter and Engineering News page: 14

)

April 2023 - Maritime Reporter and Engineering News page: 14statement. I think more readily than people that use electric stoves. Let’s face it, we it would be more accurate to say: have survived leaded gas, lead paint, loss of ozone, PCP’s, DDT, ³

-

)

February 2023 - Maritime Reporter and Engineering News page: 15

)

February 2023 - Maritime Reporter and Engineering News page: 15light microfouling only) and when it is recom- tential of Biofouling Management Measures, which highlighted mended (macrofouling, newly applied biocidal paint, or dam- the signi? cant fuel penalties caused by even a layer of slime on aged paint). While this proposal is years from being law, it is the hull

-

)

February 2023 - Maritime Reporter and Engineering News page: 13

)

February 2023 - Maritime Reporter and Engineering News page: 13. I might have come down the losers don’t. To quote another good For each column I write, MREN has the mountain, but it turned out there was one: Don’t paint yourself into a corner agreed to make a small donation to a charity of my choice. For this column I really no one there. and that goes for small

-

)

January 2023 - Marine Technology Reporter page: 36

)

January 2023 - Marine Technology Reporter page: 362 x 1/2”, or 13. Using the brush attached to the inside of the lid, 1”, of the outer jacket off the end of each cable. I use small or an acid brush, paint the entire cleaned jacket area with diagonal cutters to get underneath the outer jacket without Scotchkote. Using the brush bristles, encourage it

-

)

January 2023 - Maritime Reporter and Engineering News page: 41

)

January 2023 - Maritime Reporter and Engineering News page: 41acquired the Dixie that, whether it is galvanizing or zinc plat- and perational ef? ciency.” Trader in 2021, the 1,800-hp tug, built ing, specialized paints, or use of stainless The Dixie Trader is now out? tted with in 1972, was approaching her 50th year steel and other corrosion resistant materi-

-

)

December 2022 - Maritime Reporter and Engineering News page: 29

)

December 2022 - Maritime Reporter and Engineering News page: 292022 James R. Barker. “Designed to navigate the winding curves of the Cuyahoga River, built with Cleveland-Cliffs steel and coated with Sherwin-Williams paint, the M/V Mark W. Barker Greg Trauthwein was most signi? cantly built as part of a long-term partnership to move Lake Erie-mined salt for Cargill

-

)

December 2022 - Maritime Reporter and Engineering News page: 26

)

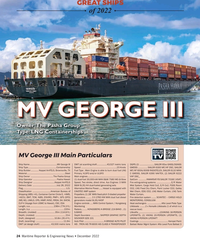

December 2022 - Maritime Reporter and Engineering News page: 26. cializes in LNG.” Apart from the hull, the ship features Hempel self-polish- “I would say if you want to help your communities and help ing copolymer paints; a full-spectrum of modern bridge kit the environment, LNG is the way to go,” said Washburn. “It – hardware and software to ensure the best route

-

)

December 2022 - Maritime Reporter and Engineering News page: 24

)

December 2022 - Maritime Reporter and Engineering News page: 24......................................................................U.S. Alternative Marine Power .......Vessel is equipped with CO2, LNG Fixed Dry Chem, Paint Locker CO2, Galley Classi? cation ...............................American Bureau of CAVOTEC AMP system Wet Chem, EDG CO2, LNG Water Curtain, LNG

-

)

December 2022 - Maritime Reporter and Engineering News page: 6

)

December 2022 - Maritime Reporter and Engineering News page: 6off and sprucing up from the hull, the ship features self-polish- Nicole Ventimiglia of some old ideas. The direction is clear, but ing copolymer paints; a full-spectrum of [email protected] the pace is not. modern bridge kit – hardware and software Corporate Staff Manager, Marketing This year’s

-

)

November 2022 - Maritime Reporter and Engineering News page: 62

)

November 2022 - Maritime Reporter and Engineering News page: 62.com [email protected] www.kienediesel.com NEW RUSTIBUS ECO 2000 ECO 2000 is our new environmentally friendly de-scaler which collects old paint and rust in its own unique catchment tray. When coupled with a vacuum it will eliminate the debris from entering the oceans. rustibus.com | sales@rusti