3410Subsea Engineering34 Petrobras Partnership

-

)

March 2024 - Marine Technology Reporter page: 44

)

March 2024 - Marine Technology Reporter page: 44NEW TECH OCEANOLOGY INTERNATIONAL 2024 Image courtesy Metron/Cellula Teledyne Marine acquires Valeport: Matt Quartley, MD, Valeport and Ole Søe-Pedersen, VP & Image courtesy Teledyne Marine GM Teledyne Marine announce the deal in London. Pictured (L-R): Cellula Robotics, President, Eric Jackson, Metron

-

)

March 2024 - Marine Technology Reporter page: 40

)

March 2024 - Marine Technology Reporter page: 40NEW TECH OCEANOLOGY INTERNATIONAL 2024 All photos courtesy MTR unless otherwise noted NEW TECH, PARTNERSHIPS LAUNCH IN LONDON With Oceanology International now one month in the rear-view mirror, MTR takes a look at some of the interesting technologies launched before, during and after the London event.

-

)

April 2024 - Maritime Reporter and Engineering News page: 37

)

April 2024 - Maritime Reporter and Engineering News page: 37SIMULATION "A simulated vessel ? ooding can help teams work together to solve the challenge using different systems on the bridge." – Jussi Siltanen, Lead, "The gami? cation of Product Marketing, learning makes it fun." Safety Solutions at NAPA – Captain Pradeep Chawla, Founder, MarinePALS Image

-

)

April 2024 - Maritime Reporter and Engineering News page: 7

)

April 2024 - Maritime Reporter and Engineering News page: 7REGISTER NOW Seawork celebrates its 25th anniversary in 2024! The 25th edition of Europe’s largest commercial marine and workboat exhibition, is a proven platform to build business networks. Seawork delivers an international audience of visitors supported by our trusted partners. Seawork is the

-

)

April 2024 - Marine News page: 19

)

April 2024 - Marine News page: 19• Investment in Infrastructure and Onshoring Man- sharing best practices. Additionally, given the global nature ufacturing: The administration is committing over $20 of maritime operations, international cooperation is essen- billion towards U.S. port infrastructure over the next tial for establishing

-

)

February 2024 - Maritime Reporter and Engineering News page: 20

)

February 2024 - Maritime Reporter and Engineering News page: 20MARKETS FPSO technology dominates the region’s FPS demand. duction and storage of low and zero emission energy carriers, In all, 18 countries in West and East Africa are expected such as methanol and ammonia. One exciting development to receive new FPSOs, FLNGs and FPUs between 2024 and leverages

-

)

February 2024 - Marine News page: 38

)

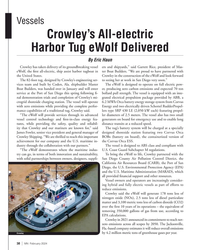

February 2024 - Marine News page: 38Vessels Crowley’s All-electric Harbor Tug eWolf Delivered By Eric Haun Crowley has taken delivery of its groundbreaking vessel ers and shipyards,” said Garrett Rice, president of Mas- eWolf, the ? rst all-electric, ship assist harbor tugboat in ter Boat Builders. “We are proud to have partnered with the

-

)

January 2024 - Marine Technology Reporter page: 56

)

January 2024 - Marine Technology Reporter page: 56FLOATING OFFSHORE WIND GAZELLE WIND POWER We’re already working on the pre-FEED, and now we’re go- clude 70 turbines of 15MW each, and has preselected Gazelle ing to be working on the engineering portion. Our main goal as one of the providers for the offshore wind platform. So, is to prove the concept

-

)

January 2024 - Marine Technology Reporter page: 12

)

January 2024 - Marine Technology Reporter page: 12INSIGHTS AERIAL DRONES & MINE HUNTING UNMANNED AERIAL SYSTEM HAS EARNED ITS SEA-LEGS By Edward Lundquist he Swiss-Swedish joint-venture UMS Skeldar V-200 mum take-off weight of 235kg, a maximum speed of 75 knots vertical take-off unmanned arial system (VTUAV) and a payload of up to 40kg. It can take

-

)

January 2024 - Maritime Reporter and Engineering News page: 29

)

January 2024 - Maritime Reporter and Engineering News page: 29ROY CAMPE, CTO, CMB.TECH But as important as the growth required to service the equipment, it from electric to charging to the fnal within the company is key, so too is could stretch and break all of the back- audits. the growth externally in the form of end support needed to run a smooth “It’s very

-

)

January 2024 - Maritime Reporter and Engineering News page: 27

)

January 2024 - Maritime Reporter and Engineering News page: 27ROY CAMPE, CTO, CMB.TECH The BeHydro Engine The MAN Engine The CMB.TECH team is fuel agnostic, and has formed partnerships with many engine makers in the quest to scale up on its quest to future proof the ? eet. The Volvo Penta Engine Volvo D4 DYNO Engine on Hydroville. CMB.TECH and Boeckmans

-

)

November 2023 - Marine Technology Reporter page: 33

)

November 2023 - Marine Technology Reporter page: 33There’s a company called Blue Forge Alliance that’s spon- solution. It’s never that. sored this amazing ad campaign called buildsubmarines.com buildsubmarines.com. You need to have partnerships with people in industry, the peo- It’s a website, but they have commercials and billboards that ple who are

-

)

November 2023 - Marine Technology Reporter page: 20

)

November 2023 - Marine Technology Reporter page: 20EYE ON THE NAVY NATO GAINS EXPERIENCE WITH UNMANNED SYSTEMS All photos courtesy NATO By Edward Lundquist allies and partners have taken Messenger is in its second year. Both are conducted at the Navy advantage of recent demon- Operational Experimentation Centre in Tróia, one of two Por- NATO strations

-

)

December 2023 - Maritime Reporter and Engineering News page: 35

)

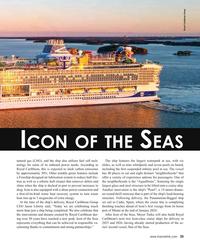

December 2023 - Maritime Reporter and Engineering News page: 35Royal Caribbean Group I SCON OF THE EAS natural gas (LNG), and the ship also utilizes fuel cell tech- The ship features the largest waterpark at sea, with six nology for some of its onboard power needs. According to slides, as well as nine whirlpools and seven pools on board, Royal Caribbean, this

-

)

December 2023 - Maritime Reporter and Engineering News page: 23

)

December 2023 - Maritime Reporter and Engineering News page: 23JUHA KYTÖLÄ, WÄRTSILÄ Inside Wärtsilä’s Sustainable Technology Hub The 150-meter-long vessel, touted by its operator as one of the world’s greenest, features an integrated package of Wärtsilä solutions, includ- ing four Wärtsilä 31 engines; exhaust treatment; LNGPac technology for LNG storage, supply

-

)

December 2023 - Maritime Reporter and Engineering News page: 13

)

December 2023 - Maritime Reporter and Engineering News page: 13equally unenlightening. that the level of PFOS is at or below 1 ppm. Ragnar Kreft- Another point to consider is that manufacturers are already ing, Founder, Lifeclean explains that the process is perfectly switching to alternative products and there is always a pos- safe and produces less wastewater than

-

)

November 2023 - Marine News page: 57

)

November 2023 - Marine News page: 57recent years, Kytölä said. In 2022, the company dedicated €241 million (about $255 million) to R&D expenditure, or 4.1% of its net sales, up from €165 million (about $175 million) and 3.2% in 2018. In particular, the company has been working to maxi- mize the ef? ciency of its portfolio of gas, diesel

-

)

November 2023 - Marine News page: 37

)

November 2023 - Marine News page: 37Feature Shipyards By Tom Ewing hen asked about the top issues facing if operating policies are murky. shipbuilders, executives at the Ship- As an example, Paxton and Zorensky cited a CBP ruling builders Council of America (SCA) linked to the installation of wind tower monopiles (steel W listed a number

-

)

November 2023 - Maritime Reporter and Engineering News page: 64

)

November 2023 - Maritime Reporter and Engineering News page: 64COMPANY IN FOCUS: W&O Company in Focus: In June 2023, Michael Hume rejoined W&O as President. W&O Image courtesy W&O or more than 48 years, W&O has focused exclusively Primary Product/Service on serving the maritime industry with products and W&O focuses solely on the maritime industry with prod- servi

-

)

November 2023 - Maritime Reporter and Engineering News page: 58

)

November 2023 - Maritime Reporter and Engineering News page: 58PORT FUNDING The ports authority found success by tailoring its projects to city has already submitted one Port Infrastructure Develop- the requirements of the grants programs. For example, for the ment Program grant and is positioned for other prospects to Colonel's Island Terminal needed to increase

-

)

November 2023 - Maritime Reporter and Engineering News page: 24

)

November 2023 - Maritime Reporter and Engineering News page: 24CTO IN FOCUS: DON HAIRSTON, AUSTAL USA ADVANCED TECHNOLOGIES Image courtesy U.S. Navy Additive Manufacturing to Support ‘One plus Two’ Austal USA Advanced Technologies is working with the US Navy on technical solutions that will power the next-gen of navy assets. Don Hairston recently took the helm of the

-

)

September 2023 - Marine Technology Reporter page: 71

)

September 2023 - Marine Technology Reporter page: 71SUBSEA EUROPE SERVICES www.subsea-europe.com/ Established at the beginning of 2020 with the goal to “simplify marine data acquisition” and make it possible for every organization to collect and evaluate marine data professionally, Subsea Europe Services provides easy access to precision sensors and

-

)

September 2023 - Marine Technology Reporter page: 68

)

September 2023 - Marine Technology Reporter page: 68MTR 100 HYDROCOMP INC. TRITECH INTERNATIONAL IMPACT SUBSEA www.hydrocompinc.com www.tritech.co.uk www.impactsubsea.com Since 1984, HydroComp has been a Tritech International Limited is dedi- Impact Subsea was founded by Ben leader in providing hydrodynamic soft- cated to providing reliable imaging

-

)

September 2023 - Marine Technology Reporter page: 66

)

September 2023 - Marine Technology Reporter page: 66MTR 100 BLUEPRINT SUBSEAS BLUE VENTURE FORUM CELLULA ROBOTICS www.blueprintsubsea.com www.blueventureforum.org www.cellula.com Designing and developing underwater The Blue Venture Forum is a program Cellula Robotics achieved a milestone acoustic sensors since 2006, Blueprint that connects existing blue