Bc Ferries

-

- Sail Safe BC Ferries’ Safety Initiative Maritime Reporter, Jun 2013 #30

BC Ferries cut time loss injuries in half; it reduced serious injuries by two-thirds; it slashed annual insurance claims costs by more than three-quarters.

What are you waiting for?

Can a vessel operator completely reshape its safety culture? Can it transform communications, training, operational practices and even employee engagement? And most importantly, if an operator is able to make such sweeping changes, what measurable difference will it make? It turns out it can make a huge difference to almost every meaningful key performance indicator, as the experience at British Columbia Ferry Services Inc. (BC Ferries) demonstrates. At BC Ferries time loss injuries have been cut in half. Serious injuries have been reduced by two-thirds. Annual insurance claims costs have been reduced by over three-quarters. And BC Ferries was able to do all this even though it was a relatively safe organization before its culture shift. This article describes SailSafe, the BC Ferries’ safety initiative and the impressive, measurable improvements in safety metrics that have been experienced as a result.

SailSafe

About five years ago BC Ferries embarked on SailSafe, a major, multi-phased initiative to improve safety. In the words of Mike Corrigan, BC Ferries President and CEO, SailSafe “reevaluates every aspect of BC Ferries safety culture, and empowers all employees to develop solutions.”

The all-encompassing SailSafe is built on the four pillars:

● Safety of People

● Safety of Assets

● Safety through Procedures

● Safety through Communication

But these pillars, as telling as they are, only barely begin to describe the direct and indirect goals of SailSafe. Aside from being about safety, SailSafe is about engagement, inclusivity, and cooperation. It is a joint program between union and management. It involves every division, every line of business, and it recognizes that nobody understands the job better than the people doing it. As such, it is driven by people at the top, by front-line employees, and by everyone in between. The key to the program’s success is that all BC ferries’ employees have a place, all have a stake SailSafe.

Phase One

SailSafe, which today is in phase three, was launched in late 2007 with the help of maritime safety and human factors experts from Force Technology and WrightWay Training. Phase one began with a series of workshops and the creation of a website designed to identify learning opportunities (or “gold dust”) to be converted into actions plans centered on the four pillars. In all, more than 400 employees contributed to the gathering of gold dust to inform these action plans.

The resulting plans included items from all areas of BC Ferries operations. It included simple items like the assessment of dollies and oil spill equipment, as well as more complex items like the assessment of operations in areas of restricted visibility. It created plans around communication, employee recognition, mentoring and access to information. It addressed topics such as wet weather gear, security planning and MED record books. In all, 49 safety-related action plans - from simple to complex - were addressed in phase one. Forty-four action plans were created, documented and approved, with five of the more complex plans being carried over to phase two.

There were many notable Phase 1 achievements. For example, rigorous risk assessment and local site investigations processes were created and rolled out. Phase 1 also resulted in the creation of a tool called the ALERT handbook for reporting. ALERT stands for “All Learning Events Reported Today,” a program by which all employees are encouraged to report any safety-related issue. The ALERTs are quickly addressed and have resulted in everything from small changes in procedures to large construction projects.

By April of 2013 approximately 4,000 ALERTs had been submitted, and this wealth of learning opportunities was fostered by a shift in BC Ferries’ safety culture. Specifically BC Ferries has adopted a “just culture,” wherein employees are not punished for honest mistakes or errors in judgment, and instead learning is gleaned from all opportunities. Because of this, employees never have a reason to conceal an incident or near-miss that can serve as a learning experience for the entire company.

Phase Two

Phase two of SailSafe was an extension of phase one. In addition to addressing the five action plans carried over from phase one, phase two focused on continuing and improving safety performance while addressing an additional 36 recommendations from the original action plan. The end of phase two also saw the creation of the SailSafe Ambassador Team – more than 350 BC Ferries employees volunteered for the job of being SailSafe representatives. Team members act as a two-way information conduit - disseminating SailSafe information, answering questions of employees, and collecting and reporting on safety suggestions.

Phase Three

As of April, 2012, SailSafe moved into phase three. This phase marked the transition from the implementation of a safety program to embodying safety as a normal part of all business activities. There were no new action plans introduced in phase three - instead it is the point where safety becomes an integral part of BC Ferries’ culture. The ultimate goal of SailSafe is for the program, itself, to no longer be necessary as safety becomes completely ingrained in every activity undertaken every day at BC Ferries.

Specifically, along with a focus on safety committees and team building, some of the primary phase three goals include the following:

● Monitoring of phase one and two action plans to ensure that their goals are realized and outcomes sustained

● Expanding awareness of SailSafe and safety in general, and engaging more employees in the process

● Continuing to build understanding of and use of the highly effective ALERT process.

In the words of a BC Ferries communication to employees, SailSafe will be successful when BC Ferries has, “…seen and experienced a cultural change in [our] workplace…When safety practices are fully known and practiced by all employees in all areas, all departments, and at all levels - from the President to the newest hire. We will be successful when all aspects of safety are accepted as ‘just the way we do it around here’”.

Training Effects

SailSafe is all-encompassing and there are concrete effects to be observed throughout the company. These include the ALERT process, open communication from the CEO to the employees, new procedures, the work of hundreds of SailSafe ambassadors, and more. In addition to all of these effects, one area greatly affected by SailSafe is training at BC Ferries. There are many aspects to this including a new and comprehensive simulation training program, leadership training, apprenticeships, certificate development programs and others.

One notable training initiative which embodies the philosophy of SailSafe is the SEA program - standing for “Standardized Education and Assessment”. The SEA program is an intensive blended (online and in-person) approach to job-, vessel-, and route-specific training which replaces the previous job-shadowing approach to vessel/terminal familiarization. It is supported by a new learning management system called MarineLMS (the company I work for), which was built in conjunction with BC Ferries and is specifically designed to support training in the maritime context. The SEA program is structured and sustainable, and produces consistent and reliable training outcomes - unlike job shadowing. Like other SailSafe initiatives, the SEA program involves all employees in its creation and maintenance.

SailSafe Outcomes

“We do SailSafe because we know it is the right thing to do,” said Mike Corrigan, President and CEO, BC Ferries. “If it saves us from one injury, it has been worth it.” But the results of SailSafe, as measured by BC Ferries since 2007 indicate multiple benefits - some expected, many more surprising. Of value for the industry as a whole is that the results are now quantified and documented - proving that attention to the safety culture and training work.

Safety Performance

The goal of SailSafe was to improve safety. It has done a remarkable job at doing so. Since 2007, the number of time loss injuries experienced at BC Ferries each year has dropped from approximately 360 to just over 150. Over the same period, the number of serious injuries has been reduced from roughly 100 to just over 40 and the days lost due to injury has declined from over 12,000 to under 7,500. These results are illustrated in Chart 1.

Cost Savings

It turns out that transforming the safety culture in a maritime organization is also good for the bottom line. When BC Ferries analyzed its insurance claims costs in the period leading up to 2012, they found that these costs had declined from roughly $3.5m to just over $800K, as shown in Chart 2.

On-time Performance

As part of improving safety at BC Ferries, one of the initiatives of SailSafe was to remove on-time performance from the employee assessment criteria for all but top level management. The intent of this was to ensure that an operational employee never compromised safety in the name of ensuring that the ferry arrived at its destination on time. Safety has to be paramount and this rule change sent that message loud and clear.

The concern of such a change was that although worthwhile it in the name of safety, this change would cause on-time performance to suffer. However, when BC Ferries looked over its on-time performance leading up to 2012, it found a remarkable thing. On-time performance had actually improved significantly, rising from approximately 85% to 92% (See Chart 3). While difficult to say why this happened, it is clear that factors such as reduced accidents, employee engagement, and a broadly improved working culture at BC Ferries all played significant roles.

SailSafe has been a successful initiative, but it is far from over. “Experts tell us [safety culture transformation] is a seven to 10 year process and we’re only [six] years into it,” said Captain Jamie Marshall, VP of Fleet Operations, BC Ferries. There is more to come - further training enhancements, further cultural transformation, and an ongoing process of continuing improvement. As such, we are observing the results of a transformation which is still underway. In some ways, it will never be over.

(As published in the June 2013 edition of Maritime Reporter & Engineering News - www.marinelink.com) -

- A BC Ferries Case Study: Lessons Learned in Setting Underwater Radiated Noise Targets Maritime Reporter, Sep 2021 #22

, the waters surrounding British Columbia’s Port of Vancouver host approximately 3,000 deep sea commercial vessels and 19 of the 35 ferries operated by BC Ferries, one of the largest ferry operators in the world. These waters are also home to a wide variety of aquatic wildlife, including the southern resident

-

- Vessel Specific Training Via Adaptive Learning Experience Maritime Reporter, Mar 2013 #34

fit him or her. How can this be applied to vessel-specific training? The best way to illustrate is to look at how British Columbia Ferry Systems Inc. (BC Ferries) uses adaptive learning to provide vessel- and route-specific training across its 35 vessels serving 47 ports on 25 routes. Adaptive Learning at

-

- SailSafe: A SEA Change for the Better Marine News, Jan 2016 #24

BC Ferries has improved its safety record, operational practices – and at the same time, its bottom line. In 2007, British Columbia Ferry Services Inc. (BC Ferries) initiated a union-management joint endeavor to create a world-class safety culture. This program, coined SailSafe, addressed a wide

-

- BC Ferry Contract Stirs Controversy Maritime Reporter, Oct 2004 #14

Schiffbau-Gesellschaft. The total value of the contracts is approximately $325 million Canadian. The new ships are called "Super Cclass" type. BC Ferries' specification for the new Super C-class vessels, which are planned to operate on BC Ferries' Horseshoe Bay-Departure Bay, and Swartz Bay-Tsawwassen

-

- Spotlight on North American Ferries Marine News, Aug 2014 #40

and AD/DC. The disclaimer reads, “Before boarding, secure all headwear, eyewear, wigs, and pitiful comb-overs. No refunds issued for bad hair days.” BC Ferries With an extensive area of service and pressure to turn a profit after being privatized in 2003, British Columbia Ferries has endured its share of

-

- Virtual Marine: Simulator Training is the Real Deal Marine News, Feb 2024 #34

;s commitment to innovation extends into other parts of the industry as well. In the passenger vessel sector, the company recently collaborated with BC Ferries to develop technology that is first-of-its-kind globally.“BC Ferries had an objective to improve the safety and competency of their workers

-

- Autonomous Vessels: Modern Ferries Evolve Marine News, Jan 2018 #30

, “…we also have our new Olympic Class ferries – the fourth of which is scheduled for delivery in July 2018.” Also on the West Coast, Vancouver-based BC Ferries is also contemplating what comes next. Captain Jamie Marshall, the ferry giant’s Vice President of Business Development and Innovation, explained

-

- Safety: A Shift in Culture Maritime Reporter, Oct 2013 #20

that employees are not punished for an honest mistake or error in judgement resulting in an accident or near miss. At British Columbia Ferries Inc. (BC Ferries) this policy, as part of their huge cultural shift, has created an environment where an employee has no reason to conceal a near miss. This has yielded

-

- The Training Implications of Subchapter M Maritime Reporter, Nov 2016 #19

, and training is easily one of the greatest drivers of safety. I have written in the past about the example of British Columbia Ferry Services Inc. (BC Ferries) and their safety culture and training transformation that began in 2007. BC Ferries undertook a comprehensive effort to instill a strong safety

-

- North American Ferries: Faster, Greener & Safer Marine News, Jan 2017 #34

conventional diesel fuel. The ripple impact on the domestic waterfront’s bottom line has not gone unnoticed. Canada’s Cup is Full Privately owned BC Ferries serves 24 routes along the coast of British Columbia under an exclusive contract with the Province, leveraging a fleet of 34 boats. The operator

-

- Leading the Charge Marine News, Nov 2021 #42

before there is a need to charge.” For long transits, a 9,800 gallon fuel reserve can power a pair of 300 kW auxiliary generators.Damen is building BC Ferries’ hybrid-electric Island Class vessels in Romania (Photo: Damen Shipyards Group)Electrification is already being deployed in the North American

-

)

April 2024 - Marine News page: 42

)

April 2024 - Marine News page: 42People & Companies Nevey to Head TAI Hires Kalla Washington State Ferries TAI Engineers appointed Amer Steve Nevey has been selected to Kalla as director of production design. serve as assistant secretary for the FMC Names Usman CIO Washington State Ferries Division, Nevey Schwandt succeeding Patty

-

)

April 2024 - Marine News page: 40

)

April 2024 - Marine News page: 40Vessels General Arnold Chasse, La. The 32-inch CSD will immediately begin work on Phase Four of the Corpus Christi Ship Channel Improvement Project. The project will bene? cially reuse 100% of the dredged material removed from the channel deepening and widening. The General Arnold is the newest,

-

)

April 2024 - Marine News page: 35

)

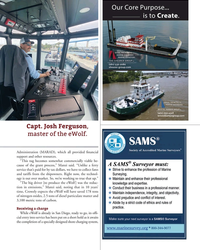

April 2024 - Marine News page: 35Capt. Josh Ferguson, master of the eWolf. Administration (MARAD), which all provided ? nancial support and other resources. “This tug becomes somewhat commercially viable be- cause of the grant process,” Manzi said. “Unlike a ferry service that’s paid for by tax dollars, we have to collect fares and

-

)

April 2024 - Marine News page: 32

)

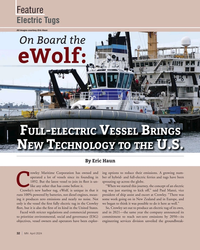

April 2024 - Marine News page: 32Feature Electric Tugs All images courtesy Eric Haun On Board the eWolf: F - V B ULL ELECTRIC ESSEL RINGS EW ECHNOLOGY TO THE N T U.S. By Eric Haun rowley Maritime Corporation has owned and ing options to reduce their emissions. A growing num- operated a lot of vessels since its founding in ber

-

)

February 2024 - Maritime Reporter and Engineering News page: 22

)

February 2024 - Maritime Reporter and Engineering News page: 22R&D MATT HART Matt Hart, Manager & Platform Leader, Marine & Stationary Power Systems, Wabtec, offers insights on how the megatrends of decarbonization, energy transition and autonomy all inspire Image courtesy Wabtec and impact the marine power solutions from Wabtec. By Greg Trauthwein Matt, to start

-

)

February 2024 - Maritime Reporter and Engineering News page: 16

)

February 2024 - Maritime Reporter and Engineering News page: 16THE PATH TO ZERO Methanol’s Superstorage Solution Technical inquiries to SRC Group ramped up after it received Approval in Principle (AIP) for a concept which ‘reinvented methanol fuel storage’ on board ships. Delivering the answers has seen technical talk converting into project discussions

-

)

February 2024 - Marine News page: 40

)

February 2024 - Marine News page: 40for the U.S main engines, John Deere gensets and diesel engine emis- sion control technologies in compliance with EPA Tier 4. Virgin Islands. The USCG Subchapter-K approved, 104- 40 | MN February 202

-

)

February 2024 - Marine News page: 39

)

February 2024 - Marine News page: 39Vessels Next WSF Vessels Could Be Built Outside of Washington State By Eric Haun The next newbuilds for Washington State Ferries (WSF) is required to award a credit of 13% of the bid price for bid could be built by a shipyard outside of Washington as the proposals for vessels constructed in the state of

-

)

February 2024 - Marine News page: 36

)

February 2024 - Marine News page: 36, we have effected a tential in the cruise and ferry industries. lot of regulatory change,” Burry said. “We were the ones who The ? nal delivery for BC Ferries includes a dozen 22- started the process of getting simulation for lifeboat training at foot trailers full of simulators, which the ferry operator

-

)

February 2024 - Marine News page: 35

)

February 2024 - Marine News page: 35algorithms, which underpin predictive decisions.” Among a number of research programs ongoing at Vir- sector, the company recently collaborated with BC Ferries tual Marine is the development of a new system leveraging to develop technology that is ? rst-of-its-kind globally. AI and machine learning to

-

)

February 2024 - Marine News page: 27

)

February 2024 - Marine News page: 27Feature Passenger Vessel Safety ? re risk and related technical issues. Canada: Transport Canada.” In the U.S., last February, the Coast Guard issued a Another top issue, just as in the U.S. – workforce re- Marine Safety Alert: “Saltwater intrusion causes damage cruitment, which he called a “key issue for

-

)

February 2024 - Marine News page: 26

)

February 2024 - Marine News page: 26Feature Passenger Vessel Safety ume is even more eye-opening. The trade association In- ect seeking to signi? cantly reduce the risk of ? res on board terferry, which represents ferry operators and businesses ro-ro (roll on–roll off) ships. Corrigan said that Interferry’s worldwide, calculates that

-

)

February 2024 - Marine News page: 25

)

February 2024 - Marine News page: 25Feature Passenger Vessel Safety Interestingly, in the Flagship docu- certain passenger vessels. growing commuter traf? c. “In addi- ment, PVA acknowledges and thanks • Crew shortages have caused tion,” he added, “several small U.S. the USCG for its help in developing a operators to change schedules.

-

)

February 2024 - Marine News page: 24

)

February 2024 - Marine News page: 24Feature Passenger Vessel Safety Any upcoming meetings? inspected passenger vessels in the U.S-? ag ? eet. • Of these, 530 are already required by domestic In early January, NTSB was asked about its working re- law to have SMSs, in accordance with lationship with the USCG. International Maritime

-

)

February 2024 - Marine News page: 23

)

February 2024 - Marine News page: 23Passenger Vessel Safety occur on a sightseeing vessel or an Ohio River dinner cruise? This contrast between speci? c – sometimes very speci? c – and general comes to mind when considering the numerous safety advisories pertaining to recent amphibious DUKW boat tragedies or the 2019 Conception dive boat

-

)

February 2024 - Marine News page: 17

)

February 2024 - Marine News page: 17Column Going Green ernize ferry operations, replace aging implemented to address grid and space increased power requirements. That vessels, and upgrade ferry terminals. constraints with electri? cation. can involve installing new conduit, The grants are critical to helping WETA is one of many U.S.

-

)

February 2024 - Marine News page: 16

)

February 2024 - Marine News page: 16Column Going Green For Ferries to Go Green, Governments Will Need to Provide the Green By Kaiya Levine, Energy & Sustainability Consultant, Arup Whether it is from international organizations ? ve nautical miles or less, meaning they have relatively low or state government agencies, there is growing

-

)

February 2024 - Marine News page: 6

)

February 2024 - Marine News page: 6Marine News February 2024 • Volume 35 Number 2 Contributors 3 1 24 6 5 7 8 1 Tom Ewing 5 Edward Lundquist is a freelance writer specializing in marine, energy and envi- is a retired naval of? cer who writes on maritime and ronmental issues. He contributes regularly to this magazine. security

-

)

February 2024 - Marine News page: Cover

)

February 2024 - Marine News page: CoverThe Information Authority for the Workboat • Offshore • Inland • Coastal Marine Markets Volume 35 • Number 2 arine FEBRUARY 2024 www.marinelink.com News M Offshore Wind The United States’ New Dawn Passenger Vessel Safety Stakeholders Highlight Top Concerns Ferry Funding Electrifcation Push Requires

-

)

January 2024 - Maritime Reporter and Engineering News page: 48

)

January 2024 - Maritime Reporter and Engineering News page: 48Index page MR Dec24:MN INDEX PAGE 1/9/2024 4:37 PM Page 1 ANCHORS & CHAINS METEOROLOGICAL INSTRUMENTS Harvest Technology Group Limited, 7 Turner Avenue, Technology Park Bentley WA 6102, Australia , tel:61 Anchor Marine & Supply, INC., 6545 Lindbergh Houston, R.M. Young Company, 2801 Aero Park Dr.

-

)

January 2024 - Maritime Reporter and Engineering News page: 41

)

January 2024 - Maritime Reporter and Engineering News page: 41Crowther will partner with Gulf Craft LLC in Frank- 1200 tons, will be built by Holland Shipyards. Besides the lin, La., to design and deliver a new USCG Subchapter-K gantry extension, the upgrade program includes an upgrade of Iapproved, 104-ft. (32-m) passenger ferry for the govern- the lifting hooks, which

-

)

January 2024 - Maritime Reporter and Engineering News page: 38

)

January 2024 - Maritime Reporter and Engineering News page: 38TECH FEATURE ALMACO: Enhanced Sustain hen it comes to sustainability in the maritime tors such as manufacturing footprint and recyclability. Even industry, there are many avenues beyond pow- weight is considered as heavier materials in items such as er and propulsion that vessel owned can ex- beds and

-

)

January 2024 - Maritime Reporter and Engineering News page: 37

)

January 2024 - Maritime Reporter and Engineering News page: 37WASTEWATER TREATMENT Fish don’t eat steak pie and chips. – Iain Milnes, President, Power Knot Cunard’s Queen Anne will have 26 Power Knot systems installed. Image courtesy Power Knot Image courtesy Power Knot Kirsch, Area Manager for Advanced Wastewater Treatment vent its discharge. President

-

)

January 2024 - Maritime Reporter and Engineering News page: 33

)

January 2024 - Maritime Reporter and Engineering News page: 33WASALINE EQUIPMENT LIST AURORA BOTNIA MAIN PARTICULARS Main engines: 4 × Wärtsilä 8V31DF (4 × 4,400 kW) Ship Type: RoPax Ferry Fuel type: LNG, biogas, battery (Leclanche) Shipbuilder: Rauma Marine Constructions Total installed power: 17,6MW Material: Steel Bow thrusters: Wärtsilä FPP