Coupler Systems

-

- The Versatile ATB Enters the LNG Game Marine News, Jul 2014 #36

EBDG’s LNG bunkering barge design receives ABS approvals as the maritime industry increasingly looks to LNG as a fuel of the future.

In early June, Federal Maritime Commissioner William P. Doyle told listeners at an LNG Bunkering conference in Vancouver, Canada that “Liquefied Natural Gas (LNG) bunkering in North America is moving forward … There is an abundant supply of natural gas in North America. Utilizing natural gas as a marine fuel would help ship owners and operators comply with the MARPOL Annex VI requirements to reduce air pollution from ocean going vessels.” That much is true.

It’s also true that there is any number of ways for vessel operators to get to the Promised Land. Nevertheless, LNG – as a fuel – has certainly stepped out into the lead on that mission. And, the race to design next generation bunker barges – those carrying LNG for all those soon-to-come LNG powered vessels on the backlogs of U.S. shipyards – is in full swing. In the thick of that race is the Seattle-based Elliott Bay Design Group (EBDG), whose EB-2000 LNG ATB Barge concept recently obtained approval in principle (AIP) from the American Bureau of Shipping (ABS). According to EBDG, the EB-2000 offers versatility in LNG transport and bunkering. The barge will be offered in both an optional spoon or ship-shaped bow combined with a (patent pending) flush trunk and foc’sle arrangement which provides proven offshore performance.

Curt Leffers, EBDG Project Manager, told MarineNews in June, “We are excited to obtain ABS approval in principal on our bunkering barge design. Our 2,000 cubic meter design is the basic platform that can be customized to meet our customer’s operational and cargo capacity requirements.” Also exciting is the prospect for yet another use for the versatile, economical and enduring ATB.

The EB-2000 LNG is just one of several LNG barge designs developed by EBDG for clients to meet growing demand for efficient and cost-effective refueling of LNG powered vessels. The innovative 257 ft. EB-2000 was designed for either an ATB or towed configuration, and features a marine diesel fuel cargo tank for refueling duel fuel vessels.

LNG: Cost, Economics and Logistics

Recent data reveals that LNG in the U.S. is now more than 50% less expensive on an energy-equivalent basis than marine residual fuel and marine distillate fuel. And, while no one can say for sure that this price advantage will continue, the obvious environmental benefits and possible boost to the bottom line has led to a sustained commitment to building dual fuel, gas ready and LNG powered merchant vessels.

Separately, the Port of Pittsburgh Commission in May began soliciting proposals to provide research support for a liquid natural gas project for the Pittsburgh marine-corridor by developing cost/benefit analyses and identifying shore-side and midstream refueling requirements. The effort will evaluate the possible business opportunities that might become available to inland waterway stakeholders should liquid natural gas be introduced as an alternative fuel for regional towboats Like the bluewater projects already announced, momentum is building for the possible conversion of inland workboats from diesel to natural gas propulsion. In fact, there are currently more than 40 vessels in North America that are under development or evaluation for conversion to LNG fuel. Any and all that come to fruition will need bunkers.

There are more than a few LNG / Dual Fuel deep draft vessels on the books in U.S. yards today. They will all eventually need a reliable, local and reputable source of bunkers. Curt Leffers, referring to EBDG’s own design, said, “There will eventually be opportunities for bunkering barge services in the pacific northwest, gulf coast, great lakes, and in the southeast region.” He declined to discuss specifics, saying only, “Although we’ve designed several LNG ATB vessels for external customers, we do not have yet a customer that has placed an order with a shipyard.”

The EBDG Concept

As a concept and design idea – the dual fuel tug, rigidly connected to the LNG bunker barge and using boil-off gas in the process – was not originated at EBDG. According to EDBG’s Leffers, “This concept has been a topic of discussion in the industry and is attractive from the standpoint of boil off management and efficiency of operation. Having dual fuel capability allows the tug to use diesel when not coupled to the barge.” That said; EDBG has embraced the idea and incorporated it into their proprietary designs.

The EBDG bunker barge will carry typical capacities of between 2,000 and 3,000 cubic meters of LNG. With the relatively low specific gravity of LNG, anticipated drafts are between 12 and 18 feet, depending on the barge design. The volume necessary to refuel a containership would be on the order of 2,000 to 3,000 cubic meters, but this ultimately depends on the size of tanks of the vessel. Leffers adds, “The maximum draft of the bunker barges is 18 feet, but this requirement is really driven by operating restrictions, since the specific gravity of LNG is relatively low. Draft has not been an issue.”

While boil-off consumption by the propelling engine is not a new concept – large LNG carriers running on steam plants have been doing just that, safely and routinely, for decades – getting that done with an ATB arrangement may be something different altogether. Curt Leffers told MarineNews that there aren’t (yet) specific regulations pertaining to a gas connection between a tug and barge in an ATB configuration. But, he cautioned, “There are numerous technical challenges that must be overcome in order to have a reliable and safe fuel connection between the tug and barge. From an operation standpoint, consideration must be given to procedures related to connection and disconnection of the gas connection.”

Emerging Regulations & Guidance

The U.S. Coast Guard issued a notice seeking public comment on two draft policy letters regarding safety measures for LNG as a marine fuel. The second of those draft policy letters discusses voluntary guidance and existing regulations applicable to vessels and land based facilities conducting LNG marine fuel bunkering operations, and provides voluntary guidance on safety, security, and risk assessment measures for these operations.

Separately, the American Bureau of Shipping (ABS) in March followed the Coast Guard policy letters with a report of their own, entitled Bunkering of Liquefied Natural Gas-Fueled Marine Vessels in North America. The objective of the report is to provide guidance to potential owners and operators of gas-fueled vessels, as well as LNG bunkering vessels and facilities, in order to help them obtain regulatory approval for projects.

Horses for Courses

The ATB has been around for a long time, with as many as 75 in operation today in North American waters and another eight on the order books in domestic shipyards. Popular in Jones Act and niche domestic trade routes, the ATB, with its reduced crewing levels, has a bright future especially if shortsea shipping gets another kickstart in the near future. And, of course, another promising outlet for this style of transportation includes use as an LNG bunkering platform. The EBDG version adds its own twist to the mix.

“One of the special design features that our 2000 CBM LNG ATB has is a diesel tank. This allows for flexibility in operation and services for the vessel owner, said Leffers, adding, “We have been designing around the Intercon coupler systems for our ATB designs.” Beyond this, he said, ATB’s are being considered for many concepts; shortsea shipping, container-on-barge for niche ports among them. “EBDG’s engineers have been brainstorming a variety of ATB applications with customers.”

The Way Forward

Leffers left MarineNews with a clear idea of where he and EBDG think things are headed next – and they intend to be there. “The way that the market is trending with LNG fueled vessel orders, the use of LNG bunker barges will be important in the fuel supply chain. Flexibility in operation is an important aspect of barge design.”

Natural gas, as a marine fuel, is strongly supported and endorsed by the Obama Administration.

FMC Commissioner Doyle, speaking last month at the Vancouver-based LNG conference, also left no doubt as to where he thinks things are going. “As this fuel source is taking hold in the commercial U.S. domestic coastwise trade, it is now gaining traction in the inland waterway system and the international container trade.” He added, for emphasis, “Appropriate, safe and secure bunkering operations are mission-critical to a successful LNG marine fuel program.” Just a few miles to the south, Elliott Bay Design Group is already working to ensure just that.

(As published in the July 2014 edition of Marine News - http://magazines.marinelink.com/Magazines/MaritimeNews)

-

- VT Halter Powers Ahead Maritime Reporter, Apr 2015 #74

150 ft. long, the 10,000 hp twin screw ATB tug is classed by ABS as A1 Towing Vessel, Dual Mode ATB, USCG Subchapter M, is equipped with Intercon Coupler Systems, and will pair up with Barge B. No. 270. The barge measures 625 x 91 x 47 ft. and has a 250,000-barrel capacity. Used to transport liquid petroleum

-

- The Enduring, Iconic U.S. Flag ATB Model Marine News, Apr 2019 #44

inland applications. Also prominent in that discussion is Bouchard Transportation Co., and its current President and CEO, Morton S. Bouchard III. ATB Coupler Systems in Use (Feb. 2017) Major ATB Operators (source MARAD)OEM / TypeNumberU.S. Flag OperatorNumber of ATB’sIntercon100Bouchard21JAK37Crowley12B

-

- Energy Markets Buoy U.S. Shipbuilding Maritime Reporter, Aug 2014 #90

with the construction of two 6000-hp ATB tugs. These newbuilds, the M/V Bouchard Boys and the M/V Evening Light, will be equipped with Intercon Coupler Systems and constructed by VT Halter Marine, Inc. Measuring 130 x 38 x 22 ft., these 6,000-hp Twin Screw ATB Tugs will be classed by ABS as XA1 Ocean

-

)

March 2024 - Marine Technology Reporter page: 4th Cover

)

March 2024 - Marine Technology Reporter page: 4th CoverGlow a little longer. Superior sensor performance on a rmance on a – – RBRtridentfraction of the power RBRtridente teee ackscatter or turbidity with hi i in n n t t th h h he e e s sa a am m m me Measure chlorophyll a, fDOM, and backscatter or turbidity within the same e e sensor package using the

-

)

March 2024 - Marine Technology Reporter page: 48

)

March 2024 - Marine Technology Reporter page: 48Index page MTR MarApr2024:MTR Layouts 4/4/2024 3:19 PM Page 1 Advertiser Index PageCompany Website Phone# 17 . . . . .Airmar Technology Corporation . . . . . . . . . .www.airmar.com . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .(603) 673-9570 9 . . . . . .Birns, Inc. . . . . . . . . . .

-

)

March 2024 - Marine Technology Reporter page: 45

)

March 2024 - Marine Technology Reporter page: 45ronments. The new agreement will address speci? c techni- cal gaps in the UUV defense and offshore energy markets especially for long duration, multi-payload mission opera- tions where communications are often denied or restricted. As part of the new alliance, Metron’s Resilient Mission Autonomy portfolio

-

)

March 2024 - Marine Technology Reporter page: 44

)

March 2024 - Marine Technology Reporter page: 44NEW TECH OCEANOLOGY INTERNATIONAL 2024 Image courtesy Metron/Cellula Teledyne Marine acquires Valeport: Matt Quartley, MD, Valeport and Ole Søe-Pedersen, VP & Image courtesy Teledyne Marine GM Teledyne Marine announce the deal in London. Pictured (L-R): Cellula Robotics, President, Eric Jackson, Metron

-

)

March 2024 - Marine Technology Reporter page: 43

)

March 2024 - Marine Technology Reporter page: 43Image courtesy Kongsberg Discovery Image courtesy Teledyne Marine New Products Teledyne Marine had its traditional mega-booth at Oi, busy start to ? nish. Image courtesy Greg Trauthwein offers quality sub-bottom pro? ling capability without the need tion of offshore windfarms. GeoPulse 2 introduces new

-

)

March 2024 - Marine Technology Reporter page: 42

)

March 2024 - Marine Technology Reporter page: 42NEW TECH OCEANOLOGY INTERNATIONAL 2024 Image courtesy Greg Trauthwein Image courtesy BIRNS MacArtney launches the new ultra-compact ø12.7 mm SubConn Nano connector. Innovative connectivity built on 45 years of ? eld-proven and market-trusted design. Image courtesy MacArtney Birns celebrated its 70th

-

)

March 2024 - Marine Technology Reporter page: 41

)

March 2024 - Marine Technology Reporter page: 41Image courtesy Outland Technology Image courtesy Exail Image courtesy Submaris and EvoLogics Vehicles The ROV-1500 from Outland Technology represents a leap forward in underwater robotics, a compact remotely operated vehicle (ROV) weighing in at less than 40 lbs (19kg) the ROV- 1500 is easy to transport

-

)

March 2024 - Marine Technology Reporter page: 40

)

March 2024 - Marine Technology Reporter page: 40NEW TECH OCEANOLOGY INTERNATIONAL 2024 All photos courtesy MTR unless otherwise noted NEW TECH, PARTNERSHIPS LAUNCH IN LONDON With Oceanology International now one month in the rear-view mirror, MTR takes a look at some of the interesting technologies launched before, during and after the London event.

-

)

March 2024 - Marine Technology Reporter page: 39

)

March 2024 - Marine Technology Reporter page: 39Photo courtesy Global Ocean Design Figure 7 A 35Ah AGM lead-acid battery is tested using the West Mountain Radio CBA to show the effect of simply ? lling the battery voids with mineral oil as a compensating ? uid. The CBA is programmed to cut-off at a voltage of 10.50v. The top line (red) shows the

-

)

March 2024 - Marine Technology Reporter page: 38

)

March 2024 - Marine Technology Reporter page: 38LANDER LAB #10 Photo courtesy West Mountain Radio Photo courtesy of Clarios/AutoBatteries.com Figure 6 The West Mountain Radio Computerized Battery Analyzer (CBA V) attaches to a Figure 5 laptop by a USB-B cable, and to a battery by Powerpole® Connectors. Exploded view of an AGM lead-acid battery.

-

)

March 2024 - Marine Technology Reporter page: 37

)

March 2024 - Marine Technology Reporter page: 37miscible barrier ? uid heavier than seawater (sg=1.026) and lighter than the battery electrolyte (sg=1.265). The original cell vent cap was screwed into the top of the riser pipe to vent the gases associated with charging. Wires were soldered to the lead (Pb) posts. The lead-acid battery was additionall

-

)

March 2024 - Marine Technology Reporter page: 36

)

March 2024 - Marine Technology Reporter page: 36LANDER LAB #10 Of special interest for marine applications, LiPo batteries are Shipping any kind of lithium battery can be a challenge, and offered in a “pouch” design, with a soft, ? at body. The pouch IATA regs vary with the batteries inside or outside an instru- is vacuum-sealed, with all voids ?

-

)

March 2024 - Marine Technology Reporter page: 33

)

March 2024 - Marine Technology Reporter page: 33regulated industry in the world.” How- ever, commercial success depends on many factors, not least a predictable OPEX. Over the past four years, SMD has worked with Oil States Industries to calculate cost per tonne ? gures for prospective customers. Patania II uses jet water pumps to Oil States’

-

)

March 2024 - Marine Technology Reporter page: 32

)

March 2024 - Marine Technology Reporter page: 32FEATURE SEABED MINING by a sea? oor plume from its pilot collection system test. pact, nodule collection system that utilizes mechanical and The Metals Company recently signed a binding MoU with hydraulic technology. Paci? c Metals Corporation of Japan for a feasibility study on The company’s SMD

-

)

March 2024 - Marine Technology Reporter page: 31

)

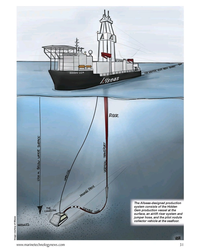

March 2024 - Marine Technology Reporter page: 31The Allseas-designed production system consists of the Hidden Gem production vessel at the surface, an airlift riser system and jumper hose, and the pilot nodule collector vehicle at the sea? oor. Image courtesy of Allseas www.marinetechnologynews.com 31 MTR #3 (18-33).indd 31 4/4/2024 2:12:41

-

)

March 2024 - Marine Technology Reporter page: 30

)

March 2024 - Marine Technology Reporter page: 30FEATURE SEABED MINING bilical. It has passive heave compensation which nulli? es the necott. “The focus since then has been on scaling while en- wave, current and vessel motions that in? uence loads in the suring the lightest environmental impact,” says The Metals power umbilical. The LARS can

-

)

March 2024 - Marine Technology Reporter page: 29

)

March 2024 - Marine Technology Reporter page: 29n January, Norway said “yes” to sea- bed mining, adding its weight to the momentum that is likely to override the calls for a moratorium by over 20 countries and companies such as I Google, BMW, Volvo and Samsung. Those against mining aim to protect the unique and largely unknown ecology of the sea?

-

)

March 2024 - Marine Technology Reporter page: 25

)

March 2024 - Marine Technology Reporter page: 25Auerbach explained that ideally, “one ? ed layers of geothermal activity,” noted changes over an area of 8,000 km2. They would have both instruments: seismom- Skett, “and the change in salinity and dis- found up to seven km3 of displaced ma- eters to detect and locate subsurface ac- solved particles for

-

)

March 2024 - Marine Technology Reporter page: 19

)

March 2024 - Marine Technology Reporter page: 19About the Author vey with the pipe tracker is not required, resulting in signi? - Svenn Magen Wigen is a Cathodic Protection and corrosion control cant cost savings, mainly related to vessel charter. expert having worked across The major advantage of using FiGS on any type of subsea engineering, design

-

)

March 2024 - Marine Technology Reporter page: 18

)

March 2024 - Marine Technology Reporter page: 18TECH FEATURE IMR There are also weaknesses in terms of accuracy because of FiGS Operations and Bene? ts signal noise and the ability to detect small ? eld gradients. In Conventional approaches to evaluating cathodic protection this process there is a risk that possible issues like coating (CP)

-

)

March 2024 - Marine Technology Reporter page: 17

)

March 2024 - Marine Technology Reporter page: 17• Integrity assessment, and otherwise covered, e.g., by rock dump. As for depletion of • Mitigation, intervention and repair. sacri? cial anodes, this can be dif? cult or even impossible to Selecting the best method for collecting the data these work- estimate due to poor visibility, the presence of

-

)

March 2024 - Marine Technology Reporter page: 15

)

March 2024 - Marine Technology Reporter page: 15sensor options for longer mission periods. About the Author For glider users working in ? sheries and conservation, Shea Quinn is the Product Line Manager the Sentinel can run several high-energy passive and active of the Slocum Glider at Teledyne Webb acoustic sensors, on-board processing, and imaging

-

)

March 2024 - Marine Technology Reporter page: 11

)

March 2024 - Marine Technology Reporter page: 11assist in identifying mines and act as a neutralization device. About the Author Bottom mines pose even greater chal- David R. Strachan is a defense analyst and founder of lenges. Unlike contact mines, bottom Strikepod Systems, a research and strategic advisory mines utilize a range of sensors to

-

)

March 2024 - Marine Technology Reporter page: 9

)

March 2024 - Marine Technology Reporter page: 9from marinas along the western coast. The exact number of lizing laser detection systems can detect mines just below the mines, as well as their locations, remains largely a mystery, surface, even those hiding in murky water. The Airborne Laser although reports suggest that over three hundred have been