Foam Systems

-

- A Proven, New Approach for Vessel Insulation Maritime Reporter, Feb 2003 #50

Special Advertising Section for Mascoat Products • www.deltacoat.com Vessel insulation has changed very little in many years. Normally hidden from direct view, thermal insulation systems can become ineffective over time due to poor installation, vibration or moisture intrusion. In fact, if moisture is ever introduced into the insulation from a leak, poor installation, or inadequate repair job, the conventional insulation methods are worse than if insulation had not been used at all.

Common Methods of Thermal Insulation Inside Vessels In the past, most shipyards and owners have been at the mercy of technology that only incorporates one aspect of heat/cold transfer known as conduction. These insulation systems have been designed to retard heat and cold over time and treat & solve heat transfer as a symptom, not as the inherit problem.

Common pin-and-blanket insulation found on most vessels requires the painstaking task of bringing the insulation material into an area, placement of attachment pins, cutting, tapping and finally fitting of the insulation.

With this multi-step process, which is quite labor intensive, only around ten square feet (one square meter) of insulation can be installed in a one-man hour time period. If not managed well, this process could lead to dramatic man-hour cost overruns. In addition, over time these blanket insulation systems lose their power to retard heat/cold and therefore are a direct gate for thermal transfer into the vessel.

Another common way of insulating vessels is to use foam-in-place insulation systems.

This system requires special equipment, highly trained personnel and usually complete shut down of other ongoing tasks of a job during an application due to safety and PPE (personnel protection equipment) concerns.

Since foam systems work on chemical reactions of component products that are highly flammable, these systems do not pass the current FTP codes and can in fact contribute to the dangers and damage caused by fire. Just recently, there have been two incidents of fires onboard crew vessels where foam insulation contributed to death.

Other problems of these foam systems include, outsourcing of personnel for an application, bonding and detachment issues, degradation of the insulation due to vibration, and most importantly corrosion under insulation. Though this is a cheaper method of insulating, foam systems have been highly scrutinized as an antiquated technology.

A New Approach to Thermal Insulation and Protection of Vessels In 1995, Mascoat Products, Houston, Texas, developed a new spray application thermal barrier system, Delta T Marine Insulating Coating, which has been successfully used worldwide on more than 200 vessels.

The system is a water-based acrylic binder that encapsulates air-filled ceramic insulating particles to help reduce or eliminate most radiant heat/cold transmission.

Delta T Marine is sprayed on the inside shell of most modern vessels at a thickness of 20- 60 mils (0.5-1.5mm). By direct bonding, a substrate becomes thoroughly protected and eliminates the potential of development for Corrosion Under Insulation. Vessels employing the coating system are now insulated and protected with a thermal transfer rating of RvE 9-13 factor when compared with conventional insulation. Thus, this spray system used alone or in conjunction with conventional wallboard provides equal or better protection of thermal transfer at a reduced cost and time effort.

Most shipyards that have used the Delta T Marine find that application is quick to learn as well as easy to apply. Normally sprayed with an airless sprayer, Delta T applies much like thick consistency paint. With little training, the existing paint crew of a shipyard can be taught to spray the coating efficiently. This allows shipyards to control insulation with existing paint crews thereby reducing the outsourcing need in most circumstances. Crews can average 1000 sq. feet (100 sq. m.)/hr.

This equates to a substantial man-hour savings and a fantastic way to trim or maintain man-hour costs.

Although the material price is somewhat higher for Delta T Marine, total installation costs after labor are dramatically reduced.

Additional benefits include escalation in the time frame of the vessel and ease of repair if change orders require additional fabrication.

Most yards see up to 50-80 percent time frame escalation and 30-45 percent reduction on total installed costs.

How can a coating replace 3-in. of conventional insulation? This is a common question that arises. According to George More, president of Mascoat Products, "Insulation has changed very little for many years. Most thermal blanket and foam insulation systems use only the principle of conduction as a sole blocking agent of heat transfer. This means using only one of five methods that reduce thermal transfer. Our system uses all basic principles of thermal dynamics to our advantage.

Our coating deals with heat or cold before it enters or penetrates typical vessel insulation. This allows our system to work more efficiently and keep thickness to a minimum.

More importantly, our system will not degrade due to vibration or moisture intrusion and is not flammable like foam systems are." Basically the coating works because Delta T Coating employs its highly reflective white surface and ceramic composition structure to reflect heat away from the substrate and back to the atmosphere. Imagine a Thermos® bottle. The coating is very similar in this respect. The coating actually reflects upward of 85 percent of the heat /cold generated back to the respective substrate or atmosphere.

Its hollow, microscopic glass and silica airfilled beads provide an excellent "k "or conductivity factor by dissipating the heat over the entire surface hindering the conductive process. This means there is no hotspot or vertical heat pipe effect like conventional insulation. (The vertical heat pipe effect is the way in which conventional insulation passes heat via free air convection through the insulation vertically. This heat is then transferred to the overhead deck area. Temperature increases can be as much as 5°C or around 25°F.) Also Delta T Coatings' unusually low emittance allows little heat to be re-radiated into the atmosphere starting a convective process.

The coating also employs other heat blocking agents of absorptance and transmittance, increasing its insulating factor. By adding up the conduction, reflection, emmisivity, transmittance and absorptance properties of Delta T Marine coating, all aspects of thermal transfer can be employed in one product.

Another beneficial aspect of the product includes its sound deadening characteristics and weight savings. Delta T Marine applied inside a vessels shell drops air borne structural noise 50-80 percent depending on thicknesses and substrate. Its lightweight composite bead structure equates to 0.07 lbs. / sq. ft.

applied as opposed to 0.51b-1.51bs sq. ft. for conventional systems. This is very important in yacht and ferry construction where sound and weight materials are highly scrutinized.

New Series of Products Just recently, Mascoat Products has introduced its second-generation series of products.

This new series employs advanced chemistry techniques to make the coating more paint-like as well as expanding the coating's insulation abilities. This allows for increased square footage per gallon and an increase in thermal efficiency.

Classifications Delta T Marine has passed rigorous testing and is classified in accordance with IMO/SOLAS guidelines. This product is certified by U.S.C.G., A.B.S., D.N.V., and Lloyd's (MCA) to the new FTP Codes. The product is packaged in one (4 liters), five (18.9 liters), and fifty-five gallon containers and is sold factory direct to the shipyard or owner or through various distributors.

For further information, contact: Sales Department, Mascoat Products, 10890 Alcott Drive, Building # 102, Houston, Texas 77043, tel:(713)465-0304, or log on to www.deltacoat.com.

Circle 199 on Reader Service Card

-

- West Coast Manly Shipyards Delivers Fisheries Patrol Vessel Leonard J. Cowley Maritime Reporter, Sep 15, 1985 #36

with a Brabazon fueling system that includes provisions for fuel maintenance onboard and can handle all grades of aviation fuel. Twin agent and foam systems are installed for firefighting on the helicopter deck. For maneuvering, the vessel is equipped with a Wagner MK-6 autopilot with adaptive steering

-

- 1986 VALVE EQUIPMENT GUIDE Maritime Reporter, Mar 1986 #38

used for magazine sprinkler valves and void filling valves. Cla- Val's dual solenoid pilot control valve is used to activate magazine sprinkler and foam systems, or anywhere a relatively large capacity solenoid valve is needed. This valve stays in either position until the opposing solenoid is energized

-

)

March 2024 - Marine Technology Reporter page: 4th Cover

)

March 2024 - Marine Technology Reporter page: 4th CoverGlow a little longer. Superior sensor performance on a rmance on a – – RBRtridentfraction of the power RBRtridente teee ackscatter or turbidity with hi i in n n t t th h h he e e s sa a am m m me Measure chlorophyll a, fDOM, and backscatter or turbidity within the same e e sensor package using the

-

)

March 2024 - Marine Technology Reporter page: 48

)

March 2024 - Marine Technology Reporter page: 48Index page MTR MarApr2024:MTR Layouts 4/4/2024 3:19 PM Page 1 Advertiser Index PageCompany Website Phone# 17 . . . . .Airmar Technology Corporation . . . . . . . . . .www.airmar.com . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .(603) 673-9570 9 . . . . . .Birns, Inc. . . . . . . . . . .

-

)

March 2024 - Marine Technology Reporter page: 45

)

March 2024 - Marine Technology Reporter page: 45ronments. The new agreement will address speci? c techni- cal gaps in the UUV defense and offshore energy markets especially for long duration, multi-payload mission opera- tions where communications are often denied or restricted. As part of the new alliance, Metron’s Resilient Mission Autonomy portfolio

-

)

March 2024 - Marine Technology Reporter page: 44

)

March 2024 - Marine Technology Reporter page: 44NEW TECH OCEANOLOGY INTERNATIONAL 2024 Image courtesy Metron/Cellula Teledyne Marine acquires Valeport: Matt Quartley, MD, Valeport and Ole Søe-Pedersen, VP & Image courtesy Teledyne Marine GM Teledyne Marine announce the deal in London. Pictured (L-R): Cellula Robotics, President, Eric Jackson, Metron

-

)

March 2024 - Marine Technology Reporter page: 43

)

March 2024 - Marine Technology Reporter page: 43Image courtesy Kongsberg Discovery Image courtesy Teledyne Marine New Products Teledyne Marine had its traditional mega-booth at Oi, busy start to ? nish. Image courtesy Greg Trauthwein offers quality sub-bottom pro? ling capability without the need tion of offshore windfarms. GeoPulse 2 introduces new

-

)

March 2024 - Marine Technology Reporter page: 42

)

March 2024 - Marine Technology Reporter page: 42NEW TECH OCEANOLOGY INTERNATIONAL 2024 Image courtesy Greg Trauthwein Image courtesy BIRNS MacArtney launches the new ultra-compact ø12.7 mm SubConn Nano connector. Innovative connectivity built on 45 years of ? eld-proven and market-trusted design. Image courtesy MacArtney Birns celebrated its 70th

-

)

March 2024 - Marine Technology Reporter page: 41

)

March 2024 - Marine Technology Reporter page: 41Image courtesy Outland Technology Image courtesy Exail Image courtesy Submaris and EvoLogics Vehicles The ROV-1500 from Outland Technology represents a leap forward in underwater robotics, a compact remotely operated vehicle (ROV) weighing in at less than 40 lbs (19kg) the ROV- 1500 is easy to transport

-

)

March 2024 - Marine Technology Reporter page: 40

)

March 2024 - Marine Technology Reporter page: 40NEW TECH OCEANOLOGY INTERNATIONAL 2024 All photos courtesy MTR unless otherwise noted NEW TECH, PARTNERSHIPS LAUNCH IN LONDON With Oceanology International now one month in the rear-view mirror, MTR takes a look at some of the interesting technologies launched before, during and after the London event.

-

)

March 2024 - Marine Technology Reporter page: 39

)

March 2024 - Marine Technology Reporter page: 39Photo courtesy Global Ocean Design Figure 7 A 35Ah AGM lead-acid battery is tested using the West Mountain Radio CBA to show the effect of simply ? lling the battery voids with mineral oil as a compensating ? uid. The CBA is programmed to cut-off at a voltage of 10.50v. The top line (red) shows the

-

)

March 2024 - Marine Technology Reporter page: 38

)

March 2024 - Marine Technology Reporter page: 38LANDER LAB #10 Photo courtesy West Mountain Radio Photo courtesy of Clarios/AutoBatteries.com Figure 6 The West Mountain Radio Computerized Battery Analyzer (CBA V) attaches to a Figure 5 laptop by a USB-B cable, and to a battery by Powerpole® Connectors. Exploded view of an AGM lead-acid battery.

-

)

March 2024 - Marine Technology Reporter page: 37

)

March 2024 - Marine Technology Reporter page: 37miscible barrier ? uid heavier than seawater (sg=1.026) and lighter than the battery electrolyte (sg=1.265). The original cell vent cap was screwed into the top of the riser pipe to vent the gases associated with charging. Wires were soldered to the lead (Pb) posts. The lead-acid battery was additionall

-

)

March 2024 - Marine Technology Reporter page: 36

)

March 2024 - Marine Technology Reporter page: 36LANDER LAB #10 Of special interest for marine applications, LiPo batteries are Shipping any kind of lithium battery can be a challenge, and offered in a “pouch” design, with a soft, ? at body. The pouch IATA regs vary with the batteries inside or outside an instru- is vacuum-sealed, with all voids ?

-

)

March 2024 - Marine Technology Reporter page: 33

)

March 2024 - Marine Technology Reporter page: 33regulated industry in the world.” How- ever, commercial success depends on many factors, not least a predictable OPEX. Over the past four years, SMD has worked with Oil States Industries to calculate cost per tonne ? gures for prospective customers. Patania II uses jet water pumps to Oil States’

-

)

March 2024 - Marine Technology Reporter page: 32

)

March 2024 - Marine Technology Reporter page: 32submerged weight, these vehicles are made with of a U.S. re? nery - the Pentagon is expected to deliver an ac- light plastic tracks and buoyant syntactic foam. The collec- tion plan on nodules by March 2024. tion vehicle uses sonar to identify the position of the nodules UK-based Soil Machine Dynamics (SMD)

-

)

March 2024 - Marine Technology Reporter page: 31

)

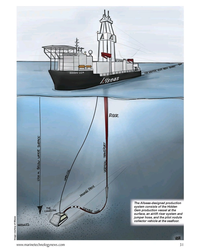

March 2024 - Marine Technology Reporter page: 31The Allseas-designed production system consists of the Hidden Gem production vessel at the surface, an airlift riser system and jumper hose, and the pilot nodule collector vehicle at the sea? oor. Image courtesy of Allseas www.marinetechnologynews.com 31 MTR #3 (18-33).indd 31 4/4/2024 2:12:41

-

)

March 2024 - Marine Technology Reporter page: 30

)

March 2024 - Marine Technology Reporter page: 30FEATURE SEABED MINING bilical. It has passive heave compensation which nulli? es the necott. “The focus since then has been on scaling while en- wave, current and vessel motions that in? uence loads in the suring the lightest environmental impact,” says The Metals power umbilical. The LARS can

-

)

March 2024 - Marine Technology Reporter page: 29

)

March 2024 - Marine Technology Reporter page: 29n January, Norway said “yes” to sea- bed mining, adding its weight to the momentum that is likely to override the calls for a moratorium by over 20 countries and companies such as I Google, BMW, Volvo and Samsung. Those against mining aim to protect the unique and largely unknown ecology of the sea?

-

)

March 2024 - Marine Technology Reporter page: 25

)

March 2024 - Marine Technology Reporter page: 25Auerbach explained that ideally, “one ? ed layers of geothermal activity,” noted changes over an area of 8,000 km2. They would have both instruments: seismom- Skett, “and the change in salinity and dis- found up to seven km3 of displaced ma- eters to detect and locate subsurface ac- solved particles for

-

)

March 2024 - Marine Technology Reporter page: 19

)

March 2024 - Marine Technology Reporter page: 19About the Author vey with the pipe tracker is not required, resulting in signi? - Svenn Magen Wigen is a Cathodic Protection and corrosion control cant cost savings, mainly related to vessel charter. expert having worked across The major advantage of using FiGS on any type of subsea engineering, design

-

)

March 2024 - Marine Technology Reporter page: 18

)

March 2024 - Marine Technology Reporter page: 18TECH FEATURE IMR There are also weaknesses in terms of accuracy because of FiGS Operations and Bene? ts signal noise and the ability to detect small ? eld gradients. In Conventional approaches to evaluating cathodic protection this process there is a risk that possible issues like coating (CP)

-

)

March 2024 - Marine Technology Reporter page: 17

)

March 2024 - Marine Technology Reporter page: 17• Integrity assessment, and otherwise covered, e.g., by rock dump. As for depletion of • Mitigation, intervention and repair. sacri? cial anodes, this can be dif? cult or even impossible to Selecting the best method for collecting the data these work- estimate due to poor visibility, the presence of

-

)

March 2024 - Marine Technology Reporter page: 15

)

March 2024 - Marine Technology Reporter page: 15sensor options for longer mission periods. About the Author For glider users working in ? sheries and conservation, Shea Quinn is the Product Line Manager the Sentinel can run several high-energy passive and active of the Slocum Glider at Teledyne Webb acoustic sensors, on-board processing, and imaging

-

)

March 2024 - Marine Technology Reporter page: 11

)

March 2024 - Marine Technology Reporter page: 11assist in identifying mines and act as a neutralization device. About the Author Bottom mines pose even greater chal- David R. Strachan is a defense analyst and founder of lenges. Unlike contact mines, bottom Strikepod Systems, a research and strategic advisory mines utilize a range of sensors to

-

)

March 2024 - Marine Technology Reporter page: 9

)

March 2024 - Marine Technology Reporter page: 9from marinas along the western coast. The exact number of lizing laser detection systems can detect mines just below the mines, as well as their locations, remains largely a mystery, surface, even those hiding in murky water. The Airborne Laser although reports suggest that over three hundred have been