Gas Injection Lines

-

- Reviewing Sapinhoá-Lula NE BSR System Marine Technology, Sep 2018 #18

The exploration and production of deepwater pre-salt plays offshore Brazil have triggered major technological challenges. Some reservoirs are located under 2,000 meters of water and have to be drilled through another 2,000 or so meters of salt. Although exploration challenges have been daunting, production challenges are no less formidable. With a number of production and injection wells placed over the large reservoirs, the difficulty of reliably and safely bringing the oil and gas to production FPSOs have been compounded by the extreme water depths involved.

In 2011 Subsea 7 was awarded a milestone subsea umbilical, riser and flowline (SURF) contract by national operator Petrobras for four decoupled riser systems to be installed in the Sapinhoá-Lula NE fields located in the Santos Basin, in the largest engineering, procurement, installation and commissioning (EPIC) SURF contract awarded to date in Brazil. The pioneering technology for connecting a large number of wells to a single FPSO was developed by the Petrobras’ research center (Cenpes) and Subsea 7, with the support of UFRJ (Federal University of Rio de Janeiro) and USP (University of São Paulo). The project required the installation of four huge 2,800ton submerged buoys approximately 250 meters below the surface. The system was designed to accommodate a combination of 45 risers/umbilicals for each field in a small area in a decoupled arrangement. Subsea 7’s scope was specifically 27 3.9km steel catenary risers of which 18 were 7.5-inch production lines, three 9.5-inch water injection lines and six 8-inch gas injection lines.

Buoy Supported Risers (BSR)

Petrobras and its partners selected the Buoy Supported Risers (BSR) system as the most effective solution for the project. Ivan Cruz, Senior Product Manager at Subsea 7, explained that in order to achieve the system’s performance and installation requirements, various innovative technologies were applied. The creation of the Angular Connection Module (ACM) proved integral to the BSR system by connecting the flexible jumpers to the pre-installed buoys. With the large number of risers installed, the buoys can take up different positions and the ACM allows connections to be made at misaligned angles of up to 15°, reliably and safely, reducing offshore hook-up time. Within the BSR system the introduction of the ACM reduced fluid flow to a single interfacing point, thereby decreasing cost and enhancing reliability by eliminating further potential leak paths.The main requirement for successful BSR mooring was to use tether adjustments to stabilize and position each buoy. The main challenge associated here was the selection of an appropriate tether material, helping to ensure that the axial stiffness was preferred in order to balance the desired tension adjustment, and to keep adjacent tethers closely together while controlling the initial slackening during fabrication and installation. Although steel air filled pipe is a commonly used material for Tension Leg Platforms (TLPs), a moderated decrease in the axial stiffness was preferred, this allowed for a simple top tension between adjacent tethers and length adjustments. A significant increase in tendon stretch, applied while the BSR was in vertical motion, would not have been an acceptable approach because of the high possibility of misalignment and damage to the system.

Another equally important technical issue which needed to be addressed was the submerged tether weight, that had the potential to minimize the impact on negative buoyancy and dimensions. Sheathed spiral strand wires (SSW) were finally chosen because the sheathed spiral strand wire has a long track record in other mooring systems and was found to meet all the requirements for 27 years of service life. The stretch is not excessive, but is enough to help minimize the effects of length measurement tolerances, being simpler to install offshore, including the locking of the lines in the connectors at the required point.

Deepwater Challenges

The development of the Sapinhoá-Lula NE reservoirs were major technological challenges. The innovative BSR concept was a unique design in the industry at the time and helped reduce the FPSO riser motions to a very minimal level. With this configuration, the movements of the floating platform are not transferred integrally to the rigid risers, reducing the damage because of the fatigue and guaranteeing their useful life even in severe meteoceanographic conditions. According to Ricardo Francis, consultant of the Management of Technology of Pipes and Risers at Cenpes, the buoys together are responsible for the production of 240,000 barrels of oil per day. “We studied a buoy system to take the dynamics of rigid lines because they internally have a coating that prevents corrosion of the steel due to the presence of gases such as H2S and CO2 and this coating has a more demanding calculation procedure, with the presence of the buoy, the useful life of these lines has increased considerably, making production feasible in the pre-salt fields. From there, flexible lines, called jumpers, are placed that connect the buoy to the production platform. In addition to bringing production to the PEUs, it is intended to absorb their dynamic movements. This is the main idea of the BSR,” he says.With the buoy holding the pipes that conduct the oil and gas from the well on the seabed to the FPSO, it relieves the load applied to the platform. Another advantage is to allow the installation of the risers even before the arrival of the production platform. “The economic advantage was the anticipation of production. If you prepare everything before you get to the production unit it simply connects the risers and you can anticipate 3 to 6 months of production,” says Ricardo. Although there were teething problems in the installation of the first BSR, which led to delays in this first installation, the operators are adamant that the system has been working smoothly and with no major problems since it started operations in 2014 and that similar systems may be used in other deepwater pre-salt plays in future.

A look at some of the Technological Challenges associated to the BSR system:

- An efficient method to install corrosion resistant alloy (CRA) mechanically lined BuBi pipe by the reeled-lay installation method;

- The development of the Angular Connection Module (ACM). This unique engineering capability greatly simplified buoy hardware by minimizing the number of connections and potential leak paths;

- A fit for purpose 400 ton tension capable riser installation tool, allowing for the reliable deployment of 27 SCRs;

- A state-of-the-art fracture mechanics engineering assessment for plastically strained pipe joints made of alloy 625 welds;

- A novel tethered tensioned mooring system, similar to that for Tension Leg Platforms (TLPs), but using spiral strand cables and chains for installation simplicity and to achieve the necessary dynamic performance;

- A tether based tensioning system capable of withstanding top angle variations associated with the buoys natural offsets and the potential length variations of the almost two kilometers long tethers;

- A bottom connector device to simplify connections to foundations. The combined result of all these innovations, some incremental and resulting from existing technologies, and others entirely new and breakthrough, gave rise to the complete BSR system, which has been vital in maintaining the production rates and low downtime for the two reservoirs.

-

- Brazil Offshore: Petrobras & Subsea Engineering Marine Technology, Nov 2013 #34

21 x associated pipeline end terminations (PLETs) of which 18 • 7.5-inch production lines, three 9.5-inch water injection lines and six 8-inch gas injection lines • 27 x anchor suction piles • 4 x monitoring systems for buoys and SCRs On October 21 Subsea 7 was awarded two new contracts with a combined

-

)

March 2024 - Marine Technology Reporter page: 44

)

March 2024 - Marine Technology Reporter page: 44NEW TECH OCEANOLOGY INTERNATIONAL 2024 Image courtesy Metron/Cellula Teledyne Marine acquires Valeport: Matt Quartley, MD, Valeport and Ole Søe-Pedersen, VP & Image courtesy Teledyne Marine GM Teledyne Marine announce the deal in London. Pictured (L-R): Cellula Robotics, President, Eric Jackson, Metron

-

)

March 2024 - Marine Technology Reporter page: 42

)

March 2024 - Marine Technology Reporter page: 42NEW TECH OCEANOLOGY INTERNATIONAL 2024 Image courtesy Greg Trauthwein Image courtesy BIRNS MacArtney launches the new ultra-compact ø12.7 mm SubConn Nano connector. Innovative connectivity built on 45 years of ? eld-proven and market-trusted design. Image courtesy MacArtney Birns celebrated its 70th

-

)

March 2024 - Marine Technology Reporter page: 39

)

March 2024 - Marine Technology Reporter page: 39Photo courtesy Global Ocean Design Figure 7 A 35Ah AGM lead-acid battery is tested using the West Mountain Radio CBA to show the effect of simply ? lling the battery voids with mineral oil as a compensating ? uid. The CBA is programmed to cut-off at a voltage of 10.50v. The top line (red) shows the

-

)

March 2024 - Marine Technology Reporter page: 37

)

March 2024 - Marine Technology Reporter page: 37(sg=1.026) and lighter than the battery electrolyte (sg=1.265). The original cell vent cap was screwed into the top of the riser pipe to vent the gases associated with charging. Wires were soldered to the lead (Pb) posts. The lead-acid battery was additionally used as an expendable ballast weight

-

)

March 2024 - Marine Technology Reporter page: 36

)

March 2024 - Marine Technology Reporter page: 36battery packs, di- If sealed with a rubber diaphragm, the battery must be vent- vided into three buses. The sub could operate off a single ed to manage gases formed during charging. (Myers, 1968) bus in emergency mode. All power and control signals were An innovative means of pressure compensation was

-

)

March 2024 - Marine Technology Reporter page: 28

)

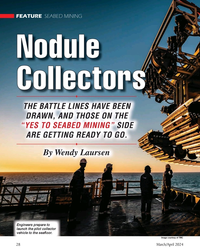

March 2024 - Marine Technology Reporter page: 28FEATURE SEABED MINING Nodule Collectors THE BATTLE LINES HAVE BEEN DRAWN, AND THOSE ON THE “YES TO SEABED MINING” SIDE ARE GETTING READY TO GO. By Wendy Laursen Engineers prepare to launch the pilot collector vehicle to the sea? oor. Image courtesy of TMC 28 March/April 2024 MTR #3 (18-33).

-

)

March 2024 - Marine Technology Reporter page: 25

)

March 2024 - Marine Technology Reporter page: 25SYSTEM just mapped. I have ‘discovered’ many mountains, hills, valleys and canyons that APPLICATIONS would rival anything seen on land.” • Shallow Gas Hazard Surveys • Oi shore Wind Turbine Phase two, mapping inside the caldera, • Geotechnical InvesO gaO on • Sand Resource InvesO gaO

-

)

March 2024 - Marine Technology Reporter page: 15

)

March 2024 - Marine Technology Reporter page: 15sensor options for longer mission periods. About the Author For glider users working in ? sheries and conservation, Shea Quinn is the Product Line Manager the Sentinel can run several high-energy passive and active of the Slocum Glider at Teledyne Webb acoustic sensors, on-board processing, and imaging

-

)

March 2024 - Marine Technology Reporter page: 13

)

March 2024 - Marine Technology Reporter page: 13nyone familiar with glider hardware options integrated for a broad Glider answers that need,” said Shea autonomous underwater ve- range of missions. Quinn, Slocum Glider Product Line hicles (AUVs) is certainly “As the use of Slocum Gliders grew, Manager at TWR. A familiar with the popular- so did

-

)

March 2024 - Marine Technology Reporter page: 12

)

March 2024 - Marine Technology Reporter page: 12TECH FEATURE TELEDYNE SLOCUM GLIDERS Teledyne Webb Research Engineers deploy the Slocum Sentinel Glider in Cape Cod Bay for testing. Teledyne Webb Research AS THE GLIDER COMMUNITY GROWS, SO DO GLIDERS By Shea Quinn, Slocum Glider Product Line Manager, Teledyne Marine 12 March/April 2024 MTR #3 (1-17).

-

)

March 2024 - Marine Technology Reporter page: 6

)

March 2024 - Marine Technology Reporter page: 6MTR Editorial Advisors Gallaudet Hardy The Honorable Tim Gallaudet, Kevin Hardy is President PhD, Rear Admiral, U.S. of Global Ocean Design, Navy (ret) is the CEO of creating components and Ocean STL Consulting and subsystems for unmanned host of The American Blue vehicles, following a career

-

)

April 2024 - Maritime Reporter and Engineering News page: 42

)

April 2024 - Maritime Reporter and Engineering News page: 42indicator (CII) meeting the shipping industry’s goal for id advances in digital technology are and EU Emissions Trading Scheme are net-zero greenhouse gas emissions by changing the way ships are operated. only early milestones on the regulatory around 2050. He also believes maritime “The maritime education

-

)

April 2024 - Maritime Reporter and Engineering News page: 41

)

April 2024 - Maritime Reporter and Engineering News page: 41Nautel provides innovative, industry-leading solutions speci? cally designed for use in harsh maritime environments: • GMDSS/NAVTEX/NAVDAT coastal surveillance and transmission systems • Offshore NDB non-directional radio beacon systems for oil platform, support vessel & wind farm applications

-

)

April 2024 - Maritime Reporter and Engineering News page: 39

)

April 2024 - Maritime Reporter and Engineering News page: 39Tech Files Latest Products, Systems and Ship Designs “Wall Climbing Robot” Danish Pilot calls gets ClassNK Nod LEGO Model "A tribute build to a work life at sea" Image courtesy MOL, Sumitomo Heavy Industries lassNK granted its Innovation Endorse- Image courtesy Espen Andersen/DanPilot ment for

-

)

April 2024 - Maritime Reporter and Engineering News page: 38

)

April 2024 - Maritime Reporter and Engineering News page: 38Consulmar Crowley's New LNG Containerships Carbon Capture @ Sea Crowley shared ? rst renderings and the names of its four new dual fuel lique? ed natural gas (LNG)-powered containerships: Quetzal, Copan, Tiscapa and Torogoz. The 1,400 TEU ves- sels were ordered in 2022 by Singapore-based Eastern Paci? c

-

)

April 2024 - Maritime Reporter and Engineering News page: 35

)

April 2024 - Maritime Reporter and Engineering News page: 35environment, which in turn can from vessel drawings. The academy program also includes reduce the time they need to spend on a simulator. This saves gas handling operations and engine room simulation courses time and money and frees up simulator time for others. offered by GTT Training and the Thet

-

)

April 2024 - Maritime Reporter and Engineering News page: 32

)

April 2024 - Maritime Reporter and Engineering News page: 32wind. The subsidies won’t be a plentiful, and then a second on a luf? ng jib. This reduces the time it would there won’t be the same downturn in oil and gas that made all ordinarily take, weeks, to recon? gure the wiring of an ordi- the high-spec construction vessels available at attractive rates, nary

-

)

April 2024 - Maritime Reporter and Engineering News page: 25

)

April 2024 - Maritime Reporter and Engineering News page: 25old or older and need to be that are government owned and operated ships, government replaced. We’re talking all the way from steam to diesel and some gas turbines. The commercial world doesn’t use owned and contract operated, and contract owned and con- steam any more, but we still have quite a few steam-pow-

-

)

April 2024 - Maritime Reporter and Engineering News page: 21

)

April 2024 - Maritime Reporter and Engineering News page: 21with our continued support to the in a UK design ? rm working in the North Sea marine industry,” said Langford. “We continue to hire key in- oil and gas platforms, the holy grail of rigorous dividuals and partner to provide best-in-class solutions.” R conditions in offshore energy production. From

-

)

April 2024 - Maritime Reporter and Engineering News page: 20

)

April 2024 - Maritime Reporter and Engineering News page: 20starts during its adolescence, common mantras are ‘learn from the established European model’ and ‘embrace technology transfer from the offshore oil and gas sector.’ In Robert Langford, the American Bureau of Shipping has all of that and more bundled in one neat package. Langford recently visited with

-

)

April 2024 - Maritime Reporter and Engineering News page: 19

)

April 2024 - Maritime Reporter and Engineering News page: 19exposed to redeployment risk and there re- mains a concern that overbuilding of a commoditized vessel may result in future oversupply as seen in the oil & gas OSV space in the 2008-2014 period. www.marinelink.com 19 MR #4 (18-33).indd 19 4/5/2024 8:13:37 A

-

)

April 2024 - Maritime Reporter and Engineering News page: 18

)

April 2024 - Maritime Reporter and Engineering News page: 18MARKETS & gas activity returns, we anticipate that supply of the vessels The Question of Emissions to offshore wind projects will reduce, driving demand for ad- Given that SOVs and CSOVs operate in a segment target- ditional CSOVs. ing reduced emissions, and many operate in the North Eu- Outside of China

-

)

April 2024 - Maritime Reporter and Engineering News page: 16

)

April 2024 - Maritime Reporter and Engineering News page: 16to a wind turbine OEM or offshore wind in-built crane and gangway. farm operator to service and maintain equipment dur- ¦Tier 2: Generally, oil & gas tonnage (MPSVs, PSVs, ing the operations period of the wind farm. A typical etc.) with ? xed gangway, serving oil & gas and SOV will accommodate

-

)

April 2024 - Maritime Reporter and Engineering News page: 14

)

April 2024 - Maritime Reporter and Engineering News page: 14Book Review Approach to Meeting Underwater Radiated Noise Limits Def ned By Raymond Fischer uantitative underwater radiated noise limits will construction inspections, 5) possible training with respect to be developed shortly by IMO, and/or countries salient design/construction essentials, 6) compliance