Hydraulic Systems

-

- Design of Hydraulic Systems for Subsea Applications Marine Technology, Apr 2015 #18

Global Growth Drives Subsea Expansion

More than two-thirds of the earth’s surface is covered by water, and there are many potential resources there that await exploration and development. Industries involved in this new frontier include mining, oil and gas, infrastructure, energy generation and natural science.

These activities all involve complex and highly technical systems. Many of them, particularly those performed beneath the sea’s surface, utilize a broad array of electro-hydraulic systems to carry out their work—lower and lift equipment to the seabed, remote operation of subsea systems, and permanent monitoring of emplaced systems such as petroleum wellheads or communications cabling.

It is frequently assumed that such hydraulic equipment needs to be specifically designed and engineered using special materials to enable operation under the pressures and corrosive conditions of different sea depths. However, many standard hydraulic systems engineered for surface use can be, with sufficient customization, utilized effectively in this demanding environment.

Ultimately, the operation of hydraulic systems—whether on land at sea level atmospheres, or deep under the sea—requires isolating the hydraulic circuit from external environments and controlling the fluid to actuate work; the principles are the same, and thus the design principles for subsea simply call for considering additional conditions.

Comparison of Subsea Requirements

In order to select the best solution for a given application, it is necessary to understand how the different subsea water depths impact the hydraulic system. The analysis used in oil and gas exploration supply an effective set of guidelines.

Shallow water: Up to 1,000 ft (305 meter)

At this depth, components must operate in saltwater, but not in significantly high water pressures. At this depth, (which includes the technical safe limit for divers not pressure suits, at 100 meters), the equipment is relatively easy to operate, put in place and retrieve. However, the surface light may penetrate up to 200 meters, thus promoting the growth of sea life over the equipment surface; this must be factored into designs of equipment such as hydraulic cylinder rods.

Deep water: from 1,000 ft. (305 m.) to 6,000 ft (to 1,830 m.)

Every 10 meters, the water column increases the environmental pressure by 1 bar; thus, at a depth of 5,000 meters the ambient pressure is 500 bar. At these depths, all work is done with remote control systems and subsea robots such as ROVs (Remote Operated Vehicles) or AUVs (Autonomous Underwater Vehicles). Here, components become exposed to high external water pressures, which may require special design features like pressure compensation or structural modifications to accommodate the increased pressures.

These depths are typically found significantly far from shore, requiring floating operational facilities such as ships and platforms, creating further challenges.

Ultra -deep water: From 6,000 ft (1,830 m) to 35,800 ft (10,911m)

Beyond 6,000 ft, there is much less experience of subsea equipment (outside of military applications and research vessels). As depths increase, even the engineering of hoisting and tether equipment construction must change, to accommodate the dimensions and weight of the systems as they increase with the water depth. Furthermore, the ocean conditions become harsher, such as the size of waves or the forces caused by maritime currents.

The Subsea Enabler: Robotics

Since divers can’t operate below 100 meters, the bulk of subsea activities must be performed by ROVs and AUVs, complex systems which utilize extensive electromechanical and electrohydraulic subsystems to accomplish tasks. Their operational depths can be in any range. Typically, robots are not submerged for long periods of time. However, it is critical they are ready when needed, and if they malfunction the downtime must be kept to a minimum.

Hydraulic drives can prove their full strength in these machines: they are powerful, compact, precise, intelligent and rugged, providing excellent power density and adroit flexibility for a wide range of tasks. ROV/AUV developers continue to seek more sophisticated performance and reliability from the electrohydraulics systems integrated into their machines.

Subsea Design Requirements

Successful growth of many subsea applications depends upon equipment that can be reliably and safely deployed and operated over extensive periods of time, without requiring overly-expensive engineering, operating and repair costs. There are built-in costs for subsea work that are unavoidable: operating equipment at a distance with remote devices, and dealing with external water pressure and corrosion conditions. Careful planning and a willingness to integrate smart design principles into subsea hydraulic systems make it possible to accomplish these goals cost-effectively.

Pressure Compensation

Pressure compensation is useful in any system which operates below water. It is used to keep the pressure between external environment (seawater) and reservoir constant, as seals are typically designed for the pressure drop in one particular direction and limited to a specified amount.

Most components readily available on the market were designed for operation in normal surface environments. Almost all machines have sealing surfaces or parts which cannot withstand high subsea external pressures or high pressure drops. One option—more difficult and expensive—is to seal pressure-sensitive components inside a protective chamber. This is usually a container with rigid construction and heavy duty seals to withstand the high external pressures.

A more effective solution is called pressure compensation. Using this system a pressure is applied inside the component equal and opposite to the ambient pressure outside. In a typical hydraulic system, the standard reservoir is replaced with a sealed reservoir containing a flexible medium separator.

In this way the external environment pressure is transferred to the reservoir, just as a normal surface system has the external air pressure on top of the oil in the reservoir. The difference is the seawater is prevented from mixing with the oil. Through this clever system any component used on the surface can be used subsea as long as all volumes that normally contain air can be vacated of air filled with fluid and connected to the reservoir to maintain the pressure balance.

Corrosion Protection and Sealing

On offshore machines, it is common to have a seal, sealing surface, seawater, and some other medium in contact and interacting with each other. On large hydraulic cylinders, for example, maintaining the integrity of the cylinder rod, which is routinely exposed to environmental conditions in operation, is essential for maintaining the long-term operating life of the system.

The rod surface needs an appropriate coating to provide a good and durable base for the cylinder’s tribological system between the cylinder head and the piston rod. There have been major advances in cylinder coating technologies, including metallic/metal mix systems applied with high velocity oxygen flame (HVOF) or cobalt alloy coatings applied via plasma arc welding.

In hydraulic actuator design there is always an interaction between seals, fluid, and material surface. The study of these three items is known as tribology. Knowledge of this is critical for system designers, to both keep seawater out of a system and keep the hydraulic fluid in.

Human Safety and Environmental Protection

Equipment engineered for subsea applications must protect both people and the ocean environment from any damage. For deep water and ultra-deep water operations, surface operators need protection from equipment failures during the whole life cycle of the subsea system.

Subsea operations are carried out in environmentally sensitive areas. Hydraulic systems that follow safety principles, such as fail-safe systems that use a de-energization principle, where the system automatically moves to a safe position if the power supply is cut off, are examples of systems with safety engineered-in.

These principles of risk assessment and functional safety have been established through international standards such as ISO 12100, ISO 13849 and ISO 4413.

Reliability and Availability

The reliability of subsea equipment with a projected long lifetime of 30 years in such a harsh environment is one of the largest challenges for the industry today. Reliable hydraulic system design for subsea application can apply different approaches at the same time:

Usage of components with a high degree of reliability: if available, a reliability indicator shall be used for comparison such as MTTF, B10 or Weibull distributions.

Redundancy — when possible and more cost-effective redundant architecture can be installed for higher system reliability: in some case, more than two components may be needed to support each other.

Integration of failure diagnostic features, such as suitable sensors as well as the correct algorithm for processing the information to detect a failure and decide the correct reaction.

In oil and gas applications, field operators expect to use subsea equipment during a well location’s entire service life (30 years or more) with minimal maintenance. Suitable sensors have to be designed, integrated and pressure-proven to detect failures and, if possible, anticipate future failures by including condition monitoring functions.

Designing for Safe and Reliable Subsea Ops

At multiple frontiers and across multiple industries, subsea applications continue to grow. The safe, reliable and effective development of such opportunities has already been proven. However, as industries move deeper under the ocean, certain fundamental technical challenges increase, particularly for hydraulically-driven systems.

These challenges can be met through a combination of standard, “off-the-shelf” systems proven to operate in rugged conditions on the land, with suitable adaptations (such as pressure compensation) and smart, cost-effective application of more advanced materials where needed. This approach can ultimately enable a more cost-effective approach to subsea development and wider access to the potential resources this emerging “frontier” offers.

(As published in the APRIL 2015 edition of Marine Technology Reporter - http://www.marinetechnologynews.com/Magazine)

-

- Mobil Oil Introduces Six Hydraulic Fluids Maritime Reporter, Dec 1986 #64

gear, vane, radial piston, and axial piston pumps where pressures and speeds require an anti-wear product. The two EP oils are recommended for hydraulic systems which require heavier oils and for lubrication of moderately loaded enclosed gear sets and bearings lubricated by circulation or bath. Applicatio

-

- Hydranautics Awarded Contract By Marathon Oil For Rig-Skidding Systems Maritime Reporter, Nov 1984 #71

Hydranautics Hydraulic Systems has received a contract from Marathon Oil UK, Ltd. for two rig-skidding systems for use on the Brae B platform for the North Brae gas condensate field in the North Sea. Each system consists of two 420- metric-ton and two 210-metric-ton, push-pull capacity hydraulic

-

- Johnson Named Manager Of Shipyard Systems For Hydranautics Hydraulic Maritime Reporter, May 1981 #10

the world's largest hydraulic shiplift elevator (approximately 100 feet by 570 feet) for ships up to 30,000 dwt. Prior to joining Hydranautics Hydraulic Systems, Mr. Johnson was responsible for program and schedule control for Aero Spacelines, Inc. His experience also includes being on the aerodynamics st

-

- J.E. Folsom Named Gulf Region Sales Manager For Hydranautics Maritime Reporter, Jan 15, 1981 #18

John E. Folsom has been appointed regional sales manager covering the Gulf of Mexico area for Hydranautics Hydraulic systems, according to James L. Bartlett, president. Mr. Folsom will direct marketing and sales efforts on all Hydranautics Hydraulic systems for shipyard and offshore- related

-

- Powering the Seafloor: Put a Socket in It Marine Technology, May 2018 #22

torque and speed,” says Strand.Current industry requirements, under API 170 (“the Xmas tree bible,” says Lundanes) is very much written for electro-hydraulic systems, however. “There’s a bureaucracy to overcome. But we will overcome it.”The downturn in the oil and gas industry has helped. There’s more open

-

- Literature Available On Foxboro's New On-Line Ferrograph Maritime Reporter, Jul 15, 1980 #33

. A p p l i c a t i o n s include marine propulsion and auxiliary machinery, gas turbines, gear boxes and transmissions, large critical bearings, hydraulic systems, and offshore production rigs. For a free copy of the new literature— PSS 6-8A1 A—write to Roger H. Rotondi, Dept. MR, Foxboro Analytical

-

- New Pall Filter Assembly Is Bi-Directional— Literature Available Maritime Reporter, Jun 15, 1980 #24

. It provides continuous filtration with either direction of flow through the filter. This new filter has been designed for use in openloop hydraulic systems and in closed-loop, reversible hydrostatic transmissions to prevent the circulation of dirt. The single compact housing contains four dual-operat

-

- ZF Helps to Harness Spirit of Ontario's Power Maritime Reporter, May 2004 #41

to be lightweight, while offering a high power density for top performance. The hardened and ground gear teeth and carefully configured hydraulic systems ensure reliability, safety, and comfort during operation. Each of the four gearboxes on the Spirit of Ontario feature ZF Antiflex Mounting

-

- Raising the Standard for Bulk Carrier Cranes Maritime Reporter, Aug 2001 #41

an extensive QFD (quality, function and deployment) analysis before entering production. Key to the design are three independent closedloop hydraulic systems for reliable and independent luffing, slewing and hoisting operations. These systems are controlled by MacGREGOR Cranes' CC2000 computer-based

-

- Hagglunds Offers Free 92-Page Publication On Cranes, Deck Machinery, Cargo Equipment Maritime Reporter, Nov 1986 #83

AB Hagglund and Soner, among the leaders in the fields of cargohandling, heavy-duty hydraulic systems for industrial, marine and offshore applications, is offering a free, 92-page collection of 12 full-color brochures on the company's marine and industrial services products. The Hagglunds publication

-

- Bardex Receives Contract For Rig Skidding S y s t em F r om Shell U . K. Maritime Reporter, May 1986 #41

skidbase skidding and two 275-ton hydraulic piston gripper jack assemblies for substructure skidding. Bardex Corporation (formerly Hydranautics Hydraulic Systems) is headquartered in Goleta, Calif., with offices in London and Houston. The company designs and manufactures heavy-load moving equipment for

-

)

March 2024 - Marine Technology Reporter page: 4th Cover

)

March 2024 - Marine Technology Reporter page: 4th CoverGlow a little longer. Superior sensor performance on a rmance on a – – RBRtridentfraction of the power RBRtridente teee ackscatter or turbidity with hi i in n n t t th h h he e e s sa a am m m me Measure chlorophyll a, fDOM, and backscatter or turbidity within the same e e sensor package using the

-

)

March 2024 - Marine Technology Reporter page: 48

)

March 2024 - Marine Technology Reporter page: 48Index page MTR MarApr2024:MTR Layouts 4/4/2024 3:19 PM Page 1 Advertiser Index PageCompany Website Phone# 17 . . . . .Airmar Technology Corporation . . . . . . . . . .www.airmar.com . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .(603) 673-9570 9 . . . . . .Birns, Inc. . . . . . . . . . .

-

)

March 2024 - Marine Technology Reporter page: 45

)

March 2024 - Marine Technology Reporter page: 45ronments. The new agreement will address speci? c techni- cal gaps in the UUV defense and offshore energy markets especially for long duration, multi-payload mission opera- tions where communications are often denied or restricted. As part of the new alliance, Metron’s Resilient Mission Autonomy portfolio

-

)

March 2024 - Marine Technology Reporter page: 44

)

March 2024 - Marine Technology Reporter page: 44NEW TECH OCEANOLOGY INTERNATIONAL 2024 Image courtesy Metron/Cellula Teledyne Marine acquires Valeport: Matt Quartley, MD, Valeport and Ole Søe-Pedersen, VP & Image courtesy Teledyne Marine GM Teledyne Marine announce the deal in London. Pictured (L-R): Cellula Robotics, President, Eric Jackson, Metron

-

)

March 2024 - Marine Technology Reporter page: 43

)

March 2024 - Marine Technology Reporter page: 43Image courtesy Kongsberg Discovery Image courtesy Teledyne Marine New Products Teledyne Marine had its traditional mega-booth at Oi, busy start to ? nish. Image courtesy Greg Trauthwein offers quality sub-bottom pro? ling capability without the need tion of offshore windfarms. GeoPulse 2 introduces new

-

)

March 2024 - Marine Technology Reporter page: 42

)

March 2024 - Marine Technology Reporter page: 42NEW TECH OCEANOLOGY INTERNATIONAL 2024 Image courtesy Greg Trauthwein Image courtesy BIRNS MacArtney launches the new ultra-compact ø12.7 mm SubConn Nano connector. Innovative connectivity built on 45 years of ? eld-proven and market-trusted design. Image courtesy MacArtney Birns celebrated its 70th

-

)

March 2024 - Marine Technology Reporter page: 41

)

March 2024 - Marine Technology Reporter page: 41Image courtesy Outland Technology Image courtesy Exail Image courtesy Submaris and EvoLogics Vehicles The ROV-1500 from Outland Technology represents a leap forward in underwater robotics, a compact remotely operated vehicle (ROV) weighing in at less than 40 lbs (19kg) the ROV- 1500 is easy to transport

-

)

March 2024 - Marine Technology Reporter page: 40

)

March 2024 - Marine Technology Reporter page: 40NEW TECH OCEANOLOGY INTERNATIONAL 2024 All photos courtesy MTR unless otherwise noted NEW TECH, PARTNERSHIPS LAUNCH IN LONDON With Oceanology International now one month in the rear-view mirror, MTR takes a look at some of the interesting technologies launched before, during and after the London event.

-

)

March 2024 - Marine Technology Reporter page: 39

)

March 2024 - Marine Technology Reporter page: 39Photo courtesy Global Ocean Design Figure 7 A 35Ah AGM lead-acid battery is tested using the West Mountain Radio CBA to show the effect of simply ? lling the battery voids with mineral oil as a compensating ? uid. The CBA is programmed to cut-off at a voltage of 10.50v. The top line (red) shows the

-

)

March 2024 - Marine Technology Reporter page: 38

)

March 2024 - Marine Technology Reporter page: 38LANDER LAB #10 Photo courtesy West Mountain Radio Photo courtesy of Clarios/AutoBatteries.com Figure 6 The West Mountain Radio Computerized Battery Analyzer (CBA V) attaches to a Figure 5 laptop by a USB-B cable, and to a battery by Powerpole® Connectors. Exploded view of an AGM lead-acid battery.

-

)

March 2024 - Marine Technology Reporter page: 37

)

March 2024 - Marine Technology Reporter page: 37miscible barrier ? uid heavier than seawater (sg=1.026) and lighter than the battery electrolyte (sg=1.265). The original cell vent cap was screwed into the top of the riser pipe to vent the gases associated with charging. Wires were soldered to the lead (Pb) posts. The lead-acid battery was additionall

-

)

March 2024 - Marine Technology Reporter page: 36

)

March 2024 - Marine Technology Reporter page: 36LANDER LAB #10 Of special interest for marine applications, LiPo batteries are Shipping any kind of lithium battery can be a challenge, and offered in a “pouch” design, with a soft, ? at body. The pouch IATA regs vary with the batteries inside or outside an instru- is vacuum-sealed, with all voids ?

-

)

March 2024 - Marine Technology Reporter page: 33

)

March 2024 - Marine Technology Reporter page: 33regulated industry in the world.” How- ever, commercial success depends on many factors, not least a predictable OPEX. Over the past four years, SMD has worked with Oil States Industries to calculate cost per tonne ? gures for prospective customers. Patania II uses jet water pumps to Oil States’

-

)

March 2024 - Marine Technology Reporter page: 32

)

March 2024 - Marine Technology Reporter page: 32its pilot collection system test. pact, nodule collection system that utilizes mechanical and The Metals Company recently signed a binding MoU with hydraulic technology. Paci? c Metals Corporation of Japan for a feasibility study on The company’s SMD Q-Collector range is available in a vari- processing

-

)

March 2024 - Marine Technology Reporter page: 31

)

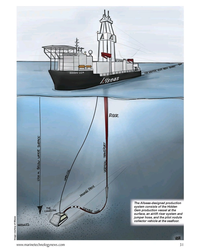

March 2024 - Marine Technology Reporter page: 31The Allseas-designed production system consists of the Hidden Gem production vessel at the surface, an airlift riser system and jumper hose, and the pilot nodule collector vehicle at the sea? oor. Image courtesy of Allseas www.marinetechnologynews.com 31 MTR #3 (18-33).indd 31 4/4/2024 2:12:41

-

)

March 2024 - Marine Technology Reporter page: 30

)

March 2024 - Marine Technology Reporter page: 30FEATURE SEABED MINING bilical. It has passive heave compensation which nulli? es the necott. “The focus since then has been on scaling while en- wave, current and vessel motions that in? uence loads in the suring the lightest environmental impact,” says The Metals power umbilical. The LARS can

-

)

March 2024 - Marine Technology Reporter page: 29

)

March 2024 - Marine Technology Reporter page: 29n January, Norway said “yes” to sea- bed mining, adding its weight to the momentum that is likely to override the calls for a moratorium by over 20 countries and companies such as I Google, BMW, Volvo and Samsung. Those against mining aim to protect the unique and largely unknown ecology of the sea?

-

)

March 2024 - Marine Technology Reporter page: 25

)

March 2024 - Marine Technology Reporter page: 25Auerbach explained that ideally, “one ? ed layers of geothermal activity,” noted changes over an area of 8,000 km2. They would have both instruments: seismom- Skett, “and the change in salinity and dis- found up to seven km3 of displaced ma- eters to detect and locate subsurface ac- solved particles for

-

)

March 2024 - Marine Technology Reporter page: 19

)

March 2024 - Marine Technology Reporter page: 19About the Author vey with the pipe tracker is not required, resulting in signi? - Svenn Magen Wigen is a Cathodic Protection and corrosion control cant cost savings, mainly related to vessel charter. expert having worked across The major advantage of using FiGS on any type of subsea engineering, design

-

)

March 2024 - Marine Technology Reporter page: 18

)

March 2024 - Marine Technology Reporter page: 18TECH FEATURE IMR There are also weaknesses in terms of accuracy because of FiGS Operations and Bene? ts signal noise and the ability to detect small ? eld gradients. In Conventional approaches to evaluating cathodic protection this process there is a risk that possible issues like coating (CP)

-

)

March 2024 - Marine Technology Reporter page: 17

)

March 2024 - Marine Technology Reporter page: 17• Integrity assessment, and otherwise covered, e.g., by rock dump. As for depletion of • Mitigation, intervention and repair. sacri? cial anodes, this can be dif? cult or even impossible to Selecting the best method for collecting the data these work- estimate due to poor visibility, the presence of

-

)

March 2024 - Marine Technology Reporter page: 15

)

March 2024 - Marine Technology Reporter page: 15sensor options for longer mission periods. About the Author For glider users working in ? sheries and conservation, Shea Quinn is the Product Line Manager the Sentinel can run several high-energy passive and active of the Slocum Glider at Teledyne Webb acoustic sensors, on-board processing, and imaging

-

)

March 2024 - Marine Technology Reporter page: 11

)

March 2024 - Marine Technology Reporter page: 11assist in identifying mines and act as a neutralization device. About the Author Bottom mines pose even greater chal- David R. Strachan is a defense analyst and founder of lenges. Unlike contact mines, bottom Strikepod Systems, a research and strategic advisory mines utilize a range of sensors to

-

)

March 2024 - Marine Technology Reporter page: 9

)

March 2024 - Marine Technology Reporter page: 9from marinas along the western coast. The exact number of lizing laser detection systems can detect mines just below the mines, as well as their locations, remains largely a mystery, surface, even those hiding in murky water. The Airborne Laser although reports suggest that over three hundred have been