Learning Management Systems

-

- Maritime Training Five Years from Now: A Look Ahead Maritime Reporter, Mar 2015 #22

For anyone involved in maritime training, now is an incredibly exciting time full of opportunity. More than ever before, there are new advanced techniques and technologies available that can significantly improve training outcomes and access to training, while keeping costs under control. Properly deployed, these advances will improve safety - on that, the research is very clear.

This article looks at training in the maritime industry and predicts how the advances will change training over the next 5 years. We are in the fortunate position of being able to say that the maritime industry is beginning to embrace the fact that training can indeed be improved - the “old” way is not always the “best” way. Now that we are on this path, there is no turning back in the face of improved outcomes. What changes will we see in maritime training over the next 5 years? There are many, but space is limited so we will focus on a few of the most notable.

Blended Learning

It is easy to argue that the biggest advance in training in the last 20 years has been blended learning. Blended learning means using more than one technique for training delivery. It is just beginning to take hold in the maritime industry and I suspect it will be the biggest story in maritime training over the next 5 years.

In practice, blended learning usually means combining on-line learning with face-to-face learning. There are many ways to “blend” the learning experience, but let’s look at one model - that of using on-line self-study as a precursor to classroom or on-board training. This is an incredibly successful model that has been proven in thousands of studies to significantly improve training while at the same time being reasonably inexpensive and easy to implement.

It is easy to understand how it can be helpful. Imagine a vessel familiarization course which begins with some online self-study followed by on-board instructor-led training. The on-line study would likely focus on foundational knowledge about the vessel, equipment, layout, routines, and so on. The instructor-led on-board training would then continue the process by developing the hands-on experience and skills to complete the learning.

There are many advantages over conventional training. First, the initial portion, being online, is very “trainee centered” meaning candidates can proceed at their own pace and on their own terms - increasing the likelihood that they will learn the required knowledge successfully. It is also a fortunate coincidence that on-line training can be comparatively inexpensive, especially since the need for travel is eliminated.

Second, the on-line portion is guaranteed to teach company-vetted best practices. Most other forms of training, whether they are classroom or (especially) job-shadowing, are subject to a wide degree of variation according to the personal experience, biases and abilities of the instructor. This lack of standardization can be dangerous in a safety-critical environment such as the maritime industry. Online training means you are in control of what is being trained.

Third, when the candidates arrive on-board or in class for their instructor-led training, all candidates now have a very uniform level of knowledge. This allows the instructor-led training to be much shorter because the “knowledge” portion of the training has already been covered. Secondly, the instructor-led training is far more efficient because the instructor has less variability to accommodate in the trainees.

If the maritime industry follows the successful path of higher education and other industries (and I see no reason to believe it will not), then blended learning will be a huge story over the next 5 years.

Analytics

Another trend that is sure to impact maritime training is the availability and use of analytics in training. A favorite business mentor of mine once said “if you can’t measure it, you can’t manage it”. Nowhere does this apply more than it does in training. Yet until recently, most organizations had no mechanism to measure the effectiveness of their training program. This is where analytics comes in. Simply said, analytics are just measurements of the health of the training we provide. Examples of analytics include measurements such as:

● Average exam scores (determine how your trainees are doing overall),

● Average exam scores segmented by competency (determine whether some competencies are not being learned),

● Average time on learning materials or in classes compared to performance scores (determine the efficiency of your training),

● Or even performance segmented by employee background (determine which kinds of backgrounds yield better performers).

The point of knowing this type of information is two-fold. First, it allows you to find hidden training problems before they become performance issues or, worse, an accident. And second, knowing these numbers allows you to apply changes to your training and then determine whether the change made a positive impact. This is the essence of continuous improvement. Without it, you are shooting in the dark.

In the past, these analytics have been very time consuming and expensive to calculate and maintain - so very few organizations (aside from the most safety conscious) took the time. Now, however, sophisticated on-line training tools called learning management systems (LMS for short) provide a broad set of actionable analytics. So as LMSs continue to spread throughout the maritime industry over the next five years, analytics will help to transform training training insight and sophistication.

Adaptive Learning

Every vessel is a world unto itself - with different equipment, different routines, different layouts, and even different corporate and flag-state regulations. So the training for personnel on any vessel - especially familiarization training, is by necessity unique to that vessel. Until recently, the only way to accomplish this efficiently is through job shadowing - a staple in the maritime industry.

Sadly, job shadowing is one of the worst forms of training. It is difficult to standardize, almost impossible to measure, and highly variable in its effectiveness. Fixing these issues requires the creation of company-vetted, best practice training resources and programs for every vessel in your fleet. That would be a very daunting and expensive process - both in terms of the initial creation and the maintenance.

Fortunately, a relatively new technique called “adaptive learning” can help to solve this problem. Adaptive learning is a feature of some learning management systems. In essence, adaptive learning tailors the training program to each individual trainee - automatically. An LMS which supports this feature asks the trainee what role and vessel they are training for, and then automatically creates a set of company-vetted learning materials from training materials in the database. Each trainee receives an online, custom textbook targeted to that trainee. Adaptive learning has been in use in other industries to varying degrees and is already in use by some safety-conscious vessel operators. No other industry that I am aware of can make use of this feature as effectively as the maritime industry. Therefore, adaptive learning is an important innovation to watch over the next 5 years.

This is an incredibly exciting time in maritime education. Change is afoot - and there is a formidable arsenal of tools waiting to be deployed for the benefit of safety in our industry.

As indicated in the introduction of this article, if you are involved in maritime training in any way, it is time to take a hard look at your training practices because there are advances available that can significantly improve training outcomes, performance and safety.(As published in the March 2015 edition of Maritime Reporter & Engineering News - http://magazines.marinelink.com/Magazines/MaritimeReporter)

-

- Maritime Training: Implementing CI in Familiarization Training Maritime Reporter, Mar 2016 #16

KPIs Overview As with many data-driven systems (and KPIs are just that - data), technology is our friend here. Computer-based learning management systems (or LMSs) generate a wealth of KPIs that track learning and assessment effectiveness. These are metrics which cannot otherwise be practically

-

- MN100: The Hornblower Group Marine News, Oct 2021 #51

component is just a piece of the puzzle, existing to compliment hands-on, onboard training. “Using Microsoft Teams, Zoom, online learning management systems allowed us to keep our crew coming back and being able to train on things that might have been done on board a vessel or in a classroom

-

- Improved Safety and Training, Step-by-step Maritime Reporter, Jun 2017 #16

until then, sail safe! The Author Murray Goldberg id CEO of Marine Learning Systems, maker of MarineLMS. A researcher and developer of learning management systems, his software has been used by millions of people and companies worldwide. (As published in the June 2017 edition of Maritime Reporter

-

- Improved Safety and Training, Part II Maritime Reporter, Jul 2017 #14

& Engineering News. The Author Murray Goldberg is CEO of Marine Learning Systems, maker of MarineLMS. A researcher and developer of learning management systems, his software has been used by millions of people and companies worldwide. (As published in the July 2017 edition of Maritime Reporter

-

- Online and Way Ahead Marine News, Sep 2013 #98

examination. If the first attempt is unsuccessful, a re-test is offered during the same session. USCG-approved eLearning Courses and associated Learning Management Systems (LMS) must satisfy the same quality standards as would be needed for a similar class given in a traditional brick and mortar environment

-

- Does e-Learning Work? Maritime Reporter, May 2014 #30

have slowed the adoption of eLearning in the industry. However, those obstacles are being (and have been) largely overcome by maritime-specific learning management systems (LMSs) and the industry is following suit by adopting eLearning methods. This study makes it clear that the benefits of eLearning are not

-

- Five Requirements for Safe Ops Maritime Reporter, Nov 2017 #22

comes in. Are you ready? The Author Murray Goldberg id CEO of Marine Learning Systems, maker of MarineLMS. A researcher and developer of learning management systems, his software has been used by millions of people and companies worldwide. (As published in the November 2017 edition of Maritime

-

- The Training Implications of Subchapter M Maritime Reporter, Nov 2016 #19

and opportunities. The Author Murray Goldberg is CEO of Marine Learninf Systems, maker of MarineLMS. A researcher and developer of learning management systems, his software has been used by millions of people and companies worldwide. (As published in the November 2016 edition of Maritime

-

)

March 2024 - Marine Technology Reporter page: 4th Cover

)

March 2024 - Marine Technology Reporter page: 4th CoverGlow a little longer. Superior sensor performance on a rmance on a – – RBRtridentfraction of the power RBRtridente teee ackscatter or turbidity with hi i in n n t t th h h he e e s sa a am m m me Measure chlorophyll a, fDOM, and backscatter or turbidity within the same e e sensor package using the

-

)

March 2024 - Marine Technology Reporter page: 48

)

March 2024 - Marine Technology Reporter page: 48Index page MTR MarApr2024:MTR Layouts 4/4/2024 3:19 PM Page 1 Advertiser Index PageCompany Website Phone# 17 . . . . .Airmar Technology Corporation . . . . . . . . . .www.airmar.com . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .(603) 673-9570 9 . . . . . .Birns, Inc. . . . . . . . . . .

-

)

March 2024 - Marine Technology Reporter page: 45

)

March 2024 - Marine Technology Reporter page: 45ronments. The new agreement will address speci? c techni- cal gaps in the UUV defense and offshore energy markets especially for long duration, multi-payload mission opera- tions where communications are often denied or restricted. As part of the new alliance, Metron’s Resilient Mission Autonomy portfolio

-

)

March 2024 - Marine Technology Reporter page: 44

)

March 2024 - Marine Technology Reporter page: 44NEW TECH OCEANOLOGY INTERNATIONAL 2024 Image courtesy Metron/Cellula Teledyne Marine acquires Valeport: Matt Quartley, MD, Valeport and Ole Søe-Pedersen, VP & Image courtesy Teledyne Marine GM Teledyne Marine announce the deal in London. Pictured (L-R): Cellula Robotics, President, Eric Jackson, Metron

-

)

March 2024 - Marine Technology Reporter page: 43

)

March 2024 - Marine Technology Reporter page: 43Image courtesy Kongsberg Discovery Image courtesy Teledyne Marine New Products Teledyne Marine had its traditional mega-booth at Oi, busy start to ? nish. Image courtesy Greg Trauthwein offers quality sub-bottom pro? ling capability without the need tion of offshore windfarms. GeoPulse 2 introduces new

-

)

March 2024 - Marine Technology Reporter page: 42

)

March 2024 - Marine Technology Reporter page: 42NEW TECH OCEANOLOGY INTERNATIONAL 2024 Image courtesy Greg Trauthwein Image courtesy BIRNS MacArtney launches the new ultra-compact ø12.7 mm SubConn Nano connector. Innovative connectivity built on 45 years of ? eld-proven and market-trusted design. Image courtesy MacArtney Birns celebrated its 70th

-

)

March 2024 - Marine Technology Reporter page: 41

)

March 2024 - Marine Technology Reporter page: 41Image courtesy Outland Technology Image courtesy Exail Image courtesy Submaris and EvoLogics Vehicles The ROV-1500 from Outland Technology represents a leap forward in underwater robotics, a compact remotely operated vehicle (ROV) weighing in at less than 40 lbs (19kg) the ROV- 1500 is easy to transport

-

)

March 2024 - Marine Technology Reporter page: 40

)

March 2024 - Marine Technology Reporter page: 40NEW TECH OCEANOLOGY INTERNATIONAL 2024 All photos courtesy MTR unless otherwise noted NEW TECH, PARTNERSHIPS LAUNCH IN LONDON With Oceanology International now one month in the rear-view mirror, MTR takes a look at some of the interesting technologies launched before, during and after the London event.

-

)

March 2024 - Marine Technology Reporter page: 39

)

March 2024 - Marine Technology Reporter page: 39Photo courtesy Global Ocean Design Figure 7 A 35Ah AGM lead-acid battery is tested using the West Mountain Radio CBA to show the effect of simply ? lling the battery voids with mineral oil as a compensating ? uid. The CBA is programmed to cut-off at a voltage of 10.50v. The top line (red) shows the

-

)

March 2024 - Marine Technology Reporter page: 38

)

March 2024 - Marine Technology Reporter page: 38LANDER LAB #10 Photo courtesy West Mountain Radio Photo courtesy of Clarios/AutoBatteries.com Figure 6 The West Mountain Radio Computerized Battery Analyzer (CBA V) attaches to a Figure 5 laptop by a USB-B cable, and to a battery by Powerpole® Connectors. Exploded view of an AGM lead-acid battery.

-

)

March 2024 - Marine Technology Reporter page: 37

)

March 2024 - Marine Technology Reporter page: 37miscible barrier ? uid heavier than seawater (sg=1.026) and lighter than the battery electrolyte (sg=1.265). The original cell vent cap was screwed into the top of the riser pipe to vent the gases associated with charging. Wires were soldered to the lead (Pb) posts. The lead-acid battery was additionall

-

)

March 2024 - Marine Technology Reporter page: 36

)

March 2024 - Marine Technology Reporter page: 36LANDER LAB #10 Of special interest for marine applications, LiPo batteries are Shipping any kind of lithium battery can be a challenge, and offered in a “pouch” design, with a soft, ? at body. The pouch IATA regs vary with the batteries inside or outside an instru- is vacuum-sealed, with all voids ?

-

)

March 2024 - Marine Technology Reporter page: 33

)

March 2024 - Marine Technology Reporter page: 33regulated industry in the world.” How- ever, commercial success depends on many factors, not least a predictable OPEX. Over the past four years, SMD has worked with Oil States Industries to calculate cost per tonne ? gures for prospective customers. Patania II uses jet water pumps to Oil States’

-

)

March 2024 - Marine Technology Reporter page: 32

)

March 2024 - Marine Technology Reporter page: 32FEATURE SEABED MINING by a sea? oor plume from its pilot collection system test. pact, nodule collection system that utilizes mechanical and The Metals Company recently signed a binding MoU with hydraulic technology. Paci? c Metals Corporation of Japan for a feasibility study on The company’s SMD

-

)

March 2024 - Marine Technology Reporter page: 31

)

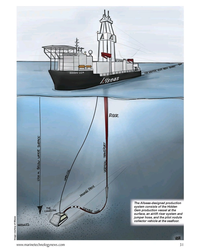

March 2024 - Marine Technology Reporter page: 31The Allseas-designed production system consists of the Hidden Gem production vessel at the surface, an airlift riser system and jumper hose, and the pilot nodule collector vehicle at the sea? oor. Image courtesy of Allseas www.marinetechnologynews.com 31 MTR #3 (18-33).indd 31 4/4/2024 2:12:41

-

)

March 2024 - Marine Technology Reporter page: 30

)

March 2024 - Marine Technology Reporter page: 30FEATURE SEABED MINING bilical. It has passive heave compensation which nulli? es the necott. “The focus since then has been on scaling while en- wave, current and vessel motions that in? uence loads in the suring the lightest environmental impact,” says The Metals power umbilical. The LARS can

-

)

March 2024 - Marine Technology Reporter page: 29

)

March 2024 - Marine Technology Reporter page: 29n January, Norway said “yes” to sea- bed mining, adding its weight to the momentum that is likely to override the calls for a moratorium by over 20 countries and companies such as I Google, BMW, Volvo and Samsung. Those against mining aim to protect the unique and largely unknown ecology of the sea?

-

)

March 2024 - Marine Technology Reporter page: 25

)

March 2024 - Marine Technology Reporter page: 25Auerbach explained that ideally, “one ? ed layers of geothermal activity,” noted changes over an area of 8,000 km2. They would have both instruments: seismom- Skett, “and the change in salinity and dis- found up to seven km3 of displaced ma- eters to detect and locate subsurface ac- solved particles for

-

)

March 2024 - Marine Technology Reporter page: 19

)

March 2024 - Marine Technology Reporter page: 19About the Author vey with the pipe tracker is not required, resulting in signi? - Svenn Magen Wigen is a Cathodic Protection and corrosion control cant cost savings, mainly related to vessel charter. expert having worked across The major advantage of using FiGS on any type of subsea engineering, design

-

)

March 2024 - Marine Technology Reporter page: 18

)

March 2024 - Marine Technology Reporter page: 18TECH FEATURE IMR There are also weaknesses in terms of accuracy because of FiGS Operations and Bene? ts signal noise and the ability to detect small ? eld gradients. In Conventional approaches to evaluating cathodic protection this process there is a risk that possible issues like coating (CP)

-

)

March 2024 - Marine Technology Reporter page: 17

)

March 2024 - Marine Technology Reporter page: 17• Integrity assessment, and otherwise covered, e.g., by rock dump. As for depletion of • Mitigation, intervention and repair. sacri? cial anodes, this can be dif? cult or even impossible to Selecting the best method for collecting the data these work- estimate due to poor visibility, the presence of

-

)

March 2024 - Marine Technology Reporter page: 15

)

March 2024 - Marine Technology Reporter page: 15sensor options for longer mission periods. About the Author For glider users working in ? sheries and conservation, Shea Quinn is the Product Line Manager the Sentinel can run several high-energy passive and active of the Slocum Glider at Teledyne Webb acoustic sensors, on-board processing, and imaging

-

)

March 2024 - Marine Technology Reporter page: 11

)

March 2024 - Marine Technology Reporter page: 11assist in identifying mines and act as a neutralization device. About the Author Bottom mines pose even greater chal- David R. Strachan is a defense analyst and founder of lenges. Unlike contact mines, bottom Strikepod Systems, a research and strategic advisory mines utilize a range of sensors to

-

)

March 2024 - Marine Technology Reporter page: 9

)

March 2024 - Marine Technology Reporter page: 9from marinas along the western coast. The exact number of lizing laser detection systems can detect mines just below the mines, as well as their locations, remains largely a mystery, surface, even those hiding in murky water. The Airborne Laser although reports suggest that over three hundred have been