Plastics

-

- The Ocean's Microplastics Mess: Technology & Technique to Identify & Clean Up Marine Technology, Jun 2020 #12

The science and technology surrounding discovery, mitigation and clean-up of microplastics in the world’s environment makes this year’s “MTR100.” Here we offer insights on the organizations, people and technologies taking the lead.

As marine journalists, scientists, technologists, activists and enthusiasts, we are aware of the large-scale impact that consumer macro-plastic products have on aquatic ecosystems. Ranging from plastic bags and straws to bottles and fishing nets, these materials pollute harbors, rivers, lakes and oceans, all while threatening the prosperity of wildlife, natural habitats and human health. To make matters worse, the chemical structure of most plastic materials prevents its complete degradation in nature, instead leaving behind microplastic particles. Measured as smaller than five millimeters in size, microplastics can be difficult to see with the naked eye and even harder to collect and identify. Microplastics are not new to the marine industry; the presence of such tiny particles in our oceans is well accepted and has spurred a cultural and technological race to understand and remove this contaminant. However, as new technologies and techniques are developed to count and identify samples, the number of microplastics in our waterways seems to be growing. The issue is unravelling itself to be larger and far more widespread than once believed, and one that is inarguably linked to culture. So, what is really going on and what should be done about it?

“A not so micro problem”Our connection to plastic goes back centuries, when Mesoamericans used organic materials like natural rubbers to create balls, bands and other objects. Dependency on man-made versions of such products grew in the developed world during the Industrial Revolution and intensified after the end of World War II, since they’re cheap, versatile and sanitary. Humans today are practically surrounded by plastics, with waste and microplastics accumulating through repeated daily use.

As defined by the National Oceanographic and Atmospheric Administration (NOAA) Marine Debris Program, microplastics can be broken down into two subsections. Primary micros, designed to be small, come in the form of resin pellets and beads, which are subsequently used to make larger items or personal care products (like microbeads in face wash). Secondary microplastics derive from bigger pieces of plastic like bags, bottles and toys, which break down in the environment due to sun, wind and waves. Also, under the secondary umbrella are microfibers, or synthetic fibers like polyester or nylon, that are used to make clothing, furnishings and even fishing lines, that break apart during general wear and washing/drying.

While we have broadly categorized microplastics based on origin material and degradation type, much remains unknown about these particles.Questions and issues often revolve around four topics: the varied composition of microplastic samples, each of which contains thousands of different particles that all react uniquely in nature; the lack of technology needed to properly collect, analyze and identify miniscule pieces; their lengthy lifespan due to an inability to breakdown naturally; and how they’re spreading over land, sea and air, and to what distance.

Virginia Institute of Marine Science (VIMS) professor Rob Hale, who is also lead author on a recently published paper titled “A Global Perspective on Microplastics,” explained the need to understand these particles. “People often assume that all plastics are the same and behave identically in the environment, but that isn’t the case at all. To resolve key questions and mitigate possible impacts, everyone—manufacturers, scientists, health-care specialists, engineers, economists, policymakers, and others—must collaborate to better understand the composition and nature of plastic products and their additives.” VIMS doctoral student Meredith Seeley, a co-author of the paper, added, “We have to recognize that microplastic pollution is an international problem that doesn’t respect political boundaries.” The microplastic problem is one of macro proportion—and with each new discovery, its influence seems to spread further across our planet.

© NOAA

© NOAA“Blowing in the Wind”

Evidence is growing to show that plastic pollution is not limited to the world’s oceans and probably never has been. Its substantial footprint has expanded; particles are often carried through the wind or evaporate from waterways into the air. Impacted parts of the planet, some just recently discovered, include the deep-sea floor, city air and even arctic snow. Research conducted at the Alfred Wegener Institute for Polar and Marine Research has discovered microplastics in the Arctic, particles transported over large distances by the atmosphere and later returned to land through precipitation.

The team, led by Dr. Melanie Bergmann and Dr. Gunnar Gerdts, conducted analyses on snow samples from regions in Germany such as Heligoland, Bavaria and Bremen, as well as the Swiss Alps and the Arctic. In each location, the snow contained high concentrations of microplastics, even in the most remote of areas (in the Arctic, samples contained up to 14,400 particles per liter). When analyzing sea ice from the Arctic Ocean, the amount and distribution of microplastics was determined by using a Fourier Transform Infrared Spectrometer (FT-IR), a device that shines a beam of light containing multiple frequencies at once and measures how much light is absorbed. Depending on each particle’s unique composition, different wave lengths will be absorbed and reflected, identifying the substance by its “optic fingerprint.” Using this approach, as Gerdts explained, “We also discovered plastic particles that were only 11 micrometers across. That’s roughly one-sixth the diameter of a human hair and explains why we found concentrations of over 12,000 particles per liter of sea ice — two to three times higher than what we’d found in past measurements.”

In the Arctic snow, types of particles found included nitrile rubber, which is often used to make gaskets and hoses, and paints containing plastics, which are used to coat the surface of buildings, ships, cars and offshore oil rigs. In the ice floes, the scientists predominantly found similar paint particles and nylon waste from fishing nets.

The question that remains is how these omnipresent particles impact living organisms.

eXXpedition founder Emily Penn studying a sample. © Eleanor Church Lark Rise Pictures

eXXpedition founder Emily Penn studying a sample. © Eleanor Church Lark Rise Pictures“Survival of the plastics”

As microplastics break down and float through the air and water, they inevitably invade entire food webs. While the full scope is unknown, the presence is undeniable. On the Galápagos Islands, investigation has already begun to quantify the distribution and impact of marine microplastic pollution on local marine vertebrates. Juan Pablo Muñoz-Pérez, a research scientist at the Galápagos Science Center (a joint effort between the Universidad San Francisco de Quito and the University of North Carolina at Chapel Hill), is on the forefront collecting and analyzing samples from the archipelago’s most threatened creatures to support the improved management of such contaminants in Ecuador. Between June and September of 2019, he and his team sampled 98 marine iguanas from nine different habitats (these locations covered four subspecies across four islands) to establish current microplastic exposure and investigate potential health risks. “The assessment of the health data indicated that the animals captured and sampled were clinically healthy based on standard vital signs, morphometrics, and blood value data. However, in total, 75 synthetic fibers and fragments were found across the scat samples from 84 animals. Each contaminated scat had between one and four synthetic particles per sample. Only the scats from one of the nine locations tested were plastic-free,” Muñoz-Pérez said. These discoveries are only the start though, as other species like the Galápagos sea lion and all four species of sea turtles in the archipelago (green sea, leatherback, hawksbill, and olive ridley) are also in danger. To Muñoz-Pérez, the future of the microplastic crisis looks dire. “Galápagos is a beacon for the entire ocean. If the Galápagos is starting to have worrisome levels of marine microplastic pollution, this represents the ultimate conservation frontier. If we can’t do something about it here, I don’t know where we can.”

Plastic pollution shouldn’t be limited to marine ecosystems. It starts early on in our waterways and often near urban areas, contaminating and breaking down in rivers, lakes and harbors. Research conducted by Theresa Talley, a California Sea Grant extension specialist and researcher at Scripps Institution of Oceanography (UC San Diego), shows that in a sample of fish from Chollas Creek, which flows into the San Diego Bay, nearly a quarter contained microplastics. With the goal of better understanding the movement of plastic through urban watersheds and its impacts on local species, the team collected sediment and fish samples, the latter to be dissected. Twenty-five categories of plastics were identified in the sediment, including pieces of film, polystyrene, microbeads and synthetic fibers, with fish consuming about half the categories. Knowing why organisms only consume certain types of plastic, and the lasting impacts of these habits, are crucial to understanding the long-term health hazards. “If we want to reduce the risks that plastic pollution poses to sea life and, ultimately humans, we need to better understand the processes underlying the entry of plastics into food webs,” Talley explained. “It’s no longer enough to document all the places we find plastics. If we want to develop solutions, we need a clearer understanding of how and why the plastics move through ecosystems.”

“Tech to the Fore”As technology advances and new techniques are discovered, available information on microplastic pollution grows. Research strategies change and adapt to fit the unconventional characteristics and spreading ability of these tiny fragments. From computer codes to satellites, the race to solve the plastic question has soared to new heights.

Also flying through the sky is Robert DeLaurentis, known also as the “Zen Pilot,” on his journey around the world. Working with Scripps marine biologist Dimitri Deheyn, DeLaurentis places a fresh set of sticky adhesives to his aircraft for each leg to collect particles as he flies. Back at the lab in San Diego, Deheyn analyzes the pieces of tape, observing and identifying stuck-on microfibers (tiny synthetic fibers that drift into the water and air from clothes). The expectation is to find different concentrations of microfibers as the plane traverses the globe, with variations influenced by whether the ground below is inhabited or not. “After finding microfibers in water samples from all over the world, it was clear that one main route of contamination had to be through the atmosphere,” said Deheyn.

An expert in ecotoxicology and biomimicry, Deheyn has begun to apply the theory and techniques behind these fields of science to the microplastic dilemma. “Nature has come with more than 3.8 billion years of trials and error through the process of evolution. This accounts for making materials with particular properties that can degrade naturally in ecosystems. But this isn’t the case for plastics, since it takes hundreds of years for those to degrade,” he said. “The biomimicry process helps you live in better unison and synchrony with nature by finding materials that fully return to the environment. We try to use this idea to raise awareness that alternatives to plastics need to be found and that nature can inspire us to find such material.”

The technique used in Deheyn’s lab to quantify and categorize microfibers was designed by engineering graduate student Jessica Sandoval and works similarly to face recognition software. The Automated Microplastics Identifier (AMI) learns about typical microfiber shapes based on diameter, curviness, length, color and possible fluorescence. Things get a little more challenging, though, when multiple microfibers overlap. “It’s like having a few strands of spaghettis on your plate. You can probably count them based on their shape, length, etc., but not when you have a full bowl. In terms of the technique, it all comes down to the computer analyzing the content of individual and contiguous pixels in an image; the continuity of these pixels defines the shape of each fiber,” Deheyn said.

Another technique for identifying microplastic particles is using a confocal Raman microspectrophotometer, which can provide the “molecular fingerprint” of a specimen’s chemical composition. Professor Gordon Taylor and PhD student Luis Medina Faull from Stony Brook University explained how this instrument worked by shining a monochromatic laser through a microscope lens onto a sample. While most of the laser light is reflected or passes through, a tiny fraction of the photons collides with chemicals in the sample and give up their energy, which causes them to vibrate at different frequencies.

“The photons released from this interaction are now many different colors. The same microscope lens collects all light scattered back from the sample, which is then directed toward the Raman spectrophotometer. Prior to entering the spectrophotometer, photons having the same color as the laser are filtered out, admitting only the lower energy photons, which are then spatially separated by a prism and imaged on a charge coupled device (CCD) camera chip,” Taylor added. The CCD chip measures the number of photons scattered at each color to produce a spectrum of peaks and valleys. The beauty of this spectrophotometer is that it can provide “fingerprints” of objects as small as about 0.3 micrometers (a human hair is about 75 micrometers thick). Also, every plastic polymer has a distinctive Raman spectrum, so this instrument enables distinguishing plastics from both natural materials and other plastics.

Realizing that one of the many knowledge gaps in microplastic research is the absence of quantitative information, Taylor’s lab has also developed an effective technique to collect, analyze and identify samples. As opposed to the common use of a manta trawl, a net made of thin mesh (330-500 micrometers) that allows for sifting through large volumes of water, Taylor plans to collect samples of seawater (0.5-2 liters) that will later be filtered through a metallic filter (0.2 m pore size). “The filters are mounted on a microscope slide and scanned by the microspectrophotometer. From these measurements, we can calculate concentrations, volumes and masses of each plastic polymer in the sample,” Taylor explained. This method allows for sampling from any depth (manta trawls are limited to the sea surface) and the data obtained is critical to formulating comprehensive assessments of the ocean’s plastic inventory.

Additional techniques explored by Taylor’s lab include 3D chemical mapping of the particles, which has revealed that some larger microplastics have multipolymer composition. A new achievement to this field, Taylor sees hope in being able to detect mass contributions of multiple polymers in individual plastic samples: “Such capabilities may improve our abilities to forensically source microplastic particles in natural waters and better understand microplastic contamination pathways.”

While identifying microplastic composition, it’s also crucial to understand that many of these particles started as something larger. Macro plastics, which break down into increasingly smaller pieces, can be cleaned from waterways early on, which will significantly reduce the quantity and impact of future microplastics. Dr. Lauren Biermann of the Plymouth Marine Laboratory (PML), in conjunction with funding from the European Space Agency (ESA), has been working to detect aggregated patches of plastics using the ESA’s Sentinel-2 satellites and corresponding data archive. “For our work, this meant scouring the archive to choose very clean and clear examples of ‘all things that float on water’ and may end up mixed in with plastics. We found our driftwood off Canada, seaweed off Barbados, wind-whipped sea foam near river mouths along the Scottish coastline, pumice that had bubbled up from an underwater volcanic eruption near Tonga, and examples of seawater from each of these locations,” Biermann said. With this information, her fellow PML colleague, Dr. Dan Clewley, then trained their Naïve Bayes classifier to automate distinction of driftwood from seaweed from sea foam from pumice, and most importantly, all of these from plastics. The team ran high-resolution, multispectral optical satellite data of coastal waters through an algorithm, subsequently creating the Floating Debris Index (FDI). “The FDI helps us to spot patches of floating material/objects/debris, no matter what these patches are composed of. It’s effective at doing so, thanks to the way it leverages the near infra-red band of the Sentinel-2 Multi-Spectral Instrument (MSI) to ‘see’ things that don’t completely fill a 10m x 10m pixel. From this point, spectral signature becomes key for discrimination, and we use that to check each highlighted pixel for similarity to the spectral shape of plastic,” Biermann added.

The role of satellites and other overhead technology like drones, Biermann acknowledged, is one that is becoming increasingly important in the field of plastic contamination. “The problem of marine plastics is not a mystery—we know how and where plastics are produced, we know at best less than 30% of plastics make it to recycling, and we know which countries produce the most, recycle the least and ship off the rest to developing countries.” But, satellites can play a meaningful role in plastic detection through active removal. Even early on in our waterways, like in rivers and lakes, such technology can make a huge difference by detecting floating plastics for removal before they enter the ocean.

As Biermann and fellow scientists at the PML detect macro plastic pollution in our waterways, scientists and activists at The Ocean Cleanup are already at work to remove both river and marine macro particles. “Rivers are the main source of ocean plastic pollution; they are the arteries that carry waste from land to the ocean. Our research found that 1000 rivers are responsible for roughly 80% of the pollution. To rid the oceans of plastic, we need to not only clean up what is already out there, but also stop new plastic from entering the ocean: we need to close the tap,” the organization explained. The solution: the Interceptor, the company’s solar-powered, autonomous answer to catching plastic at the start. Functioning as a barrier and a conveyor belt, the Interceptor concentrates and extracts plastic from rivers: “The barrier concentrates the debris as it floats with the current and directs it to a permeable conveyer belt. At this point, the waste is transferred up the belt to an automated shuttle that distributes the waste between one of six containers located on a separate barge. Once full, the barge is exchanged, and the waste is transferred to a local waste management facility.” Currently functioning Interceptor systems are in Jakarta, Indonesia, and Klang, Malaysia, with more to come in Vietnam and the Dominican Republic.

The Ocean Cleanup is also tackling marine plastic pollution, although the challenges of cleaning the gyres are far from few, as contaminants are spread across millions of square miles and travel in all directions. The organization’s system consists of a floater that sits at the surface and provides buoyancy, and a skirt that prevents debris from escaping and leads into the retention system. What makes this solution unique, though, is in its design: “For an area of this size, active cleanup methods would be too energy-intensive; this is why we have chosen a passive design. The cleanup systems rely on natural forces to navigate the patches—a feature that also increases its survivability in the harsh ocean environment. Both the plastic and system are being carried by the wind, waves and current.” Better yet, models predict that a full-scale cleanup system roll-out could clean 50% of the Great Pacific Garbage Patch in only five years. While technology and technique are important, getting to the root cause and enacting cultural shift from plastics is the longer term play.

The Ocean Cleanup System 001 deployed in the Great Pacific Garbage Patch, October 2018 © The Ocean Cleanup

The Ocean Cleanup System 001 deployed in the Great Pacific Garbage Patch, October 2018 © The Ocean Cleanup“Kicking the habit”

The “why” can be tied back to that historic dependency, as well as convenience, low costs and a lack of available and equally popular materials. The question of how to change cultural mindset is trickier.

eXXpedition was co-founded in 2014 by Emily Penn to contribute to microplastic research while providing women from all walks of life a chance to sail the world and manage the plastic problem hands on. Penn’s inspiration to create such an organization came while hitchhiking to Australia on a bio-fueled boat in 2008. “During that journey, I couldn’t believe that I was seeing so much plastic in the remotest areas of our planet. The nearest people to us were in the space station above our heads and I was seeing a toothbrush washing across the deck of the boat.” The plastic problem transcends geographic or political boundaries. “A big part of our approach to solving the plastic pollution issue is that there’s no silver bullet solution, but there are hundreds of different ways that we can solve it. So, we need experts in every field—it’s about saying, great, you’re an engineer, let’s look at ways we can improve waste management. You’re a chemist, let’s look at ways we can reinvent plastic or a biodegradable material. You’re a teacher, let’s talk about it. You’re a policy maker, let’s legislate it,” said Penn.

The guest crews experience the microplastic crisis up close by conducting research and analyzing findings on each leg of the tour. On board, the crews use a manta trawl to sample the surface of the ocean and a Niskin bottle to test sub-surface water from a depth of 25 meters. In coastal waters, they also collect sediment samples. For particle analysis, the boat houses a PerkinElmer Spectrum Two FT-IR spectrometer and both sediment and Niskin samples are sent to the lab at the University of Plymouth to be analyzed.

This past June 8, on World Oceans Day, Penn and global technology leader SAP launched the SHiFT Platform, a program that uses innovative technology to help users identify their role in tackling ocean plastic pollution. “A big challenge for many people is knowing where to start. That’s why I first developed the SHiFT methodology—a journey of discovery to help people understand the crux of a problem and weigh up where they have the biggest opportunity to make an impact,” said Penn. “We’re in this amazing position at the moment where there is a lot of awareness compared to a few years ago, but now we find people saying to us ‘OK, we get there’s a problem and we care about it, now what can we do?’”

Founded in 2005, The 5 Gyres Institute takes on similar stance of using science to influence cultural and societal mindsets. Bearing the motto “science to solution,” co-founders Marcus Eriksen and his wife were inspired by the unknown reality of marine plastic pollution and spent years conducting research and collecting evidence to prove the danger of microplastic pollution. Eriksen fondly credits a moment in 2015, when President Obama signed a bill banning microplastics from consumer products after 5 Gyres published a paper about microbeads discovered in the Great Lakes. Eriksen and his wife have taken on a more guiding position and shifted to include activism in their work. “There is enough research to act on, so we are now focused more on engaging the leaders of tomorrow in science, policy and entrepreneurship. We are still about ‘science to solutions,’ but understanding that to build a larger movement you need to provide tools to the next generation.” Some of these tools come in the form of education and helping to organize local campaigns. 5 Gyres offers English-Spanish virtual programs, called Trash Academy (Academia de Basura), that chronicle the life cycle of plastic and address potential solutions, offered online for public access.

“The clock is ticking”Microplastic research, while gaining significant traction in recent years, has only scratched the surface of this widespread, invisible contaminant. Drifting through the ocean, frozen in arctic snow, eaten by wildlife, disintegrating from our clothes—these particles are ubiquitous and still their full impact, specifically on humans, remain unknown. There is no single solution, rather a combined effort to reduced production and consumption; emphasizing proper disposal; policy creation to encourage sustainable alternatives; education and awareness campaigns should guide and motivate communities; as well as scientific research and technological advance identify, quantify and mitigate. There’s so much we don’t know, but this, we do: the menace may be miniscule, the response must be massive.

Scientists from AWI collect arctic sea ice to test for microplastic contamination. © Mar Fernandez

Scientists from AWI collect arctic sea ice to test for microplastic contamination. © Mar Fernandez -

- Plastics in the Ocean Marine Technology, Jan 2013 #12

pieces of plastic. From the deck of the ship on a calm day with no swell, this plastic debris look like confetti. But when the winds pick up, these plastics become almost invisible to the naked eye. “If you are not specifically looking for plastic with a net or doing visual surveys,” says Emelia DeForce

-

- Panama Canal Installs Marine Fendering System From Solidur Plastics Maritime Reporter, Mar 1991 #70

Solidur Plastics Co., Delmont, Pa., supplied an Ultra-High Molecular Weight Polyethylene (UHMWPE) marine fender system for the locks at the Panama Canal to protect oceangoing ships from the damaging impacts of bumping into the lockwalls. Jorge Quijano, chief of the Locks Division, Panama Canal, said

-

- DOT Regulations Prohibit Dumping Plastics At Sea Maritime Reporter, Jun 1989 #96

environment," said Secretary of Transportation Samuel K. Skinner recently in announcing an interim final rule that prohibits the dumping of plastics, including synthetic fishing nets and other shipgenerated garbage at sea. The interim final rule, issued by the Coast Guard, implements Annex V

-

- Meet the CARTHE Drifter Marine Technology, Sep 2017 #44

to reduce storage space during shipment and deployment at sea. Ocean plastic pollution is a rapidly-emerging global crisis. Several million tons of plastics are discarded into marine environments every year and accumulate in oceanic regions. Petroleum based plastics have a very low biodegradability and

-

- International Paint Names Donald S. Otto Maritime Reporter, Jul 15, 1977 #23

Division of International Paint Company, Inc., New York, N.Y. Mr. Otto, a graduate of Cornell University, has a broad background in the chemical and plastics industries where he has held positions in commercial development, sales and marketing with some of the nation's largest corporations. Most recently

-

- Literature Available On New Marine Products Made From 'Orkot' Maritime Reporter, Apr 1989 #15

Orkot Engineering Plastics, Carlsbad, Calif., is offering free literature on 'Orkot' bearings, bushings, wear pads and other components ideal for marine use. 'Orkot' is a laminated material made by bonding various fabrics with thermosetting resins. Its mechanical and chemical characteristics may be

-

- Nippon Foundation Addresses Global Ocean Threats Maritime Reporter, Jun 2018 #18

is not only the problems that come from the developed countries, but there are a lot of developing countries that contribute to that threat, as well.The plastics that you have mentioned, as well as the PVCs – the vinyls – those are flowing into the sea and being eaten by many of the lives that’s living in the

-

- International Compactor Offers High-Performance Trash Compactors Maritime Reporter, Apr 1989 #76

maritime industry now faces a new challenge on how to handle its on-board trash and waste. The MARPOL 73/ 78 regulations prohibit the discharge of plastics, including plastic garbage bags, into the navigational waters of the U.S. or EEZ. The regulations also prohibit the discharge of certain types

-

- Acetylene Gas Used To Straighten Ships' Decks Maritime Reporter, Aug 1978 #

Co., Inc. G E O R G I A — S a v a n n a h Southern M a r i n e S u p p l y Co., Inc. L O U I S I A N A — N e w Orleans H u b e v o M a r i n e Plastics, of N e w Orleans, Inc. M A I N E — P o r t l a n d Chase, Leavitt & Co., Inc. M A R Y L A N D — B a l t i m o r e Tate Temco, Inc. N E W JERSEY—Linde

-

- Lander Lab #3: Buoyancy Marine Technology, Apr 2022 #20

. Lead is 11.3. Marine grade HDPE is 0.96, which means it floats. We don’t use HDPE for flotation, but it subtracts zero from the buoyancy budget. Most plastics are not prone to corrosion, though some are hygroscopic and absorb some percentage of water over time. A great reference is Steven Dexter’s text

-

- Owens-Corning Booklet Describes New LNG Containment System Maritime Reporter, Feb 15, 1977 #20

A booklet from Owens-Corning Fiberglas Corporation describes its recently developed Fiberglas/ plastics (FRP) and polyurethane insulating and containment system for liquefied natural gas carriers. It is the first nonmetallic system to combine high strength and impact resistance with low thermal

-

)

March 2024 - Marine Technology Reporter page: 32

)

March 2024 - Marine Technology Reporter page: 32FEATURE SEABED MINING by a sea? oor plume from its pilot collection system test. pact, nodule collection system that utilizes mechanical and The Metals Company recently signed a binding MoU with hydraulic technology. Paci? c Metals Corporation of Japan for a feasibility study on The company’s SMD

-

)

January 2024 - Maritime Reporter and Engineering News page: 39

)

January 2024 - Maritime Reporter and Engineering News page: 39the walls of their store rooms with a line to ALMACO also works with its partners to ? nd ways to limit indicate maximum loading height. single-use plastics and reduce food waste, whether through “It's about the learning,” Tenovuo said. “How to teach, learn equipment engineering, logistics improvements

-

)

January 2024 - Maritime Reporter and Engineering News page: 37

)

January 2024 - Maritime Reporter and Engineering News page: 37submerged ultra? ltration membranes remove food waste stream. Most recently, that relationship has meant solids including bacteria, viruses and microplastics. Addi- that Cunard’s Queen Anne will have 26 Power Knot systems tionally, the system does not involve the use of ? occulants or installed when

-

)

December 2023 - Maritime Reporter and Engineering News page: 30

)

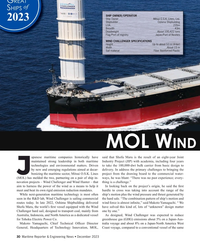

December 2023 - Maritime Reporter and Engineering News page: 30G REAT of HIPS S SHIP OWNER/OPERATOR Ship Owner Mitsui O.S.K. Lines, Ltd. 2023 Shipbuilder Oshima Shipbuilding LOA 235m Breadth 43m Deadweight About 100,422 tons Flag/Port of registry Japan/Port of Noshiro WIND CHALLENGER SPECIFICATIONS Height Up to about 53 m (4-tier) Width About 15 m Sail

-

)

May 2023 - Maritime Reporter and Engineering News page: 28

)

May 2023 - Maritime Reporter and Engineering News page: 28. The petrochemicals sector provides key nomics stack up. The quest now, he says, is to identify ‘ad- components for many everyday products – including plastics, vantaged’ oil and gas. This means lower cost, lower carbon, fertilizers, rubbers, clothes, medical equipment, detergents, better access to markets

-

)

March 2023 - Marine Technology Reporter page: 61

)

March 2023 - Marine Technology Reporter page: 61? shing nets and lines is a bigger propylene at high rates. With increased threat for whales than whaling is. fragmentation, surface plastic gener- Microplastics are so small that they ates additional methane and ethylene. will never be removed from the water. Sunlight increases the off-gasing. And the smaller

-

)

March 2023 - Marine Technology Reporter page: 60

)

March 2023 - Marine Technology Reporter page: 60The Final Word Ocean Plastics Taking ocean plastic seriously: It’s Time Copyright dottedyeti/AdobeStock he oceans are choking on plastics ( 5 to 50 cm) and microplastics the ocean is only now being taken se- plastic waste, increasingly (less than the width of a human hair). riously. Each year the

-

)

March 2023 - Marine Technology Reporter page: 42

)

March 2023 - Marine Technology Reporter page: 42LANDER LAB #7 SUBSEA HOUSINGS With purge systems such as the Global Ocean Design Deck the plastic valve from exposure to any ocean pressure. Purge Box (DPB-107), a vacuum leak test may be performed after the ? rst draw down to ½ atmosphere. The vacuum gauge One example of an open port purge port is

-

)

January 2023 - Maritime Reporter and Engineering News page: 12

)

January 2023 - Maritime Reporter and Engineering News page: 12Eye on the Navy U.S. Navy photo by Mass Communication Specialist 3rd Class Bradley Rickard Machinery Repairman 1st Class Cory Hover, leading petty of? cer for the where the Phillips Hybrid system is a wire-fed laser system Wasp-class amphibious assault ship using a directed energy deposition (DED)

-

)

January 2023 - Maritime Reporter and Engineering News page: 11

)

January 2023 - Maritime Reporter and Engineering News page: 11units that make relatively small plastic parts. The feedback technology in shipboard research use cases, but created a self- we were getting from the ? eet is that they need larger metal contained, mobile 3D metal printshop by out? tting a common parts,” said Jim Pluta, additive manufacturing (AM)

-

)

January 2023 - Maritime Reporter and Engineering News page: 10

)

January 2023 - Maritime Reporter and Engineering News page: 10Eye on the Navy NAVY BUILDS UP ADDITIVE MANUFACTURING ON SHIPS By Edward Lundquist The U.S. Navy has long valued the potential of additive While there are many things one can do with AM, such as manufacturing (AM) and 3D Printing. rapid prototyping, the holy grail has been the ability to fabri- AM

-

)

November 2022 - Marine Technology Reporter page: 40

)

November 2022 - Marine Technology Reporter page: 40LANDER LAB #5 BATTERIES o (Charge battery, then discharge with CBA V Pro and tested them to 18,000-psi. They held up ? ne. to this value. Explained below.) Placing a pressure compensated LiPo battery outside the hull ? Shipping voltage (30% of full charge): 3.71V/cell means you only subtract the

-

)

November 2022 - Marine Technology Reporter page: 39

)

November 2022 - Marine Technology Reporter page: 39Figure 1 A look inside a Southwest Electronic Energy SeaSafe II pressure compensated Lithium Polymer battery shows placement of the prismatic LiPo cells, the individual Battery Management Systems PCBs, and the Power Booster boards for intelligent control of the output. partly be blamed on those

-

)

November 2022 - Marine Technology Reporter page: 30

)

November 2022 - Marine Technology Reporter page: 30GLIDERS Digital Thin Line Array, a miniaturised (20mm), low power drophones. While there were issues with plastic in the ocean towed passive acoustic array, King told MATS. It’s already jamming the thruster and rudder, the trial proved the ability to been trialled with traditional autonomous underwater

-

)

September 2022 - Marine Technology Reporter page: 76

)

September 2022 - Marine Technology Reporter page: 76MTR 100 PLYMOUTH MARINE LABORATORY TRITECH INTERNATIONAL XSENS PLYMOUTH MARINE LABORATORY A team of scientists from Plymouth Marine Laboratory have ‘trained’ an Ar- ti? cial Intelligence (AI) model to recog- nize and classify the different types of marine plastic captured in images shot by a video

-

)

September 2022 - Marine Technology Reporter page: 71

)

September 2022 - Marine Technology Reporter page: 71L L L L L L L L L L L L L L L L L L L L LA A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A AN N N N N N N N N N N N N N N N N N N N N N N N N N N N N N N N N N N N N N N N N N N N N N N N

-

)

September 2022 - Maritime Reporter and Engineering News page: 45

)

September 2022 - Maritime Reporter and Engineering News page: 45SHIP DESIGN COSTA TOSCANA dustry, we are committed to ensuring that the highest standards the tanks. On LNG the range is broadly similar to when run- for safety are maintained, working together with authorities, ning on MGO to allow for our two-week autonomy. Anyway, classi? cation society, shipyard and

-

)

July 2022 - Marine Technology Reporter page: 27

)

July 2022 - Marine Technology Reporter page: 27both manual and autonomous,” Hardiman added. “Sensors fragile water environments in a very non-intrusive way.” mounted onboard send the data captured back to our web por- The need to understand the deep blue sea holds even more im- tal for customers to analyze. portance in the face of the climate crisis

-

)

July 2022 - Marine Technology Reporter page: 26

)

July 2022 - Marine Technology Reporter page: 26the ocean’s back in 2011 when I was watching men in my hometown in surface while recording accurate location information. It can South Africa clean plastics from water using a net and a large operate at sea for up to 30 days at a time and perform surveys boat,” said Founder and CEO Richard Hardiman.

-

)

June 2022 - Marine News page: 43

)

June 2022 - Marine News page: 43Products 1 2 VETUS In-Mar Solutions Rhosonics 3 Voyager Worldwide 4 to make it easy to remove the sen- other team members to signi? cant 1. HPW Series Waterlocks The heavy-duty HPW series of wa- sor without interrupting the process. operational changes, with options to terlocks from VETUS can

-

)

May 2022 - Marine Technology Reporter page: 43

)

May 2022 - Marine Technology Reporter page: 43applications where our technology isn’t currently seen. So over “That is such an important story for our business, even though the next 10 to 20 years, it’s my goal to continue to grow the mar- it happened a long time ago, because that’s what we still do to- kets where our technology is possible and

-

)

May 2022 - Marine Technology Reporter page: 27

)

May 2022 - Marine Technology Reporter page: 27Figure 9 Acknowledgements: This column is meant to serve the ocean com- munity in the manner of Make Magazine, Forrest Mims’ Engineer’s Mini-Notebooks, or other DIY communities. I hope it will promote creative thinking and curiosity to try new things, as I have bene? tted over time from members of the

-

)

May 2022 - Marine Technology Reporter page: 26

)

May 2022 - Marine Technology Reporter page: 26LANDER LAB #3 BUOYANCY ? ber glassing the exterior of the syntactic part will substantially reduce the potential for water absorption. You can try your hand at it for not much money. Polymer Composites (Ontario, CA) [https://theepoxyexperts.com/ high-strength-hollow-glass-microspheres-1-5-pounds/]

-

)

May 2022 - Marine Technology Reporter page: 24

)

May 2022 - Marine Technology Reporter page: 24. We all love the shrunken Styrofoam cups, but that just shows the poor bulk modulus of Styrofoam. Closed cell rigid polyurethane foams: General Plastics (Taco- ma, WA) [www.generalplastics.com] offers marine grade rig- id foams in a range of densities and depth ratings, engineered for shallow to mid-water