Probabilistic Neural Networks

-

- Intelligent Software Agents for Machinery Diagnostics Maritime Reporter, Dec 2001 #47

Machinery plant maintenance represents a major expense for ship operators. In addition to normal maintenance expenditures, unexpected breakdowns have a significant cost impact. Recognizing the importance of preventing equipment failures, companies continue to adopt automation for machinery monitoring at a rapid pace. Continual improvements in the price/performance ratio of automation systems have also fueled their increased use in shipboard machinery plant monitoring.

As a result, more ships with automated machinery plants exist today than ever before. However, just as a typical Internet search can easily create "information overload", so too can process automation create a "data overload" situation for the engineering crews responsible for equipment operation and maintenance. Modern shipboard automation systems typically monitor upwards of over 5,000 real-time process variables, allowing engineers to view massive amounts of data.

This is one example of how automation systems can create too much data. Who is responsible for or has the time to monitor the 5,000 data points? How many people will this take and how much will it cost?

The trends toward more automation, too much data, and too few people make it difficult for companies to assimilate data into information useful for optimal maintenance management. Machinery performance monitoring and maintenance management is an area where immediate exploitation of software agent technology can yield substantial benefits. Software agents can serve as expert assistants in monitoring, controlling, and troubleshooting complex machinery processes.

Agents can perform tedious, repetitive, and analytically complex tasks without being constantly controlled by people. They can also provide valuable assistance in maintenance management decision-making.

Meet Dexter MACSEA has offered its DEXTER machinery diagnostic system since 1991. This system monitors alarm conditions, detects trends, diagnoses machinery faults, and predicts impending problems. DEXTER's artificial intelligence is based on neural network technology that diagnoses machinery faults and ranks them by their probability. The company has recently adapted its diagnostic technology into a team of cooperating, real-time agents, allowing users to create as many agent assistants as needed for their particular condition monitoring requirements. The agents "plug-and-play" with most process control software and automation systems in use throughout industry. Tools are provided to build diagnostic knowledgebases that cause neural networks to be created automatically. The neural networks are then attached to different agents, which gives them the artificial intelligence to carry out their monitoring and diagnostic tasks.

DEXTER's agents run continuously in the background under Windows NT. Users can deploy multiple agents simultaneously, with each monitoring a different piece of equipment. Human-like animated characters provide a simple user-agent interface employing the latest speech synthesis and recognition technologies.

Agent characters issue alerts only when they have diagnosed or predicted problems in the machinery plant. They appear on a computer screen, no matter what other software you may be running at the time. At other times, the agent characters remain hidden, working silently in the background. Since the agents are designed to run in a Windows NT environment, distributed operation over local area networks is supported.

With machinery plant maintenance often accounting for up to 40 percent of total costs in a company, clearly knowledge assets in the maintenance area can be valuable. DEXTER is a tool that allows an organization to capture, organize, manage, and distribute machinery diagnostic knowledge assets within your organization. Even the newest maintenance worker can immediately benefit from your diagnostic knowledge assets that are embedded into DEXTER's neural networks.

This knowledge can be distributed and exploited across your entire maintenance operation, be it contained in a single factory or in several locations around the globe. The bottom line will be improved profitability through avoiding, reducing, or eliminating the consequences of machinery failures. Downtime due to equipment failure impacts both profitability and productivity by reducing output, increasing operating costs, and interfering with customer service. Maintenance plays a critical role in preserving the physical, financial, and competitive health of your company.

Smart companies need to equip themselves now with smart tools for condition-based maintenance; smart tools like DEXTER.

Cloning Human Intelligence A knowledgebase encapsulates valuable engineering knowledge about a machinery plant and its equipment.

A knowledgebase is typically developed through an expert-level assessment of machinery failure modes. In maintenance circles, this is called a Failure Mode and Effects Analysis (FMEA) of the machinery plant. The FMEA involves enumerating all likely machinery faults based on information gathered from historical experience, manufacturers' troubleshooting information, and assessments of industry experts. Each fault is then characterized by its measurable symptoms in the plant, as monitored by the available sensor instrumentation and plant automation. A symptom is defined as an alarm condition, such as a particular temperature measuring HIGH, with respect to a set point limit.

The FMEA forms the basis of diagnostic knowledge about the plant. A comprehensive FMEA of a machinery plant typically involves a substantial amount of time and effort. Because of this, any knowledgebase created from the FMEA becomes a valuable corporate intellectual asset, particularly when it is used with DEXTER as part of a condition-based, reliability-centered maintenance program. A knowledgebase is a collection of information relating machinery faults and symptoms derived from the FMEA.

The BRAINS tool allows a user to create and manage diagnostic knowledgebases that are used by DEXTER's agents. DEXTER's diagnostic neural networks automatically learn the fault-symptom relationships you enter into each knowledgebase. Its software agents are then able to perform real-time diagnostics and prognostics of machinery plant problems.

Besides entering a fault name and description, a user can also indicate any corrective actions or special instructions that the maintenance engineer should follow if the fault is detected. The information entered on this form will be displayed when this fault is detected by one of DEXTER's diagnostic agents.

When specifying symptoms in BRAINS, a list of available tag names and their descriptions are obtained directly through the interface between DEXTER and a user's automation system.

For example, if the automation software defines a Process Database containing all measured sensor inputs in the plant, DEXTER interrogates the automation software for this list. A user can then simply pick from a drop-down list of data points when building a diagnostic. This makes it very easy for a user to integrate DEXTER into plant automation.

The various software agents within DEXTER are "knowledgebase- centric". This means that each agent is linked to a specific knowledgebase. The knowledgebase defines both the data source and the specific data points that an agent will monitor. Because DEXTER agents are knowledgebase-centric, the amount of setup information that you must specify to configure an agent is kept to a minimum. A user simply select a knowledgebase to be used by your agent and it then knows exactly which set of data points to monitor.

Before a user builds any knowledgebases, a user must first configure DEXTER to work with a specific a real-time data source. DEXTER is designed for interoperability with most of the major process control software packages on the market, such as Intellution FIX, Wonderware, Rockwell Automation, National Instruments, etc. All of these software packages have a mechanism for storing real-time sensor data in a database.

BRAINS will automatically extract a list of all data points defined in the process control software database. The user will then be able to select data points from this list when the faults and symptoms for a knowledgebase are entered.

A user can create multiple knowledgebases using BRAINS, storing each one under a different name. Each knowledgebase can pertain to a separate machinery plant, specific system within a plant, or even an individual piece of equipment. A user has complete flexibility in how knowledgebases are defined and used. A user should consider what types and how many agents are desired when creating knowledgebases.

Transforming Knowledge into Artificial Intelligence A major concern in deploying software agents for diagnostics and prognostics is the robustness of their artificial reasoning with respect to correctly identifying real problems when they occur. Missing, noisy, or corrupted sensor data, which are all common real-world occurrences, must be tolerated and not mistaken as equipment faults. Faulty sensor data introduces uncertainty into the diagnostic inferencing process. The reasoning technique should handle such uncertainties in some statistically valid way. The diagnostic agent's robustness can directly impact maintenance and repair costs.

Robustness can be quantified by the accuracy of the diagnostic call. An incorrect diagnosis is declaring a fault different from the one actually present. A missed diagnosis is declaring that nothing is wrong, when, in fact, one or more faults exist. A false alarm involves declaring a fault when there is none. Each of these diagnostic conditions can lead to unnecessary expenditures of maintenance resources and/or reductions in plant reliability, not to mention loss of faith in the diagnostic system. DEXTER's goal is to minimize the probability of each of these cases and to maximize the probability of a correct diagnosis.

DEXTER uses probabilistic neural networks for its diagnostic and prognostic reasoning about machinery faults.

DEXTER's neural networks automatically learn to associate patterns of alarm conditions with the machinery faults you enter into your knowledgebases. DEXTER's neural network learning occurs instantaneously, as compared to other neural network techniques, allowing you to rapidly build, modify, and deploy diagnostic agents on the factory floor. This allows you to immediately put agents to work, without any programming.

DEXTER agent characters are driven by Microsoft Agent software.

-

)

March 2024 - Marine Technology Reporter page: 20

)

March 2024 - Marine Technology Reporter page: 202024 Editorial Calendar January/Februay 2024 February 2024 March/April 2024 Ad close Jan.31 Ad close March 21 Ad close Feb. 4 Underwater Vehicle Annual Offshore Energy Digital Edition ?2?VKRUH:LQG$)ORDWLQJ)XWXUH ?2FHDQRJUDSKLF?QVWUXPHQWDWLRQ 6HQVRUV ?6XEVHD'HIHQVH ?6XEVHD'HIHQVH7KH+XQWIRU ?0DQLS

-

)

March 2024 - Marine Technology Reporter page: 2nd Cover

)

March 2024 - Marine Technology Reporter page: 2nd CoverSMART SUBSEA SOLUTIONS • Delivering data in most adverse conditions: underwater acoustic modems with advanced communication technology and networking • Accurate USBL, LBL and hybrid positioning of underwater assets, navigation for divers • Modem emulator and multiple cost-saving developer tools • Sonobot

-

)

April 2024 - Maritime Reporter and Engineering News page: 39

)

April 2024 - Maritime Reporter and Engineering News page: 39Tech Files Latest Products, Systems and Ship Designs “Wall Climbing Robot” Danish Pilot calls gets ClassNK Nod LEGO Model "A tribute build to a work life at sea" Image courtesy MOL, Sumitomo Heavy Industries lassNK granted its Innovation Endorse- Image courtesy Espen Andersen/DanPilot ment for

-

)

April 2024 - Maritime Reporter and Engineering News page: 7

)

April 2024 - Maritime Reporter and Engineering News page: 7REGISTER NOW Seawork celebrates its 25th anniversary in 2024! The 25th edition of Europe’s largest commercial marine and workboat exhibition, is a proven platform to build business networks. Seawork delivers an international audience of visitors supported by our trusted partners. Seawork is the

-

)

April 2024 - Marine News page: 21

)

April 2024 - Marine News page: 21Feature Navigation “Wind Turbines: The Bigger, the Better” – USDOE Of? ce of Energy Ef? ciency & Renewable Energy, August 24, 2023 ast December the Bureau of Ocean Energy Man- Agencies write: we want to advance wind energy, but ocean agement (BOEM) published a proposed sale no- areas can only yield so

-

)

April 2024 - Marine News page: 8

)

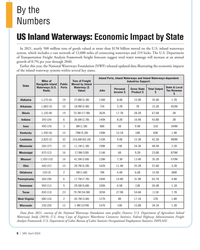

April 2024 - Marine News page: 8By the Numbers US Inland Waterways: Economic Impact by State In 2021, nearly 500 million tons of goods valued at more than $158 billion moved on the U.S. inland waterways system, which includes a vast network of 12,000 miles of connecting waterways and 219 locks. The U.S. Department of Transportation

-

)

February 2024 - Maritime Reporter and Engineering News page: 29

)

February 2024 - Maritime Reporter and Engineering News page: 29AMERICAN ROLL-ON ROLL-OFF CARRIER (ARC) operate a US ? ag ship just for the MSP customer through that global network. As an example of “clarity and con- stipend. It’s a cargo driven industry, and We are certainly a unique business unit sistency,” Ebeling points ? rst to “the those cargoes help to

-

)

February 2024 - Maritime Reporter and Engineering News page: 28

)

February 2024 - Maritime Reporter and Engineering News page: 28COVER FEATURE times of con? ict or in other national said Ebeling. “If you look at Iraq and tors bring to the table, all provided by emergencies, and the program also Afghanistan, 98% of those cargoes the MSP ? eet, and it would cost the provides DoD access to MSP partici- were transported to the

-

)

February 2024 - Maritime Reporter and Engineering News page: 26

)

February 2024 - Maritime Reporter and Engineering News page: 26COVER FEATURE ARC KEEPING THE CARGO ROLLING With a ? eet of nine U.S.-? ag RoRo ships, American Roll-On Roll-Off Carrier Group (ARC), is the U.S.’ premier commercial RoRo carrier of U.S. government and military cargo. As the world becomes an increasingly contentious place, Eric P. Ebeling, President

-

)

January 2024 - Marine Technology Reporter page: 3rd Cover

)

January 2024 - Marine Technology Reporter page: 3rd CoverSMART SUBSEA SOLUTIONS Delivering data in most adverse conditions: underwater acoustic modems with advanced communication technology and networking Accurate USBL and LBL positioning of underwater assets Modem emulator and other cost-saving developer tools Autonomous surface vehicle for bathymetry, monitoring

-

)

January 2024 - Marine Technology Reporter page: 59

)

January 2024 - Marine Technology Reporter page: 59All images courtesy Oceanology International participants and to deliver another packed three days of exhi- Oi24 Events and Features bition and conference activity, features, workshops and one- Oceanology International is able to capitalize on the advan- to-one meetings.” tages of ExCeL’s expansive 18

-

)

January 2024 - Marine Technology Reporter page: 53

)

January 2024 - Marine Technology Reporter page: 532024 Editorial Calendar January/Februay 2024 February 2024 March/April 2024 Ad close Jan.31 Ad close March 21 Ad close Feb. 4 Underwater Vehicle Annual Offshore Energy Digital Edition ?2?VKRUH:LQG$)ORDWLQJ)XWXUH ?2FHDQRJUDSKLF?QVWUXPHQWDWLRQ 6HQVRUV ?6XEVHD'HIHQVH ?6XEVHD'HIHQVH7KH+XQWIRU ?0DQLS

-

)

January 2024 - Marine Technology Reporter page: 20

)

January 2024 - Marine Technology Reporter page: 20TECH FEATURE WAVE POWER “We found an interesting market and application where we’re deploying the MARINE technology: decarbonizing oil and gas. TECHNOLOGY TV I’m talking about powering sub-sea Watch the full interview with Cameron McNatt: equipment in the oil and gas sector.” Cameron McNatt, Mocean

-

)

January 2024 - Marine Technology Reporter page: 13

)

January 2024 - Marine Technology Reporter page: 13“This program has proven that deploy- for safety reasons on ships. We did it, and facilities for manned helicopter ing sonobuoys from Rotary Wing UAS with all the senior leaders—admirals operations from their ships but could with a compact logistical footprint is a and generals--watching. Our competito

-

)

January 2024 - Marine Technology Reporter page: 12

)

January 2024 - Marine Technology Reporter page: 12INSIGHTS AERIAL DRONES & MINE HUNTING UNMANNED AERIAL SYSTEM HAS EARNED ITS SEA-LEGS By Edward Lundquist he Swiss-Swedish joint-venture UMS Skeldar V-200 mum take-off weight of 235kg, a maximum speed of 75 knots vertical take-off unmanned arial system (VTUAV) and a payload of up to 40kg. It can take

-

)

January 2024 - Maritime Reporter and Engineering News page: 43

)

January 2024 - Maritime Reporter and Engineering News page: 43steps to implement the recommendations, such as stating Guard was required to obtain and report. Careful monitoring that it will begin to require shipbuilding programs to com- of migrant interdiction data is all the more important given plete the functional design of major systems before starting recent

-

)

January 2024 - Maritime Reporter and Engineering News page: 29

)

January 2024 - Maritime Reporter and Engineering News page: 29ROY CAMPE, CTO, CMB.TECH But as important as the growth required to service the equipment, it from electric to charging to the fnal within the company is key, so too is could stretch and break all of the back- audits. the growth externally in the form of end support needed to run a smooth “It’s very

-

)

November 2023 - Marine Technology Reporter page: 3rd Cover

)

November 2023 - Marine Technology Reporter page: 3rd CoverSMART SUBSEA SOLUTIONS Delivering data in most adverse conditions: underwater acoustic modems with advanced communication technology and networking Accurate USBL and LBL positioning of underwater assets Modem emulator and other cost-saving developer tools Autonomous surface vehicle for bathymetry, monitoring

-

)

November 2023 - Marine Technology Reporter page: 39

)

November 2023 - Marine Technology Reporter page: 392024 Editorial Calendar January/Februay 2024 February 2024 March/April 2024 Ad close Jan.31 Ad close March 21 Ad close Feb. 4 Underwater Vehicle Annual Offshore Energy Digital Edition ?2?VKRUH:LQG$)ORDWLQJ)XWXUH ?2FHDQRJUDSKLF?QVWUXPHQWDWLRQ 6HQVRUV ?6XEVHD'HIHQVH ?6XEVHD'HIHQVH7KH+XQWIRU ?0DQLS

-

)

November 2023 - Marine Technology Reporter page: 27

)

November 2023 - Marine Technology Reporter page: 27is access to a physical station where you can connect sensors to a network, for example on a buoy or at a shore station, or perhaps if it’s a lit- tle bit earlier stage in a test tank or in a pressure test facility,” said Ruhl. Successful applicants will also have access to technicians and techni- cal

-

)

November 2023 - Marine Technology Reporter page: 19

)

November 2023 - Marine Technology Reporter page: 19to see if it can be increased. ISO-NE noted the upper limit About the Authors for a single system contingency to be 2,000 MW -- instead of the stated 2,200 MW -- and sought study up to that lower Paradise 2,000 MW limit. While a 2,000 MW operating ceiling would Theodore Paradise is a accommodate the

-

)

November 2023 - Marine Technology Reporter page: 14

)

November 2023 - Marine Technology Reporter page: 14CYBERSECURITY SUBSEA system is integrated into a patrol vessel’s C2, the entire port in false location readings for surfaced AUVs, risking mis- security network, and, by extension, possibly the larger port sion failure or vehicle capture. Or man-in-the-middle attacks, C2 system, is then vulnerable to

-

)

November 2023 - Marine Technology Reporter page: 12

)

November 2023 - Marine Technology Reporter page: 12CYBERSECURITY SUBSEA DEEP DATA: CYBERSECURITY IN THE SUBSEA DOMAIN By David Strachan, Defense Analyst and Founder of Strikepod Systems rogue nuclear program is sabotaged by a highly threat vectors that can be used by malicious actors to inject cy- advanced computer worm. Malware targeting an ber payloads

-

)

December 2023 - Maritime Reporter and Engineering News page: 9

)

December 2023 - Maritime Reporter and Engineering News page: 9A MULTI-PLATFORM MARKETING SOLUTION LEVERAGE THE FULL POWER OF THE MARITIME MEDIA NETWORK WITH A FEATURED CONTENT PACKAGE A multi-platform featured content package is a great way to built brand awareness to the industry’s largest veri?ed circulation - in print and digital! With this powerful marketing