Subsea Applications

-

- Design of Hydraulic Systems for Subsea Applications Marine Technology, Apr 2015 #18

Global Growth Drives Subsea Expansion

More than two-thirds of the earth’s surface is covered by water, and there are many potential resources there that await exploration and development. Industries involved in this new frontier include mining, oil and gas, infrastructure, energy generation and natural science.

These activities all involve complex and highly technical systems. Many of them, particularly those performed beneath the sea’s surface, utilize a broad array of electro-hydraulic systems to carry out their work—lower and lift equipment to the seabed, remote operation of subsea systems, and permanent monitoring of emplaced systems such as petroleum wellheads or communications cabling.

It is frequently assumed that such hydraulic equipment needs to be specifically designed and engineered using special materials to enable operation under the pressures and corrosive conditions of different sea depths. However, many standard hydraulic systems engineered for surface use can be, with sufficient customization, utilized effectively in this demanding environment.

Ultimately, the operation of hydraulic systems—whether on land at sea level atmospheres, or deep under the sea—requires isolating the hydraulic circuit from external environments and controlling the fluid to actuate work; the principles are the same, and thus the design principles for subsea simply call for considering additional conditions.

Comparison of Subsea Requirements

In order to select the best solution for a given application, it is necessary to understand how the different subsea water depths impact the hydraulic system. The analysis used in oil and gas exploration supply an effective set of guidelines.

Shallow water: Up to 1,000 ft (305 meter)

At this depth, components must operate in saltwater, but not in significantly high water pressures. At this depth, (which includes the technical safe limit for divers not pressure suits, at 100 meters), the equipment is relatively easy to operate, put in place and retrieve. However, the surface light may penetrate up to 200 meters, thus promoting the growth of sea life over the equipment surface; this must be factored into designs of equipment such as hydraulic cylinder rods.

Deep water: from 1,000 ft. (305 m.) to 6,000 ft (to 1,830 m.)

Every 10 meters, the water column increases the environmental pressure by 1 bar; thus, at a depth of 5,000 meters the ambient pressure is 500 bar. At these depths, all work is done with remote control systems and subsea robots such as ROVs (Remote Operated Vehicles) or AUVs (Autonomous Underwater Vehicles). Here, components become exposed to high external water pressures, which may require special design features like pressure compensation or structural modifications to accommodate the increased pressures.

These depths are typically found significantly far from shore, requiring floating operational facilities such as ships and platforms, creating further challenges.

Ultra -deep water: From 6,000 ft (1,830 m) to 35,800 ft (10,911m)

Beyond 6,000 ft, there is much less experience of subsea equipment (outside of military applications and research vessels). As depths increase, even the engineering of hoisting and tether equipment construction must change, to accommodate the dimensions and weight of the systems as they increase with the water depth. Furthermore, the ocean conditions become harsher, such as the size of waves or the forces caused by maritime currents.

The Subsea Enabler: Robotics

Since divers can’t operate below 100 meters, the bulk of subsea activities must be performed by ROVs and AUVs, complex systems which utilize extensive electromechanical and electrohydraulic subsystems to accomplish tasks. Their operational depths can be in any range. Typically, robots are not submerged for long periods of time. However, it is critical they are ready when needed, and if they malfunction the downtime must be kept to a minimum.

Hydraulic drives can prove their full strength in these machines: they are powerful, compact, precise, intelligent and rugged, providing excellent power density and adroit flexibility for a wide range of tasks. ROV/AUV developers continue to seek more sophisticated performance and reliability from the electrohydraulics systems integrated into their machines.

Subsea Design Requirements

Successful growth of many subsea applications depends upon equipment that can be reliably and safely deployed and operated over extensive periods of time, without requiring overly-expensive engineering, operating and repair costs. There are built-in costs for subsea work that are unavoidable: operating equipment at a distance with remote devices, and dealing with external water pressure and corrosion conditions. Careful planning and a willingness to integrate smart design principles into subsea hydraulic systems make it possible to accomplish these goals cost-effectively.

Pressure Compensation

Pressure compensation is useful in any system which operates below water. It is used to keep the pressure between external environment (seawater) and reservoir constant, as seals are typically designed for the pressure drop in one particular direction and limited to a specified amount.

Most components readily available on the market were designed for operation in normal surface environments. Almost all machines have sealing surfaces or parts which cannot withstand high subsea external pressures or high pressure drops. One option—more difficult and expensive—is to seal pressure-sensitive components inside a protective chamber. This is usually a container with rigid construction and heavy duty seals to withstand the high external pressures.

A more effective solution is called pressure compensation. Using this system a pressure is applied inside the component equal and opposite to the ambient pressure outside. In a typical hydraulic system, the standard reservoir is replaced with a sealed reservoir containing a flexible medium separator.

In this way the external environment pressure is transferred to the reservoir, just as a normal surface system has the external air pressure on top of the oil in the reservoir. The difference is the seawater is prevented from mixing with the oil. Through this clever system any component used on the surface can be used subsea as long as all volumes that normally contain air can be vacated of air filled with fluid and connected to the reservoir to maintain the pressure balance.

Corrosion Protection and Sealing

On offshore machines, it is common to have a seal, sealing surface, seawater, and some other medium in contact and interacting with each other. On large hydraulic cylinders, for example, maintaining the integrity of the cylinder rod, which is routinely exposed to environmental conditions in operation, is essential for maintaining the long-term operating life of the system.

The rod surface needs an appropriate coating to provide a good and durable base for the cylinder’s tribological system between the cylinder head and the piston rod. There have been major advances in cylinder coating technologies, including metallic/metal mix systems applied with high velocity oxygen flame (HVOF) or cobalt alloy coatings applied via plasma arc welding.

In hydraulic actuator design there is always an interaction between seals, fluid, and material surface. The study of these three items is known as tribology. Knowledge of this is critical for system designers, to both keep seawater out of a system and keep the hydraulic fluid in.

Human Safety and Environmental Protection

Equipment engineered for subsea applications must protect both people and the ocean environment from any damage. For deep water and ultra-deep water operations, surface operators need protection from equipment failures during the whole life cycle of the subsea system.

Subsea operations are carried out in environmentally sensitive areas. Hydraulic systems that follow safety principles, such as fail-safe systems that use a de-energization principle, where the system automatically moves to a safe position if the power supply is cut off, are examples of systems with safety engineered-in.

These principles of risk assessment and functional safety have been established through international standards such as ISO 12100, ISO 13849 and ISO 4413.

Reliability and Availability

The reliability of subsea equipment with a projected long lifetime of 30 years in such a harsh environment is one of the largest challenges for the industry today. Reliable hydraulic system design for subsea application can apply different approaches at the same time:

Usage of components with a high degree of reliability: if available, a reliability indicator shall be used for comparison such as MTTF, B10 or Weibull distributions.

Redundancy — when possible and more cost-effective redundant architecture can be installed for higher system reliability: in some case, more than two components may be needed to support each other.

Integration of failure diagnostic features, such as suitable sensors as well as the correct algorithm for processing the information to detect a failure and decide the correct reaction.

In oil and gas applications, field operators expect to use subsea equipment during a well location’s entire service life (30 years or more) with minimal maintenance. Suitable sensors have to be designed, integrated and pressure-proven to detect failures and, if possible, anticipate future failures by including condition monitoring functions.

Designing for Safe and Reliable Subsea Ops

At multiple frontiers and across multiple industries, subsea applications continue to grow. The safe, reliable and effective development of such opportunities has already been proven. However, as industries move deeper under the ocean, certain fundamental technical challenges increase, particularly for hydraulically-driven systems.

These challenges can be met through a combination of standard, “off-the-shelf” systems proven to operate in rugged conditions on the land, with suitable adaptations (such as pressure compensation) and smart, cost-effective application of more advanced materials where needed. This approach can ultimately enable a more cost-effective approach to subsea development and wider access to the potential resources this emerging “frontier” offers.

(As published in the APRIL 2015 edition of Marine Technology Reporter - http://www.marinetechnologynews.com/Magazine)

-

- MTR 100: Southwest Electronic Energy Marine Technology, Jul 2014 #77

50 years of providing innovative custom energy management solutions, particularly lithium and lithium-ion battery technology for oil and gas and subsea applications. SWE is at the forefront of providing advanced technology battery solutions, helping make offshore oil and gas more accessible and affordable

-

- RL-K 7500 Subsea Crane Marine Technology, Jan 2013 #44

demands of the AHC the hydraulic hybrid drive system Pactronic, originally developed for Liebherr mobile harbor cranes, was specially adapted for subsea applications. Pactronic is characterized by an additional energy storage device. A hydraulic accumulator supplements the fluid pump in delivering power to

-

- Fiber-Optic Connector Technology for O&G Ops Marine Technology, Feb 2017 #22

Fiber-optics (FO) technology is finding new uses in subsea applications. Fiber allows longer transmission distances and higher data rates than copper — a fortuitous development, as offshore drilling moves to deeper depths. Petroleum exploration and production are also becoming smarter, as operators pursue

-

- LVDT Linear Position Sensors Survive Operation Underwater Marine Technology, Nov 2013 #57

upon ocean temperature and depth levels. In shallow warm waters, Monel is ideal as its metal composition resists sea life forming on it. In subsea applications with depths of 7,500 feet and external pressures surpassing 3,500 psi, Inconel offers excellent protection against corrosion due to higher content

-

- BIRNS Millennium Connectors Marine Technology, Mar 2014 #89

Millennium connector series. The BIRNS Millennium series is a six km rated, high density metal shell connector line trusted worldwide for demanding subsea applications, from manned and unmanned submersibles to sensors and towed arrays. The series is specifically engineered for challenging power and signal applicatio

-

- Innovative Solutions Mark SWE’s Heritage Marine Technology, Sep 2014 #24

is the foundation of its innovative custom energy management solutions, particularly Lithium and Lithium-Ion battery technology for oil and gas and subsea applications. After extensive research, development and testing, SWE successfully found a way to provide safe, long lasting battery power for deep subsea

-

- MTR100: EvoLogics GmbH Marine Technology, Aug 2015 #46

systems, as well as novel robotic solutions. The company’s advanced spread-spectrum technology allows to deliver optimal results for various subsea applications. EvoLogics products include several series of underwater acoustic modems, underwater acoustic positioning systems (USBL, LBL), as well as the

-

- John E. Lawson Named By National Supply Maritime Reporter, Sep 1981 #16

in mechanical engineering from the University of Houston. The company offers a complete line of well control products for land and subsea applications covering drilling, testing, capping, reentry and production from fixed or floating platforms. National Supply pioneered the technology

-

- From Tiny Electrical Impulses Grows a $2.6B Giant MOOG Marine Technology, Jul 2013 #74

Scotia Research Foundation, its concentration was in a couple of areas, said Glister. One of those areas was the use of fiber optics for marine and subsea applications and its first application was a towed array for the Canadian submarines. The other area was developing an electrical slip ring for marine use

-

- MTR100: Tritech International Marine Technology, Aug 2016 #52

company’s imaging ranges (mechanical and multibeam), to bathymetric sensors, to hydraulic and mechanical equipment, Tritech is able to support many subsea applications from the traditional ROV/ AUV markets to aquaculture and cave diving. Tritech offers its Gemini multibeam imaging sonar to monitor and often

-

- MTR100: Kongsberg Maritime Marine Technology, Jun 2019 #21

and solutions for defense customers. In line with other marine sectors, Kongsberg Maritime is also at the forefront of digitalization for subsea applications. Mapping Cloud, which provides easy storage of different types of data within the Cloud, offers an accessible and practical means of uploading

-

)

March 2024 - Marine Technology Reporter page: 48

)

March 2024 - Marine Technology Reporter page: 48. . . . . . . . . . . . . . . . . . .www.birns.com . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Please visit us online 19 . . . . .Blueprint Subsea . . . . . . . . . . . . . . . . . . . .www.blueprintsubsea.com . . . . . . . . . . . . . . . . . . . . . .+44 (0) 1539 531536 5 . . . . . .Deep Ocean

-

)

March 2024 - Marine Technology Reporter page: 45

)

March 2024 - Marine Technology Reporter page: 45in 1969, designs and manufactures instrumentation for the oceanographic and hydrographic communities with a world- wide customer base that includes: subsea, hydrographic, metrological and positioning, oceanographic, ports, har- bours, dredging, energy and scienti? c research sectors. • Greensea IQ Signs

-

)

March 2024 - Marine Technology Reporter page: 44

)

March 2024 - Marine Technology Reporter page: 44NEW TECH OCEANOLOGY INTERNATIONAL 2024 Image courtesy Metron/Cellula Teledyne Marine acquires Valeport: Matt Quartley, MD, Valeport and Ole Søe-Pedersen, VP & Image courtesy Teledyne Marine GM Teledyne Marine announce the deal in London. Pictured (L-R): Cellula Robotics, President, Eric Jackson, Metron

-

)

March 2024 - Marine Technology Reporter page: 42

)

March 2024 - Marine Technology Reporter page: 42made a splash at Oi at the company’s Power Forward event, with the celebration of the company’s 70th anniversary, and the launch of a new high amperage subsea connector se- ries, the 225 Amp BIRNS Meridian line. The Meridian line, a robust, custom engineered dry-mate connector series is open face rated

-

)

March 2024 - Marine Technology Reporter page: 41

)

March 2024 - Marine Technology Reporter page: 41for optimal performance. The vide a visual identi? cation of the vehicle’s surroundings. Quadroin now features a Nortek Nucleus1000 integrated subsea The newly integrated EvoLogics AI-powered object recogni- navigation package that couples Nortek’s DVL technology with tion module allows detecting

-

)

March 2024 - Marine Technology Reporter page: 40

)

March 2024 - Marine Technology Reporter page: 40Uncrewed Surface Ves- In addition, the new USV is able to launch and recover a wide sel (USV), the DriX O-16. Bene? tting from an autonomy of range of subsea assets such as Remotely Operated Towed Ve- 2,500 Nm and a unique naval architecture that enables the USV hicles (ROTVs), inspection-class Remotely

-

)

March 2024 - Marine Technology Reporter page: 36

)

March 2024 - Marine Technology Reporter page: 36LANDER LAB #10 Of special interest for marine applications, LiPo batteries are Shipping any kind of lithium battery can be a challenge, and offered in a “pouch” design, with a soft, ? at body. The pouch IATA regs vary with the batteries inside or outside an instru- is vacuum-sealed, with all voids ?

-

)

March 2024 - Marine Technology Reporter page: 35

)

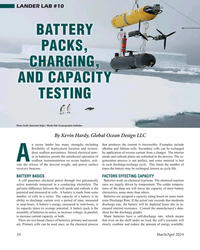

March 2024 - Marine Technology Reporter page: 35Figure 1 A self-righting vehicle design with buoyancy high and weight low, WHOI’s SeaBED AUV captures the attention of a pair of curious Antarctic penguins as it is deployed from the British research vessel James Clark Ross. Vehicle designers allowed for temperature reduction of battery capacity. Recharge

-

)

March 2024 - Marine Technology Reporter page: 34

)

March 2024 - Marine Technology Reporter page: 34LANDER LAB #10 BATTERY PACKS, CHARGING, AND CAPACITY TESTING Photo Credit: Hanumant Singh / Woods Hole Oceanographic Institution. By Kevin Hardy, Global Ocean Design LLC n ocean lander has many strengths including that produces the current is irreversible. Examples include ? exibility of deployment

-

)

March 2024 - Marine Technology Reporter page: 30

)

March 2024 - Marine Technology Reporter page: 30. The physical connection and disconnection als conducted in 2022 where TMC collected 3,000 tonnes of between collector and power umbilical is performed subsea, nodules have helped further advance the design. and the LARS is ? tted with a routing system that keeps the Digital twin technology analyzes data

-

)

March 2024 - Marine Technology Reporter page: 25

)

March 2024 - Marine Technology Reporter page: 25months after HT-HH system differed; the volcano was devoid erupted, scientists from NIWA and the of biology but features as close as 15 km Surfacing Subsea Discoveries Nippon Foundation of Japan mobilized away still had abundant life, including the Tonga Eruption Seabed Mapping Even before the recent

-

)

March 2024 - Marine Technology Reporter page: 20

)

March 2024 - Marine Technology Reporter page: 20?8QGHUZDWHU&RPPXQLFDWLRQV ?&DEOHV &RQQHFWRUV Event Distribution: MTR E-Magazine Edition: Oceanology International, /RQGRQ8. Event Distribution: Subsea Expo Oceanographic 2?VKRUH7HFKQRORJ\&RQIHUHQFH27& $EHUGHHQ8. +RXVWRQ7;86$ Floating Wind Solutions 8'7 +RXVWRQ7;86$ /RQGRQ8. (XURSH2?VKRUH:LQG

-

)

March 2024 - Marine Technology Reporter page: 19

)

March 2024 - Marine Technology Reporter page: 19and corrosion control cant cost savings, mainly related to vessel charter. expert having worked across The major advantage of using FiGS on any type of subsea engineering, design, modelling, structure is the large amount of accurate information obtained project management, inspection, over a relatively

-

)

March 2024 - Marine Technology Reporter page: 16

)

March 2024 - Marine Technology Reporter page: 16the elec- odes must be regularly surveyed to determine when replace- trochemical process than the steel used in pipelines and other ments are required. subsea structures. When connected to a structure, the anodes willingly ‘sacri? ce’ themselves by corroding ? rst, effectively Survey Methods redirecting

-

)

March 2024 - Marine Technology Reporter page: 15

)

March 2024 - Marine Technology Reporter page: 15sensor options for longer mission periods. About the Author For glider users working in ? sheries and conservation, Shea Quinn is the Product Line Manager the Sentinel can run several high-energy passive and active of the Slocum Glider at Teledyne Webb acoustic sensors, on-board processing, and imaging

-

)

March 2024 - Marine Technology Reporter page: 8

)

March 2024 - Marine Technology Reporter page: 8INSIGHTS SUBSEA DEFENSE Copyright RomanenkoAlexey/AdobeStock WHEN THE SHOOTING STOPS: BLACK SEA MINE CLEARANCE WILL FEATURE ADVANCED TECH, CONOPS By David Strachan, Senior Analyst, Strikepod Systems ince the beginning of the war in Ukraine, mine warfare mines have been the weapon of choice for both

-

)

March 2024 - Marine Technology Reporter page: 4

)

March 2024 - Marine Technology Reporter page: 4(212) 477-6700; Fax: (212) 254-6271 tional in London, perennially one Lof the world’s most important Justin Zuure CEO events serving the global subsea market. John C. O’Malley [email protected] Personally, it was my ? rst return to London for this event since 2018, as the 2020 ‘50th Anniversary’

-

)

March 2024 - Marine Technology Reporter page: 2

)

March 2024 - Marine Technology Reporter page: 2March/April 2024 On the Cover Volume 67 • Number 3 Image courtesy NIWA-Nippon Foundation TESMaP / Rebekah Parsons-King 8 Subsea Defense Black Sea Mines When the shooting stops in the Ukraine, the tough work of clearing mines will commence. By David Strachan 12 Gliders Slocum Sentinel 22 Teledyne

-

)

March 2024 - Marine Technology Reporter page: 2nd Cover

)

March 2024 - Marine Technology Reporter page: 2nd CoverSMART SUBSEA SOLUTIONS • Delivering data in most adverse conditions: underwater acoustic modems with advanced communication technology and networking • Accurate USBL, LBL and hybrid positioning of underwater assets, navigation for divers • Modem emulator and multiple cost-saving developer tools • Sonobot

-

)

March 2024 - Marine Technology Reporter page: Cover

)

March 2024 - Marine Technology Reporter page: Cover.marinetechnologynews.com Oceanographic Instrumentation Exploring Submarine Volcanoes When the Shooting Stops Black Sea Mine Clearance Subsea Mining The Nodule Collectors Lander Lab Volume 67 Number 3 Battery Packs MarineTechnologyReporter Cover MarApr2024.indd 1 4/4/2024 1:07:18 P

-

)

April 2024 - Maritime Reporter and Engineering News page: 41

)

April 2024 - Maritime Reporter and Engineering News page: 41Nautel provides innovative, industry-leading solutions speci? cally designed for use in harsh maritime environments: • GMDSS/NAVTEX/NAVDAT coastal surveillance and transmission systems • Offshore NDB non-directional radio beacon systems for oil platform, support vessel & wind farm applications

-

)

April 2024 - Maritime Reporter and Engineering News page: 33

)

April 2024 - Maritime Reporter and Engineering News page: 33both mooring and hook-up operations and of- fers a ? exible deck layout and speci? c provisions for mission equipment inte- gration, including electric subsea cranes. Electri? cation enhances operational smoothness and reduces downtime. Inman sees strong market potential for the FWIV. “Floating offshore

-

)

April 2024 - Maritime Reporter and Engineering News page: 16

)

April 2024 - Maritime Reporter and Engineering News page: 16MARKETS SOVs – Analyzing Current, Future Demand Drivers By Philip Lewis, Director of Research, Intelatus © Björn Wylezich/AdobeStock t a high-level, there are three solutions to transferring Lower day rate CTVs are often used for daily transfer of technicians from shore bases to offshore wind farms

-

)

April 2024 - Maritime Reporter and Engineering News page: 9

)

April 2024 - Maritime Reporter and Engineering News page: 9A third opportunity to develop a safety and will help to further a strong ing safety considerations an ever-pres- strong BBS culture is through obser- safety culture. The above are only a few ent factor in everything we do - from vational assessments. Here, when con- of the many practices that can