Baltic Sea

-

- Green Ships & Compliance Maritime Reporter, Aug 2016 #80

Environmental regulations for ships are getting more stringent, but automated sensor technology could help ship operators remain in compliance.

The recent agreement signed in Paris, at the UN Climate Change Conference, will require all industries to keep reducing their greenhouse gas (GHG) emissions. Although there was no specific mention of shipping, the aim of keeping global temperature rises below 2ºC this century will require the industry to play its part – as it is responsible for about 2% of global CO2 emissions.Environmental rules for the industry are enshrined in the MARPOL (standing for ‘Marine Pollution’) regulations as well as several local regulations, such as VGP (Vessel general permit) 2013, which set strict emission limits. Emission targets in open water are less stringent, allowing high-sulphur fuel to be used there, for example. However, closer to shore – or in special areas such as the Baltic Sea – these targets are far stricter, so ships must switch over to a ‘cleaner’ fuel. These rules are only going to get tougher: as a special area under Annexe IV of MARPOL, the Baltic Sea will fall under tough new regulations for waste water discharge, for example. The rules will be introduced in 2016 for new passenger vessels and 2018 for existing vessels.The punishment for breaking MARPOL rules can be severe, particularly in the U.S. For example, recent cases include a German management company fined $800,000 for breaking the Clean Water Act, and an Italian ship owner fined $2.75 million for infringing the Act to Prevent Pollution from Ships. In each case, both the operating company and individual members of the crew were held to be at fault and received fines or community service orders.At the same time, the U.S. Coast Guard recently issued a Safety Alert, regarding the use of ultra-low sulphur (ULS) fuel. It recommends that switching to ULS fuel – which can result in loss of propulsion – is accomplished “outside of busy traffic lanes” (generally 200 nautical miles off the main U.S. coast). As part of the guidance, it says: “Ensure all sensors, controls and alarms are operational and function as designed.”Condition Monitoring (CM) uses sensors to assess the health of components such as bearings and is commonplace in the manufacturing industry. CM has taken a few tentative steps into shipping, but it is early days: many ship owners, while recognising the benefits, are reticent to invest in such systems.This type of automated, sensor-based system can also be used for so-called ‘functional monitoring’: instead of spotting bearing failure, it could automatically monitor critical environmental attributes such as fuel consumption and GHG emissions. This is the basis behind SKF’s BlueMon. Often the necessary sensors are already on board, and are monitored by the crew. What BlueMon does is automate the whole process and add an extra level of security by helping the crew avoid mistakes. Most importantly, it overlays all this information with positional data. Marrying environmental and GPS data is a vital resource that helps ship owners and operators to stay within the MARPOL regulations. For example, BlueMon will sound a warning when the ship is approaching the shore – meaning that it must shift to a cleaner fuel, for example, or must not discharge bilge water overboard.Bilge water must be fed through a separator until it is clean enough to be discharged. Out at sea, it can contain 15 parts per million of oil and be safely discharged. Closer to shore, the levels can drop to 5ppm – or even to zero bilge water discharge. By knowing the exact position of the ship – and correlating it with sensor readings – the system will take charge, and shut off the bilge water discharge valve if necessary.With BlueMon, data is logged automatically by the system and kept for 24 months. In the case of a dispute, a log of all activities – from fuel-switching to bilge discharge – is available, with a precise location.It is worth noting that offences under the various pollution and discharge acts can be punished even the offence takes place outside territorial waters. For example, a recent prosecution in the U.S. went ahead on the basis that fraudulent log book claims were presented to U.S. officials. It goes to show how important it is stay within the rules – and to keep accurate records.BlueMon could comfortably handle tightening emission levels – and the changing boundaries of special areas such as the Baltic Sea – with simple software updates: the warning alarm of a special area could be triggered earlier, to account for a boundary change, for example.BlueMon has been adopted by operators of tankers and liquid natural gas (LNG) carriers, due mainly to their presence in sensitive areas. The sensitivity factor could also see it deployed on ships that ply their trade in the Arctic – especially as these routes are more often open, due to melting ice.For now, the system is restricted to the ship itself. There is no ship-to-shore transmission of data – although this is likely to be introduced in future. Such an arrangement is already in place for on-board CM: rather than having multiple maintenance experts on every ship, a fleet owner can transmit CM data back to shore, where remote experts can analyse all the data and act accordingly. This type of remote monitoring is already being used for route optimization. Data is transmitted to onshore experts, who may determine that the most cost-effective route is a longer journey using heavier fuel, for example.A ship is sometimes considered a floating factory, as it has so much machinery to maintain. Consider, though, that a traditional land-based factory only needs to abide by local environmental regulations. A ship is a moving target – with multiple regulations to obey – so anything that can ease this burden is to be welcomed.The AuthorClaus Beiersdorfer studied process engineering at the University in Cologne and obtained the degree as Mechanical engineer (FH) in 1995. Since then he has gained a worldwide expereince as sales engineer for marine products which require integration in different ship machineries. Today Claus Beiersdorfer heads the sales teams for newbuilding equipment at SKF Marine GmbH in Hamburg.(As published in the August 2016 edition of Maritime Reporter & Engineering News) -

- The German Shipbuilding Rebound Maritime Reporter, Apr 2015 #78

two rescue and special ships for the Russian offshore business. FSG (Flensburger Schiffbau-Gesellschaft), is currently the second shipyard at the Baltic Sea, which manufactures special vessels for oil and gas extraction. Their order intake level is good for up to 2016. Ship Repair & Conversion The

-

- Choke Points are Flash Points Maritime Reporter, Sep 2016 #28

staff Rear Admiral Sergei Popov after they reportedly refused to follow orders to confront Western ships.” The Baltic is of vital importance to the Baltic Sea nations and Europe. Half of Finland’s international trade is with her Baltic Sea neighbors. The Swedish port of Gothenburg, at the entrance to

-

- All Aboard with Fire Safety Marine News, Jul 2019 #44

an on board blaze. A risk assessment report on ship fires produced by the Finnish Border Guard and Finnish Transport Safety Agency and for use in the Baltic Sea Maritime Incident Response Group (Baltic Sea MIRG) project concluded that it is very difficult to prevent ship fires and minimizing their consequences

-

- DeLong Jack Systems Described In Brochure Maritime Reporter, Oct 15, 1977 #55

York's East River to the Orinoco, as well as in the North Sea, Arabian Gulf, West Africa, Japan, Gulf of Mexico, North Atlantic, Caribbean, Borneo, Baltic Sea — in fact, just about anywhere. For a free copy of this brochure, contact Donald J. Mac- Pherson, Operations Manager, De- Long Corporation

-

- EU to Develop Sulfur Strategy Maritime Reporter, May 2002 #43

, says Adams. An EU study now underway will quantify ship emissions of S02, NOx, C 0 2 and hydrocarbons in the North Sea, Irish Sea, English Channel, Baltic Sea, Black Sea and Mediterranean, on the basis of year 2000 ship movements. The commission is also taking advice on the costs to the oil industry

-

- Baltic Wind Success Paves Way for Ecosse Marine Technology, Oct 2013 #23

challenging soil conditions. EnBW Baltic 2 is an 80 turbine development located 32km north of Rügen island in the German exclusive economic zone of the Baltic Sea and owned by the German utility company EnBW. The 27 sq. km site spans water depths ranging from 20m to 45m LAT and has a wide array of soil conditions

-

- Ecospeed Fuel Savings Calculator Maritime Reporter, Nov 2013 #87

of the underwater hull. PARTNERSHIP –covers the in-water cleaning service availability by Hydrex on major shipping routes like the North Sea and Baltic Sea. www.hydrex.be (As published in the November 2013 edition of Maritime Reporter & Engineering News - www.marinelink.com

-

- Carnival's Newest Superliner, Luxurious 70,000-GRT Fantasy, Nears Completion At Wartsila Yard Maritime Reporter, Oct 1989 #49

, which was christened by Mrs. Tellervo Koivisto, wife of the President of Finland, has completed her four-day test, which was conducted July 4-7 in the Baltic Sea by the Wartsila shipyard. Capt. Vittorio Fabietti, Carnival's chief coordinator of new ship construction, who was on board the vessel along

-

- Desulfurization of Exhaust Gases in Shipping Maritime Reporter, Jul 2014 #26

systems which are already in use. January 1, 2015 By this date all diesel engines of all sea-going vessels in the area of the entire North- and Baltic Sea, the English Channel and as well in a 200 nautical miles zone along the U.S. Atlantic and Pacific coast line, must be operated either with fuels

-

- Finnish Passenger Ship To Be Powered By Turbo Power & Marine Systems Gas Turbines Maritime Reporter, Mar 1974 #17

, which will 'build the ship for Enso-iGutzeit Osakeyhtio, Finland's largest concern and parent company of Finnlines. The Finnjet will begin serving Baltic Sea traffic in 1977. Finnjet is designed to carry 1,500 passengers and up to 220 cars and 30 trucks; it is being built to operate year-round and

-

- Finnish Shipbuilding and Arctic Operations Maritime Reporter, Jun 2013 #54

16MW icebreaker for the Russian Ministry of Transport. The vessel is to be delivered in 2015. The icebreaker is intended for year-round operation in the Baltic Sea and is during the summer season to work in Arctic Russia. The icebreaking capability is 1.5m. The four main diesel-generator sets have a total power

-

)

March 2024 - Marine Technology Reporter page: 48

)

March 2024 - Marine Technology Reporter page: 48Index page MTR MarApr2024:MTR Layouts 4/4/2024 3:19 PM Page 1 Advertiser Index PageCompany Website Phone# 17 . . . . .Airmar Technology Corporation . . . . . . . . . .www.airmar.com . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .(603) 673-9570 9 . . . . . .Birns, Inc. . . . . . . . . . .

-

)

March 2024 - Marine Technology Reporter page: 43

)

March 2024 - Marine Technology Reporter page: 43Image courtesy Kongsberg Discovery Image courtesy Teledyne Marine New Products Teledyne Marine had its traditional mega-booth at Oi, busy start to ? nish. Image courtesy Greg Trauthwein offers quality sub-bottom pro? ling capability without the need tion of offshore windfarms. GeoPulse 2 introduces new

-

)

March 2024 - Marine Technology Reporter page: 41

)

March 2024 - Marine Technology Reporter page: 41Image courtesy Outland Technology Image courtesy Exail Image courtesy Submaris and EvoLogics Vehicles The ROV-1500 from Outland Technology represents a leap forward in underwater robotics, a compact remotely operated vehicle (ROV) weighing in at less than 40 lbs (19kg) the ROV- 1500 is easy to transport

-

)

March 2024 - Marine Technology Reporter page: 37

)

March 2024 - Marine Technology Reporter page: 37miscible barrier ? uid heavier than seawater (sg=1.026) and lighter than the battery electrolyte (sg=1.265). The original cell vent cap was screwed into the top of the riser pipe to vent the gases associated with charging. Wires were soldered to the lead (Pb) posts. The lead-acid battery was additionall

-

)

March 2024 - Marine Technology Reporter page: 36

)

March 2024 - Marine Technology Reporter page: 36LANDER LAB #10 Of special interest for marine applications, LiPo batteries are Shipping any kind of lithium battery can be a challenge, and offered in a “pouch” design, with a soft, ? at body. The pouch IATA regs vary with the batteries inside or outside an instru- is vacuum-sealed, with all voids ?

-

)

March 2024 - Marine Technology Reporter page: 34

)

March 2024 - Marine Technology Reporter page: 34LANDER LAB #10 BATTERY PACKS, CHARGING, AND CAPACITY TESTING Photo Credit: Hanumant Singh / Woods Hole Oceanographic Institution. By Kevin Hardy, Global Ocean Design LLC n ocean lander has many strengths including that produces the current is irreversible. Examples include ? exibility of deployment

-

)

March 2024 - Marine Technology Reporter page: 33

)

March 2024 - Marine Technology Reporter page: 33regulated industry in the world.” How- ever, commercial success depends on many factors, not least a predictable OPEX. Over the past four years, SMD has worked with Oil States Industries to calculate cost per tonne ? gures for prospective customers. Patania II uses jet water pumps to Oil States’

-

)

March 2024 - Marine Technology Reporter page: 32

)

March 2024 - Marine Technology Reporter page: 32FEATURE SEABED MINING by a sea? oor plume from its pilot collection system test. pact, nodule collection system that utilizes mechanical and The Metals Company recently signed a binding MoU with hydraulic technology. Paci? c Metals Corporation of Japan for a feasibility study on The company’s SMD

-

)

March 2024 - Marine Technology Reporter page: 31

)

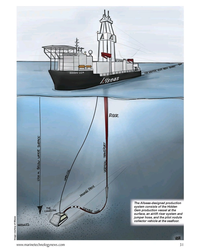

March 2024 - Marine Technology Reporter page: 31The Allseas-designed production system consists of the Hidden Gem production vessel at the surface, an airlift riser system and jumper hose, and the pilot nodule collector vehicle at the sea? oor. Image courtesy of Allseas www.marinetechnologynews.com 31 MTR #3 (18-33).indd 31 4/4/2024 2:12:41

-

)

March 2024 - Marine Technology Reporter page: 29

)

March 2024 - Marine Technology Reporter page: 29n January, Norway said “yes” to sea- bed mining, adding its weight to the momentum that is likely to override the calls for a moratorium by over 20 countries and companies such as I Google, BMW, Volvo and Samsung. Those against mining aim to protect the unique and largely unknown ecology of the sea?

-

)

March 2024 - Marine Technology Reporter page: 28

)

March 2024 - Marine Technology Reporter page: 28FEATURE SEABED MINING Nodule Collectors THE BATTLE LINES HAVE BEEN DRAWN, AND THOSE ON THE “YES TO SEABED MINING” SIDE ARE GETTING READY TO GO. By Wendy Laursen Engineers prepare to launch the pilot collector vehicle to the sea? oor. Image courtesy of TMC 28 March/April 2024 MTR #3 (18-33).

-

)

March 2024 - Marine Technology Reporter page: 27

)

March 2024 - Marine Technology Reporter page: 27SEA-KIT USV Maxlimer returning from HT-HH caldera in Tonga. © SEA-KIT International data and further assess ecosystem recov- ery. What is known, noted Caplan-Auer- bach, is that the impact of submarine vol- canoes on humans is rare. “The HT-HH eruption was a tragedy, but it was very unusual. It let us

-

)

March 2024 - Marine Technology Reporter page: 26

)

March 2024 - Marine Technology Reporter page: 26FEATURE OCEANOGRAPHIC INSTRUMENTATION & SENSORS Kevin Mackay, TESMaP voyage leader and Center head of the South and West Paci? c Regional Centre of Seabed 2030. Kevin in the seismic lab at Greta Point looking at the Hunga Tonga-Hunga Ha’apai volcano 3D map completed with data from the TESMaP voyage

-

)

March 2024 - Marine Technology Reporter page: 25

)

March 2024 - Marine Technology Reporter page: 25Auerbach explained that ideally, “one ? ed layers of geothermal activity,” noted changes over an area of 8,000 km2. They would have both instruments: seismom- Skett, “and the change in salinity and dis- found up to seven km3 of displaced ma- eters to detect and locate subsurface ac- solved particles for

-

)

March 2024 - Marine Technology Reporter page: 23

)

March 2024 - Marine Technology Reporter page: 23elatively inactive since 2014, the Hunga Tonga–Hunga Ha‘apai (HT-HH) submarine volcano began erupting on December 20, 2021, reaching peak intensity on January 15, 2022. This triggered tsunamis throughout the Pa- R ci? c, destroyed lives and infrastructure, and generated the largest explosion recorded

-

)

March 2024 - Marine Technology Reporter page: 22

)

March 2024 - Marine Technology Reporter page: 22FEATURE OCEANOGRAPHIC INSTRUMENTATION & SENSORS Aerial view of HT-HH volcano, showing new multibeam depth data overlaid on islands satellite image. © SEA-KIT, NIWA-Nippon Foundation TESMaP 22 March/April 2024 MTR #3 (18-33).indd 22 4/4/2024 9:08:10 AM

-

)

March 2024 - Marine Technology Reporter page: 11

)

March 2024 - Marine Technology Reporter page: 11assist in identifying mines and act as a neutralization device. About the Author Bottom mines pose even greater chal- David R. Strachan is a defense analyst and founder of lenges. Unlike contact mines, bottom Strikepod Systems, a research and strategic advisory mines utilize a range of sensors to

-

)

March 2024 - Marine Technology Reporter page: 8

)

March 2024 - Marine Technology Reporter page: 8INSIGHTS SUBSEA DEFENSE Copyright RomanenkoAlexey/AdobeStock WHEN THE SHOOTING STOPS: BLACK SEA MINE CLEARANCE WILL FEATURE ADVANCED TECH, CONOPS By David Strachan, Senior Analyst, Strikepod Systems ince the beginning of the war in Ukraine, mine warfare mines have been the weapon of choice for both

-

)

March 2024 - Marine Technology Reporter page: 2

)

March 2024 - Marine Technology Reporter page: 2March/April 2024 On the Cover Volume 67 • Number 3 Image courtesy NIWA-Nippon Foundation TESMaP / Rebekah Parsons-King 8 Subsea Defense Black Sea Mines When the shooting stops in the Ukraine, the tough work of clearing mines will commence. By David Strachan 12 Gliders Slocum Sentinel 22 Teledyne

-

)

March 2024 - Marine Technology Reporter page: Cover

)

March 2024 - Marine Technology Reporter page: CoverMARINE TECHNOLOGY REPORTER March/April 2024March/April2024 www.marinetechnologynews.com Oceanographic Instrumentation Exploring Submarine Volcanoes When the Shooting Stops Black Sea Mine Clearance Subsea Mining The Nodule Collectors Lander Lab Volume 67 Number 3 Battery Packs MarineTechn

-

)

April 2024 - Maritime Reporter and Engineering News page: 43

)

April 2024 - Maritime Reporter and Engineering News page: 43“The industry is an ecosystem which includes owners, managers, mariners, shipyards, equipment makers, designers, research institutes and class societies: all of them are crucial,” – Eero Lehtovaara, Head of Regulatory & Public Affairs, ABB Marine & Ports All images courtesy ABB Marine and Ports provi

-

)

April 2024 - Maritime Reporter and Engineering News page: 41

)

April 2024 - Maritime Reporter and Engineering News page: 41Nautel provides innovative, industry-leading solutions speci? cally designed for use in harsh maritime environments: • GMDSS/NAVTEX/NAVDAT coastal surveillance and transmission systems • Offshore NDB non-directional radio beacon systems for oil platform, support vessel & wind farm applications

-

)

April 2024 - Maritime Reporter and Engineering News page: 40

)

April 2024 - Maritime Reporter and Engineering News page: 40TECH FEATURE SITUATIONAL AWARENESS SITUATIONAL AWARENESS SYSTEM BATTLES COGNITIVE FATIGUE IN WATCHKEEPERS All images courtesy Groke Technologies Today’s evolving maritime security risks pose all-too-familiar threats to international shipping, and as just one of the many causes of fatigue, they add

-

)

April 2024 - Maritime Reporter and Engineering News page: 39

)

April 2024 - Maritime Reporter and Engineering News page: 39Tech Files Latest Products, Systems and Ship Designs “Wall Climbing Robot” Danish Pilot calls gets ClassNK Nod LEGO Model "A tribute build to a work life at sea" Image courtesy MOL, Sumitomo Heavy Industries lassNK granted its Innovation Endorse- Image courtesy Espen Andersen/DanPilot ment for