Reef Association

-

)

March 2024 - Marine Technology Reporter page: 41

)

March 2024 - Marine Technology Reporter page: 41Image courtesy Outland Technology Image courtesy Exail Image courtesy Submaris and EvoLogics Vehicles The ROV-1500 from Outland Technology represents a leap forward in underwater robotics, a compact remotely operated vehicle (ROV) weighing in at less than 40 lbs (19kg) the ROV- 1500 is easy to transport

-

)

April 2024 - Maritime Reporter and Engineering News page: 43

)

April 2024 - Maritime Reporter and Engineering News page: 43“The industry is an ecosystem which includes owners, managers, mariners, shipyards, equipment makers, designers, research institutes and class societies: all of them are crucial,” – Eero Lehtovaara, Head of Regulatory & Public Affairs, ABB Marine & Ports All images courtesy ABB Marine and Ports provi

-

)

April 2024 - Marine News page: 15

)

April 2024 - Marine News page: 15Q&A time, sometimes we win in game seven, but it really takes now to make sure that folks understand that tug and barge a united industry, and so I just really appreciate the great transportation is the most sustainable mode of freight work of AWO members, of coalition partners, shippers, transportation?

-

)

April 2024 - Marine News page: 6

)

April 2024 - Marine News page: 6Marine News April 2024 • Volume 35 Number 4 Contributors 1 2 3 5 4 6 7 1 Tom Ewing 5 Barry Parker is a freelance writer specializing in marine, energy and envi- of bdp1 Consulting Ltd provides strategic and tac- ronmental issues. He contributes regularly to this magazine. tical support, including

-

)

February 2024 - Marine News page: 27

)

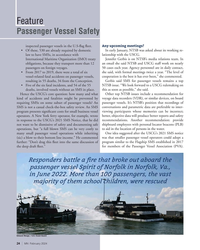

February 2024 - Marine News page: 27Feature Passenger Vessel Safety ? re risk and related technical issues. Canada: Transport Canada.” In the U.S., last February, the Coast Guard issued a Another top issue, just as in the U.S. – workforce re- Marine Safety Alert: “Saltwater intrusion causes damage cruitment, which he called a “key issue for

-

)

February 2024 - Marine News page: 26

)

February 2024 - Marine News page: 26Feature Passenger Vessel Safety ume is even more eye-opening. The trade association In- ect seeking to signi? cantly reduce the risk of ? res on board terferry, which represents ferry operators and businesses ro-ro (roll on–roll off) ships. Corrigan said that Interferry’s worldwide, calculates that

-

)

February 2024 - Marine News page: 25

)

February 2024 - Marine News page: 25Feature Passenger Vessel Safety Interestingly, in the Flagship docu- certain passenger vessels. growing commuter traf? c. “In addi- ment, PVA acknowledges and thanks • Crew shortages have caused tion,” he added, “several small U.S. the USCG for its help in developing a operators to change schedules.

-

)

February 2024 - Marine News page: 24

)

February 2024 - Marine News page: 24Feature Passenger Vessel Safety Any upcoming meetings? inspected passenger vessels in the U.S-? ag ? eet. • Of these, 530 are already required by domestic In early January, NTSB was asked about its working re- law to have SMSs, in accordance with lationship with the USCG. International Maritime

-

)

February 2024 - Marine News page: 19

)

February 2024 - Marine News page: 19ment, work processes and technology progress, and it can if you start the new year out by listening to your workforce be hard to keep up with the latest changes. In 2024, keep and implementing necessary changes to work practices an eye out for updates to existing standards and implement based on their

-

)

February 2024 - Marine News page: 18

)

February 2024 - Marine News page: 18Column Safety Zone Five Tips to Keep Workers Safe in 2024 By Zach Walden, Director of Port Safety, Hampton Roads Shipping Association to improve your maritime safety performance and start the The maritime industry new year out strong. accounts for more than 90% of global trade and employs over 3

-

)

February 2024 - Marine News page: 6

)

February 2024 - Marine News page: 6Marine News February 2024 • Volume 35 Number 2 Contributors 3 1 24 6 5 7 8 1 Tom Ewing 5 Edward Lundquist is a freelance writer specializing in marine, energy and envi- is a retired naval of? cer who writes on maritime and ronmental issues. He contributes regularly to this magazine. security

-

)

January 2024 - Marine Technology Reporter page: 59

)

January 2024 - Marine Technology Reporter page: 59All images courtesy Oceanology International participants and to deliver another packed three days of exhi- Oi24 Events and Features bition and conference activity, features, workshops and one- Oceanology International is able to capitalize on the advan- to-one meetings.” tages of ExCeL’s expansive 18

-

)

January 2024 - Marine Technology Reporter page: 57

)

January 2024 - Marine Technology Reporter page: 57DEEP DIVE Podcast Debuts In episode one of the DEEP DIVE podcast, host Rhonda Moniz Meet the Host hosts Dan Shropshire, Vice President Business Development and Rhonda J. Moniz is an ac- Program Execution at Teledyne Marine Vehicles & Emily Shum- complished underwater chenia, Director - Regional Wildlife

-

)

January 2024 - Marine Technology Reporter page: 26

)

January 2024 - Marine Technology Reporter page: 26SUBSEA VEHICLES DEFENSE Orca Extra Large Unmanned Undersea Test Vehicle. The Navy’s top of? cer wants more players on the ? eld Unmanned Underwater Systems = Force Multiplier Source: Boeing By Edward Lundquist peaking at the Surface Navy Association’s an- (i.e., a mix of ships that avoids ‘putting too

-

)

January 2024 - Marine Technology Reporter page: 6

)

January 2024 - Marine Technology Reporter page: 6MTR Editorial Advisors Gallaudet Hardy The Honorable Tim Gallaudet, Kevin Hardy is President PhD, Rear Admiral, U.S. of Global Ocean Design, Navy (ret) is the CEO of creating components and Ocean STL Consulting and subsystems for unmanned host of The American Blue vehicles, following a career

-

)

November 2023 - Marine Technology Reporter page: 40

)

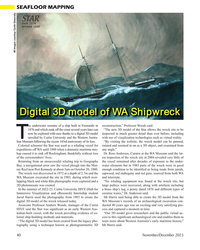

November 2023 - Marine Technology Reporter page: 40of exposure to the under- Bay, a navigational error saw the vessel plough into the Mur- water elements but in 1983 parts of the wreck were in good ray Reef near Port Kennedy at about 3am on October 20, 1880. enough condition to be identi? ed as being made from jarrah, The wreck was discovered in 1972 at

-

)

December 2023 - Maritime Reporter and Engineering News page: 25

)

December 2023 - Maritime Reporter and Engineering News page: 25UNDERWATER NOISE he main thing holding the shipping industry back from reducing its underwater radiated noise (URN) is not a lack of appropriate technology. It’s argued that many of the technologies being REDUCING implemented today to reduce fuel consumption T also reduce noise. So, the noise reduction

-

)

November 2023 - Marine News page: 37

)

November 2023 - Marine News page: 37Feature Shipyards By Tom Ewing hen asked about the top issues facing if operating policies are murky. shipbuilders, executives at the Ship- As an example, Paxton and Zorensky cited a CBP ruling builders Council of America (SCA) linked to the installation of wind tower monopiles (steel W listed a number

-

)

November 2023 - Marine News page: 19

)

November 2023 - Marine News page: 19gains from vessel sales by excluding from taxable income any the United States or, if manufactured outside the United amounts from such sources that are deposited into a CCF States, not produced in the United States in suf? cient and account established through a contract with MARAD. Earn- reasonably

-

)

November 2023 - Maritime Reporter and Engineering News page: 30

)

November 2023 - Maritime Reporter and Engineering News page: 30WAVE DATA & SHIP DESIGN NEW WAVE DATA © ??????? ???????/AdobeStock UNDERPINS SHIP STRUCTURAL INTEGRITY We have enough data about ocean waves to keep ships safe. Or do we? By Wendy Laursen he loss of the Stellar Daisy in 2017 was a tragic signi? cant wave height is less. reminder of the importance of

-

)

September 2023 - Marine Technology Reporter page: 31

)

September 2023 - Marine Technology Reporter page: 31Metron Inc. www.metsci.com Metron is a provider of advanced research, scienti? c, and software solutions for government and commercial markets. Its multi-domain experience spans Bayesian inference, probabilistic modeling, signal processing, ar- ti? cial intelligence, machine learning, and data fusion.

-

)

September 2023 - Marine Technology Reporter page: 8

)

September 2023 - Marine Technology Reporter page: 8MTR 100 Hydrus Exploring Ningaloo Reef. Advanced Navigation President/CEO: Xavier Orr, Chris Shaw www.advancednavigation.com Advanced Navigation__ Advanced Navigation develops AI navigation systems and Advanced Navigation will be among one of the ? rst Austra- robotic technologies for air, land, sea and

-

)

October 2023 - Marine News page: 24

)

October 2023 - Marine News page: 24Feature Alternative Fuels However, the AMR notes there are no commitments now Fire Protection Association dealing with safeguards for the from any vessel owners or gas companies for H2 offtake. “generation, installation, storage, piping, use, and han- In summarizing work so far, the AMR states that

-

)

October 2023 - Marine News page: 6

)

October 2023 - Marine News page: 6Marine News October 2023 • Volume 34 Number 10 Contributors 1 24 35 9 7 6 8 10 1 Jim Bunsey uting writer for Marine News and MarineLink.com. is the director of commercial business development at the Propane Education & Research Council. 6 Edward Lundquist is a retired naval of? cer who writes