Bow Thruster

-

- Hydrex Broadens Its Hori^on^With Ney Bow Thruster Replacement Methods Maritime Reporter, Oct 2002 #18

According to Boud van Rompay, executive director of Hydrex, "This new development will change the face of underwater repair work, as it provides a fast, yet top quality means to carry out such major jobs as thruster replacement and repairs." Rompay is referring to the successful replacement of the removal, repair and subsequent replacement of the vessel's seven-ton bow thruster and propeller - all of which was performed within the loading and unloading schedule of a 5,477 teu container vessel — in the Port of Rotterdam.

Relying on more than 30 years experience, Hydrex engineers developed the cofferdam principle and adapted to what is today known as the "mobdock" (mobile mini dry dock).

In this particular situation, the design of the vessel was studied in advance, followed by a technical plan that was created to remove the thruster underwater.

Problems addressed included the shape of the vessel surrounding the bow thruster. Being irregular, it had to be measured precisely in order to construct specially designed mobdocks — on both the port and starboard sides. The thruster tunnel had to be sealed completely in order to prevent any water entering while dismantling work was completed.

In response, a double-mobdock system was designed and manufactured before work commenced. Due to the degree of difficulty related to this task, Hydrex, (under Germanischer Lloyd certification) developed a new way to calculate, design and construct mobdocks for this purpose.

The new installation techniques require exact precision in order to ensure water tightness, safety of workers and project success. Because weather conditions at the time of installation were inclement, installation was a challenge.

However, since the mobdocks were well-designed, and the seals remained watertight, a secure and dry environment was present to commence the work 26-33 ft. (8-10 m) beneath the surface.

Following the first inspection, it was obvious that one of the propeller blades had been broken off. In response, the three remaining blades and blanks have to be secured over the positions where they had been. A support system for the block and tackle was then welded into place on the ship's hull and two large metal supports were cut away from the gearbox, at which time the thruster was lowered and secured so that it could be removed once the mobdocks were taken away.

The mobdock removal process involved bringing it back to the surface with the propeller blades inside. The thruster itself was then taken out from underwater, raised to the dockside and taken to the factory.

The vessel was able to sail on its next leg of the journey after loading with containers was complete. Repairs were performed on the thruster engine and propellers, and all was readied for the return of Hanjin Vienna to Rotterdam within the next couple of weeks. This time the procedure for fitting the mobdocks in place differed from the first time, as they were already lowered underwater prior to arrival of the vessel.

Circle 39 on Reader Service Card www.mariHmereporterinfo.com

-

- Advanced Bow Thruster Efficiency Aided By Stator Screen From Shipwrights Maritime Reporter, Nov 1991 #132

An unusual new stator screen has been developed to significantly increase the efficiency and power in bow thrusters. Harnessing the power from the water moved by the thruster's twin props is an advancement in bow thruster technology, now exclusive to the Twin Prop system manufactured by Shipwrights

-

- Bird-Johnson Receives Bow Thruster Contract Maritime Reporter, Jul 15, 1978 #32

Bird-Johnson Company, Walpole, Mass., has been awarded a contract for a 990-hp bow thruster by AmShip Division of The American Ship Building Company. The unit will be installed as a replacement on the S/S Elton Hoyt 2nd. The Hoyt, a Great Lakes bulk freighter capable of carrying 23,200 gross tons of

-

- Interview: Tim Leach, Glosten, Discusses Efficient Refit by Design Maritime Reporter, Jan 2021 #36

from small maintenance items to the complete repowering of the vessel. In addition to the repowering, other major items included replacement of the bow thruster, Ballast Water Treatment System installation, HVAC (Heating, Ventilation, and Air Conditioning) upgrades, noise mitigation of Engine Room fans,

-

- Ship Repair: Inside the $60m Refit of RV Roger Revelle Maritime Reporter, Jan 2021 #30

transformers, as well as the propulsion motors and drives.BWMS: An Optimarin ballast water management system to help stop the spread of invasive species.Bow thruster: The installation of a new retractable ZF bow thruster to improve performance, vibration and noise.Cranes: An overhaul and replacement of overboard

-

- WESMAR Delivers Fire Boat Thruster Marine News, Dec 2014 #56

Western Marine Electronics has delivered its powerful bow thruster systems to a Fire Boat for the City of San Francisco. Per specifications her ability to maneuver in tight situations and hold steady during firefighting operations will be facilitated by WESMAR’s Model V2-20 NS 100 HP stainless steel, dual

-

- 1st Annual OUTSTANDING VESSELS REVIEW Maritime Reporter, Dec 1980 #18

systems Johnson Controls, thermostatic controls Joy Mfg., vent fans & motors Kingsbury, main thrust bearing Leslie Co., control valves Lips, bow thruster Magnetics, transformers Mapeco, Pilgrim nut Maricon Instruments, satellite nav. equipment Marine Safety Equipment, lifeboat winch Mario Coil

-

- There’s No Such Thing as a Routine Grounding Marine News, May 2014 #22

needed to navigate around some large debris in the river caused by recent heavy rains, preventing it from turning to port and possibly damaging the bow thruster. So, after weighing anchor and confirming with the ship’s mate that the bow thruster was ready, the pilot ordered half starboard thruster with the

-

- OUTSTANDING OFFSHORE/SHALLOW-DRAFT VESSELS OF 1983 Maritime Reporter, Jan 1984 #18

a ratio of 6:1. Two 230-bhp, 8V71 Detroit Diesel engines power the 99-kw General Electric generators. The vessel is equipped with a 200-hp Jastram bow thruster providing a thrust of 4,000 pounds. The steering system is by SSI. The vessel's capacities include 44,000 gallons of fuel oil, 12,000 gallons

-

- OUTSTANDING OCEANGOING SHIPS OF 1984 Maritime Reporter, Dec 1984 #12

with a ramp at the stern and has two fixed cranes of 25 tons capacity and 6.89-foot outreach, both installed on the port side. She is fitted with a bow thruster controlled from the bridge that has a thrust of 3.5 tons. Main propulsion engines are two 6-cylinder diesels coupled to two line shafts and

-

- OUTSTANDING OFFSHORE/SHALLOW-DRAFT VESSELS OF 1984 Maritime Reporter, Jan 1985 #16

o n t r o l l a b l e - p i t c h propellers through Reintjes reduction gears with a ratio of 2.5:1. A water jet, hydraulically operated bow thruster supplied by Frank Mohn is installed in each hull. Electric power is provided by two Mercedes Benz/Stamford diesel generators, each of 50 kw

-

- Two Tuna Seiners Christened At Peterson Builders Yard Maritime Reporter, Aug 1981 #14

D3412 hydraulic system prime mover, rated 520 horsepower and a Caterpillar 3406 engine rated 400 horsepower driving a 50-inch Michigan Jastram bow thruster through a Twin Disc 1.5:1 reverse/reduction gear. Mathers pneumatic controls are provided for both main propulsion and bow thruster systems

-

)

March 2024 - Marine Technology Reporter page: 42

)

March 2024 - Marine Technology Reporter page: 42NEW TECH OCEANOLOGY INTERNATIONAL 2024 Image courtesy Greg Trauthwein Image courtesy BIRNS MacArtney launches the new ultra-compact ø12.7 mm SubConn Nano connector. Innovative connectivity built on 45 years of ? eld-proven and market-trusted design. Image courtesy MacArtney Birns celebrated its 70th

-

)

March 2024 - Marine Technology Reporter page: 36

)

March 2024 - Marine Technology Reporter page: 36LANDER LAB #10 Of special interest for marine applications, LiPo batteries are Shipping any kind of lithium battery can be a challenge, and offered in a “pouch” design, with a soft, ? at body. The pouch IATA regs vary with the batteries inside or outside an instru- is vacuum-sealed, with all voids ?

-

)

March 2024 - Marine Technology Reporter page: 15

)

March 2024 - Marine Technology Reporter page: 15sensor options for longer mission periods. About the Author For glider users working in ? sheries and conservation, Shea Quinn is the Product Line Manager the Sentinel can run several high-energy passive and active of the Slocum Glider at Teledyne Webb acoustic sensors, on-board processing, and imaging

-

)

March 2024 - Marine Technology Reporter page: 14

)

March 2024 - Marine Technology Reporter page: 14TECH FEATURE TELEDYNE SLOCUM GLIDERS to hold over 3.5 times as many lithium primary batteries as the the water column and its thrusters give it the ability to stay standard Slocum Glider, and to physically accommodate up to on track in strong currents or other dif? cult ocean condi- 8 different sensor

-

)

April 2024 - Marine News page: 33

)

April 2024 - Marine News page: 33Feature Electric Tugs ing tug design. ABB was brought on as systems integrator, and Coden, Ala. shipbuilder Master Boat Builders began building the vessel later that year. The result of these efforts is the 82-foot-long tug eWolf, built to ABS class and is compliant with U.S. Coast Guard Subchapter M

-

)

February 2024 - Maritime Reporter and Engineering News page: 36

)

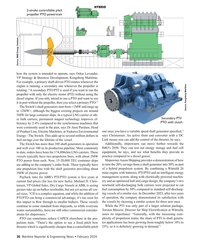

February 2024 - Maritime Reporter and Engineering News page: 36reduce CAPEX elsewhere in the pro- plexity of propulsion trains, the share of PTI in shaft genera- pulsion train. “There’s the option to use a ? xed pitch bow tor applications has been growing from roughly below 10% to thruster which is signi? cantly cheaper than a controllable pitch 25%, so it is de?

-

)

January 2024 - Marine Technology Reporter page: 43

)

January 2024 - Marine Technology Reporter page: 43he world beneath the ocean’s surface remains and extreme environments, including the deepest parts of one of the last frontiers of exploration, where the ocean, venturing into uncharted territories, and discover- the mysteries of the deep beckon to be uncov- ing new species and geological phenomena. ered.

-

)

January 2024 - Marine Technology Reporter page: 33

)

January 2024 - Marine Technology Reporter page: 33four of its 18 Ohio-class SSBNs and They can also operate without the wires, These weapons are launched over the side converted them to conventional cruise using their own active or passive sensors. of surface ships with the ubiquitous MK missile carriers. The ? rst four Ohio- They are programmed to

-

)

January 2024 - Marine Technology Reporter page: 20

)

January 2024 - Marine Technology Reporter page: 20scaling up, so we’re The front of the machine has this big slope plate that ensures working on the larger scale technology, the Blue Horizon. So that the bow always stays submerged. Waves are over topping we have a project to get that in the water in a couple of years. (the unit) and that’s a natural load

-

)

January 2024 - Marine Technology Reporter page: 19

)

January 2024 - Marine Technology Reporter page: 19. cameras on the machine. The front of the machine has this big And if you move more in waves, you generate more power. slope plate that ensures that the bow always stays submerged. (To develop the machine) we developed a software optimiza- Waves are over topping (the unit) and that’s a natural load tion

-

)

January 2024 - Maritime Reporter and Engineering News page: 41

)

January 2024 - Maritime Reporter and Engineering News page: 41(AiP) for an Am- ti? cation. Combining her eco-friendly CAT engines with monia FSRU (Ammonia Floating Storage and Regasi? cation Markey winches on the bow and stern makes the American- Unit) jointly developed by Mitsui O.S.K. Lines, Ltd. (MOL) made GRACE one of the most advanced and powerful ship- and

-

)

January 2024 - Maritime Reporter and Engineering News page: 33

)

January 2024 - Maritime Reporter and Engineering News page: 33RoPax Ferry Fuel type: LNG, biogas, battery (Leclanche) Shipbuilder: Rauma Marine Constructions Total installed power: 17,6MW Material: Steel Bow thrusters: Wärtsilä FPP 2*1500kW Ship Owner: Kvarken Link Propulsion: ABB Azipods (2 × 5.8 MW) Ship Operator: NLC ferry (Wasaline) Generators:

-

)

January 2024 - Maritime Reporter and Engineering News page: 32

)

January 2024 - Maritime Reporter and Engineering News page: 32CRUISE FEATURE uilt by Rauma Marine Constructions, in Rauma, control system and bow thruster motors. Finland, and launched in 2021, the 150-meter-long In addition to the engines, Wärtsilä also supplied its LNG- Aurora Botnia boasts a long list of onboard equip- Pac technology for LNG storage, supply

-

)

November 2023 - Marine Technology Reporter page: 29

)

November 2023 - Marine Technology Reporter page: 29New EverClean Robot Greensea IQ launched of its most advanced EverClean service robot, a leap forward in the realm of supervised reliable autonomy with Over the Horizon (OTH) operational capability for underwa- ter hull maintenance. The EverClean robot is packed with features like depth aided navigation

-

)

November 2023 - Marine Technology Reporter page: 25

)

November 2023 - Marine Technology Reporter page: 25site housed an active dam approach- transforming the way professionals nav- nology provides unparalleled precision ing the end of its lifespan and histori- igate and explore underwater environ- and ef? ciency. Elevate your operations cal remains of a previous dam from the ments. From military and governmen

-

)

November 2023 - Marine Technology Reporter page: 23

)

November 2023 - Marine Technology Reporter page: 23by the company. The vessel was built, in line with the Jones Act, at the Thoma-Sea yard in Louisiana. Key design features include a wave piercing bow, which reduces fuel Portable System Requires only consumption and reduces slamming in Wavelet 2KW at 250ms Ping Rate CorrelaO on > 0.96 rough

-

)

December 2023 - Maritime Reporter and Engineering News page: 43

)

December 2023 - Maritime Reporter and Engineering News page: 43ironing/ shoreside (MARAD), where he was the Maritime power, more ef? cient propulsion hull upgrades and bulbous Environmental and Energy Technical bows, wind sails, engine monitoring, slow streaming, hull Adviser. His opinions are his own and not coats, and propeller design matter. None of these

-

)

December 2023 - Maritime Reporter and Engineering News page: 37

)

December 2023 - Maritime Reporter and Engineering News page: 37Copyright Shimizu Corporation The Self-Elevating Platform vessel Blue Wind even with obstructions at the quay. was built by Japan Marine United for Shimizu The ship is equipped to work in varying sea Corporation, a ship with the size and the lifting conditions, out? tted with 90m legs, able to be

-

)

December 2023 - Maritime Reporter and Engineering News page: 29

)

December 2023 - Maritime Reporter and Engineering News page: 29propulsion motors 2 sets in series with an output of 9,000 kW Full speed 18 knots with 15% sea margin Cruising speed 12 knots with 15% sea margin Bow thruster 1800 kW, retractable Stern thruster 890 kW MPIRE TATE S VII instructors, too, and started well before the ? rst ship was cy response when needed

-

)

December 2023 - Maritime Reporter and Engineering News page: 26

)

December 2023 - Maritime Reporter and Engineering News page: 26UNDERWATER NOISE ICS ICS NCE IWSA Chris Dr. Jesse Gavin Waddington: Seyedvahid Spence: Allwright: If considered at Having wind Vakili It’s not just an early stage, onboard also estimates that a and by careful a case of enables range 10% reduction in consideration to be extended speed

-

)

December 2023 - Maritime Reporter and Engineering News page: 23

)

December 2023 - Maritime Reporter and Engineering News page: 23JUHA KYTÖLÄ, WÄRTSILÄ Inside Wärtsilä’s Sustainable Technology Hub The 150-meter-long vessel, touted by its operator as one of the world’s greenest, features an integrated package of Wärtsilä solutions, includ- ing four Wärtsilä 31 engines; exhaust treatment; LNGPac technology for LNG storage, supply

-

)

November 2023 - Marine News page: 57

)

November 2023 - Marine News page: 57recent years, Kytölä said. In 2022, the company dedicated €241 million (about $255 million) to R&D expenditure, or 4.1% of its net sales, up from €165 million (about $175 million) and 3.2% in 2018. In particular, the company has been working to maxi- mize the ef? ciency of its portfolio of gas, diesel

-

)

November 2023 - Marine News page: 54

)

November 2023 - Marine News page: 54development.” tegrates Teknicraft’s signature symmetrical and asymmetri- Capable of 18- to 24-knot cruising speeds, Shackleford cal combined hull shape, bow wave piercer and a patented is equipped with twin EPA Tier 3 Caterpillar C-18 diesel hydrofoil-assisted hull design. The hull and hull components

-

)

November 2023 - Marine News page: 53

)

November 2023 - Marine News page: 53, equipped with 3516E Tier IV Caterpillar engines powering twin Schottel SRP 490 Z-drive units. The 93- by 38-foot tug features Markey winches on the bow and stern and achieved over 91 short tons during its ABS bollard pull certi? cation. JANE MCALLISTERJANE MCALLISTER McAllister president and CEO,