John Erickson

-

- Innovation in the Engine Space Maritime Reporter, Mar 2002 #27

Turn of the century photographs of dirty, hot, cramped machine spaces filled with boilers, engines, gratings and bulkheads begin to tell the story of the state of steam power just after the birth of the propeller. Oil squirt cans, dancing connecting rods, and sweating coal passers and firemen characterized the engine rooms of the late 1800s when paddle wheels were gradually being replaced with the screw.

Pioneers of screw propulsion experimented with an assortment of propeller designs before commercial application of the concept began. The first screw-driven vessel in the U.S. Navy was the Princeton, built in 1843 by John Erickson. Even though the prop had many advantages over the paddle wheel, the fact that during the 1840s and 50s most ships were still made of wood posed significant challenges in terms of power, thrust, and managing the final drive to the propeller shaft.

In terms of engine design and construction, screw technology of the 1850s was much the same as paddle propulsion. Engineers tried a number of existing prime movers including beam, oscillating, and horizontal engines before finally deciding that the vertical direct-acting engine was the best solution.

One of the first installations of a beam engine turned sideways was by shipbuilder Todd & Mac- Gregor who laid down a 1,600-ton iron steamer in 1849. The ship's overhead beam engine had two 66 in. bore by 5 ft. stroke cylinders, each connected to its own beam by means of a connecting rod.

By 1862, the two-cylinder geared oscillating engine was adopted for the Cunard screw steamer China. The cylinders were 80 in. diameter and the stroke 5 ft. 6in. The gear wheels, more widely used than chain drives, contained four rows of wooden teeth, these being less noisy, easier to cut and less of a problem to lubricate than metal teeth.

Horizontal engines were the first truly successful plants for screw-driven vessels. Initially, readily available horizontal engines used for naval steamers were fitted into merchant ships. However the limited width of many merchant ships presented problems with fitting direct-drive horizontal engines.

The solution, according to many builders, was a vertical arrangement. By the mid-1800s, the vertical inverted direct-acting condensing engine became the main engine used on nearly all screwdriven vessels. Cylinders of an inverted engine were mounted on supports bolted to the bedplate, the piston rod of each cylinder passing through its lower cylinder cover and connecting with a crosshead running in guides attached to the cylinder supports. When owners realized that the inverted cylinder engine saved on engine-room floor space, allowing for more cargo, cabins or coal, inverted cylinders arranged vertically above the crankshaft became the norm for screw propul- Compound and Triple Expansion Engines Until this point all steam expansion took place in one cylinder. But with ongoing improvements in compound engines, the days of the simple expansion engine were numbered. By the 1870s compound engines were considered reliable, and the fuel saving advantages of compound expansion were clear. The first of these engines operated at about 60 psi while later compounds would use pressures of 80 to 100 psi. During the early years.

crankshaft strength limited engine power. Not until the introduction of higher quality steel were high output powers possible.

Use of the compound was followed by the triple expansion steam engine, considered reliable by the 1880s. In these engines, which needed a minimum of 120 psi to operate, the steam was exhausted from the high-pressure cylinder to the intermediate cylinder, then to a low-pressure cylinder. A triple expansion engine could operate at around 200 psi with a condenser vacuum of 26 inches of mercury.

The cranks were placed at 120° to give more uniform torque to the shaft. To operate with a higher pressure and offer smoother power, quadruple expansion engines were built as well. However, triple expansion technology dominated until the advent of the steam turbine.

Steam Turbine Invented in the 18th century, the rotary engine was not practical until 1884 when Sir Charles Parsons invented a turbine to operate an electrical generator.

The first turbine-powered vessel was the HMS Turbinia in 1897. This direct-drive engine operated at a relatively slow speed. The main problem with turbines was their high rotation speed — which required use of a reduction gear — and the fact that they were not reversible.

Yet, because of their favorable size-to-power ratio, steam turbines had been adopted for use in many large express passenger liners by the early 1900s. Canadian Pacific's 21,517-gross ton trans-Pacific liner Empress of Canada, which entered service in 1922, typified the period. Her propulsion plant consisted of two sets of Brown-Curtis turbines employing double reduction gearing, each set consisting of four separate turbines in series. During the war the turbine reigned supreme, driving First World War ships from large battleships to destroyers.

During the 1930s, manufacturers were preparing for war production. The main industrial wartime strategies were achieving standardization and developing increased manufacturing capacity and efficiency. Technology temporarily regressed in favor of producibility.

Because of an acute shortage of turbine, gear, and large diesel engine manufacturing capability, the approximately 3,000 ships built during WWII were powered with triple-expansion reciprocating steam engines. The 2,700 Liberty ships supplied by the Allies served the war effort in an exemplary fashion. Despite a significantly behind-the-times fuel rate of about 1.2 lb/ihp-hr, the ships' plants were capable of being operated by relatively inexperienced personnel.

To encourage o u r - ~ age exploitation of better fuel rates and alleviate the anticipated shortage of steam turbines and gears, a few experimental diesel installations took place just before and after the start of WWII. The direct-drive, British-patented, opposed-piston Doxford diesel engines were built in 3-, 4-, and 5-cylinder versions with 6,000 and 7,500 bhp continuous ratings.

These became the popular, American-made, large diesel engines, built by the Sun Shipbuilding and Drydock Company of Pennsylvania.

Postwar Progress After WWII, the unending quest for reduced weight and machinery space continued. By the late 1940s most steam merchant ships were turbine powered.

Striving for heat and space efficiency inevitably led to pressure-fired boilers, or supercharged steam generators.

In such boilers air from a turbine-driven compressor, powered by furnace exhaust gas was fed to the furnace at about 65 psi/490°F.

In the early 1960s U.S. operators of ocean-going vessels began to move toward increased speed and cargo system improvements. Grace lines' four Santa Magdalena- class (with a 20.5 knot speed) became the modern cargo carriers of the day. Both plants, which were of about 18,000 shp maximum, had two oil-fired Dtype water tube boilers supplying 600 lb steam to a single set of cross compound steam turbines driving double reduction gears and a single propeller. This design represented a conservative standard for U.S. power plants for the next decade.Relief from wartime restrictions led to more experimentation. More than 1,000 nearly new Liberty ships were targeted as working test beds and outfitted with a steam turbine, a free piston gas turbine, a regenerative gas turbine, or a diesel engine. The most notable of the Liberties was the John Sergeant converted in 1956 with a 6,000 shp opencycle regenerative gas turbine, double-reduction gears, and a controllable, reversible-pitch propeller.

Gas Turbine When the U.S. Navy made the transition to light dis- tillate fuel in the late 1960s and early 70s, the shift paved the way for a transition to more diesel- and gas turbine-powered combatants. By effectively equalizing the cost of the basic propulsion fuel, the cost advantage of the steam plant was lost and a logistical advantage for gas turbine power was born.

The gas turbine was touted as a compact, fuel-efficient plant that offered high power per unit weight.

While the concept predates the 20th century, it was not until after WWII that gas turbines began to find wide acceptance and application in power generation and propulsion. The first U.S. gas turbine-propelled merchant ship was the above-mentioned John Sergeant. Its low compression ratio, heavy-duty, industrial-type gas turbine's fuel consumption rate was a respectable 0.52 lb/shp-hr. By 1965 the Navy had installed many gas turbines for electric and auxiliary power, but only 78 for propulsion. One major step was the Navy's combined- diesel-or-gas propulsion plant for patrol motor gunboats, using diesel engines for cruising and a GE LM1500 gas turbine of 14,000 hp for high-speed operations.

Diesel Engine Drives Throughout the 1920s and 1930s the diesel engine found increasing favor with many ship owners because it was more economic to operate. Scandinavian ship owners turned almost exclusively to diesel. Only in terms of the large express liner could steam be classed as more economic than diesel in the late 1930s.

In the years preceding WWII, most diesels installed in the U.S. were direct drive reversing engines. Rapid expansion of demand for engines in the 50s and 60s led to a wide range of engines for propulsion varied from about 100 to about 5,000 bhp. Single reduction gear sets fitted with controllable reversing propellers or reversing reduction gears were available in a variety of sizes and the installation and capital costs of this arrangement were considerably lower than those of a steam plant.

Postwar diesel engine development proceeded in two almost diametrically opposed directions. For naval applications, engines were small, high-speed, and light-weight. Yet in merchant ships the trend was toward large, slow-speed engines of high power and high efficiency that burned costly fuels and maintained lower rpm to match lower propeller speeds. Diesel propulsion became more and more dominant in merchant ships even before the oil shortage in the 1970s overshadowed all other considerations in selecting machinery.

Marine Power Plants Today In the late 80s and early 90s engineers began to recognize the attributes of gas turbine power that would make it acceptable for commercial use. To preserve the maximum amount of ship space for generating revenue, owners sought compact and lightweight power solutions. The first main commercial use for gas turbines was in fast ferries. Today, space concerns and environmental interests have led some cruise lines to take another look at gas turbine technology.

Citing a goal to produce "the most environmentally sensitive cruise ships in the world," Demetrios Kaparis broke new ground in 2000 with his decision to implement gas turbine power — a technology he considers to be the "future of marine power plants" — on Celebrity's Millennium. While fuel cr ' are greater because of the use of distillates, some cruise lines have discovered an economic advantage to gas turbine-based plants, according to Dave Luck, manager of marine applications and ship integration at GE. "Having more cabins in the ship can more than offset the higher fuel cost." said Luck. In addition, pending environmental regulations and increased concern about exhaust emissions in some of the regions cruise ships serve have further influenced the decision to choose gas turbines.

Increasing environmental concern has also garnered new attention to earlier experiments with liquified natural gas (LNG) carriers. By next year, if all goes according to plan.

Statoil will become the first operator on the Norwegian continental shelf to feature LNG powered propulsion on its vessels.

While the construction cost of each vessel increased by $6 million, the company chose LNG technology because it would greatly reduce emissions.

Sources: Steam at Sea, by Dennis Griffiths, Conway Maritime Press, 1997.

Smoke Ash and Steam: Steam Engines on the West Coast of North America, by Robin E. Slieret. Western Isle & Cruise Drive Co. Ltd. 1997.

A Half Century of Maritime Technology 1943-1993, Ed.

by Harry Benford and William A. Fox: Powering Section written by David O'Neil, the Society of Naval Architects and Marine Engineers, 1993.

A freelance journalist for Newsweek, Rolling Stone, and Newsday, among other publications, Jessica DuLong is also assistant chief engineer on retired New York City fire - boat John J. Harvex.

-

)

March 2024 - Marine Technology Reporter page: 4

)

March 2024 - Marine Technology Reporter page: 4; Fax: (212) 254-6271 tional in London, perennially one Lof the world’s most important Justin Zuure CEO events serving the global subsea market. John C. O’Malley [email protected] Personally, it was my ? rst return to London for this event since 2018, as the 2020 ‘50th Anniversary’ edition

-

)

April 2024 - Maritime Reporter and Engineering News page: 28

)

April 2024 - Maritime Reporter and Engineering News page: 28to provide all of the end-to-end logistics the force will require in a future major con? ict. U.S. Navy photo by Mass Communication Specialist 2nd Class John Bellino 28 Maritime Reporter & Engineering News • April 2024 MR #4 (18-33).indd 28 4/5/2024 8:27:05 A

-

)

April 2024 - Maritime Reporter and Engineering News page: 27

)

April 2024 - Maritime Reporter and Engineering News page: 27Sailors. We have 14 Henry J. Kaiser-class ? eet replen- high-speed craft (HSC) training. So, MyMSC will help track ishment oilers and three of the new John Lewis class of ? eet and manage all of those different things in one place. We’re replenishment oilers, with more on the way. We have 14 Lew- hoping

-

)

April 2024 - Maritime Reporter and Engineering News page: 6

)

April 2024 - Maritime Reporter and Engineering News page: 6St., 2nd Floor following the tragedy that New York, NY 10010 USA T +1.212.477.6700 Tunfolded in Baltimore in the wee hours of Tuesday, March 26, CEO John C. O’Malley when the containership Dali apparently [email protected] lost propulsion and the ability to steer, President & COO Publisher & Editor cra

-

)

April 2024 - Marine News page: 33

)

April 2024 - Marine News page: 33SRP 430 LE azimuthing thrusters, fea- turing propeller diameters of 2.5 meters. The vessel also has From left: Chairman Frank Urtasun, Board of two small John Deere generators on board for emergency Port Commissioners, Port of San Diego; Paul use and to enable long distance transits at a reduced speed. Manzi

-

)

April 2024 - Marine News page: 30

)

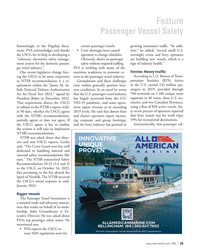

April 2024 - Marine News page: 30The offshore wind sector has seen a number of contracts Wind (CVOW) project, is bringing in a capital infusion for crew transfer vessels (CTV). St. Johns Ship Building from alternative investor StonePeak Infrastructure Partners. in Palatka, Fla. announced a contract with Windea CTV Philly Shipyard

-

)

April 2024 - Marine News page: 4

)

April 2024 - Marine News page: 4.marinelink.com The current period of time is one of swift transition for the maritime industry, CEO as regulatory and technological evolutions John C. O’Malley • [email protected] increasingly make their presence felt across Publisher & Editorial Director Greg Trauthwein • trauthwein@marinelink

-

)

February 2024 - Maritime Reporter and Engineering News page: 29

)

February 2024 - Maritime Reporter and Engineering News page: 29units in the group, and there are a lot of synergies,” said Ebeling. “But we have an independent board of US directors at ARC. Our chairman is General John Handy, a former commander of U.S. Transportation Command. We have a strong U.S. citizen leadership team also, and that’s really to make sure that

-

)

February 2024 - Maritime Reporter and Engineering News page: 6

)

February 2024 - Maritime Reporter and Engineering News page: 6HQ 118 E. 25th St., 2nd Floor becomes a geopolitical New York, NY 10010 USA T +1.212.477.6700 quagmire, with Russia’s Awar in the Ukraine soon CEO John C. O’Malley entering year three and disparate groups [email protected] aiming to disrupt commerce by ? ring President & COO Publisher & Editor rocke

-

)

February 2024 - Marine News page: 42

)

February 2024 - Marine News page: 42People & Companies Rella Hired as Wiltshire Leading Port Everglades St. Johns President Glenn A. Wiltshire has taken over as Joe Rella has been appointed as presi- acting director of Broward County’s Port Rella Barton dent of St. Johns Ship Building. Everglades Department. Barton Named Vineyard CEO New

-

)

February 2024 - Marine News page: 41

)

February 2024 - Marine News page: 41& WINDEA Courageous The ? rst two designed, BV-classed CTVs for WINDEA CTV. The third newbuild crew and fourth vessels are under construction at St Johns, and transfer vessels construction of the ? fth vessel is well underway at Breaux (CTV) for WIN- Brothers in Louisiana. DEA CTV—a At 30 meters long

-

)

February 2024 - Marine News page: 40

)

February 2024 - Marine News page: 40Islands Ferry foot vessel will service the tourist and commuter route be- tween Red Hook on the island of St. Thomas, and Cruz Bay on the island of St. John, with capacity for up to 300 passen- gers. Incat Crowther said it designed the simple yet stylish new ferry with accessibility and an elevated customer

-

)

February 2024 - Marine News page: 25

)

February 2024 - Marine News page: 25mid- January 2024. Bigger vessels The Passenger Vessel Association is a national trade and advocacy associa- tion that works on behalf of its mem- bership. John Groundwater is Ex- ecutive Director. He was asked about PVA’s top passenger safety issues. He mentioned two: • PVA expects the USCG to issue SMS

-

)

February 2024 - Marine News page: 4

)

February 2024 - Marine News page: 4477-6700; fax: (212) 254-6271 www.marinelink.com Down but not out. That’s how I’d de- scribe the current state of the U.S. offshore CEO wind industry. John C. O’Malley • [email protected] Philip Lewis, director of research at busi- Publisher & Editorial Director Greg Trauthwein • trauthwein@marinelink

-

)

January 2024 - Marine Technology Reporter page: 52

)

January 2024 - Marine Technology Reporter page: 52Smith, Southwest Research Institute management of batteries, EVs and 4. “Electric Vehicle Battery Thermal Issues and Thermal Management Techniques”, John data centers via Immersion Cooling. P. Rugh, Ahmad Pesaran, Kandler Smith; presented at SAE 2011 Alternative Refriger- ant and System Ef? ciency

-

)

January 2024 - Marine Technology Reporter page: 4

)

January 2024 - Marine Technology Reporter page: 4(though not for attribution or reporting) Justin Zuure on the path, direction and importance of the CEO subsea vehicle market. Sitting at that table John C. O’Malley [email protected] that night were several U.S. Navy Admirals as well as the CEOs from about a dozen autonomous underwater vehicle

-

)

January 2024 - Maritime Reporter and Engineering News page: 41

)

January 2024 - Maritime Reporter and Engineering News page: 41ist and commuter route between Red Hook on the island of St. the vessel to accommodate the latest hammer size. Thomas, and Cruz Bay on the island of St. John. Currently, two other Incat Crowther-designed 28-m vessels service this AiP: World’s Largest Car Carrier route. The ferry will transport up to 300

-

)

January 2024 - Maritime Reporter and Engineering News page: 6

)

January 2024 - Maritime Reporter and Engineering News page: 6Editorial MARITIME REPORTER AND ENGINEERING NEWS M A R I N E L I N K . C O M HQ 118 E. 25th St., 2nd Floor New York, NY 10010 USA T +1.212.477.6700 CEO John C. O’Malley It’s all about [email protected] President & COO Publisher & Editor Greg Trauthwein the Molecule Photo Justin Zurre trauthwein@marinelink

-

)

November 2023 - Marine Technology Reporter page: 4

)

November 2023 - Marine Technology Reporter page: 4is arguably one of the most challenging. This Justin Zuure month I’m pleased to highlight two stories CEO that I think embody ingenuity – and needs – John C. O’Malley [email protected] in the sector. Massa Products Corporation is no stranger to the subsea space, as the company – led by President

-

)

December 2023 - Maritime Reporter and Engineering News page: 6

)

December 2023 - Maritime Reporter and Engineering News page: 6Editorial MARITIME REPORTER AND ENGINEERING NEWS M A R I N E L I N K . C O M HQ 118 E. 25th St., 2nd Floor New York, NY 10010 USA T +1 212 477 6700 CEO John C. O’Malley What’s in [email protected] President & COO Publisher & Editor Greg Trauthwein Store in ‘24? [email protected] t has been

-

)

November 2023 - Marine News page: 58

)

November 2023 - Marine News page: 58VP and head of rine Engineers (SNAME). marine, Ascot U.S. USMMA Honors Bukoski Newport News’ Horne Jeffery Bukoski, president of Promoted to VP St. Johns Ship Building, has been David Horne has been promoted to awarded the RADM Lauren S. Mc- Merlino Dunsford Anzai Cready Award, which recognizes

-

)

November 2023 - Marine News page: 41

)

November 2023 - Marine News page: 41Philly Shipyard “[The VCM model] helped us build vessels. That’s what we do best.” – John Bond, Project Director and NSMV Program Manager, Philly Shipyard, Inc. “The IDIQ approach,” Linares explained, “provided the right ? exibility to support the initial funding/construction of the ? rst two

-

)

November 2023 - Marine News page: 39

)

November 2023 - Marine News page: 39up to ? ve NSMVs. Keel laying for the Empire State was in May 2021. Ben Christian is TOTE Services’ VP for Business Devel- opment and New Construction. John Bond is Project Di- rector and NSMV Program Manager for Philly Shipyard, Inc. The two were asked for their insights and advisories about the VCM process

-

)

November 2023 - Marine News page: 4

)

November 2023 - Marine News page: 4254-6271 www.marinelink.com Give credit where credit is due. MARAD, TOTE Services, Philly Shipyard and all CEO parties involved in the National Security John C. O’Malley • [email protected] Multi-Mission Vessel (NSMV) build pro- Publisher & Editorial Director Greg Trauthwein • trauthwein@marinelink