Robert Kunkel

-

- INSIGHTS Focus: Robert Kunkel Talks Power and Propulsion Marine News, Jul 2014 #12

Those MarineNews readers who are not familiar with Bob Kunkel probably should be. That’s because Kunkel, President of Alternative Marine Technologies, previously served as the Federal Chairman of the Short Sea Shipping Cooperative Program under the Maritime Administration and Department of Transportation from 2003 until 2008. He is a past Vice President of the Connecticut Maritime Association, a contributing writer for many maritime and technical trades publications, including Maritime Professional Magazine and MarineNews. He continues as the Technical Advisor for several Private Equity firms, financial institutions and Coastal Connect, developing the maritime component of short sea shipping and offshore wind energy along the coasts of United States.

A graduate of the Massachusetts Maritime Academy, Kunkel sailed with several U.S flag companies as a licensed engineer, was commissioned as a Navy Officer and continued his career in ship construction at National Steel and Shipbuilding , San Diego, Hyundai Heavy Industries, South Korea , Chengxi Shipyard and Dalian New Shipyard in Mainland China. He is a senior member of the Special Committee on Ship Operation with the American Bureau of Shipping and an elected member of the National Cargo Bureau. Amtech is currently involved in several construction supervision projects in Korea and the United States building for the Product Carrier, Chemical Carrier and Offshore markets. Bob Kunkel’s experience with marine construction and propulsion is too long to list within the pages of this publication. What he has to say about today’s challenges in the engine room is not. Follow along as Bob provides the ultimate propulsion primer as this month’s INSIGHTS focus.

What’s the number one driver for engine selection today for workboat operators? Would it be emissions control, fuel consumption, or both?

The problem in today’s market is the amount of technology available and as a result no single driver to make the selection. The operator will first consider engine cost, performance and the ability to contract with a single manufacturer to control his fleet spares, crew experience and inventory. In the foreign markets, the decision is fuel performance based – everything we see in Asian construction is “ECO” driven. Heavy fuel is still being utilized and the construction takes into account the fuel tank sizes and the switch between low sulfur fuel use and heavy fuel use when entering an emissions zone. The U.S. markets, operating solely in the emissions control areas (ECA), wrestle with the emissions driven selection as they are locked into the most heavily regulated trading areas. Dual Fuel engines using natural gas as a primary fuel looked to be the answer. That said, the infrastructure to support that engine selection has not moved forward at the speed most hoped for and gas prices have been moving up. The latest buzz is now liquid gas injection (LGI) and dual fuel methanol. As we discuss emissions issues, remember there are two “Tiers” to watch: the International IMO tiers and the U.S. EPA Tiers. There is a lot of confusion in the U.S. markets on this issue.

What’s the number one mistake today’s marine operators make when making repower solutions for their fleet?

In our experience, the lead mistake involves the lack of communication between the operator’s commercial department and his technical department or the inability of a marine consultant to address the synergy between the two groups. A successful repowering or propulsion selection must take into account the trading patterns, operating tempo and load patterns of the propulsion system. Does the engine run at a normal continuous rating (say 85% load) for long periods of time? Does the vessel operate at low loads for intermittent periods? Is speed or fuel efficiency the major factor for profitability? What is the optimal horsepower range and have all of the vessel’s operating patterns taken that power into account? Commercial input helps to make the project economically feasible. Anyone with a pile of money can build the space shuttle. The successful operator builds one that pays the bills and is profitable.

Diesel electric drive is once again hot. For what reasons and under what circumstances would you advise a client to go that route?

Variable Frequency drives, digital automation and advanced electronics has moved diesel electric back toward the head of the class. The systems are more compact and reliability has increased through documented trend analysis in the offshore markets. You will see this propulsion package move into bluewater and coastal shipping in the near future as it fits with our discussions regarding operating tempos and hybrid applications. Diesel Electric drives provide a more flexible load analysis and an opportunity to place the asset into niche trading beyond its basic operating scenario. Dynamic Positioning becomes an easier option, slow steaming and a greater selection of speed is a better fit and the azimuth units can add a new range of maneuverability. The emissions issue also sneaks into this trend as the engine manufacturers have a much easier time getting their Tier ratings if the engines run at a fixed RPM. This has driven some owners away from the historical clutch and direct drive to CPP and Diesel Electric. All of these “plus” factors must always be weighed against a higher cost of construction and future maintenance. We like the propulsion options in coastal operations and vessels employed on shorter routes and multiple port entries; in other words, schedules that require flexible speed ranges and maneuverability.

LNG is the so-called hot, new fuel for workboat operators. It is now in the process of penetrating the market for OSV’s and designs are being submitted for bunker barges, infrastructure to support LNG, LNG tugs, etc. What’s your take on LNG in the marine fuel pecking order?

We completed one of the first LNG/CNG design projects on a compact RoRo for Coastal Connect back in 2007 when “green” fuel applications and the reduction of CO2 was the focus. The major hurdle at that time was the “urban legend” of the dangers of LNG and the lack of infrastructure to support the fuel in the U.S. The price of natural gas at that time was low and the gas producers were looking for a large consumer. The cost advantages as a propulsion fuel looked to be the correct move forward. Unfortunately, the infrastructure has not developed and as we get closer to U.S. export opportunities, we believe the price of natural gas will rise to international levels and may take that cost advantage away. Natural gas propulsion reduces sulfur emissions by over 80%. CO2 is reduced by approximately 15% and NOx reduction is still an issue that may require scrubbing once Tier III international regulations and EPA Tier 4 come into effect. LNG as a propulsion fuel is a huge investment; both on board the vessel and ashore where bunkering facilities and liquefaction are required. No doubt the move to gas is a move to a cleaner fuel. The issue becomes the payback on your investment and the industry’s ability to support it.

Talk about the cost premiums for installing a dual fuel and / or LNG engine over that of a conventional engine burning distillates. Is it really worth it?

There isn’t one operator that does not support the quest for a cleaner burning fuel or the easy answer to solving the mandated emissions regulations. The dual fuel gas engine is not the issue and the cost for a DF engine depending on horsepower and size ranges between $750,000 to $1million above an engine capable of burning heavy fuels. The cost of this fuel modification is the delivery system – tankage, refrigeration, double wall piping, compression stations, etc. That additional construction cost can reach $10 million, depending propulsion size and power. With the exception of one or two offshore projects, most of the construction contracts in place for dual fuel propulsion in the U.S. are “LNG Ready.” That tag only prepares the vessel with a dual fuel capable engine and the space to install the delivery equipment. We can answer the “is it really worth it?” question when you see construction describing “LNG delivered.” That next stage can be reached only when the bunkering infrastructure is in place. Simply put, if the gas price stays well below the low sulfur distillate price and someone takes up the infrastructure issue then a payback scenario on the investment will be worth it. Until then, other fuel choices are available to comply with the regulations.

Looking at the typical OSV, tug, pushboat and any other conventional workboat platform – do any really have the room for after-treatment as a way to reduce emissions? Assuming space is at a real premium, what are the options otherwise?

Most do not and it all depends on the system installed; closed loop, open loop, exhaust gas recirculation, the list goes on and on. Many systems require a horizontal exhaust run and we have been designing ships and workboats for years to make sure there were limited horizontal piping runs in your exhaust system. There are also deck mounted options if space is a premium. The simple answer is to burn low sulfur marine diesel oil or gas oil until all of the regulations fall into place. NOx reduction will be the most difficult regulation to meet and exhaust gas recirculation looks to be the answer to solve that problem.

You’ve been quoted as saying that methanol will overtake LNG as the new fuel of choice in the future. Why, how and when?

Methanol burns with similar characteristics as natural gas and without methane slip. A 95% reduction in SOx and a 24% reduction on NOx is available in two stroke applications. Keep in mind the first diesel engines burned alcohol so the introduction of this fuel is not a technological reach. It does not require the refrigeration characteristics of LNG for storage and is liquid form at injection. MAN B&W has been successful with the diesel cycle using MeOH or Methyl Alcohol in their two stroke LGI engines. The formation of formaldehyde in the exhaust of the four stroke engine in the Otto cycle still remains a problem for this fuel to be introduced at the workboat or tugboat level. We have seen the Europeans move to two stroke engines in their tugs and offshore workboats to solve that issue. Using Methanol and Ethanol solves the sulfur issue with a 95% reduction, and reduces the NOx to levels that can be handled by exhaust gas recirculation (EGR) or Selective Catalytic Reduction (SCR). All of these modifications can work towards simpler retrofits and the reduction of the fuel delivery costs that LNG requires. Large Bluewater vessel have been ordered with ME-LGI engines, and more movement towards this fuel type in 2015 could occur as the Tier II keel laying dates disappear and the new Tier III/Tier 4 regulations come into place.

Retrofit (re-power) or rebuild: that is the question. What should today’s workboat operators do and why?

Our advice would be to make the necessary changes to your fuel delivery and lubrication systems to meet Tier II regulations and safely use ultra-low sulfur in your existing engines. Most of that work requires only timing changes and new fuel injectors. Remember, this fuel type has been required by the EPA for road transportation since 2006 under the Clean Air Act and the latest discussion lead us to believe that the price of ultra-low sulfur fuels may not reach the levels some are predicting as the refineries have already made modifications to meet the road transportation requirements. Meeting those levels and burning that fuel will get you to 2020. From there, EGR and SCR requirements will be needed to reduce NOx emissions. On existing vessels, meet Tier II/2 and take a break. Your new construction is a different story. That is where big decisions on what fuel you will burn are taking place.

What do you think the repower market looks like in the near term for Workboats? If operators decide not to repower, will there be a rush for replacement tonnage?

New construction slots in the U.S. shipyards are limited and most of the contracts in place took into account the dates required for Tier 2 and Tier 3 compliance. Historically, this market was built on the analysis of supply and demand, not regulatory advances. We see repowering and or engine modification as the first step in compliance. That said, most owners will ride out the “grandfather” period and then make their decisions for replacement tonnage. Technological advances move quickly in this Internet world and the best advice now is to let this regulatory market develop and move on a slow bell.

Which existing engines are “grandfathered” under the new EPA Tier rules? Can an existing 10 year old engine stay in operation even it doesn’t meet future or existing Tier requirements. Lead us through that matrix.

The answer to this question and the route through the regulatory matrix is complicated. Engine size, application, date built all come into play. At this point in time the best course is to ask the manufacturer if you can comply with Tier II/2 and operate on distillate fuels until 2020.

You advise a myriad of clients on all sorts of power plant decisions. What’s new and what do you tell your clients when they ask about power options?

We advise our clients to first look at their operating parameters and trading patterns; then look to fuel efficiency. The first thing that should be understood is the less fuel you burn, the less in emissions that are produced. Look for slower revolutions in your engines, larger propellers and optimum efficiency in the power train. Analysis of the full propulsion system from engine to wheels is important. Listen to all of the engine manufacturers and then take on a company that is capable of integrating the correct system for you. The analysis goes well beyond engine type or size. From a fuel perspective the current situation is an interesting dynamic and it is dependent on market sector. For new construction operating within an ECA, we have recommended the use of low sulfur diesel as the primary fuel for four stroke applications and the removal of heavy fuel equipment to save costs. We are also looking at the installation of two stroke engines in this market sector – one that historically bought and installed four stroke equipment. At our foreign construction sites in the tanker and chemical markets, we have continued with the use of low sulfur heavy fuel operation and extended the size of the vessel’s low sulfur marine diesel fuel tankage. This allows for extend periods in the ECAs when the vessel is trading those areas. The engines to this date are Tier II compliant. We have seen over 150 new construction slots filled in Korea in the Product tanker and chemical tanker sector. Not one has installed after treatment systems.

One of your more exciting jobs perhaps was the research / classroom vessel up in Connecticut. Tell us about the power requirements on that vessel. Didn’t it have an electric mode for quiet operation?

The Marine transportation sector historically is late in adjusting to new technology. If you look to the Automotive and Airline industry, major changes are occurring in power and again most of these changes take place in the interest of fuel efficiency. The airlines are moving away from hydraulics and into digital electrical systems fueled by lithium powered batteries. The automotive industry has also moved to Hybrid powered fueled by advanced lithium powered energy. This battery source integrates well with marine transportation at several levels. In the research vessel project, we were tasked with providing a “green” propulsion platform. As we discussed above, the vessels operating tempo and trade was part of the analysis. The vessel used limited periods of peak engine power, towed ROV and arrays at slow speed and was used as an education platform to teach students. One of the major complaints was engine noise during those classroom sessions. We partnered with Northern Lights, BAE Hybrid, Incat and Derecktor shipyard to develop a 65’ catamaran that held seventy students and operated on Corvus Lithium powered batteries. The power requirement is about 500 horsepower to make 12 knots full speed. Two variable frequency Lugger generators provide charging power to the lithium battery packs which drive two electric traction motors. The generators start automatically under certain load requirements and when the battery discharge reaches 27%. The operation during classroom sessions and sonar research is completely silent and emissions during operation were reduced to near zero. We are now working to apply this technology to a Chemical ATB project using Marflex Variable Frequency deepwell pumps for silent cargo operations on the U.S. West Coast where complaints of terminal noise have forced limited cargo operations. Hybrid operations will gain traction in the workboat sector as the batteries provide an energy buffer and allow diesel generators to run at optimum potential despite reduced load requirements. The excess energy is stored and when the batteries are charged, the engines can be stopped. And all of us know the best way to achieve lower emissions and better fuel economy is to simply not run the engine.

(As published in the July 2014 edition of Marine News - http://magazines.marinelink.com/Magazines/MaritimeNews) -

- Interview: Robert Kunkel, Alternative Marine Technologies Marine News, Apr 2018 #14

Bob Kunkel needs no introduction to Marine News readers. Kunkel, President of Alternative Marine Technologies, previously served as the Federal Chairman of the Short Sea Shipping Cooperative Program under the Maritime Administration and Department of Transportation from 2003 until 2008. A past Vice President

-

- Marine Hybrid quietly arrives … positioned to explode Marine News, Mar 2019 #48

Hybrid is not only here, it is growing, and with that growth it will soon reach far beyond coastal applications.For those who were around for the arrival of Y2K, you will remember the anticipation, preparation and perspiration as the maritime world waited for the failure of communications, navigation

-

- Rewrite the Rules: The Path to Zero Emissions Marine News, Mar 2020 #30

With social media updates and conference agendas addressing the subjects of climate change, emissions reductions and alternative fuels, it’s a wonder we are not climbing the Himalayans in search of the Jedi Master that will provide us with the magic potion. Yoda’s blessing with a calming breath

-

- Shipping through the Pandemic: Perfect Storm or Wake up Call? Maritime Reporter, Aug 2020 #24

The global pandemic news has been horrific and certainly an historic moment in domestic and worldwide shipping. For many businesses, the action was simple; hang the “closed” sign, furlough or layoff staff and wait for the approval to re-open. Or not, depending how long the virus will linger and continue to

-

- Will Customers Redefine Design and the Science of Marine Propulsion? Maritime Reporter, Sep 2020 #26

It is “pre-COVID ” April of 2018, and 174 member states of IMO adopt a new strategy to reduce greenhouse gases from shipping. The meetings are considered “urgent” and the target is to reduce carbon emissions in half by 2050. Prior to those “targets” shipping dealt with regulations to address SOx and NOx

-

- Moving Forward with Emissions - Is it Tiers, Tears or Fears? Marine News, Jul 2021 #26

the zone. From a financial perspective or an investment opportunity, this created another hiccup in exit strategy should domestic markets fail.(Photo: Robert Kunkel)Owners have been forced to deal with the continuing regulation amendments when making decisions with assets that were financially modeled to trade

-

- Green with Envy: the “ECO” Ship is Calling Maritime Logistics Professional, Q2 2013 #30

When Energy flows to Money There is no argument: International maritime transport is the most energy efficient mode of mass transportation available today. The entire world fleet contributes less than 2.7% to global CO2 emissions according to a 2007 IMO report and those emissions are shrinking as “slow-steam

-

- Fortunes Return to the Sea as the Wind Blows Offshore Marine News, Nov 2022 #30

The results of fortunes and failures are often described as a “perfect storm”. The COVID pandemic, domestic inflation, labor issues and current geopolitical events have brought that description to a peak. A promise of a “new normal” emerged post pandemic, with a vision of alternative

-

- Propulsion Decisions or Smoke on The Water? Marine News, Feb 2023 #20

In no uncertain terms, the goal of “future capable” ship’s propulsion is confusing. We have been pressed into a regulatory environment that asks us to reduce emissions, and in the same breath deliver power sufficient to meet commercial schedules and allow the vessel to weather a storm and

-

- Labor Shortages, Climate Change & Technology: They’re All Related Marine News, Aug 2023 #18

to make changes to their world.Brien McMahon High School students recently sent a “drifter” on a voyage from the U.S. to Norway. (Photo: Robert Kunkel)We have no less than four maritime academies located in the Tri-State/New England area stretching from New York to Maine. The U.S. East Coast is

-

- Will the Effort to Reach Zero Emissions Go Nuclear? Marine News, Nov 2023 #22

On December 8, 1953 President Dwight D. Eisenhower addressed the 470th Plenary Meeting of the United Nations General Assembly. The speech he delivered is often recognized as his effort to introduce “Atoms for Peace”, a program to move nuclear fission and technology away from weapons development

-

)

April 2024 - Maritime Reporter and Engineering News page: 24

)

April 2024 - Maritime Reporter and Engineering News page: 24Adm. Philip Sobeck (right) Commander of U.S. Military Sealift Command (MSC) explains the tradition of the Navy ‘looping ceremony’. Lt. Robert P. Ellison assumes the title of MSC’s Flag Aide during the ceremony. NEEDS MILITARY MORE SEALIFT MARINERS, NEW SHIPS COMMAND Founded as the Military

-

)

April 2024 - Maritime Reporter and Engineering News page: 20

)

April 2024 - Maritime Reporter and Engineering News page: 20adolescence, common mantras are ‘learn from the established European model’ and ‘embrace technology transfer from the offshore oil and gas sector.’ In Robert Langford, the American Bureau of Shipping has all of that and more bundled in one neat package. Langford recently visited with Maritime Reporter

-

)

April 2024 - Marine News page: 48

)

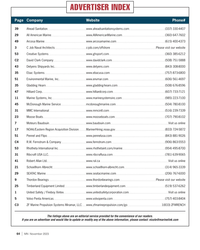

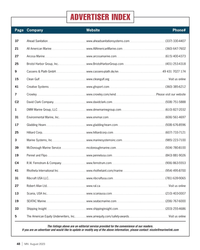

April 2024 - Marine News page: 48.com (504) 780-8100 C4 R.W. Fernstrum & Company www.fernstrum.com (906) 863-5553 3 Raymarine www.raymarine.com/commercial (603) 864-9668 25 Robert Allan Ltd. www.ral.ca Please visit our website 15 Scania, USA Inc. www.scaniausa.com (210) 403-0007 13 Schoellhorn Albrecht www.schoellhorn-albrecht

-

)

April 2024 - Marine News page: 28

)

April 2024 - Marine News page: 28. Master Boat Builders is also constructing more conven- tional vessels. In mid-2023, it announced an order for two 92-foot escort tugs, with design by Robert Allan, Ltd. to be built for Moran Towing, based in Connecticut. Though us- ing conventional fuel, the boats will feature Caterpillar 3516 EPA Tier

-

)

April 2024 - Marine News page: 6

)

April 2024 - Marine News page: 6. He contributes regularly to this magazine. tical support, including analytics and communica- tions, to businesses across the maritime spectrum. 2 Robert Kunkel, He is a freelance writer and regular contributor to president of Alternative Marine Technologies and First this magazine. Harvest Navigation

-

)

February 2024 - Marine News page: 35

)

February 2024 - Marine News page: 35building the simulators, Virtual Marine owns and operate a series of training centers, including three in the Americas: Newfoundland, Broussard, La. and Robert, La. Harnessing the power of technology Over the years, Virtual Marine has witnessed signi? cant advancements in technology, particularly in virtual

-

)

February 2024 - Marine News page: 6

)

February 2024 - Marine News page: 6and ronmental issues. He contributes regularly to this magazine. security issues. He is a regular contributor to New Wave Media titles. 2 Robert Kunkel, president of Alternative Marine Technologies and First 6 Barry Parker Harvest Navigation, served as the Federal Chairman of of bdp1 Consulting

-

)

November 2023 - Marine News page: 64

)

November 2023 - Marine News page: 64(906) 863-5553 53 Rhotheta International Inc www.rhothetaint.com/marine (954) 495-8700 31 Ribcraft USA LLC. www.ribcraftusa.com (781) 639-9065 41 Robert Allan Ltd. www.ral.ca Visit us online 21 Schoellhorn Albrecht www.schoellhorn-albrecht.com (314) 965-3339 29 SEATAC Marine www.seatacmarine

-

)

November 2023 - Marine News page: 27

)

November 2023 - Marine News page: 27unit. The same yard has two tugs un- signi? cant inherent differences in vessel categories and their der construction for Moran Towing; also with a Robert Allan operating conditions, there is no ‘one-size-? ts-all’ approach to design, set for 2025 delivery. Most recently, Gulf LNG Tugs future low-

-

)

November 2023 - Marine News page: 22

)

November 2023 - Marine News page: 22Column Nuclear Will the Effort to Reach Zero Emissions Go Nuclear? By Bob Kunkel, President, Alternative Marine Technologies On December 8, 1953 merchant ship. She was built in the late 1950s at a cost President Dwight D. Eisenhower addressed the 470th Ple- of $46.9 million and launched on July 21

-

)

November 2023 - Marine News page: 13

)

November 2023 - Marine News page: 13.” feedback to try to develop a better product, this was all At the end of October, DMI performed sea trials for Ar- super attractive to me.” temis, a new Robert Allan Ltd. RApport 2500 tug for Br- Manning said his attention to the relationships side of usco, to be chartered by Crowley. It is also currently

-

)

November 2023 - Marine News page: 6

)

November 2023 - Marine News page: 6on the Board of Directors for In- land Rivers, Ports, and Terminals Inc. 8 Myra Shannon-Fuller is a marketing and communications manager at ABB 4 Robert Kunkel, Marine & Ports and a Massachusetts Maritime Academy president of Alternative Marine Technologies and graduate with 15+ years of industry experience

-

)

November 2023 - Marine News page: 2

)

November 2023 - Marine News page: 2Frank Manning, 58 People & Company News 22 Is Maritime Going Nuclear? Diversi? ed Marine, Inc. 59 New Products By Robert Kunkel, AMT By Eric Haun 62 Classi? ed Advertising 64 Advertisers Index On the Cover Empire State is the lead vessel in a series of ? ve new ships

-

)

November 2023 - Maritime Reporter and Engineering News page: 74

)

November 2023 - Maritime Reporter and Engineering News page: 74of more The Author than 90 Starlink terminals for the Fleet. The only obstacles Riley to even broader application of the technology are necessary Robert Riley is the Information Technology testing and approval in accordance with the Department of & Networks Branch Chief at the USCG Defense’s Risk

-

)

November 2023 - Maritime Reporter and Engineering News page: 73

)

November 2023 - Maritime Reporter and Engineering News page: 73OPINION: The Final Word The Next Evolution in Maritime Communication is Now By Robert Riley, Information Technology & Networks Branch Chief, USCG R&D Center ny Coastie who has served onboard a Coast nology not only works, it exceeds expectations at every level. Guard vessel of any size, or class can

-

)

November 2023 - Maritime Reporter and Engineering News page: 70

)

November 2023 - Maritime Reporter and Engineering News page: 70in Türkiye are undergoing sea trials ahead of being delivered to SAAM Towage’s Canadian ? eet. The tugs are based on the ElectRA 2300SX design from Robert Allan Ltd (RAL). They were launched on April 8 and September 9 respectively, and measure 23.4m LOA, with an 11.9m beam and maximum draft of 5.5m

-

)

November 2023 - Maritime Reporter and Engineering News page: 27

)

November 2023 - Maritime Reporter and Engineering News page: 27Maersk Godmother of Laura Mærsk, EU Commission President Ursula von der Leyen, in front of the vessel with Ane Maersk Mc-Kinney Uggla, Maersk Chair, Robert Uggla, Maersk CEO Vincent Clerc, Denmark’s Minister of Business, Morten Bodskov, President and CEO of HD Hyundai, Kisun Chung ? anked by the Captains

-

)

November 2023 - Maritime Reporter and Engineering News page: 4

)

November 2023 - Maritime Reporter and Engineering News page: 4and maritime sectors. t: (212) 477-6700 f: (212) 254-6271 Ewing MarineLMS. Tom Ewing is a freelance writer Riley specializing in energy and envi- Haun Robert Riley is the Information ronmental issues. Eric Haun is editor of Marine Technology & Networks Branch News. He has covered the com- Chief at the

-

)

October 2023 - Marine News page: 14

)

October 2023 - Marine News page: 14in control, have been unmis- Barry developed. Left to right: Scott Kreis, vice president of sales and engineering; Jeff Dempke, general manager; Robert LeCoque, technical manager; and Blaine Dempke, CEO. 14 | MN October 202

-

)

October 2023 - Marine News page: 6

)

October 2023 - Marine News page: 6land Rivers, Ports, and Terminals Inc. businesses across the maritime spectrum. He is a freelance writer and regular contributor to this magazine. 5 Robert Kunkel, president of Alternative Marine Technologies and First 10 Jeff Vogel Harvest Navigation, served as the Federal Chairman of is a partner

-

)

September 2023 - Maritime Reporter and Engineering News page: 64

)

September 2023 - Maritime Reporter and Engineering News page: 64. . . . . . . . . . . . . . . . . . . . .www.youngusa.com . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .(231) 946-3980 3 . . . . . .Robert Allan Ltd. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .www.ral.ca . . . . . . . . . . . . . . . . . . . . . . . . . . . .

-

)

September 2023 - Maritime Reporter and Engineering News page: 58

)

September 2023 - Maritime Reporter and Engineering News page: 58kW hour. ment, and in ? ve years’ time, we might not consider this a big The ESS will be deployed across four battery rooms and project at all,” said Robert Clifford, Incat Chairman. 6770 HP, Tier IV Class McAllister Tug Arrives in Virginia cAllister Towing announced the arrival of the tug Jane McAllister

-

)

June 2023 - Marine News page: 6

)

June 2023 - Marine News page: 6on the Board of Directors for In- land Rivers, Ports, and Terminals Inc. 7 Jeff Vogel is a partner in Cozen O’Connor’s transportation & trade 4 Robert Kunkel, group. He focuses his practice on strategic and operation- president of Alternative Marine Technologies and First al matters affecting the

-

)

August 2023 - Marine News page: 48

)

August 2023 - Marine News page: 48(906) 863-5553 41 Rhotheta International Inc www.rhothetaint.com/marine (954) 495-8700 31 Ribcraft USA LLC. www.ribcraftusa.com (781) 639-9065 27 Robert Allan Ltd. www.ral.ca Visit us online 13 Scania, USA Inc. www.scaniausa.com (210) 403-0007 19 SEATAC Marine www.seatacmarine.com (206)