Sam Raymond

-

- Lander Lab: Technologies, Strategies and Use of Ocean Landers Marine Technology, Jan 2022 #42

Moon landers held my attention in the 1960’s as a teenager. Unmanned robotic vehicles like Surveyor, descend out of a dark sky onto an alien world, and took the first look around.

The deep and dark ocean seemed as distant and alien. SEALAB II, bathyscaphe Trieste, and the Scripps Institution of Oceanography in my hometown of San Diego had immense gravitational pull on my curiosity.

Ocean Landers, unmanned robotic vehicles, like Scripps Professor John Issacs’ Monster Camera, descend out of a dark sea onto an alien world, and took the first look around. Our first glimpse of The Other Earth.

Why Landers?There are multiple classes of unmanned undersea vehicles (UUVs): Remotely Operated Vehicles (ROVs), Autonomous Undersea Vehicles (AUVS), Gliders, midwater SOLO drifter floats, towed platforms, and Ocean Landers, also called “free vehicles”. Each unmanned vehicle has a unique set of strengths and weaknesses, often complementary to another class. Ocean Landers are the oldest, but an overlooked platform for many seagoing projects.

Ocean Lander construction is straightforward: Buoyancy high, weight low for stability. The vehicle is self-buoyant, weighed down by an expendable anchor, usually iron. Proper design minimizes cross-section perpendicular to the direction of vertical travel, known as the vehicle’s frontal projected area. Water drag provides a terminal velocity. A positively buoyant lander floats above its anchor, making it independent of the seafloor rocks, mud and slope. No legs required for many missions. A dual or triple redundant release system gives multiple chances for return. Designers can choose from a suite of release mechanisms to suit the mission profile. On return to the surface, the vehicle becomes a spar buoy. It’s top most structure is raised out of the water, providing a line-of-sight to the ship for a radio and strobe light, or to the sky for a satellite tracking system. A flag is always a good thing, and reflective tape can help with a searchlight at night. We always add a tag for someone to contact the lander’s owner should it go AWOL. Davy Jones can be such a prankster.

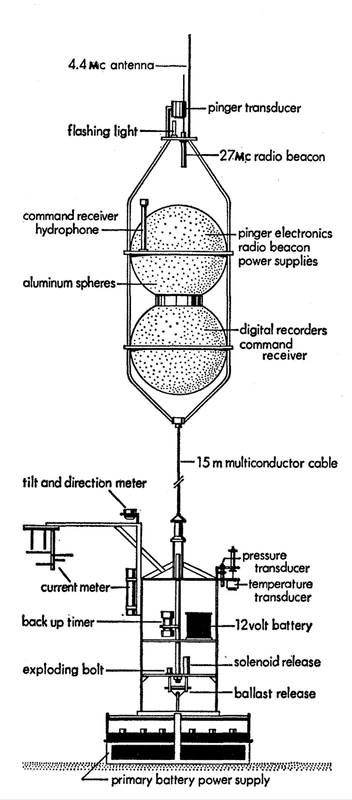

Figure 3. Then-and-Now. Munk/Snodgrass Deepsea Tide capsule (1968). Twin 24” diameter, 1” wall, spun 7075-T6 aluminum spheres provide buoyancy and house electronics. A 15m EM cable tethers the spheres to the sensor frame. Modified automotive wet cell batteries provide system power and negative ballast. The battery ballast remains on the seafloor when the capsule is recovered. (Photo Credit: Deep Sea Instrument Capsule, Frank E. Snodgrass, Science, Vol. 162, No. 3849 (Oct. 4, 1968), pp. 78-87.)

Figure 3. Then-and-Now. Munk/Snodgrass Deepsea Tide capsule (1968). Twin 24” diameter, 1” wall, spun 7075-T6 aluminum spheres provide buoyancy and house electronics. A 15m EM cable tethers the spheres to the sensor frame. Modified automotive wet cell batteries provide system power and negative ballast. The battery ballast remains on the seafloor when the capsule is recovered. (Photo Credit: Deep Sea Instrument Capsule, Frank E. Snodgrass, Science, Vol. 162, No. 3849 (Oct. 4, 1968), pp. 78-87.)Ocean Landers can carry every imaginable sensor and sampler. They can even recover sediment cores by using a clever sword-in-a-sheath design by a chap named David Moore of the USN NEL-San Diego. He had to solve the “core extraction problem” caused by gloppy mud. Sam Raymond and Benthos turned this idea into a product it sold for years called the Pogo Corer.

Materials have to handle the pressure. A lunar lander travels 400,000 km to the moon and the ambient pressure changes 1 bar. Ocean vehicles experience that every 10m of depth. Some buoyancy materials overcome the pressure by specific gravity and bulk modulus, other buoyancy materials do it by displacement and the compressive strength of the material.

We’ll discuss all of these elements in the course of this column. Like Edison’s ratio of inspiration-to-perspiration, our profession calls it R&D, with emphasis on the D.

The concept of ocean landers/free vehicles for geophysical research was first proposed in 1938 in a brilliant paper by Maurice Ewing (Lamont) and Allyn Vine (WHOI), titled “Deep-Sea Measurements Without Wires or Cables,” published in Transactions of the American Geophysical Union. Many of its insights are still valid today. The authors cited operational benefits of ocean landers/free vehicles including:

- Much less specialized and expensive equipment required on the ship;

- Long, undisturbed placement of recording instruments on the bottom;

- Recall by time-clock or signal from the surface;

- Once a free vehicle is released, the ship is free to move to another position to deploy another free vehicle, meaning large survey areas are possible;

- Stations at specified distances or heights off the bottom;

- Unlimited depth;

- Ballast release by contact with the bottom is possible if no bottom dwell time is required;

- Operators can follow progress down and up by sound-ranging;

- Initial lifting force when leaving the seafloor may be multiplied by a pulley-system;

- The ballast is on the bottom and left behind, minimizing the danger of being stuck in the mud.

Other benefits not mentioned in the Ewing-Vine article include:

1. Flexible Configuration: A lander can be configured to whatever ship-of-opportunity presents itself. Small vessel, small lander; Large vessel with an A-frame, larger lander. Lander frames can be bolted together like building blocks. Side pods provide additional buoyancy or instrument bays;

2. Interchangeable payloads: Like a pick-up truck to the deep sea, if a payload fits within physical, weight, electrical, and control parameters, it can be delivered to any place in the ocean, and recovered on command;

3. Profiler: The zone of interest maybe the water column between the surface and seafloor;

4. Ships-of-opportunity: A less specialized but appropriately sized seaworthy vessel may be found in a smaller harbor closer to a point of interest, during a more advantageous time, at a more modest cost;

5. Test bed: Ocean landers make excellent test beds for systems destined for more advanced vehicle types or more advanced Lander missions. Materials, sensors, cameras, lights, batteries, thrusters (without props), solenoid releases, recovery beacons, acoustic comms, and a lot more can be tested using small landers, from small vessels, with smaller budgets, and less worry. It doesn’t bet the farm to test a hunch;

6. Training: An ocean lander provides operational training on launch-and-recovery techniques for larger systems, giving engineers and scientists the field experience and confidence that comes from a successful deployment and recovery;

7. Collaboration: Researchers can combine a variety of instruments to measure and sample the ocean from distinctly separate, but interacting points of view. With similar landers at dispersed universities, researchers need only plan on bringing their instrument as their colleagues have a similar lander, so they know their instrument fits;

8. Persistence: Expanding on Ewing & Vine, a lander can remain on the seafloor for an entire year or longer if needed. Using glass, plastic and titanium, landers are capable of long duration deployments of even multiple years. One application may be to surround the base of an offshore oil platform where they can continuously monitor for a hydrocarbon leak, communicating with each other and back to the platform;

9. Baited lure: The lander can be used to lure animals towards its position by the use of bait. Low-light cameras using red LEDs can image animal behavior without disturbance, or await the arrival of an ROV or manned submersible;

10. Scout: Landers can precede a manned submersible or ROV operation to determine a specific area of interest. They can also stand-by as a rescue vehicle, using their full buoyancy to help bring another vehicle back to the surface;

11. Pack horse: Working with manned or unmanned vehicles with mobility but limited VB to carry samples, a lander can act like a chest-of-drawers to hold the samples collected by the mobile craft. The mobile craft is recovered first, and the lander is recalled with its payload to the surface afterwards;

12. Cheap anchors: Only scrap iron is needed for anchors, so the ballast weight may be purchased in the port of operation, saving the cost of shipment of a heavy drop weight;

During COVID, when barbell weights became very expensive and hard to find, the idea came to make ferrocement anchors, replacing the gravel with readily available scrap steel stampings. The scrap stamped steel was valued at 4 cents/pound. The anchor worked great, and would later corrode and dissolve into ocean friendly materials. Non-magnetic SS stampings are likewise available, if magnetic signature is an issue. Figure 5. Ferrocement expendable anchors, where steel stampings replace coarse gravel in the mix. Cheap, heavy, and biodegradable. Photo by Kevin Hardy.

Figure 5. Ferrocement expendable anchors, where steel stampings replace coarse gravel in the mix. Cheap, heavy, and biodegradable. Photo by Kevin Hardy.13. Shipping: A lander and its surface support gear can be shipped by overnight air freight from point-of-origin to point-of-operation, allowing rapid deployment to an active site of interest. One research group brought a small lander as check-on luggage to Fiji, where they used it to gather samples at a maximum depth of 2km.

14. Disruptive technology: Landers are simple enough to be used by any size institution anywhere in the world. I’ve mentored high school through graduate students in lander design and construction, and had them build and deploy their own. Their use in the ocean at any depth for any length of time provides unique observational and sampling capability. Ocean Landers are a UUV technology that empowers and enables all nations during the UN Decade of Ocean Science for Sustainable Development (2021-2030). Figure 6. Without winch and wire, or the big boat. The author, Kevin Hardy, then with Scripps, deploys Ocean Lander DOV Patty into the 10,700m Sirena Deep off Guam in 2011. The Munk/Snodgrass design influence is easily seen. Our ship-of-opportunity is the 62-ft Super Emerald out of Saipan. (Photo by Elizabeth Strickland, IEEE)

Figure 6. Without winch and wire, or the big boat. The author, Kevin Hardy, then with Scripps, deploys Ocean Lander DOV Patty into the 10,700m Sirena Deep off Guam in 2011. The Munk/Snodgrass design influence is easily seen. Our ship-of-opportunity is the 62-ft Super Emerald out of Saipan. (Photo by Elizabeth Strickland, IEEE)It was noted by Ewing and Vine that locating the free vehicle after it had returned to the surface was a serious problem. Today, Ocean Landers have the advantage of RDF and satellite trackers. They sink and rise pretty fast. Currents are relatively thin layers, and the vehicle passes through them fairly quickly, minimizing offset. The surface location problem has become more manageable.

Landers have been my muse to develop new undersea vehicle component technologies. Looking to send landers to the deepest trenches on a limited budget, I was looking for both buoyancy and housings. In 2001, I approached Gerald Albich, then General Manager of the German company Nautilus Marine Service (NMS), manufacturers of the impressive Vitrovex line of hollow glass spheres for ocean science. My suggestion was to leave the 17” OD the same, but make the ID smaller, creating a thicker wall. We discussed modifications to the tooling. The thick-wall glass spheres, serving as both flotation and as a housing, would be capable of reaching the floor of the deepest ocean trench. With funding from Japan, whose researchers wanted to study the deeper waters of the western Pacific, NMS completed the development. Exploration of the ultra-deep sea changed dramatically after that.

Ocean Landers inspire such invention. Come along on the journey.

References: Copies of the Ewing & Vine (1938), Snodgrass (1968), and other papers are available for download at <https://www.globaloceandesign.com/other-lander-reference-papers.html>.Post-script: I am very grateful to MTR Editor Greg Trauthwein for his invitation to write this column. I am, in perhaps my favorite self-image, an educator. There is enough material to continue the column for some time, and perhaps, in the end, bind the articles into a Handbook of Ocean Lander Design. We imagine supplementing the articles with video “How to’s”, and share some drawings of useful lander lab gear. We’ll share experiences and designs from other Landerians from around the world, and suggest Yet-To-Be-Done ideas waiting their turn.

I look forward to receiving your comments, suggestions, and most importantly, your contributions to future articles. Please send your thoughts and photos to me at: Kevin Hardy <[email protected]>Listen to Kevin Hardy discuss the rationale behind the new "Lander Lab" article series for Marine Technology Reporter.

-

- Lander Lab #3: Buoyancy Marine Technology, Apr 2022 #20

, as I have benefitted over time from members of the marine community who shared their expertise and enthusiasm with me. From earlier days at Benthos, Sam Raymond and Robert Catalano stand out in my memory. I learned so much working with the TR-6000. Jim Teague, then at Emerson-Cuming/Grace Syntactics, who

-

)

April 2024 - Maritime Reporter and Engineering News page: 15

)

April 2024 - Maritime Reporter and Engineering News page: 15hydro-acoustic design of a propulsor that delays cavitation meets its underwater noise limits. This will require specialized inception and cavitating area. The third approach should be test sites or specialized mobile underwater testing equipment. isolation mounting of a vibro-active equipment and

-

)

April 2024 - Maritime Reporter and Engineering News page: 14

)

April 2024 - Maritime Reporter and Engineering News page: 14Book Review Approach to Meeting Underwater Radiated Noise Limits Def ned By Raymond Fischer uantitative underwater radiated noise limits will construction inspections, 5) possible training with respect to be developed shortly by IMO, and/or countries salient design/construction essentials, 6) compliance

-

)

April 2024 - Maritime Reporter and Engineering News page: 4

)

April 2024 - Maritime Reporter and Engineering News page: 4Authors & Contributors MARITIME REPORTER AND ENGINEERING NEWS M A R I N E L I N K . C O M ISSN-0025-3448 USPS-016-750 No. 4 Vol. 86 Maritime Reporter/Engineering News (ISSN # 0025-3448) is published monthly Cooper Fischer Goldberg except for March, July, and October by Maritime Activity Reports, Inc.

-

)

January 2024 - Maritime Reporter and Engineering News page: 33

)

January 2024 - Maritime Reporter and Engineering News page: 33WEG Ship Designer(s): Foreship (outline) RMC (build) Engine controls: Wärtsilä (Valmarine) Delivery Date: August 2021 Radars: Wärtsilä (SAM) Classi? cation: DNV, Finnish Ice Class 1A Super; SOLAS 2020; Depth Sounders: Wärtsilä (SAM) Stockholm Agreement Auto Pilot: Wärtsilä (SAM) Flag:

-

)

November 2023 - Maritime Reporter and Engineering News page: 55

)

November 2023 - Maritime Reporter and Engineering News page: 55, a frequent requirement for many grant programs; lining up political support; and registering for grant information on the websites Grants.gov and Sam.gov. This kind of pre-positioning work can increase grant award success, identify funding streams and allow for greater emphasis on performance measuremen

-

)

November 2023 - Maritime Reporter and Engineering News page: 42

)

November 2023 - Maritime Reporter and Engineering News page: 42on board for al- ternative energy sources without having to replace the electric Volvo Penta and propulsion system. CMB.TECH have collaborated to Sam Gombra, co-founder of ÈTA Shipping, came up with create dual-fuel, a highly ? exible solution for a coastal cargo ship. The design, hydrogen engines

-

)

September 2023 - Marine Technology Reporter page: 31

)

September 2023 - Marine Technology Reporter page: 31suite for fully autonomous, AUV ro- The company produces three main product lines: Pro? l- botic systems without any human in the loop that could ers, Samplers, and Flotation. Samplers include Sediment easily integrate across independent component capabili- Traps, the Remote Access Sampler (RAS), Particle

-

)

July 2023 - Marine Technology Reporter page: 45

)

July 2023 - Marine Technology Reporter page: 45Data Processing FORCE Technology introduced a Corrosion and BlueStream launched GeoAcoustics released GS4 soft- new generation of its P-Scan ultra- ‘ICCP-SAM’, touted as sustainable ware v1.0.25 for GeoSwath bathy- sound scanner for subsea inspections. P- corrosion protection of XX(X)L mono- metric sonars

-

)

January 2023 - Maritime Reporter and Engineering News page: 9

)

January 2023 - Maritime Reporter and Engineering News page: 9about those items we did not test. There are many common testing practices that break the audit effect entirely. One such example is giving the same test to multiple learn- ers. Doing so will create an incentive in them to share the test details, removing their incentive to study broadly and our

-

)

November 2022 - Marine News page: 19

)

November 2022 - Marine News page: 19Column Washington Watch training and licensing, inland waterways, harbor improve- Democrats retain control and Rep. Sam Graves (R-Mo.), ments, coastal zone management, both the U.S. Coast the current Ranking Member of House T&I, is the most Guard Academy and the U.S. Merchant Marine Academy likely

-

)

October 2022 - Marine News page: 40

)

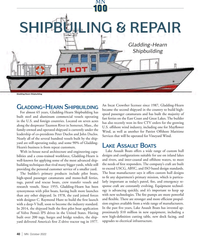

October 2022 - Marine News page: 40MN Gladding-Hearn Shipbuilding Gladding-Hearn Shipbuilding An Incat Crowther licensee since 1987, Gladding-Hearn G -H SLADDING EARN HIPBUILDING became the second shipyard in the country to build high- For almost 65 years, Gladding-Hearn Shipbuilding has speed passenger catamarans and has built the

-

)

May 2022 - Marine Technology Reporter page: 27

)

May 2022 - Marine Technology Reporter page: 27I have bene? tted over time from members of the marine community who shared their expertise and enthusiasm with me. From earlier days at Benthos, Sam Raymond and Robert Catalano stand out in my memory. I learned so much working with the TR-6000. Jim Teague, then at Emerson-Cuming/Grace Syntactics

-

)

May 2022 - Marine News page: 40

)

May 2022 - Marine News page: 402025. value of this contract to $142,906,420. The contract was The YRBM barge is an ABS A1 Accommodation Barge competitively procured via the beta.sam.gov website, with with a 151’-4” x 49’-4” x 14’ footprint. The vessel provides six offers received. pier side living accommodations capable of berthing

-

)

March 2022 - Marine Technology Reporter page: 36

)

March 2022 - Marine Technology Reporter page: 36c community. In 2018, true to this to support dives down to 200 m. It can also use a dynamic goal, the ? rst Submaran (it’s initial name) mission saw it sam- buoyancy system to loiter or operate something like a glider, pling seawater for harmful algal bloom (HAB) cells and tox- and/or its dual thrusters

-

)

March 2022 - Marine Technology Reporter page: 26

)

March 2022 - Marine Technology Reporter page: 26species observed by the landers and preserved in the MVC could be evidence of a change in the system. This result supports the need for more and diverse sam- pling efforts in ecological research and proves ef? cacy of the landers as tools to study nearshore submarine canyon communities. Pico-D180: Swell

-

)

March 2022 - Maritime Reporter and Engineering News page: 36

)

March 2022 - Maritime Reporter and Engineering News page: 36c community. In 2018, true to this to support dives down to 200 m. It can also use a dynamic goal, the ? rst Submaran (it’s initial name) mission saw it sam- buoyancy system to loiter or operate something like a glider, pling seawater for harmful algal bloom (HAB) cells and tox- and/or its dual thrusters

-

)

March 2022 - Maritime Reporter and Engineering News page: 26

)

March 2022 - Maritime Reporter and Engineering News page: 26species observed by the landers and preserved in the MVC could be evidence of a change in the system. This result supports the need for more and diverse sam- pling efforts in ecological research and proves ef? cacy of the landers as tools to study nearshore submarine canyon communities. Pico-D180: Swell

-

)

September 2020 - Marine Technology Reporter page: 49

)

September 2020 - Marine Technology Reporter page: 49UC San Diego students Mi- chelle Sit, Raymond Young, Hunter Woodruff, and Jacob Springman collaborate via Zoom on their team project, which is sponsored by Boe- ing. The group is developing a software suite of autonomous unmanned surface vehicle be- haviors that could help scien- tists monitor the

-

)

September 2020 - Marine Technology Reporter page: 46

)

September 2020 - Marine Technology Reporter page: 46technology to oth- er needs, like endangered species and environmental impact assessments. One of the biggest hurdles was that eDNA tools require custom sampling equipment and expert users to gen- erate useful data and insights. The project looked speci? cally at GenBank, an admittedly clunky software

-

)

January 2022 - Marine Technology Reporter page: 56

)

January 2022 - Marine Technology Reporter page: 56Who’s News? Latest People & Company News Photo Courtesy NOC Photo Courtesy NOC Professor Ed Hill receiving CBE insignia from HRH The Duke of Cambridge. Obituary: Raymond Pollard upper ocean. He led numerous major Professor Ed Hill Honored Obituary: Raymond Pollard The National Oceanography Center’s The

-

)

January 2022 - Marine Technology Reporter page: 43

)

January 2022 - Marine Technology Reporter page: 43set of NEL-San Diego. He had to solve the “core extraction problem” strengths and weaknesses, often complementary to another caused by gloppy mud. Sam Raymond and Benthos turned this idea into a product it sold for years called the Pogo Corer. class. Ocean Landers are the oldest, but an overlooked plat- form

-

)

December 2021 - Maritime Reporter and Engineering News page: 44

)

December 2021 - Maritime Reporter and Engineering News page: 44, Clittaford Road Southway, RUST AND PAINT REMOVAL Plymouth, Devon PL6 6DE United Kingdom , UK , tel:+44 (AIS) AND VHF DATA EXCHANGE Rustibus, 2901 WEST SAM HOUSTON PKWY, N. SUITE (0) 1752 723330, [email protected] E-325 HOUSTON, TX 77043 , tel:(832) 203-7170, fax:(832) SYSTEM (VDES) NAVAL ARCHITECTS

-

)

November 2021 - Maritime Reporter and Engineering News page: 75

)

November 2021 - Maritime Reporter and Engineering News page: 75, Clittaford Road Southway, RUST AND PAINT REMOVAL Plymouth, Devon PL6 6DE United Kingdom , UK , tel:+44 (AIS) AND VHF DATA EXCHANGE Rustibus, 2901 WEST SAM HOUSTON PKWY, N. SUITE (0) 1752 723330, [email protected] E-325 HOUSTON, TX 77043 , tel:(832) 203-7170, fax:(832) SYSTEM (VDES) NAVAL ARCHITECTS

-

)

October 2021 - Marine News page: 26

)

October 2021 - Marine News page: 26M N 0 0 1 SHIPBUILDING & REPAIR EASTERN SHIPBUILDING GROUP synonymous with pilot boats, having built more launches cal charities year on year. In Galveston, Gulf Cooper has than any other shipyard. In 1978, the yard joined forces expanded the economic growth since taking over the Todd with designer C.