Teresa Drugatz

-

- Online Monitoring Systems Can Improve Your Bottom Line Maritime Reporter, Mar 2014 #22

All operators, regardless of vessel type, size, location or function, are plagued by the same worries: “When will my next outage happen, and what is it going to cost me?” In an effort to ease these concerns, millions of dollars are invested every year into commercial/workboat maintenance programs. But how can maintenance be maximized without blowing budgets? What’s the most thorough way to monitor equipment? How can all mechanical components be watched for possible issues and failures? According to Rich Merhige, President of Advanced Mechanical Enterprises, a South Florida mechanical engineering services firm, these answers can be found in the oil and gas industries, in the form of online monitoring systems.

What is online performance monitoring? Today, online performance monitoring can be described as the process of gathering data from machinery to assess the overall operating capacity of the system it is a part of. Data is compared either against an existing database (trending), or a model (model-based), to diagnose existing issues and show the beginnings of wear and tear on mechanical components.

Technically speaking, “engine” diagnostics, and performance monitoring go back to the 1700s. These “primitive” forms of monitoring where ahead of their times and monitored cylinder pressure with steam engines, then diesel engines, and later critical compressors and engines. Portable diagnostic monitoring really gained footing in the 1960s, when oscilloscopes were used for data collection and analysis in the field. Over the next 30 years, these systems increased in popularity and became known for their successes. In the 1990s, amongst rapidly evolving technology, and, a booming economy, the oil and gas industry (primarily in gas compression) started utilizing online monitoring as an extension of the successful use of portable engine and compressor analyzers. Over the last two decades, these systems have evolved rapidly as the hardware computing power and software capabilities have advanced. Data collection used to take days to collect and analyze on mechanical systems using hand calculations. This can now be done instantaneously and presented in easily readable graphics and reports.

With a need to provide ship operators with better forms of maintenance to forecast problems in an efficient and timely manner, engineering professionals, such as Merhige, have started to apply this technology to the maritime industry. His system of choice? The 6320/PA by Windrock. Windrock’s portable analyzers and fixed systems have enjoyed much success in the oil and gas industries worldwide. Engineers and maintenance professionals use Windrock’s products, both portable and stationary, to monitor, analyze, and troubleshoot machinery. Data can be collected from reciprocating and rotating machinery to trend stress, vibration, proximity, cylinder pressure and temperature. In this capacity, the products have been utilized by big oil to track vital pieces of equipment like compression trains, pumps, reciprocating engines and even specific components like cylinders, injectors, liners, bearings, valves, rings, and crankshafts. By utilizing systems such as these, remote engineering has become very real, allowing for non-intrusive monitoring on a consistent basis with minimal supervision, which translates to minimal expense. What does the marine industry stand to gain from these systems? How can ship operators facilitate an online monitoring program, and what will it mean for their budgets?

Windrock, like many of the other online monitoring systems currently on the market, has its roots in oil and gas, so their technologies and capabilities tend to be tried, tested and perfected to avoid the financial blunders of an unplanned outage. This has given them, particularly Windrock with their portable and on-line systems, a reputation for being reliable, which has increased its popularity with military fleets, such as the U.S. Navy, U.S. Coast Guard, Royal Canadian Navy and the Spanish Navy (Armada Española). It’s only natural that the workboat sector should, and will follow suite, especially since this is proving to be a perfect tool to enhance condition based monitoring.

“For years, I have been an advocate of online monitoring systems, namely the Windrock On-Guard family of products, which we often recommend to our commercial and workboat clients.” said Merhige. “By collecting data over an extended period of time, remotely, you can get a very accurate picture of what is going on mechanically. Because the data collection is done from afar, minimal labor is needed, making it extremely affordable and attractive to maintenance professionals. By way of gathering a constant stream of data, you’re in the best possible position to prevent catastrophic failures, which is always something of great interest to ship operators. When their bottom line is better, it makes them look better.”

An online monitoring system can be installed and setup on a vessel’s machinery in a short time frame with a minimal amount of downtime. The sensors would be placed on engines, gear boxes, frames, and cylinder heads. Once set it place data collection can begin immediately, and, within only 15 minutes, it could produce readings that can be analyzed. Traditionally, scheduled maintenance programs have been the norm, whereas mechanical elements are periodically checked based on manufacturers’ recommendations, similarly to how we take our cars to get oil changes at recommended intervals. With the newer technology emerging, such as these online performance monitoring systems, traditional methods of maintenance are being replaced by predictive maintenance programs, thereby reducing budgets tremendously. According to the Electrical Power Research institute scheduled maintenance programs cost about $24 per horsepower. Another option typically employed, but not recommended, corrective/reactive maintenance, which comes in averaging $17 per horsepower. This, however, doesn’t put a price tag on the other factors involved in this scenario, like downtime costs, and stress. When a predictive maintenance program is in place, such as condition monitoring by online systems, you can reduce your costs to around $9 per horsepower, which is a huge savings. Another reason why engineers love these systems is because they’ve been designed to reduce maintenance schedules by about 20,000 hours. With reduced hours, minimal downtime, and non-invasive monitoring, budgets remain just as healthy as equipment.

“Class has also recognized the inherent value in condition based monitoring and has issued guidelines for implementing such programs. Another benefit: with the switch from diesel to dual fuel engines, enhanced monitoring will provide further information on the mechanical health of the engines and the condition of the control systems for the controlling of cylinder pressures,” explained Ed Kelleher Manager of International Sales, Windrock. “auto-balancing” of cylinder firing pressures with the patented Windrock AutoBalance system on larger natural gas engines has been successfully used to control emissions, reduce fuel costs and reduce the overall mechanical degradation of mechanical components due to imbalances.”

“The push towards online monitoring is a progressive and exciting movement in the maritime industry,” commented Merhige. “Besides the economic benefits to maintenance budgets, this is also a cost effective way to be more “green,” by increasing, and maintaining mechanical efficiency and optimization. This is becoming increasingly important to companies that own and operate these vessels.”

What online monitoring boils down to is working smarter, rather than harder. And, as this technology is quickly and continuously evolving, “smarter” is only going to get easier and more economical for operators.

The Authors

Rich Merhige has over 31 years of condition monitoring experience. He founded/is President of AME, which is recognized as an external specialist for condition monitoring by ABS.

[email protected]

Teresa Drugatz joined AME in 2010 as Office/Marketing Manager. She holds a bachelor of science in communication from the University of Miami.

[email protected]

(As published in the March 2014 edition of Maritime Reporter & Engineering News - www.marinelink.com)

-

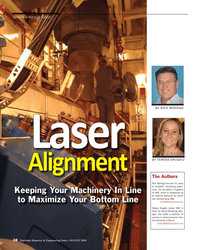

- Keeping Machinery in Line with Laser Alignment Maritime Reporter, Aug 2014 #38

experience. He founded/is President of AME, which is recognized as an external specialist for condition monitoring by ABS. [email protected] Teresa Drugatz joined AME in 2010 as Office/Marketing Manager. She holds a bachelor of science in communication from the University of Miami. teresa@AMEsolutions

-

)

November 2019 - Maritime Reporter and Engineering News page: 77

)

November 2019 - Maritime Reporter and Engineering News page: 77of medi- cal care. In reality, no one in this freight Supplier of electric hawser and tow winches for market can afford those costs; certainly M/V Delta Teresa not on an international, multi-national scale. Alternatively, shipowners can roll International Workboat Show 2019 December 4-6 the dice and hope

-

)

November 2017 - Maritime Reporter and Engineering News page: 94

)

November 2017 - Maritime Reporter and Engineering News page: 94also had Advanced Mechanical Enterprises Chester Springs, PA With a lifting capacity ranging from 2 ton to be accepted as a “standard” product, e: [email protected] Ee: [email protected] meters to 300 ton meters, Effer Knuck- equivalent or superior to its domestic www.amesolutions.com www

-

)

August 2017 - Marine News page: 18

)

August 2017 - Marine News page: 18AME Appleton Marine, Aspin Kemp & Solutions Inc. Associates (AKA) 217 SW 28th St Fort Lauderdale, FL 33315 Tel: (954) 764-2678 E-mail: [email protected] Website: amesolutions.com 23 Brook Street CEO/President: Richard Merhige Montague, PE COA 1RO Canada Tel: (519) 270-5840 THE COMPANY: E-mail:

-

)

September 2016 - Marine Technology Reporter page: 10

)

September 2016 - Marine Technology Reporter page: 10and inside the ship. tory at age 10. documenting the wreck; together they created the ? rst-ever Just four years later, growing up near the Santa Teresa foot- 3-D map of her tangled and scattered remains. Preserving Ti- hills in San Jose, California (now famed as “Silicon Valley”), tanic’s legacy for

-

)

August 2016 - Marine News page: 18

)

August 2016 - Marine News page: 18Lauderdale, FL 33315 Email: [email protected] Tel: (504) 831-3685 Tel: (954) 764-2678 Website: www.beieris.com Email: [email protected] Email: [email protected] CEO/President: Karl Beier Website: www.bakerlyman.com Website: http://amesolutions.com CEO/President: Corinne Titus CEO/President:

-

)

June 2016 - Maritime Reporter and Engineering News page: 69

)

June 2016 - Maritime Reporter and Engineering News page: 69569269 POTOMAC Tank Barge 78,000 Kirby Offshore Marine 7026900 TASMAN SEA 1193787 DBL 104 Tank Barge 101,129 Kirby Offshore Marine 9175016 TERESA 1049252 ACADIA Tank Barge 136,000 Kirby Offshore Marine 7005841 VALIANT 630287 EVERGLADES Tank Barge 175,000 Kirby Offshore Marine 7309780

-

)

June 2016 - Maritime Reporter and Engineering News page: 35

)

June 2016 - Maritime Reporter and Engineering News page: 35later, growing up near dive while working as an historian and remains. Preserving Titanic’s legacy for plorers. The man who has spent more the Santa Teresa foothills in San Jose, archaeologist for the National Park Ser- future generations is, like all the work than 43 years immersed in the world of Californi

-

)

November 2014 - Maritime Reporter and Engineering News page: 38

)

November 2014 - Maritime Reporter and Engineering News page: 38. He founded/is President of AME, which is recognized as an external specialist for condi- tion monitoring by ABS. [email protected] Teresa Drugatz joined AME in 2010 as Offi ce/Marketing Man- ager. She holds a bachelor of science in communication from the University of Miami. teresa@AMEsolu

-

)

August 2014 - Maritime Reporter and Engineering News page: 38

)

August 2014 - Maritime Reporter and Engineering News page: 38experi- ence. He founded/is President of AME, which is recognized as an external specialist for condi- tion monitoring by ABS. [email protected] Drugatz joined AME in 2010 as Of Þ ce/Marketing Man- ager. She holds a bachelor of science in communication from the University of Miami. teresa@AMEsolutions

-

)

September 1978 - Maritime Reporter and Engineering News page: 32

)

September 1978 - Maritime Reporter and Engineering News page: 32and Quebec and representatives of in- dustry, the traditional bottle of champagne was broken against the hull of the 5 De Septiembre by Mrs. Maria Teresa Rordiguez de Alzugaray, wife of the Consul General of Cuba in Montreal. The new tanker is of the Marindus design originated by Marine Industrie

-

)

March 2014 - Maritime Reporter and Engineering News page: 23

)

March 2014 - Maritime Reporter and Engineering News page: 23. He founded/is President of AME, which is recognized as an external spe- cialist for condition monitoring by ABS. [email protected] Teresa Drugatz joined AME in 2010 as Offi ce/ Marketing Manager. She holds a bachelor of sci- ence in communication from the University of Miami. teresa@AMEsoluti

-

)

March 2014 - Maritime Reporter and Engineering News page: 2

)

March 2014 - Maritime Reporter and Engineering News page: 2USCG takes center stage. By Dennis L. Bryant 22 PREVENTATIVE MAINTENANCE Online monitoring systems can improve your bottom line. By Rich Merhige & Teresa Drugatz 28 USCG: THE FLEET FACES FORWARD The Coast Guard is perpetually reinventing itself, and is embarked on a historic program to bring online

-

)

March 1992 - Maritime Reporter and Engineering News page: 96

)

March 1992 - Maritime Reporter and Engineering News page: 96Columbia. The theme of the show will be "The Towing Industry in a Modern Environment." For further information, contact: Peter Woodward or Teresa Ledesmaat(604) 687-9677, or B.C. Towboat Industry Conference, 200- 1575 West Georgia Street, Vancouver, British Columbia V6G 2V3 Canada; telephone:

-

)

October 1973 - Maritime Reporter and Engineering News page: 32

)

October 1973 - Maritime Reporter and Engineering News page: 32New York Shipbuild- ing Corp. property. The lighter is an ex-Navy berthing barge. McAllister operates 10 vessels in the port, including the powerful Teresa McAllister, which is especially outfitted with flanking rud- ders and Kort nozzle for increased maneuver- ability and power. For the last five

-

)

June 15, 1969 - Maritime Reporter and Engineering News page: 4

)

June 15, 1969 - Maritime Reporter and Engineering News page: 4U.S.-Flag Ship Designed j^be^AndMessef5 To Carry Refrigerated Anhydrous Ammonia Division Vice"Pre!^!± Marine Eagle is escorted on her first trip by the Teresa Moron of Moran Towing and Transportation Company. Ernest W. Neben Elwin Messer H. Lee White, president of Marine Trans-port Lines, Inc., has announced

-

)

October 2013 - Maritime Reporter and Engineering News page: 22

)

October 2013 - Maritime Reporter and Engineering News page: 22ex-perience. He founded/is President of AME, which is recognized as an external specialist for condition moni-toring by ABS. E: [email protected] Drugatz joined AME in 2010 as Mar-keting Manager. She holds a bachelor of science in com-munication from the Univer- sity of Miami. E: teresa@amesolutions

-

)

October 2013 - Maritime Reporter and Engineering News page: 4

)

October 2013 - Maritime Reporter and Engineering News page: 422 HOW WELL DO YOU LISTEN?Predictive, preventative maintenance using vibration analysis can save a lot of time and money. By Rich Merhige & Teresa Drugatz INSURANCE 24 HIDDEN EXPOSURE CAN SINK A BUSINESSShip repairers and equipment installers take heed, as hidden exposure can severely damage your

-

)

August 2013 - Maritime Reporter and Engineering News page: 32

)

August 2013 - Maritime Reporter and Engineering News page: 32plays includ-ing the pre-salt. In March 2013, Jon Willmann CFO and Deputy CEO for Sevan Drilling, gave a presentation at the exclusive Ho-tel Santa Teresa in the hills overlooking Rio de Janeiro. According to Willmann the company has a management and op-erating organization well positioned for further

-

)

July 2013 - Marine News page: 36

)

July 2013 - Marine News page: 36. Geo Shipyard Inc. recently delivered the R/V Apalachee?, an aluminum catamaran for Florida State University Coast- al and Marine Laboratory, St Teresa, Florida. Designed by Fyffe Yachts with NC lofting by Eli Ring, VP of Advance Fabricating, both of Kemah, Texas, the 48 passenger T-boat will support

-

)

June 1998 - Maritime Reporter and Engineering News page: 151

)

June 1998 - Maritime Reporter and Engineering News page: 151PASS/RoRo CARGO SHIP 1998 PENDIK 030 4 500 OIL PROD. TANKER 1999 PENDIK 022 4 000 RoRo CARGO SHIP 1999 PENDIK 023 4 000 RoRo CARGO SHIP 1999 EMILIA TERESA 2 900 CHEM. TANKER 1998 UAE004054 — UAE DUBAI DRYDOCKS S9990 320 TUG 1998 UDL Engineering Pte. Ltd. — Singapore UDL SINGAPORE 8629 3 300 OIL

-

)

March 1998 - Maritime Reporter and Engineering News page: 36

)

March 1998 - Maritime Reporter and Engineering News page: 36ft. (62 m) Beam 159 ft. (49 m), including bridge wing Draft 26 ft. (8 m) Flag Liberia Ship builder Fincantieri, Italy Designer Giacomo Mortola, Teresa Anderson Classification Lioyds and Rina Tonnage 109,000 Decks 18 1 /1 Engines (2) fixed propellers Propulsion Siemens Electric propulsion

-

)

February 1999 - Maritime Reporter and Engineering News page: 39

)

February 1999 - Maritime Reporter and Engineering News page: 39of the cafe expanded its size to 10,000 sq. ft., and the seat- ing capacity to approximately 400. The new interiors were designed and configured by Teresa Anderson of Princess Cruises and Giacomo Mortola of GEM. The ship was dry- docked at Cascade General in Portland, Ore. for the work. Circle

-

)

December 1994 - Maritime Reporter and Engineering News page: 16

)

December 1994 - Maritime Reporter and Engineering News page: 16plant in Hanover, Md., and also from its Cana- dian facility near Toronto, Ontario. Dunagin Named Boston Whaler's Marketing/PR Manager Teresa Dunagin has been promoted to man- ager of marketing, communications and public relations for Boston Whaler. Ms. Dunagin joined the Edgewater,

-

)

December 1993 - Maritime Reporter and Engineering News page: 64

)

December 1993 - Maritime Reporter and Engineering News page: 64Materials (ASTM) Shipbuilding and Operation in the 21st Cen- tury: December 8, Hyatt Regency Dallas-Fort Worth Airport, Dallas, Texas Contact: Teresa Cendrowska, tel: (215) 299-5546 or Terry Kaminski, tel: (215) 299-5513, ASTM, 1916 Race Street, Philadelphia, Pa. 19103. JANUARY 1994 84th