Virginia Ship

-

- Synergies Foster Shipyards Success Maritime Reporter, Jan 2014 #26

In the U.S. and across the globe, shipyards create solid, long-term economic stability in their regions. Ship construction and repair requires an extraordinary amount of expertise, time and resources. This work is made even more challenging because current economic pressures drive companies to reduce costs wherever possible without hindering production or quality. Having multiple shipyards in a region creates a naturally interdependent, yet highly competitive culture. This is because the industry shares a geographically close environment and has to rely on shared resources to protect common interests even while competing for projects. Shipyards have the potential to create innovative cultures because their master craftsmen have perfected techniques, efficiencies and quality controls that can be passed down to apprentice levels. This frees up the craftsmen’s time to further improve upon existing practices. Competition could impede synergies that would potentially strengthen the industry as a whole. Even though companies seek competitive advantages, they must maintain a focus on commonalities to ensure collaboration on overall industry expertise and capacity improvements. In Virginia, we have nine shipyards, 250+ companies and more than 40,000 workers working in the industry. The synergies that emerge from interdependent environments can breed efficiency and innovation. Companies in Virginia realize that working together on specific cost-saving projects can benefit the entire industry without diminishing their individual business advantages.

These companies have several examples of collaborative projects that have resulted in identifying key elements that make joint efforts more likely to succeed. For example, ship work is extremely challenging from a safety perspective, and requires a high level of diligence and preventative measures. In Virginia, shipyards have implemented a common Safety Orientation. This provides all workers access to consistent resources that establish baseline expectations. This reduces costs by eliminating duplicate training, while helping to prevent misunderstandings when projects are performed by multiple companies on the same ship. The ability for an individual shipyard to singularly control their working environments is also complicated by having such a highly fluid workforce. Shipyard workers who have acquired a great deal of expertise over time may work at multiple facilities to accomplish complex jobs. This may cause challenges in the area of quality assurance. To address this issue, the companies collectively created a quality assurance audit program. The program allows all companies to utilize a common system of standards which eliminates the need for multiple audits and allows the yards to collectively monitor where improvements might be made. This audit program provides cost savings for everyone. The success of these two examples involved consistent commitment from dozens of companies.

The following list outlines key elements identified by these companies that make such joint efforts more likely to succeed.

1. Find the point of synergy. This is the target identified that affects all companies equally without infringing on competitive advantage. Safety and quality mentioned above are examples of common core issues that impact every company in our industry.

2. Leadership. Everyone is invited to the table, but the largest and most relevant companies must believe that addressing a particular point of synergy has benefits for everyone and is worth an investment of their time and resources.

3. Neutral Facilitation. The administration and execution regarding the point of synergy should be facilitated by a neutral party. It is important that no one competitor thinks another one is driving the train to their own advantage. Even though some companies may benefit more than others, or the effort may be more strongly supported by some companies than others, the neutral party takes the role of keeping the focus on what is advantageous to the industry overall. In Virginia, the industry association may serve in this capacity, usually through a committee and staff liaison that gathers inputs to ensure everyone has the opportunity to contribute.

4. Recognition of differences. Inevitably, companies will at times reject part of a proposal because they have a different philosophy, practice or need. These are recognized, but the group continually goes back to keeping the focus on the synergy point and drives the group to a consensus on solutions that do not diminish business autonomy, but employs commonalities.

5. Key Ground Rule: Highest Standard. No matter what individual company practice or expectation exists, the standard for the project is to use the higher level practice to establish the common expectation. This often resolves issues that arise when recognizing differences. For example, some of yards have different safety requirements: While cloth safety shoes are acceptable under federal regulations, companies agree the leather option is better for shipyard environments and should be the one presented in the safety orientation. Although each individual company may enforce that standard differently, they all as agree it is the expectation to be taught.

6. Frequent meetings with minimal scheduling changes. Collaboration projects take a lot of attention, focus and man hours. Meeting often with consistency initially is imperative to maintain the flow of discussion and decisions. Always providing thorough notes on decisions and progress is important to keeping the group moving forward. As work progresses, meeting frequency may be reduced.

7. Implementation. There must always be a few companies that agree to be the first out of the gate in testing and implementing. This provides the opportunity to tweak any issues that arise, as well as to help with promotion and broad dissemination.

8. Quarterly or annual reviews must be established for the resolution of issues and keeping updates to maintain the integrity and quality of the initiative.

Internationally, the shipbuilding and repair industry is continuously subject to increased economic pressures, material resource constraint and skilled workforce issues.

A valuable resource would be for an appropriate organization to create a forum where points of synergy could be identified so collaboration efforts can be leveraged.

The Authors

William W. “Bill” Crow, President of the Virginia Ship Repair Association, is a retired 30 year Navy Surface Warfare Officer heavily involved in fleet maintenance. His last Navy Command assignment included extensive oversight of collaboration efforts regarding the consolidation of Navy-Army installations.

Michelle L. Tomaszewski, Ph.D. has worked with VSRA for nine years developing new initiatives. She has 20 years of experience facilitating public-private partnerships in workforce and economic development for maritime and manufacturing industries.

(As published in the January 2014 edition of Maritime Reporter & Engineering News - www.marinelink.com)

-

- Insights: John Lotshaw, Gulf Coast Director of Training and Workforce Development Ingalls Shipbuilding Marine News, Jul 2013 #12

not either. We are trying to get the word out about this effort. Our membership currently includes several trade associations, including GSSC and the Virginia Ship Repair Association. We have presented at a number of conferences and association meetings across the country. NMEC is a membership-based organization

-

- Apprenticeship Training & Academic Degree: The Pathway to Success Maritime Reporter, Nov 2013 #64

my four years, and graduated from with my Associate’s Degree in Maritime Technologies from Tidewater Community College as valedictorian. I was also Virginia Ship Repair Association (VSRA) Junior Tradesman of the Year for the area. My instructor was my mentor. He was very knowledgeable, and I really looked

-

- Beyond Shipbuilding: Training and Recruitment Maritime Logistics Professional, Q4 2013 #24

used to train workers should not either. Today’s NMEC membership of 20+ organizations includes several trade associations, including GSSC and the Virginia Ship Repair Association and some larger, Gulf Coast-based shipyards. Once the programs have had time to prove their mettle and get benchmarked, that’s

-

)

March 2024 - Marine Technology Reporter page: 45

)

March 2024 - Marine Technology Reporter page: 45ronments. The new agreement will address speci? c techni- cal gaps in the UUV defense and offshore energy markets especially for long duration, multi-payload mission opera- tions where communications are often denied or restricted. As part of the new alliance, Metron’s Resilient Mission Autonomy portfolio

-

)

March 2024 - Marine Technology Reporter page: 36

)

March 2024 - Marine Technology Reporter page: 36LANDER LAB #10 Of special interest for marine applications, LiPo batteries are Shipping any kind of lithium battery can be a challenge, and offered in a “pouch” design, with a soft, ? at body. The pouch IATA regs vary with the batteries inside or outside an instru- is vacuum-sealed, with all voids ?

-

)

March 2024 - Marine Technology Reporter page: 11

)

March 2024 - Marine Technology Reporter page: 11assist in identifying mines and act as a neutralization device. About the Author Bottom mines pose even greater chal- David R. Strachan is a defense analyst and founder of lenges. Unlike contact mines, bottom Strikepod Systems, a research and strategic advisory mines utilize a range of sensors to

-

)

March 2024 - Marine Technology Reporter page: 7

)

March 2024 - Marine Technology Reporter page: 7Set a Course for your Career Become a NOAA professional mariner! Sail with NOAA’s fleet of research marinerhiring.noaa.gov 1-833-SAIL-USA (724-5872) and survey ships! - Detects all iron and steel Get your next salvage - Locate pipelines, anchors and job done faster chains with a JW Fishers

-

)

April 2024 - Maritime Reporter and Engineering News page: 46

)

April 2024 - Maritime Reporter and Engineering News page: 46MARKETPLACE Professional www.MaritimeProfessional.com GILBERT ASSOCIATES, INC.GILBERT ASSOCIATES, INC. Naval Architects and Marine Engineers SHIP DESIGN & ENGINEERING SERVICES Join the industry’s #1 Linkedin group )NNOVATION

-

)

April 2024 - Maritime Reporter and Engineering News page: 43

)

April 2024 - Maritime Reporter and Engineering News page: 43“The industry is an ecosystem which includes owners, managers, mariners, shipyards, equipment makers, designers, research institutes and class societies: all of them are crucial,” – Eero Lehtovaara, Head of Regulatory & Public Affairs, ABB Marine & Ports All images courtesy ABB Marine and Ports provi

-

)

April 2024 - Maritime Reporter and Engineering News page: 42

)

April 2024 - Maritime Reporter and Engineering News page: 42OPINION: The Final Word Seeing the Ship as a System Shipping must engage with the decarbonization realities that lie ahead by changing the way it crafts maritime legislation to re? ect its place in the interconnected, interdependent world economy, said Eero Lehtovaara, ABB Marine & Ports. ABB Marine &

-

)

April 2024 - Maritime Reporter and Engineering News page: 41

)

April 2024 - Maritime Reporter and Engineering News page: 41Nautel provides innovative, industry-leading solutions speci? cally designed for use in harsh maritime environments: • GMDSS/NAVTEX/NAVDAT coastal surveillance and transmission systems • Offshore NDB non-directional radio beacon systems for oil platform, support vessel & wind farm applications

-

)

April 2024 - Maritime Reporter and Engineering News page: 40

)

April 2024 - Maritime Reporter and Engineering News page: 40TECH FEATURE SITUATIONAL AWARENESS SITUATIONAL AWARENESS SYSTEM BATTLES COGNITIVE FATIGUE IN WATCHKEEPERS All images courtesy Groke Technologies Today’s evolving maritime security risks pose all-too-familiar threats to international shipping, and as just one of the many causes of fatigue, they add

-

)

April 2024 - Maritime Reporter and Engineering News page: 39

)

April 2024 - Maritime Reporter and Engineering News page: 39Tech Files Latest Products, Systems and Ship Designs “Wall Climbing Robot” Danish Pilot calls gets ClassNK Nod LEGO Model "A tribute build to a work life at sea" Image courtesy MOL, Sumitomo Heavy Industries lassNK granted its Innovation Endorse- Image courtesy Espen Andersen/DanPilot ment for

-

)

April 2024 - Maritime Reporter and Engineering News page: 38

)

April 2024 - Maritime Reporter and Engineering News page: 38Tech Files Latest Products, Systems and Ship Designs Zero-Emission Mooring Service of a Tanker Consulmar achieved a milestone by executing what it calls ing boat Castalia, which operates on full electric propulsion. the world's ? rst zero-emissions mooring service for a tanker. Equipped with two 150 kW

-

)

April 2024 - Maritime Reporter and Engineering News page: 37

)

April 2024 - Maritime Reporter and Engineering News page: 37SIMULATION "A simulated vessel ? ooding can help teams work together to solve the challenge using different systems on the bridge." – Jussi Siltanen, Lead, "The gami? cation of Product Marketing, learning makes it fun." Safety Solutions at NAPA – Captain Pradeep Chawla, Founder, MarinePALS Image

-

)

April 2024 - Maritime Reporter and Engineering News page: 35

)

April 2024 - Maritime Reporter and Engineering News page: 35SIMULATION e have a close relationship with tech- Realism is prized beyond immersive, photo-realistic visu- nology, evidenced by, for example, als, and providers are introducing increasingly accurate func- the phones we are estimated to un- tionality. FORCE Technology’s upcoming DEN-Mark2 math- lock around

-

)

April 2024 - Maritime Reporter and Engineering News page: 34

)

April 2024 - Maritime Reporter and Engineering News page: 34FEATURE Image courtesy Kongsberg Digital Simulators Track our Changing Relationship with Technology Simulation-based training has its whole-of-ship/ whole-of-team scenarios, but zooming in, the industry is now working on more speci? c targets. By Wendy Laursen Image above: Kongsberg Digital has integrated

-

)

April 2024 - Maritime Reporter and Engineering News page: 29

)

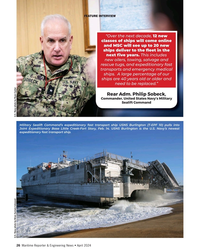

April 2024 - Maritime Reporter and Engineering News page: 29RADM PHILIP SOBECK, MILITARY SEALIFT COMMAND U.S. Navy photo by Bill Mesta/released U.S. Navy photo by Ryan Carter Rear Adm. Philip Sobeck, Commander, United States Navy’s Military Sealift Command, visits USNS Patuxent (T-AO 201) for a tour of the ship at Naval Station Norfolk, Va., November 20, 2023.

-

)

April 2024 - Maritime Reporter and Engineering News page: 28

)

April 2024 - Maritime Reporter and Engineering News page: 28FEATURE INTERVIEW track missiles and warheads for the Mis- sile Defense Agency, and it travels with its support ship, the MV Hercules. For our Service Support ships, we have the two hospital ships, USNS Mer- cy and Comfort; two rescue and salvage ships; two submarine tenders; and the Sixth Fleet ?

-

)

April 2024 - Maritime Reporter and Engineering News page: 27

)

April 2024 - Maritime Reporter and Engineering News page: 27RADM PHILIP SOBECK, MILITARY SEALIFT COMMAND With COVID, we had to make some hard choices for our Do your CIVMARs have upward mobility? mariners because we couldn’t rotate. Many of our mariners The Navy has Sailors who become “Mustangs,” and work found other employment, and were able to use their skills

-

)

April 2024 - Maritime Reporter and Engineering News page: 26

)

April 2024 - Maritime Reporter and Engineering News page: 26FEATURE INTERVIEW “Over the next decade, 12 new classes of ships will come online and MSC will see up to 20 new ships deliver to the ? eet in the next ? ve years. This includes new oilers, towing, salvage and rescue tugs, and expeditionary fast transports and emergency medical ships. A large

-

)

April 2024 - Maritime Reporter and Engineering News page: 25

)

April 2024 - Maritime Reporter and Engineering News page: 25RADM PHILIP SOBECK, MILITARY SEALIFT COMMAND Photo by Brian Suriani USN Military Sealift Command From a global supply chain perspective, What makes MSC so vital to the we’ve learned a lot about dealing with Navy’s ? eet and our military disruptions. COVID delivered a big forces around the world? wake-up

-

)

April 2024 - Maritime Reporter and Engineering News page: 24

)

April 2024 - Maritime Reporter and Engineering News page: 24FEATURE INTERVIEW U.S. Navy photograph by Brian Suriani/Released Rear Adm. Philip Sobeck (right) Commander of U.S. Military Sealift Command (MSC) explains the tradition of the Navy ‘looping ceremony’. Lt. Robert P. Ellison assumes the title of MSC’s Flag Aide during the ceremony. NEEDS MILITARY MORE

-

)

April 2024 - Maritime Reporter and Engineering News page: 22

)

April 2024 - Maritime Reporter and Engineering News page: 22DELAYS AND RE-BIDS. ROB LANGFORD, VP, GLOBAL OFFSHORE WIND, ABS “Some of them do understand, but I think there’s more work projects and lease areas. Virginia Offshore Wind and Revolu- to do in that regard to meet the renewable energy goals.” tion is in construction; Southfork is into installation, “so

-

)

April 2024 - Maritime Reporter and Engineering News page: 20

)

April 2024 - Maritime Reporter and Engineering News page: 20INTERVIEW One-on-One with ROB LANGFORD, VP, GLOBAL OFFSHORE WIND As the U.S. offshore wind industry endures a predictable number of stops and starts during its adolescence, common mantras are ‘learn from the established European model’ and ‘embrace technology transfer from the offshore oil and gas

-

)

April 2024 - Maritime Reporter and Engineering News page: 19

)

April 2024 - Maritime Reporter and Engineering News page: 19SOVs Source: Intelatus Global Partners built vessel fell from ~25% in early 2021 to ~12% today. Visit Us The biggest new building premium is found in the USA, for at OTC Houston, TX a variety of reasons, where the three tier one SOVs are being Booth 2121 built for ~€87-168 million. VARD is a leader in

-

)

April 2024 - Maritime Reporter and Engineering News page: 15

)

April 2024 - Maritime Reporter and Engineering News page: 15hydro-acoustic design of a propulsor that delays cavitation meets its underwater noise limits. This will require specialized inception and cavitating area. The third approach should be test sites or specialized mobile underwater testing equipment. isolation mounting of a vibro-active equipment and