Hull Plating

-

- Industry-Wide Interoperability Investment Paying Off Maritime Reporter, Jul 2002 #12

The Integrated Shipbuilding Environment (ISE) project sponsored by the National Shipbuilding Research Program is a three-year effort to develop and deploy an industry-wide architecture for computer interoperability. ISE is targeting cost and cycle time reduction for both Navy and commercial customers by providing real-time digital connectivity between shipbuilders and their suppliers. ISE also targets the total ownership costs during the 40-year life of a ship in that it provides access to configuration data during the life of a ship or ship class - regardless of computer system upgrades.

The expected benefits of this project are very high. For each shipyard, conservative benefits are a 15 percent reduction in pre-contract labor, six percent reduction in production labor and a two percent reduction in material costs.

Business Case The ISE business case is simple: radically reduce the costly, time-consuming and error-prone manual re-entry of complex 3-D design information through reliable and efficient digital data transfer of: • Part information from vendor electronic libraries into shipyard parts libraries, 3-D design data from CAD files to the sophisticated computer analysis and simulation tools used to validate the design of each ship system, and • 3-D design data between diverse CAD systems and versions at shipyards specializing in defense work, commercially oriented U.S. yards, and marine suppliers. This capability is significant because second tier shipyards and marine suppliers rarely use the sophisticated high-end CAD tools used by U.S.

yards supporting DoD programs, and because even a single vendor's CAD product installations at different facilities routinely result in interoperability issues. The patchwork solutions currently used to address this increasingly significant cost driver include time consuming and very expensive modification of direct point-to-point translators every time a new version of a CAD system is implemented at any point in the supply chain, or among co-design or co-production partners — a frequent occurrence.

ISE's end goal is a cost effective, integrated, and functional information system that will provide toolsets for realtime collaboration and information sharing among shipyards, suppliers, owner/operators, and regulators.

Toolset capabilities include: • Direct download of piping and structural parts data from vendor electronic catalogs into shipyard digital parts libraries; • Export of detailed CAD data to (a) analysis tools, (b) simulation programs, and (c) ship classification software; and.

• Electronic exchange of molded form data (complex geometric shapes of steel hull plating) between four different shipbuilding CAD systems.

These capabilities flow from adherence to international standards for data structures — a practice adopted across most manufacturing industries worldwide.

Typically during the life cycle of a ship or ship class, the Navy, shipbuilders and/or suppliers will face one or more Computer-Aided Design (CAD), Computer- Aided Manufacturing (CAM), Enterprise Resource Planning (ERP), and or Product Data Management (PDM) system transitions. The consensus ISE standards and protocols being developed enable new systems to access the data from previous systems and enable new versions of existing systems to access data from all previous versions — a capability whose absence in current systems is costly.

ISE's key asset is the critical mass of committed stakeholders — an empowered team with representatives from U.S. shipyards, CAD/CAM vendors, regulatory bodies and software vendors.

The team has developed and approved an architecture for interoperability that includes agreement on information requirements and data exchange standards and protocols. The ISE architecture uses readily available Internet technologies as well as data exchange standards being developed in conjunction with the International Standards Organization (ISO).

Progress, Implementations and Early Results Shipyards are already using ISE tools in warship production on the submarine and Carrier programs. These tools enable shipyards to select digital tools (simulation, analysis, ERP, CAD, PDM.

etc.) best suited to their business, yet fully participate in co-design and coproduction arrangements that rely on other information systems to design, build and maintain war ships. Highlights of the project's on-budget, onschedule successes include: • Development/agreement of industry- wide interoperability architecture • Publication of hundreds of use cases defining requirements for information sharing at many shipyards • Development of common data element definitions and common taxonomy for transferring data between parts libraries and supplier catalogs • Development, demonstration and distribution of tool sets for inter-organizational sharing of piping system information.

including: parts catalog information, system diagrams and simulation engines, and detailed design and analysis systems. Available, proven tools are a mix of open source software available on the project's website and commercially available tools in the product lines of collaborative design, co-production, integrated supply chain, and standardized parts.

The project recently completed the second of three years with a highly successful demonstration of capabilities.

The April 4 demonstration showcased the impressive "eShipDesign" capabilities of the consensus architecture, standards, protocols, and toolsets developed to date. The following capabilities were demonstrated: • Direct download of piping and structural parts data from vendor electronic catalogs into shipyard digital parts libraries.

• Export of detailed CAD data to analysis tools, such as Anteon's Proteus Flagship Suite, simulation programs such as SIMSMART. and ship classification software such as the ABS Safe Hull program.

• Successful electronic exchange of molded form data (complex geometric shapes of steel hull plating) between four different CAD systems (Dassault's CATIA, Sener's FORAN, KCS' TRIBON and Intergraph's GSCAD).

Examples of estimated savings are: Cost to link two IPDE (Integrated Product Development Environment) systems for co-design or co-production is estimated to be $30 million. If there are three programs over the next 10 years that use an IPDE, the total cost would be $90 million. It has been estimated that the ISE developed tools will save 40 percent or $36 million.

• A top down projection of savings for the design process for Navy programs is $188 million over 10 years (see chart, previous page).

Circle 1 on Reader Service C a rd w w w . m a r i t i m e r e p o r t e r i n f o . c om Any queries regarding this article may be directed to the Program Administrator (Advanced Technology Institute): Tel: 843- 760-3331; Email: [email protected]

-

- UMC Opens New Underwater Repair Facility in Portland, U.K. Maritime Reporter, Mar 2001 #29

in Poland, and fitting a new rudder to a general cargo vessel. Other jobs have included underwater hull cleaning, surveys and replacing defective hull plating. Part of the investment being made by UMC at Portland will include two mini- Pamper underwater hull cleaning machines and Jones expects the

-

- Solutions in Panama Maritime Reporter, Oct 2003 #38

. Once complete, the team started to cut out a part of the bulkhead over the area where the external plating had to be replaced. The defective hull plating was then cropped out, corners rounded off. Fitting of the insert in place was performed next, and once this had been positioned correctly the

-

- Dravo SteelShip Delivers Two Pushboats To Louisiana Owners Maritime Reporter, Oct 1980 #34

air horn, and Perko searchlights. Each of the vessels has two steering and four flanking rudders, a 27-foot eye level in the pilothouse, %-inch hull plating, and accommodations for a crew of six

-

- Alario And Associates Named To Represent Shipyard In Greece Maritime Reporter, Oct 1978 #33

capabilities include a fully equipped machine shop for full ship servicing of engines, shafts, rudders, blades and deck machinery; steel works for hull plating and superstructure components, as well as the restoration of stainless tanks; boiler shop for complete boiler repairs, including retubing

-

- A Bundle of Advanced Technology Maritime Reporter, Feb 2002 #38

, the hull had to be constructed using 500 Mpa yield strength TMCP steel with excellent impact strength properties, supplied by Rautaruukki. The hull plating of icebreakers and other ice-going vessels is subjected to ice erosion that can remove protective paint coatings and leave the hull exposed

-

- A Future in Composites Maritime Reporter, Nov 2004 #52

the initiatives relates to a scheme for the "double hulling" of existing, single-hull vessels, by using prefabricated SPS panels to form the inner hull plating. IE has also developed UR S21-compliant SPS hatch covers for panamax and capesize bulk carriers, and is working with industry partners on lightweight

-

- Wtirtsilti Delivers Advanced Icebreaker To Finnish Board Of Navigation Maritime Reporter, Mar 1986 #64

deck, below the helicopter deck, resulting in simpler cable and piping systems. The heavy fuel tanks are placed amidships well away from the hull plating, which decreases the risk of pollution. A new feature in comparison with earlier Finnish icebreakers is the "power station" type of machinery

-

- Aluminum Boats Prove Their Mettle Maritime Reporter, Feb 2004 #44

primers and undercoats, aluminum holds paint very well. Aluminum alloys used for hull construction-commonly 5086 and 5083-are also easy to weld. Hull plating of 3/16 of an inch and above easily accommodates MIG (metal inert gas) welding for much of the basic construction. with TIG (tungsten inert

-

- Innovators Recognized At Patent Ceremony Maritime Reporter, Jun 2001 #62

. Unlike a stern flap that extends aft of the transom, wedges are located completely under the hull beneath the t r a n s om (inlayed into the hull plating). The critical geometry parameters for both wedges and flaps are chord length, span across the transom, and angle. T r a n s om wedges

-

- Reduce Boatbuilding Risk by Starting with Requirements Maritime Logistics Professional, Q1 2013 #16

structure module predicts the structural loads and, based upon the selected material properties and starting with a minimum plating gauge, it sizes the hull plating and structural scantlings to resist the predicted seaway loads and then sums up the structure weights. The resistance module then calculates the

-

- GPS Spoofing and the Potential Perils to Ships at Sea Maritime Reporter, Sep 2013 #26

. The damage to the ship was relatively minor. The Royal Majesty was refloated by tugs the next day and completed its voyage into Boston, with some hull plating deformation and a lot of embarrassment. Things easily could have been much worse. In the intervening years, most navigators have become more,

-

)

March 2024 - Marine Technology Reporter page: 37

)

March 2024 - Marine Technology Reporter page: 37miscible barrier ? uid heavier than seawater (sg=1.026) and lighter than the battery electrolyte (sg=1.265). The original cell vent cap was screwed into the top of the riser pipe to vent the gases associated with charging. Wires were soldered to the lead (Pb) posts. The lead-acid battery was additionall

-

)

March 2024 - Marine Technology Reporter page: 36

)

March 2024 - Marine Technology Reporter page: 36DOV MIKE demon- can be exposed to high ambient pressure, and can be mounted strated the practicality of this approach, diving the Challenger outside the hull, as was done on the bathyscaph DSV Trieste Deep in the Mariana Trench using PBOF, BMS-protected lith- in the early 1960’s. If exposed to seawater

-

)

March 2024 - Marine Technology Reporter page: 35

)

March 2024 - Marine Technology Reporter page: 35Figure 1 A self-righting vehicle design with buoyancy high and weight low, WHOI’s SeaBED AUV captures the attention of a pair of curious Antarctic penguins as it is deployed from the British research vessel James Clark Ross. Vehicle designers allowed for temperature reduction of battery capacity. Recharge

-

)

March 2024 - Marine Technology Reporter page: 34

)

March 2024 - Marine Technology Reporter page: 34LANDER LAB #10 BATTERY PACKS, CHARGING, AND CAPACITY TESTING Photo Credit: Hanumant Singh / Woods Hole Oceanographic Institution. By Kevin Hardy, Global Ocean Design LLC n ocean lander has many strengths including that produces the current is irreversible. Examples include ? exibility of deployment

-

)

March 2024 - Marine Technology Reporter page: 23

)

March 2024 - Marine Technology Reporter page: 23elatively inactive since 2014, the Hunga Tonga–Hunga Ha‘apai (HT-HH) submarine volcano began erupting on December 20, 2021, reaching peak intensity on January 15, 2022. This triggered tsunamis throughout the Pa- R ci? c, destroyed lives and infrastructure, and generated the largest explosion recorded

-

)

April 2024 - Maritime Reporter and Engineering News page: 39

)

April 2024 - Maritime Reporter and Engineering News page: 39Tech Files Latest Products, Systems and Ship Designs “Wall Climbing Robot” Danish Pilot calls gets ClassNK Nod LEGO Model "A tribute build to a work life at sea" Image courtesy MOL, Sumitomo Heavy Industries lassNK granted its Innovation Endorse- Image courtesy Espen Andersen/DanPilot ment for

-

)

April 2024 - Maritime Reporter and Engineering News page: 19

)

April 2024 - Maritime Reporter and Engineering News page: 19where the three tier one SOVs are being Booth 2121 built for ~€87-168 million. VARD is a leader in the design and construction of SOVs and CSOVs, building hulls in Romania, Spain and Vietnam that are completed and commissioned in Norway. The compa- ny is also building a vessel through its Fincantieri Bay Ship- buil

-

)

April 2024 - Maritime Reporter and Engineering News page: 18

)

April 2024 - Maritime Reporter and Engineering News page: 18SOV and CSOV owners have generally sought pricing from two on long-term charter for operators and one for an OEM. Norwegian yards (who generally build the hulls in countries Construction and commissioning have been supported by including Vietnam, Turkey, Romania, and Spain) and China. several Gulf of Mexico

-

)

April 2024 - Marine News page: 39

)

April 2024 - Marine News page: 39shipyards convenience and ef? ciency of using can achieve unparalleled quality, ef? - pre-primed steel. The choice between 4. Erection joints and ? nal hull coat- ciency and cost-effectiveness in their in-house processing and outsourcing ing: Optimize with technology operations. This integrated approach

-

)

April 2024 - Marine News page: 33

)

April 2024 - Marine News page: 33. On the inside, it’s something altogether different. “A tug is a tug in a lot of ways,” said Garrett Rice, president at Master Boat Builders. “The eWolf’s hull and structure are very similar to those of some other tugs we’ve built and we’ll continue to build. But once we got into the out? tting stage, everything

-

)

February 2024 - Maritime Reporter and Engineering News page: 36

)

February 2024 - Maritime Reporter and Engineering News page: 36ve years at management system, along with electrically powered machin- current fuel prices (far less for new fuels). Michael D. Chris- ery and an optimized hull and cargo design, the company’s two tensen, VP Global Sales, Dry Cargo Vessels at ABB, is seeing newbuild self-discharging bulk carriers were projected

-

)

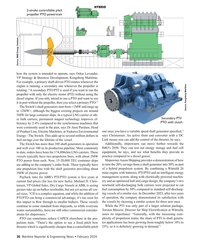

February 2024 - Maritime Reporter and Engineering News page: 35

)

February 2024 - Maritime Reporter and Engineering News page: 35to the variable speed ment needs to be installed into the engineroom drives that enable them to provide constant power over a wid- through a hole in the hull. A new section of er engine speed range. Rshaft is usually required. This added potential is mostly evidenced in the newbuild mar- That a few shipowners

-

)

February 2024 - Maritime Reporter and Engineering News page: 28

)

February 2024 - Maritime Reporter and Engineering News page: 28. citizen ships. Those are all crewed by U.S. mercial ships can also operate in places merchant mariners. citizen merchant mariners; that’s that a gray hull might not be able.” Ebeling is understandably support- important. Taking a more recent look, He cites the Navy League’s most ive of the Maritime Security

-

)

February 2024 - Maritime Reporter and Engineering News page: 16

)

February 2024 - Maritime Reporter and Engineering News page: 16THE PATH TO ZERO Methanol’s Superstorage Solution Technical inquiries to SRC Group ramped up after it received Approval in Principle (AIP) for a concept which ‘reinvented methanol fuel storage’ on board ships. Delivering the answers has seen technical talk converting into project discussions

-

)

February 2024 - Maritime Reporter and Engineering News page: 15

)

February 2024 - Maritime Reporter and Engineering News page: 15only a single cargo van on the pier. Multiple robots can be deployed simultaneously. Precision navigation ensures that the robots clean the targeted hull areas in an op- timal pattern, typically overlapping passes running along the length of the hull without wasting time by repeatedly cover- ing the

-

)

February 2024 - Maritime Reporter and Engineering News page: 14

)

February 2024 - Maritime Reporter and Engineering News page: 14effectiveness of proactive cleaning can be viewed sim- nuisance species (ANS). Left unchecked, it can also become a ply as the removal of fouling from a hull. It’s quite obvious maintenance problem. Simply, biofouling is both an economic that if biofouling isn’t removed, the cleaning wasn’t terribly (fuel

-

)

February 2024 - Maritime Reporter and Engineering News page: 5

)

February 2024 - Maritime Reporter and Engineering News page: 5now includes EverClean IQ Our groundbreaking data solution designed to assist commercial vessel owners in understanding the general health of their hulls. VISIT GREENSEAIQ.COM or ?nd us at Oceanology International, CMA Shipping, Posidonia, and SMM in 2024. ©2024 Greensea Systems, Inc. | Greensea® is

-

)

January 2024 - Marine Technology Reporter page: 52

)

January 2024 - Marine Technology Reporter page: 52TECH FEATURE BATTERY SAFETY Images courtesy Engineered Fluids Inc. This experiment has since been replicated with other batteries and cell con? gurations, and demonstrates the inherent ? re safety of SLIC Technology. jacent cells were not affected, and continued to operate nor- Failures) of electronic

-

)

January 2024 - Marine Technology Reporter page: 50

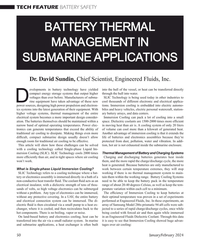

)

January 2024 - Marine Technology Reporter page: 50MANAGEMENT IN SUBMARINE APPLICATIONS Dr. David Sundin, Chief Scientist, Engineered Fluids, Inc. evelopments in battery technology have yielded into the hull of the vessel, or heat can be transferred directly compact energy storage systems that output higher through the hull into water. voltages than ever

-

)

January 2024 - Marine Technology Reporter page: 44

)

January 2024 - Marine Technology Reporter page: 44ease. Its plankton ? ltering algo- rithm is also AI bolstered, automatically optimizing visuals, monitoring tasks across aquaculture, search and rescue, hull check-ups and more, and even its laser scaling and measure- ment systems use AI automation for increased accuracy and the ability to identify damage

-

)

January 2024 - Marine Technology Reporter page: 32

)

January 2024 - Marine Technology Reporter page: 32carried MK-48 heavyweight ? tted with the Virginia Payload Module (VPM) within a 70- torpedoes, submarine launched mines, and both Tomahawk foot hull section to carry Tomahawk cruise missiles and the and Harpoon missiles. Later ships in the class had vertical Conventional Prompt Strike hypersonic

-

)

January 2024 - Marine Technology Reporter page: 20

)

January 2024 - Marine Technology Reporter page: 20TECH FEATURE WAVE POWER “We found an interesting market and application where we’re deploying the MARINE technology: decarbonizing oil and gas. TECHNOLOGY TV I’m talking about powering sub-sea Watch the full interview with Cameron McNatt: equipment in the oil and gas sector.” Cameron McNatt, Mocean

-

)

January 2024 - Marine Technology Reporter page: 19

)

January 2024 - Marine Technology Reporter page: 19the back that we call wave channels. They do a number of of operation, you’re in trouble. We’ve seen some big storms somewhat nuanced and complex hydrodynamic things, but this past year, we have some great videos on YouTube from basically they cause the machine to move a lot more in waves. cameras on

-

)

January 2024 - Marine Technology Reporter page: 11

)

January 2024 - Marine Technology Reporter page: 11to mine counter- measures (MCM) – “? nd, ? x, ? nish” – will need to quickly evolve. For warships operating in contested littoral areas, ad- vanced hull-mounted sonars, such as the AN/SQQ-89A installed aboard Arleigh Burke-class destroyers which can detect and track a wide range of underwater contacts