Cad

-

- Advances in CAD and CAM System Integration Maritime Reporter, Sep 2002 #30

Over the past 25 years CAD and CAM have become a vital part of shipbuilding.

The individual tools have evolved into highly capable products of today. This has included the change from 2-D to 3- D CAD, a dramatic increase in the level of usability (example: from batch mode to fancy 3-D GUI's) and increased functionality within the tools themselves.

With the development of these tools has also come improved integration of the CAD and CAM data. While 2-D CAD drawings were originally entered into the CAM system manually, it has now become commonplace to utilize a fully integrated product model environment from vendors such as Dassault Systems (Catia), Intergraph (ISDP), Nupas-Cadmatic, Sener (Foran) and Tribon Solutions (Tribon Ml).

Even today, some current installations utilize a complete 3-D product model for the design of a system such as piping or HVAC, but then create a paper drawing to transfer data to the production (CAM) system.

CAD and CAM integration has always been a primary problem for U.S.

shipbuilders. U.S. naval shipbuilders have tended to use general-purpose mechanical CAD systems such as CADDS or CATIA because of their exceptional 3-D model viewing capabilities.

An Integrated Solution Because these systems lacked shipbuilding CAM capabilities, they had to be combined with separate shipbuilding CAM systems such as AUTOKON or SPADES. Few options were open as to how to integrate these CAD and CAM systems, and yards have normally created the connections themselves by writing dedicated custom interfaces. These interfaces must then be maintained by the shipyard (or sub-contractor) and be modi f i ed to a c c ommo d a t e sof twa r e upgrades or new tools.

In general European shipyards have tended to utilize shipbuilding specific CAD/CAM systems such as Tribon, Foran and Nupas. These systems provide an integrated CAD/CAM solution as part of a single system. Such monolithic systems utilize proprietary data architecture, to provide seamless links between the two systems. In this case the shipyard is tied to a single vendor and may have to compromise on the available features in one part of the system in order to have the desired features of the other part. Additionally, many shipyards implemented the sole source vendor's products while they were in the early stages of product development and were left to create many custom interfaces to other shipyard systems themselves.

Up until now, major Japanese shipbuilders have employed either their own homegrown systems such as Mitsubishi Heavy Industry's MATES or specialized shipbuilding CAD/CAM systems such as Tribon. Like their European counterparts, the Japanese put more emphasis on CAM and production than the U.S.

yards, which, as mentioned, tend to emphasize model viewing.

Regardless of the type of configuration, once the shipyard finally gets all of its connections in place, little flexibility remains to adopt new. improved products or practices. In order to make changes to a single system, a major revision to the connection architecture is normally required.

Additionally, several manual steps might be necessary to perform the actual data transfer. These environments typically don't have support for data management, putting a heavy burden on the systems user. This is especially true in the "one of a kind" production in shipbuilding, where the CAD to CAM data transfer happens often.

Research, Development, Sharing = Better CAD Systems As the implementation of 3-D product modeling becomes the norm in more shipyards, the need for a flexible CAD and CAM integration solution will increase. The need for flexibility is compounded by the worldwide consolidations taking place in the industry. Acquisitions and mergers have created families of companies working together in ways that would have seemed impossible just five years ago.

The current direction from the large product model vendors is to allow an open standard format as an optional output from their product model.

This is demonstrated by vendor involvement in projects such as NSRP, ISE / ESTEP. Use of open standards would support a local integrated architecture and provide data access between systems used by sister shipyards or subcontractors.

Two open-standard formats; STEP and STEP-NC are destined to compete with proprietary solidmodel formats. These important standards allow the sharing of model data between different systems and will provide a better integration of CAD and CAM.

STEP or ISO 10303 (http://www.diffuse.Org/products.html#STEP) is a vendor neutral standard that describes how to represent (and therefore exchange) digital product information. STEP-NC or ISO 14649 (www.stepnc.

org) provides a neutral NC-programming interface to support information transfer between CAD and CAM and NC systems. Recent emphasis has been on milling operations; however further exploitation of this standard for other applications such as shipbuilding is currently underway.

There are several U.S.-based R & D projects currently underway that are intended to better integrate CAD, with the current and planned CAM systems.

The Integrated Steel Processing Environment (ISPE) is an NSRP-ASE funded research project.

Headed by Northrop Grumman Ship Systems, the project goal is to create an interoperable solution that removes the dedicated link from one CAD system to one CAM system for the design and production of steel plate.

STEP Tools (Troy, NY) currently is working on an U.S. Navy, ONR funded research project to examine the technical merits of utilizing STEP-NC for manufacturing operations in the shipbuilding industry. STEP Tools will study applying STEPNC technology to control pipe bending and cutting at Electric Boat, Quonset Point, RI.

Atlantec Enterprise Solutions (Annapolis, MD)

-

- Scanner Gives Peterson Builders Edge In Navy Shipbuilding Project Maritime Reporter, Apr 1985 #98

was that the drawings had been created manually, and re-creating them in digital format would require thousands of hours of computer work by experienced CAD operators. More than 750 assembly drawing sheets would have to be converted to a CAD database in less than eight months. Using conventional digitizing

-

- Digital Feature Extraction with PropCad Premium 2018 Marine News, Nov 2018 #72

A new utility automates feature extraction from 3D CAD data.Marine propellers can last a long time – it is not uncommon to find a vessel running on its original set of propellers. Sometimes, these propellers even outlive the companies that produced them. For example, some large volume propeller manufacturers

-

- Exploring Class Approvals, Supported by CAD Marine News, Oct 2018 #40

and marine engineering arm of Crowley Maritime Corp, and ABS have completed a precedent-setting pilot project using three-dimensional computer-aided design (CAD) models to support plan reviews for class approval.In what is believed to be an industry first, the innovative pilot was not proprietary to specific

-

- Complete Vessel Structure Modeling and Part Nesting by Autoship Maritime Reporter, Jul 2004 #16

Autoship Systems Corporation (ASC) has developed a complete CAD/CAM suite to meet the CAD/CAM needs in marine vessel design and construction, including two key programs in the CAD/CAM suite: Autostructure 3.0 and Production Manager 3.0. Autostructure and Production Manager are key components in the

-

- Industry-Wide Interoperability Investment Paying Off Maritime Reporter, Jul 2002 #12

and efficient digital data transfer of: • Part information from vendor electronic libraries into shipyard parts libraries, 3-D design data from CAD files to the sophisticated computer analysis and simulation tools used to validate the design of each ship system, and • 3-D design data between

-

- Total CAD/CAM Solution for Ship Design and Building Maritime Reporter, Jul 2002 #15

Autoship Systems Corp. (ASC) has initiated a new 'total system' approach to CAD/CAM software for shipyards, aiming to eliminate what it terms the most expensive CAD/CAM inefficiencies within the design-to-manufacture process: data exchange and interface discontinuities between specialized products

-

- From 2D CAD to the Integrated Product Model Maritime Reporter, Aug 2004 #34

One of the most important improvements in ship production has been the introduction of CAD/CAM. The initial use of computers for drafting, lofting and automation of steel cutting has been extended from the design office and the mold loft throughout the shipyard and beyond by integrating the Internet

-

- Scale Reproductions Installs Auto CAD System To Design Ship Models Maritime Reporter, Nov 1991 #93

Scale Reproductions, Fairhope, Ala., recently installed an Auto CAD system for designing. The computer, which will be used in production of scale models, will be able to use the computer files of the shipyards and designers. Blue prints can also be traced with a large digitizing table. The models

-

- Saint John Shipbuilding Upgrades Its CAD/CAM For Big Frigate Program Maritime Reporter, Apr 1984 #5

Saint John Shipbuilding & Dry Dock Company, Ltd., in New Brunswick, Canada, has chosen AUTOKON and AUTOFIT as its CAD/CAM systems for carrying out the big Canadian Navy Frigate Program contract. The Saint John yard has been awarded prime contractor responsibility for the detailed design, procurement

-

- PTC Launches New CAD/CAM Shipbuilding Solution Maritime Reporter, Sep 2000 #25

PTC, a leader in the CAD/CAM marketplace with its software in use at more than 28,000 companies including companies such as Caterpillar, Lucent, Mitsubishi, Nike and Siemens, has launched a shipbuilding specific product. Working with partners like Hyundai Heavy Industries, BAE SYSTEMS, DCN, B1W

-

- FPSO Retrofit Design Accelerated With CAD Maritime Reporter, Sep 2000 #54

for the Usige Gorm. In the past, Merpro would have generated the documentation for a project such as this by using one program to create P&IDs, AutoCAD to create electrical schematics such as junction box layouts and instrumentation loops, and a spreadsheet application to generate instrument and

-

)

August 2023 - Maritime Reporter and Engineering News page: 12

)

August 2023 - Maritime Reporter and Engineering News page: 12he had barely seen This made me wonder how many other neat engineering the design. “Uh, how do you know Johan?” tricks will disappear in our world of CAD, FEA and AI. “Because all boats that I design have good balance with the I have mentioned “Beam is Cheap” in a prior column, but mast at station four

-

)

October 2022 - Marine News page: 55

)

October 2022 - Marine News page: 55maritime training sign tools for naval architecture and the propeller trades— school in the United States, serving more than 12,000 stu- from concept to 3D CAD, and consulting services—Hy- dents annually, training for careers in both the commercial droComp’s core mission is providing engineering tools to

-

)

September 2022 - Marine News page: 16

)

September 2022 - Marine News page: 16were not born in Canada, our work have been the advancements in software. It started which makes for a diverse workforce. And we’ve had good with AutoCAD and other products like AutoCAD, CAD luck hiring straight out of university. But really, the way drafting, computerated drafting, but it’s gone well

-

)

September 2022 - Marine News page: 13

)

September 2022 - Marine News page: 13Robert Allan Ltd. Naval Architects CEO, NETSCo whether that’s economic studies that look at, “Hey, should of the early adopters of computer aided design (CAD) and I go slower? What are some of the things that I should be began exploring laser scanning technology as soon as it ap- doing in order to reduce

-

)

February 2022 - Maritime Reporter and Engineering News page: 32

)

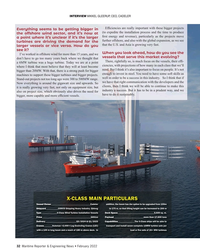

February 2022 - Maritime Reporter and Engineering News page: 32INTERVIEW MIKKEL GLEERUP, CEO, CADELER Ef? ciencies are really important with these bigger projects Everything seems to be getting bigger in (to expedite the installation process and the time to produce the offshore wind sector, and it’s now at ? rst energy and revenue), particularly as the projects

-

)

February 2022 - Maritime Reporter and Engineering News page: 11

)

February 2022 - Maritime Reporter and Engineering News page: 113D models for class surveys in April 2020. “We are very focused philo- sophically on being flexible, re- gardless of file format, regardless of pure CAD or PLM involvement, effectively making it easy for ev- eryone,” said Ryan. “ABS does not want to dictate to the shipyards what format or what file

-

)

February 2022 - Maritime Reporter and Engineering News page: 10

)

February 2022 - Maritime Reporter and Engineering News page: 10safety. turing perspective of the elimination of waste.” “ABS started focusing on this (pure digital process) “(I’ve been saying for more than a decade that) engi- in 2018 with a series of joint development R&D proj- neering drawings are a waste in the lean manufacturing ects,” said Ryan. sense because

-

)

November 2021 - Marine Technology Reporter page: 11

)

November 2021 - Marine Technology Reporter page: 11? ghter “Svanced Naval Technology Ex- and providing that forum for DOD, indus- The Naval Air Warfare ercises” that are held around the country, try and academia to participate and show- Center Aircraft ANTX is truly a sum greater than its parts. case capabilities and how they would in- ANTXs are conducted

-

)

November 2021 - Marine News page: 72

)

November 2021 - Marine News page: 72Hawaii. Thordon Announces Leadership Changes Thordon Bearings appointed Anthony Hamilton as its new technical director to lead the company’s engineering, CAD, and Wesson Williams Marshall new product development teams. Thor- don has also selected Michael Skrzypczak to oversee the company’s global service

-

)

September 2021 - Marine News page: 37

)

September 2021 - Marine News page: 37best ? ts their operation.” to mark the plate for stiffener place- enables welders to quickly and easily ment. The plate is then moved to the download CAD ? les then edit welds Stiffener Mounting Portal (SMP) out- and robot con? gurations as necessary. ? tted with a gantry that loads the stiff- One

-

)

April 2021 - Maritime Reporter and Engineering News page: 24

)

April 2021 - Maritime Reporter and Engineering News page: 24models in a with ship’s drawings which then resulted in a repair plan. large steel repair job, the recent installation of Ballast Water There may be CAD drawings and even a rudimentary 3D Treatment systems and scrubbers has made much more use of model, but only the newest ships would be fully built

-

)

April 2021 - Maritime Reporter and Engineering News page: 23

)

April 2021 - Maritime Reporter and Engineering News page: 23The ‘Cutting Edge’ in Ship Repair • Full digital construction model 3D CAD is nice, but where digital modeling becomes really valuable is the inclusion of detailed parts information. Ship- builders are operating at this level, but repair yards rarely are provided with these details. • Laser scanning Laser

-

)

March 2021 - Marine News page: 37

)

March 2021 - Marine News page: 37Tech File Autohydro: User-friendly Engineering Software for Class Approval utoship Systems Corporation (ASC) supplied Bok- CAD/CAM design program suite. sa Marine Design (BMD) with its latest Autohydro “We use Autohydro to submit stability books to classi- 6.10, offering yet more features and tools

-

)

September 2020 - Maritime Reporter and Engineering News page: 52

)

September 2020 - Maritime Reporter and Engineering News page: 52cation requirements and is available Vessel-Propulsor-Drive Simulation for order now. According to Mitsubishi Marine Development in 2020 for HydroComp NavCad offers new features Engine Manager Takeshi Yoshida, bucking the for all three parts of NavCad’s Vessel-Propulsor-Drive system simu- industry trend

-

)

September 2020 - Maritime Reporter and Engineering News page: 51

)

September 2020 - Maritime Reporter and Engineering News page: 51the world. ASC has also been providing world-class load planning systems and loading instruments to the marine shipping industry. Shaftmaster The line of CAD/CAM software is used for design through to construction of all vessel types. Products include; Autoship (surface modeling), Autohydro (stability &

-

)

September 2020 - Maritime Reporter and Engineering News page: 41

)

September 2020 - Maritime Reporter and Engineering News page: 412. Reverse Engineering: Based on the scanned 3D pro? le, and takes care of the production and replacement of the instal- Thermamax develops a CAD model of the engine. For this lation if hotspots are detected. it ? rst generates a polygon network in STL format from the available data. This

-

)

August 2020 - Marine News page: 13

)

August 2020 - Marine News page: 13production seagoing tugs, shallow draft towing vessels and ? reboats for working drawings and procurement support. Use of the major world ports. latest CAD technologies expedites and improves the ac- The ? rm’s experience includes designs for hundreds of curacy of every aspect of the ship design process

-

)

July 2020 - Maritime Reporter and Engineering News page: 11

)

July 2020 - Maritime Reporter and Engineering News page: 11capabilities of Vortex Studio,” te Voortwis adds, “you can’t feasibly execute something like this. The feld-testing costs would be astronomical.” Based on CAD models for the ship, a ship pedestal crane, and the rigging, as well as the basic simulation algorithm All- seas was going to use, CM Labs provided

-

)

June 2020 - Marine News page: 43

)

June 2020 - Marine News page: 43positional data out to 1.5 kilometers and over a 90-degree ?eld of view. In this mode, the sonar returns are used to generate computer aided detec- tion (CAD) markers, which alert the operator (or a third- party arti?cial intelligence based processor) to the presence of navigationally relevant obstacles

-

)

May 2020 - Marine Technology Reporter page: 38

)

May 2020 - Marine Technology Reporter page: 38The Xplorer engineering team, con- line which has a small offset from the tion. This makes deployment and recov- sisting of ARV and HiveGround, then CAD drawing. The software has an AI ery faster and saves the vehicle battery, performed a further two offshore tri- module that processes real-time multi-

-

)

May 2020 - Marine News page: 58

)

May 2020 - Marine News page: 58as extend the service life of the pro- Kongsberg Maritime will supply its pulsion system. In addition to that, KONGSBERG US255 L PM FP az- PropCad 2020 a new oil cleaning system ensures oil imuth thrusters for a new fully-elec- HydroComp’s PropCad 2020 soft- quality and prolongs oil service

-

)

November 2019 - Marine News page: 85

)

November 2019 - Marine News page: 85CAD/CAM SOFTWARE TrueProp Software, they used man- ual methods to assess and repair their propellers. “We cleaned the prop a bit, assessed whether it was repairable with manual gauges, and beat the propeller with rawhide or brass hammers to get it to lay on a pitch block,” says Dorothy. “Then we beat

-

)

November 2019 - Marine News page: 84

)

November 2019 - Marine News page: 84CAD/CAM SOFTWARE Software Tools for Propeller Professionals TrueProp is software for propeller inspection devices, assisting propeller manufacturers and repair shops to identify damage, repair and tune propellers to improve performance and save fuel. By Adam Kaplan aving the right tools for the

-

)

October 2019 - Maritime Reporter and Engineering News page: 67

)

October 2019 - Maritime Reporter and Engineering News page: 67Blockchain Autoship Systems Corporation (ASC) is a marine software developer of load planning software, loading instrument software and integrated CAD/CAM programs. For over 35 years ASC has continued to provide innovative software solutions that save clients valuable time and money on each project