Cam System

-

- Advances in CAD and CAM System Integration Maritime Reporter, Sep 2002 #30

Over the past 25 years CAD and CAM have become a vital part of shipbuilding.

The individual tools have evolved into highly capable products of today. This has included the change from 2-D to 3- D CAD, a dramatic increase in the level of usability (example: from batch mode to fancy 3-D GUI's) and increased functionality within the tools themselves.

With the development of these tools has also come improved integration of the CAD and CAM data. While 2-D CAD drawings were originally entered into the CAM system manually, it has now become commonplace to utilize a fully integrated product model environment from vendors such as Dassault Systems (Catia), Intergraph (ISDP), Nupas-Cadmatic, Sener (Foran) and Tribon Solutions (Tribon Ml).

Even today, some current installations utilize a complete 3-D product model for the design of a system such as piping or HVAC, but then create a paper drawing to transfer data to the production (CAM) system.

CAD and CAM integration has always been a primary problem for U.S.

shipbuilders. U.S. naval shipbuilders have tended to use general-purpose mechanical CAD systems such as CADDS or CATIA because of their exceptional 3-D model viewing capabilities.

An Integrated Solution Because these systems lacked shipbuilding CAM capabilities, they had to be combined with separate shipbuilding CAM systems such as AUTOKON or SPADES. Few options were open as to how to integrate these CAD and CAM systems, and yards have normally created the connections themselves by writing dedicated custom interfaces. These interfaces must then be maintained by the shipyard (or sub-contractor) and be modi f i ed to a c c ommo d a t e sof twa r e upgrades or new tools.

In general European shipyards have tended to utilize shipbuilding specific CAD/CAM systems such as Tribon, Foran and Nupas. These systems provide an integrated CAD/CAM solution as part of a single system. Such monolithic systems utilize proprietary data architecture, to provide seamless links between the two systems. In this case the shipyard is tied to a single vendor and may have to compromise on the available features in one part of the system in order to have the desired features of the other part. Additionally, many shipyards implemented the sole source vendor's products while they were in the early stages of product development and were left to create many custom interfaces to other shipyard systems themselves.

Up until now, major Japanese shipbuilders have employed either their own homegrown systems such as Mitsubishi Heavy Industry's MATES or specialized shipbuilding CAD/CAM systems such as Tribon. Like their European counterparts, the Japanese put more emphasis on CAM and production than the U.S.

yards, which, as mentioned, tend to emphasize model viewing.

Regardless of the type of configuration, once the shipyard finally gets all of its connections in place, little flexibility remains to adopt new. improved products or practices. In order to make changes to a single system, a major revision to the connection architecture is normally required.

Additionally, several manual steps might be necessary to perform the actual data transfer. These environments typically don't have support for data management, putting a heavy burden on the systems user. This is especially true in the "one of a kind" production in shipbuilding, where the CAD to CAM data transfer happens often.

Research, Development, Sharing = Better CAD Systems As the implementation of 3-D product modeling becomes the norm in more shipyards, the need for a flexible CAD and CAM integration solution will increase. The need for flexibility is compounded by the worldwide consolidations taking place in the industry. Acquisitions and mergers have created families of companies working together in ways that would have seemed impossible just five years ago.

The current direction from the large product model vendors is to allow an open standard format as an optional output from their product model.

This is demonstrated by vendor involvement in projects such as NSRP, ISE / ESTEP. Use of open standards would support a local integrated architecture and provide data access between systems used by sister shipyards or subcontractors.

Two open-standard formats; STEP and STEP-NC are destined to compete with proprietary solidmodel formats. These important standards allow the sharing of model data between different systems and will provide a better integration of CAD and CAM.

STEP or ISO 10303 (http://www.diffuse.Org/products.html#STEP) is a vendor neutral standard that describes how to represent (and therefore exchange) digital product information. STEP-NC or ISO 14649 (www.stepnc.

org) provides a neutral NC-programming interface to support information transfer between CAD and CAM and NC systems. Recent emphasis has been on milling operations; however further exploitation of this standard for other applications such as shipbuilding is currently underway.

There are several U.S.-based R & D projects currently underway that are intended to better integrate CAD, with the current and planned CAM systems.

The Integrated Steel Processing Environment (ISPE) is an NSRP-ASE funded research project.

Headed by Northrop Grumman Ship Systems, the project goal is to create an interoperable solution that removes the dedicated link from one CAD system to one CAM system for the design and production of steel plate.

STEP Tools (Troy, NY) currently is working on an U.S. Navy, ONR funded research project to examine the technical merits of utilizing STEP-NC for manufacturing operations in the shipbuilding industry. STEP Tools will study applying STEPNC technology to control pipe bending and cutting at Electric Boat, Quonset Point, RI.

Atlantec Enterprise Solutions (Annapolis, MD)

-

- German Yard Implements Nupas-Cadmatic Maritime Reporter, Jul 2000 #43

The Peene-Werft in Wolgast, Germany, has chosen Nupas-Cadmatic software solution as their main CAD/CAE/CAM system. During an implementation project of about two months, the shipyard will implement Nupas-Cadmatic for the complete Hull structure, Piping, Machinery and Outfitting including special

-

- SENER Debuts Latest FORAN Release Maritime Reporter, Apr 2015 #99

At Sinaval-Eurofishing in Bilbao, Spain, Sener will present enhancements in the shipbuilding CAD/CAM system FORAN, in all disciplines (forms, naval architecture and general arrangement, hull structure, machinery and outfitting, electrical design and drafting). The naval architecture modules have been

-

- New FORAN Update from SENER Maritime Reporter, Aug 2015 #83

SENER Ingeniería y Sistemas SA launched a new version of its marine CAD/CAM system, the FORAN V80. The new version is fully compatible with the previous ones and includes improvements in all of its modules. The main upgrades come from the initial and basic project stages, where the calculations and

-

- STX Canada Marine purchases the FORAN System Marine News, Nov 2013 #57

STX Canada Marine (STXM), has signed a contract with Sener Ingeniería y Sistemas, S.A. (SENER) for the license to use the FORAN CAD/CAM System. After the implementation of FORAN in its headquarters in Vancouver, STXM is conducting a learning process during the summer focused in the early design process in 3D.

-

- ASMAR Uses FORAN for New Research Vessel Marine Technology, Jan 2014 #59

FORAN has been the CAD/CAM System used by the Chilean shipyard ASMAR in the development of an Oceanographic and Fisheries Research Vessel, a state of the art design built for worldwide oceanographic and fishing service and geological research. The vessel, Cabo de Hornos, has been already delivered. With a

-

- Far East-Levingston Upgrades Facilities Maritime Reporter, Oct 1981 #44

take the numerical outputs produced by the AUTOKON system. The AUTOKON software is a computer-aided-design (CAD) and computer-aided-manufacturing (CAM) system that performs engineering designs, computerized drafting and generates information to facilitate numerically controlled plate cutting. The

-

- CANADIAN SHIPBUILDING AND REPAIR YARDS Maritime Reporter, Sep 15, 1985 #28

Division—including a well equipped Heavy Machine Shop and a large Stress Relieving Furnace. The shipyard has been using the AUTOKON CAD/CAM system for steel definition and manufacturing since 1970, and in late 1983, purchased the latest interactive AUTOKON modules that will serve for both

-

- Is 3-D Product Modeling Practical For Small U.S. Shipyards? Maritime Reporter, Dec 2000 #47

Engineering in Stevensville, MD. He is the North American representative of SENER, Ingenieria y Sistemas, S.A., the developers of the FORAN CAD/CAE/CAM system

-

- From 2D CAD to the Integrated Product Model Maritime Reporter, Aug 2004 #34

(small buoy tenders). The Yard was also the first federal organization to be ISO 9001 certified. Thus, when the Yard implemented a production CAD/CAM system it was systematically integrated into the production process, through the use of Total Quality Management techniques, looking for changes and

-

- FKAB Designs Large Dredger with Nupas-Cadmatic Marine News, Mar 2013 #10

detail design and related production drawings. In order to complete the commission swiftly and efficiently, FKAB has chosen Nupas-Cadmatic as their CAD/CAM system for the project. FKAB is part of the Swedish Mattson Gruppen, which is an independent engineering company mainly active in the marine and shipbuilding

-

- Maritime E-Business Growth Continues Maritime Reporter, Nov 2002 #52

with e-commerce. Tribon in Malmo, Sweden is a leader in design and information systems for shipyards, and has now added a "marketplace" to their CAD/CAM systems. According to Tribon's Magnus Feldt, "A designer can select a component and virtually place it into the three-dimensional product model of the

-

)

March 2024 - Marine Technology Reporter page: 4th Cover

)

March 2024 - Marine Technology Reporter page: 4th CoverGlow a little longer. Superior sensor performance on a rmance on a – – RBRtridentfraction of the power RBRtridente teee ackscatter or turbidity with hi i in n n t t th h h he e e s sa a am m m me Measure chlorophyll a, fDOM, and backscatter or turbidity within the same e e sensor package using the

-

)

March 2024 - Marine Technology Reporter page: 48

)

March 2024 - Marine Technology Reporter page: 48Index page MTR MarApr2024:MTR Layouts 4/4/2024 3:19 PM Page 1 Advertiser Index PageCompany Website Phone# 17 . . . . .Airmar Technology Corporation . . . . . . . . . .www.airmar.com . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .(603) 673-9570 9 . . . . . .Birns, Inc. . . . . . . . . . .

-

)

March 2024 - Marine Technology Reporter page: 45

)

March 2024 - Marine Technology Reporter page: 45ronments. The new agreement will address speci? c techni- cal gaps in the UUV defense and offshore energy markets especially for long duration, multi-payload mission opera- tions where communications are often denied or restricted. As part of the new alliance, Metron’s Resilient Mission Autonomy portfolio

-

)

March 2024 - Marine Technology Reporter page: 44

)

March 2024 - Marine Technology Reporter page: 44NEW TECH OCEANOLOGY INTERNATIONAL 2024 Image courtesy Metron/Cellula Teledyne Marine acquires Valeport: Matt Quartley, MD, Valeport and Ole Søe-Pedersen, VP & Image courtesy Teledyne Marine GM Teledyne Marine announce the deal in London. Pictured (L-R): Cellula Robotics, President, Eric Jackson, Metron

-

)

March 2024 - Marine Technology Reporter page: 43

)

March 2024 - Marine Technology Reporter page: 43Image courtesy Kongsberg Discovery Image courtesy Teledyne Marine New Products Teledyne Marine had its traditional mega-booth at Oi, busy start to ? nish. Image courtesy Greg Trauthwein offers quality sub-bottom pro? ling capability without the need tion of offshore windfarms. GeoPulse 2 introduces new

-

)

March 2024 - Marine Technology Reporter page: 42

)

March 2024 - Marine Technology Reporter page: 42NEW TECH OCEANOLOGY INTERNATIONAL 2024 Image courtesy Greg Trauthwein Image courtesy BIRNS MacArtney launches the new ultra-compact ø12.7 mm SubConn Nano connector. Innovative connectivity built on 45 years of ? eld-proven and market-trusted design. Image courtesy MacArtney Birns celebrated its 70th

-

)

March 2024 - Marine Technology Reporter page: 41

)

March 2024 - Marine Technology Reporter page: 41. It is also to enable automatic col- tic sea? oor imaging. Additionally, two full-HD underwater lision avoidance through a front-looking sonar system. cameras—one forward-facing at a 45-degree angle and one The hardware and propulsion systems were redesigned with downward-facing—equipped with dimmable

-

)

March 2024 - Marine Technology Reporter page: 40

)

March 2024 - Marine Technology Reporter page: 40NEW TECH OCEANOLOGY INTERNATIONAL 2024 All photos courtesy MTR unless otherwise noted NEW TECH, PARTNERSHIPS LAUNCH IN LONDON With Oceanology International now one month in the rear-view mirror, MTR takes a look at some of the interesting technologies launched before, during and after the London event.

-

)

March 2024 - Marine Technology Reporter page: 39

)

March 2024 - Marine Technology Reporter page: 39Photo courtesy Global Ocean Design Figure 7 A 35Ah AGM lead-acid battery is tested using the West Mountain Radio CBA to show the effect of simply ? lling the battery voids with mineral oil as a compensating ? uid. The CBA is programmed to cut-off at a voltage of 10.50v. The top line (red) shows the

-

)

March 2024 - Marine Technology Reporter page: 38

)

March 2024 - Marine Technology Reporter page: 38LANDER LAB #10 Photo courtesy West Mountain Radio Photo courtesy of Clarios/AutoBatteries.com Figure 6 The West Mountain Radio Computerized Battery Analyzer (CBA V) attaches to a Figure 5 laptop by a USB-B cable, and to a battery by Powerpole® Connectors. Exploded view of an AGM lead-acid battery.

-

)

March 2024 - Marine Technology Reporter page: 37

)

March 2024 - Marine Technology Reporter page: 37miscible barrier ? uid heavier than seawater (sg=1.026) and lighter than the battery electrolyte (sg=1.265). The original cell vent cap was screwed into the top of the riser pipe to vent the gases associated with charging. Wires were soldered to the lead (Pb) posts. The lead-acid battery was additionall

-

)

March 2024 - Marine Technology Reporter page: 36

)

March 2024 - Marine Technology Reporter page: 36rate lower than 1C. (See Lander Lab #5, MTR, November/December 2022) Lead-acid wet-cells must remain upright or the electrolyte, a On March 26, 2012, James Cameron’s DEEPSEA CHAL- 35% sulphuric acid and 65% water solution, will spill. They LENGER submersible and ocean lander DOV MIKE demon- can be exposed

-

)

March 2024 - Marine Technology Reporter page: 33

)

March 2024 - Marine Technology Reporter page: 33regulated industry in the world.” How- ever, commercial success depends on many factors, not least a predictable OPEX. Over the past four years, SMD has worked with Oil States Industries to calculate cost per tonne ? gures for prospective customers. Patania II uses jet water pumps to Oil States’

-

)

March 2024 - Marine Technology Reporter page: 32

)

March 2024 - Marine Technology Reporter page: 32FEATURE SEABED MINING by a sea? oor plume from its pilot collection system test. pact, nodule collection system that utilizes mechanical and The Metals Company recently signed a binding MoU with hydraulic technology. Paci? c Metals Corporation of Japan for a feasibility study on The company’s SMD

-

)

March 2024 - Marine Technology Reporter page: 31

)

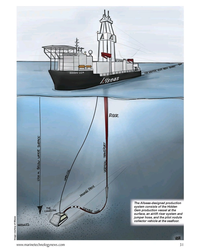

March 2024 - Marine Technology Reporter page: 31The Allseas-designed production system consists of the Hidden Gem production vessel at the surface, an airlift riser system and jumper hose, and the pilot nodule collector vehicle at the sea? oor. Image courtesy of Allseas www.marinetechnologynews.com 31 MTR #3 (18-33).indd 31 4/4/2024 2:12:41

-

)

March 2024 - Marine Technology Reporter page: 30

)

March 2024 - Marine Technology Reporter page: 30FEATURE SEABED MINING bilical. It has passive heave compensation which nulli? es the necott. “The focus since then has been on scaling while en- wave, current and vessel motions that in? uence loads in the suring the lightest environmental impact,” says The Metals power umbilical. The LARS can

-

)

March 2024 - Marine Technology Reporter page: 29

)

March 2024 - Marine Technology Reporter page: 29n January, Norway said “yes” to sea- bed mining, adding its weight to the momentum that is likely to override the calls for a moratorium by over 20 countries and companies such as I Google, BMW, Volvo and Samsung. Those against mining aim to protect the unique and largely unknown ecology of the sea?

-

)

March 2024 - Marine Technology Reporter page: 25

)

March 2024 - Marine Technology Reporter page: 25Auerbach explained that ideally, “one ? ed layers of geothermal activity,” noted changes over an area of 8,000 km2. They would have both instruments: seismom- Skett, “and the change in salinity and dis- found up to seven km3 of displaced ma- eters to detect and locate subsurface ac- solved particles for

-

)

March 2024 - Marine Technology Reporter page: 19

)

March 2024 - Marine Technology Reporter page: 19About the Author vey with the pipe tracker is not required, resulting in signi? - Svenn Magen Wigen is a Cathodic Protection and corrosion control cant cost savings, mainly related to vessel charter. expert having worked across The major advantage of using FiGS on any type of subsea engineering, design

-

)

March 2024 - Marine Technology Reporter page: 18

)

March 2024 - Marine Technology Reporter page: 18TECH FEATURE IMR There are also weaknesses in terms of accuracy because of FiGS Operations and Bene? ts signal noise and the ability to detect small ? eld gradients. In Conventional approaches to evaluating cathodic protection this process there is a risk that possible issues like coating (CP)

-

)

March 2024 - Marine Technology Reporter page: 17

)

March 2024 - Marine Technology Reporter page: 17• Integrity assessment, and otherwise covered, e.g., by rock dump. As for depletion of • Mitigation, intervention and repair. sacri? cial anodes, this can be dif? cult or even impossible to Selecting the best method for collecting the data these work- estimate due to poor visibility, the presence of

-

)

March 2024 - Marine Technology Reporter page: 15

)

March 2024 - Marine Technology Reporter page: 15several high-energy passive and active of the Slocum Glider at Teledyne Webb acoustic sensors, on-board processing, and imaging hardware Research. Quinn came to Teledyne Webb Research from Lockheed Martin. He simultaneously for months at a time, extending deployments earned his Bachelor of Science in

-

)

March 2024 - Marine Technology Reporter page: 11

)

March 2024 - Marine Technology Reporter page: 11assist in identifying mines and act as a neutralization device. About the Author Bottom mines pose even greater chal- David R. Strachan is a defense analyst and founder of lenges. Unlike contact mines, bottom Strikepod Systems, a research and strategic advisory mines utilize a range of sensors to

-

)

March 2024 - Marine Technology Reporter page: 9

)

March 2024 - Marine Technology Reporter page: 9from marinas along the western coast. The exact number of lizing laser detection systems can detect mines just below the mines, as well as their locations, remains largely a mystery, surface, even those hiding in murky water. The Airborne Laser although reports suggest that over three hundred have been