Digital Camera

-

- 3D Laser Scanning for the Marine Industry Maritime Logistics Professional, Q4 2013 #46

FARO 3D laser scanning allows the Chief Engineer or Project Manager to work in detail with 3D model shots of machinery spaces with increased accuracy and reduced costs.

The time to install a Ballast Water Treatment (BWT) System or maybe an Exhaust Gas Scrubber is rapidly approaching. Or, perhaps, you are an inland vessel operator watching the subchapter M drama with great interest. In all of these cases, most vessels have limited space in which to install these items. That said; as the regulatory uncertainty with regard to the impending regulations dissolves, the high cost of installing these systems will not go away – unless, of course, emerging technologies can ease that pain somewhat. Fortunately, and just ahead of the regulatory enforcement, comes FARO’s new 3D Laser Scanning system.

Even without new environmental requirements, the marine Industry is in great need of applying emerging technologies like 3D Laser Scanning to a myriad of new tasks. Tens of thousands of aging vessels will soon need equipment retrofits, most of which involves navigating narrow, tight, and limited space areas. Even for those owners who have archives of original drawings, those general arrangement depictions may not accurately reflect the current situation on a given vessel, especially one which has been around for a while and seen its share of repair yard insertions. Hence, equipment retrofit is typically extensive, costly, time consuming, and fraught with measurement errors. It doesn’t have to be that way.

Old School

The typical approach when performing ship checks is to bring designers and/or engineers on board where, using tape measures, they record measurements of the existing systems and spaces. These measurements are then used in developing scope and construction documents. However, the uncertainty of the measurements requires allowances be included to account for discrepancies between the measurements and reality. These allowances can be expensive and/or prevent the installation of new equipment in a certain location because the space was considered too small, when in fact there was adequate clearance. Or, conversely, maybe not enough at the time of installation.

3D Laser Scanning

A better approach involves scanning ship spaces with a 3D laser scanner to create a very detailed and accurate 3D point cloud model. Today’s high speed laser scanners are quite suitable for this purpose as they can take tens of millions of measurements in just a few minutes. Scans are taken from various positions in order to provide sufficient coverage around equipment. The scans are then registered together to bring them all into the same coordinate system. Done properly, with the latest FARO Focus3D scanner, the laser scan data can be accurate to within 3 mm over 10 meter distances.

Benefits of using 3D laser scanning:- Laser scanning can often be done while the ship is in operation.

- Vibration is one of the few limitations.

- Measurements: more comprehensive and precise compared to hand measurements.

- Reduces or eliminates the need for follow-up site visits.

- Design work can be carried out in office & within the created 3D Point Cloud Model.

- Data allows larger portion of new or replacement pipe spools to be pre-fabricated in shop @ lower cost.

- Data increases number of bolt-up tie-ins & reduces field welds, reducing shipyard costs & downtime.

With all these benefits, the use of 3D Laser Scanning, despite its availability, nevertheless has not become a mainstream practice in ship repair and retrofit operations. The reasons why come down to three main issues. These include cost of hardware, capability and difficulty of use, computing power limitations and inconsistent workflow and software solutions. Fortunately, most of these issues have been addressed, as depicted below:

1. Hardware Cost and Difficulty of Use

Until recently, laser scanning equipment was cumbersome (multiple components with total weight over 150 lbs) expensive ($150,000+), requiring highly skilled crews to operate. With the recent offerings from FARO, however, the new Focus3D scanners weigh in at just 12 pounds, at about one-third the cost and are similar in operation to a high end digital camera. The new scanners can, with one person, take significantly better measurements in one day than a ‘ship check’ team can accomplish in a week’s time. More significant, perhaps, is that every vessel can perhaps justify having a scanner on board, allowing the Chief Engineer or Project Manager to direct work in detail within 3D model shots of his machinery spaces. With this approach, the cost required to obtain accurate measurements has been greatly reduced – and can be accomplished from far out to sea, well in advance of the repair procedure.

2. Computing Power Limitations

Another barrier to wide acceptance of 3D Laser Scanning was the huge data sets that bog down computers and made it difficult for managers to visualize their projects in the 3D Point Cloud. Autodesk ReCap and Bentley Pointools among others have and are making great strides to overcome this barrier.

3. Difficult Workflow and Software Solutions

The next limiting factor is the work flow and software that allows CAD Designers to work directly in the 3D Laser Scan Point Cloud model and apply statistically valid algorithms to the point cloud data for feature extraction of system components such as piping, structure, and more. The software available on the market to meet this need has grown considerably over the last few years and is available from such companies as Kubit, Innovmetric, Edgewise and Kohera3D – just to name a few.

“We Haven’t the Money, So We’ve Got to Think”

It was Ernest Lord Rutherford who is credited with saying, “We haven’t the money, so we’ve got to think.” A renowned Physicist, Rutherford proved time and time again that thinking saves money, but what drove him was his love of solving problems in more efficient and cost effective ways. The new 3D laser scanning technology is the perfect fit for this way of thinking.

In 2007, Summit Engineering and Design, LLC moved to FARO scanners and at the same time, began to develop software solutions so CAD designers could work directly in the Point Cloud model. Summit had learned the hard way that the further away from the Point Cloud the designer was removed, the more likely simple, yet costly design mistakes would be made. Data sets were needed that (a.) AutoCAD could handle, (b.) would allow clients to direct their project scope, and (c.) allow all to see the progress of the design efforts. Ultimately, this led to the ability to isolate (or classify or segment) the point cloud model into individual layers where they could be worked with in AutoCAD and visualized in Navisworks.

By loading high resolution “corridors” or volume boxes of specific areas within the point cloud model, this provided designers with the detail they needed to “thread the needle” on tight pipe routings while at the same time maintaining reasonable stability and performance speeds of the CAD system. In other words, the perfect tool for that tight ballast water treatment retrofit.

But even with all these options, designers were still tracing and eyeballing the new design over the scan data. In response, Summit developed statistically valid feature extraction algorithms to give the designers “Basic Modeled Parts” which included such things as cylinder fits, pipe centerlines, face of flange and top of steel locations. These Basic Modeled Parts provided “snap-to-points” in AutoCAD. In addition to these Basic Modeled Parts, it was discovered that loading high resolution “corridors” or volume boxes of specific areas within the point cloud model also provided designers with the detail they needed, while at the same time maintaining reasonable stability and performance speeds of the CAD system.

Design & Retrofit – The Way Forward

Although it is possible to continue using the “brute force” methods of the past, 3D Laser Scanning has emerged as a valuable and accessible technology that will continue to make measurable strides in the shipyard industry, and beyond. But, if you’ve got all the time and money in the world, and you don’t like to think too much, then continue on as before.

(As published in the 4Q 2013 edition of Maritime Professional - www.maritimeprofessional.com)

-

- I can see clearly now ... Via Resolution Optics Marine Technology, Mar 2014 #66

through the sample. Part of the light wave is scattered by objects present within the volume and both unscattered and scattered waves reach a digital camera sensor, producing an interference pattern. This interference pattern image is known as a hologram and is recorded by the camera sensor. That is

-

)

March 2024 - Marine Technology Reporter page: 48

)

March 2024 - Marine Technology Reporter page: 48Inc. . . . . . . . . . . . . . . . . .www.detyens.com . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Please visit us online 27 . . . . .Digital Edge Subsea Ltd . . . . . . . . . . . . . . . .www.digitaledgesubsea.com . . . . . . . . . . . . . . . . . . . . . .+44 (1229) 206456 C2 . . . .

-

)

March 2024 - Marine Technology Reporter page: 43

)

March 2024 - Marine Technology Reporter page: 43system is a drop-in replacement for the GeoPulse Pinger EM 124 or EM 304 MBES systems – which is in most cases using the 5430A transmitter. It is fully digital and features a va- already available on board the vessel. Essentially, the EM SBP riety of waveforms unavailable with the previous generation of

-

)

March 2024 - Marine Technology Reporter page: 41

)

March 2024 - Marine Technology Reporter page: 41Image courtesy Outland Technology Image courtesy Exail Image courtesy Submaris and EvoLogics Vehicles The ROV-1500 from Outland Technology represents a leap forward in underwater robotics, a compact remotely operated vehicle (ROV) weighing in at less than 40 lbs (19kg) the ROV- 1500 is easy to transport

-

)

March 2024 - Marine Technology Reporter page: 36

)

March 2024 - Marine Technology Reporter page: 36LANDER LAB #10 Of special interest for marine applications, LiPo batteries are Shipping any kind of lithium battery can be a challenge, and offered in a “pouch” design, with a soft, ? at body. The pouch IATA regs vary with the batteries inside or outside an instru- is vacuum-sealed, with all voids ?

-

)

March 2024 - Marine Technology Reporter page: 30

)

March 2024 - Marine Technology Reporter page: 30and power umbilical is performed subsea, nodules have helped further advance the design. and the LARS is ? tted with a routing system that keeps the Digital twin technology analyzes data gathered from mul- umbilical in a single plane during collector operations. tiple sensors and assets to enable 3D visualizat

-

)

March 2024 - Marine Technology Reporter page: 20

)

March 2024 - Marine Technology Reporter page: 202024 February 2024 March/April 2024 Ad close Jan.31 Ad close March 21 Ad close Feb. 4 Underwater Vehicle Annual Offshore Energy Digital Edition ?2?VKRUH:LQG$)ORDWLQJ)XWXUH ?2FHDQRJUDSKLF?QVWUXPHQWDWLRQ 6HQVRUV ?6XEVHD'HIHQVH ?6XEVHD'HIHQVH7KH+XQWIRU ?0DQLSXODWRU$UPV 7RROV 8;2

-

)

March 2024 - Marine Technology Reporter page: 3

)

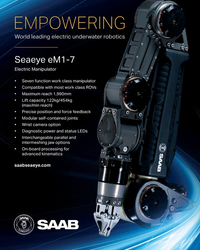

March 2024 - Marine Technology Reporter page: 3EMPOWERING World leading electric underwater robotics Seaeye eM1-7 Electric Manipulator • Seven function work class manipulator • Compatible with most work class ROVs • Maximum reach 1,990mm • Lift capacity 122kg/454kg (max/min reach) • Precise position and force feedback • Modular self-contained

-

)

April 2024 - Maritime Reporter and Engineering News page: 43

)

April 2024 - Maritime Reporter and Engineering News page: 43and Ports providers on developing standards and print and accelerate the commercialized tection. The work would also demand a regulations to help digitalization nurture scaling-up of solutions. review of SOLAS formulations for the decarbonization. New energy saving devices, alterna- design, planning

-

)

April 2024 - Maritime Reporter and Engineering News page: 42

)

April 2024 - Maritime Reporter and Engineering News page: 42plays in Regulators are fully aware that rap- tion’s carbon intensity indicator (CII) meeting the shipping industry’s goal for id advances in digital technology are and EU Emissions Trading Scheme are net-zero greenhouse gas emissions by changing the way ships are operated. only early milestones

-

)

April 2024 - Maritime Reporter and Engineering News page: 41

)

April 2024 - Maritime Reporter and Engineering News page: 41decision-making. With a timely achievement. With increasing that could ease the investigative work re- better decision-making comes improved use of digital shipping technology, com- quired for concluding claims. safety. Improved safety in turn helps to bined with a global shortage of experi- It can

-

)

April 2024 - Maritime Reporter and Engineering News page: 40

)

April 2024 - Maritime Reporter and Engineering News page: 40TECH FEATURE SITUATIONAL AWARENESS SITUATIONAL AWARENESS SYSTEM BATTLES COGNITIVE FATIGUE IN WATCHKEEPERS All images courtesy Groke Technologies Today’s evolving maritime security risks pose all-too-familiar threats to international shipping, and as just one of the many causes of fatigue, they add

-

)

April 2024 - Maritime Reporter and Engineering News page: 37

)

April 2024 - Maritime Reporter and Engineering News page: 37tools, as farer is going to have to be more technol- these will play a major role in autono- ogy-savvy than in previous years,” says mous ships. “Digital training solutions Vassilios Kroustallis, VP, Global Busi- like this also help accelerate innovation ness Development, ABS. “Quite apart and research

-

)

April 2024 - Maritime Reporter and Engineering News page: 36

)

April 2024 - Maritime Reporter and Engineering News page: 36courtesy ABS – Terje Heierstad, VP Business – Vassilios Kroustallis, VP, Global Development, Maritime Business Development, ABS Simulation, Kongsberg Digital Clou u u ud d d d d d d s si im mu ul lati io on n n n n t t training g Image courtesy Kongsberg Image courtesy Kongsberg Digital 36 Maritime Reporter

-

)

April 2024 - Maritime Reporter and Engineering News page: 35

)

April 2024 - Maritime Reporter and Engineering News page: 35and bite- Simulators are becoming as interconnected as onboard sys- size training materials, including micro-learning videos, gam- tems. Kongsberg Digital has integrated NORBIT’s oil spill ing apps, VR programs and online mentoring. detection system with its K-Pos DP system for simulation- “These digital

-

)

April 2024 - Maritime Reporter and Engineering News page: 34

)

April 2024 - Maritime Reporter and Engineering News page: 34FEATURE Image courtesy Kongsberg Digital Simulators Track our Changing Relationship with Technology Simulation-based training has its whole-of-ship/ whole-of-team scenarios, but zooming in, the industry is now working on more speci? c targets. By Wendy Laursen Image above: Kongsberg Digital has integrated

-

)

April 2024 - Maritime Reporter and Engineering News page: 11

)

April 2024 - Maritime Reporter and Engineering News page: 11evolution towards a safer, more transpar- methodology enhances the effectiveness of the SIRE program, ent, and ef? cient future. By leveraging digital innovation and ensuring that it remains a relevant and powerful tool for im- fostering a collaborative, improvement-driven culture, SIRE proving

-

)

April 2024 - Maritime Reporter and Engineering News page: 10

)

April 2024 - Maritime Reporter and Engineering News page: 10, heralds a new era in vessel inspection, compliance, ensuring stakeholders are well-equipped to navigate the new and reporting, marrying the latest digital technologies with es- inspection framework. tablished inspection practices to elevate maritime safety and SIRE 2.0 brings digital reporting and

-

)

April 2024 - Maritime Reporter and Engineering News page: 2nd Cover

)

April 2024 - Maritime Reporter and Engineering News page: 2nd CoverBy pairing our technical knowledge with the latest digital technologies, ABS leads the maritime industry in providing customers with innovative, tailored sustainability solutions that deliver results. Learn more today www.eagle.org/sustainability COV2, C3 &C4 MR Apr 2024.indd 1 3/22/2024 9:12:58

-

)

April 2024 - Marine News page: 37

)

April 2024 - Marine News page: 37Feature Electric Tugs could change down the road. “What do we really need an In San Diego, eWolf’s transits will typically run 20-30 engineer to do? There are no moving parts. So, how does minutes, “not the optimal operation to really see a lot of that [role] change? How does that change where we work?

-

)

April 2024 - Marine News page: 19

)

April 2024 - Marine News page: 19chal- government, industry and international entities, the mari- lenges by providing guidance for incorporating cybersecu- time sector can navigate these digital waters more safely. Im- rity into Facility Security Assessments (FSAs) and Facility plementing these solutions will not only safeguard national Security

-

)

April 2024 - Marine News page: 18

)

April 2024 - Marine News page: 18chain attacks on the rise, works, while foundational, have not evolved in tandem and nation-state attackers constantly looking for new ways with these digital threats, leaving gaps that could be ex- to disrupt national security and economic stability, one of ploited. The International Ship and Port Facility

-

)

April 2024 - Marine News page: 14

)

April 2024 - Marine News page: 14Insights tion on a couple of issues, including engine room crew- For AWO, as an organization, what is its top ing on ATBs with automated systems. This is an issue priorities for the coming six to 12 months and that Congress thought that it addressed in the last Coast what’s being done to address them? Gua

-

)

February 2024 - Maritime Reporter and Engineering News page: 20

)

February 2024 - Maritime Reporter and Engineering News page: 20production unit operations and maintenance performance, in- analyses the commercial and technical potential vessel capac- cluding IoT connectivity, digital twins and autonomous opera- ity and capability gaps in detail as well as why the commercial tions. conditions don’t yet really exist for sustained

-

)

February 2024 - Maritime Reporter and Engineering News page: 2nd Cover

)

February 2024 - Maritime Reporter and Engineering News page: 2nd CoverBy pairing our technical knowledge with the latest digital technologies, ABS leads the maritime industry in providing customers with innovative, tailored sustainability solutions that deliver results. Learn more today at www.eagle.org/sustainability COV2, C3 &C4 MR Feb 2024.indd 1 2/5/2024 2:21:21