Page 41: of Marine News Magazine (September 2011)

The Environmental Edition

Read this page in Pdf, Flash or Html5 edition of September 2011 Marine News Magazine

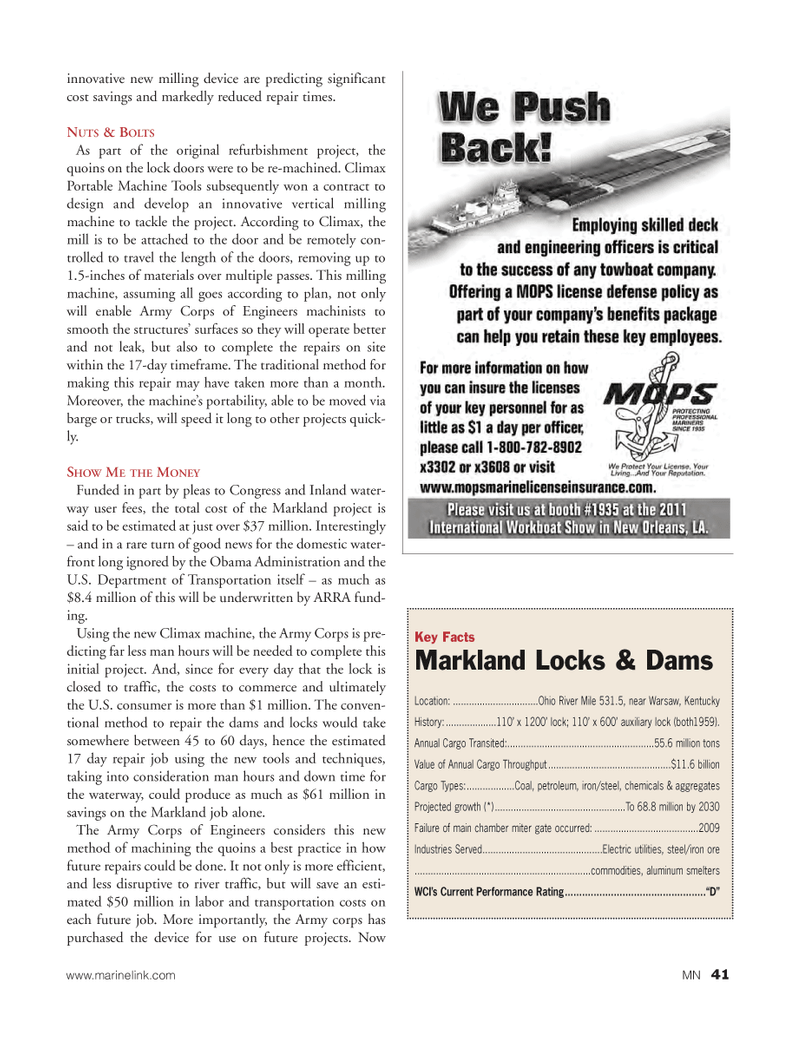

www.marinelink.com MN41innovative new milling device are predicting significant cost savings and markedly reduced repair times. NUTS & BOLTS As part of the original refurbishment project, the quoins on the lock doors were to be re-machined. Climax Portable Machine Tools subsequently won a contract to design and develop an innovative vertical milling machine to tackle the project. According to Climax, the mill is to be attached to the door and be remotely con- trolled to travel the length of the doors, removing up to 1.5-inches of materials over multiple passes. This milling machine, assuming all goes according to plan, not only will enable Army Corps of Engineers machinists to smooth the structures? surfaces so they will operate better and not leak, but also to complete the repairs on site within the 17-day timeframe. The traditional method for making this repair may have taken more than a month. Moreover, the machine?s portability, able to be moved via barge or trucks, will speed it long to other projects quick- ly. SHOW METHE MONEY Funded in part by pleas to Congress and Inland water- way user fees, the total cost of the Markland project is said to be estimated at just over $37 million. Interestingly ? and in a rare turn of good news for the domestic water- front long ignored by the Obama Administration and the U.S. Department of Transportation itself ? as much as $8.4 million of this will be underwritten by ARRA fund- ing.Using the new Climax machine, the Army Corps is pre- dicting far less man hours will be needed to complete thisinitial project. And, since for every day that the lock is closed to traffic, the costs to commerce and ultimately the U.S. consumer is more than $1 million. The conven- tional method to repair the dams and locks would take somewhere between 45 to 60 days, hence the estimated 17 day repair job using the new tools and techniques, taking into consideration man hours and down time for the waterway, could produce as much as $61 million in savings on the Markland job alone. The Army Corps of Engineers considers this new method of machining the quoins a best practice in how future repairs could be done. It not only is more efficient, and less disruptive to river traffic, but will save an esti- mated $50 million in labor and transportation costs on each future job. More importantly, the Army corps has purchased the device for use on future projects. Now Key FactsMarkland Locks & DamsLocation:................................Ohio River Mile 531.5, near Warsaw, Kentucky History:...................110? x 1200? lock; 110? x 600? auxiliary lock (both1959). Annual Cargo Transited:.......................................................55.6 million tons Value of Annual Cargo Throughput..............................................$11.6 billion Cargo Types:..................Coal, petroleum, iron/steel, chemicals & aggregates Projected growth (*).................................................To 68.8 million by 2030 Failure of main chamber miter gate occurred:.......................................2009 Industries Served.............................................Electric utilities, steel/iron ore ..................................................................commodities, aluminum smeltersWCI?s Current Performance Rating.................................................?D? MN#9 (32-49):MN 2011 Layouts 9/6/2011 12:26 PM Page 41

40

40

42

42