Page 49: of Marine News Magazine (August 2014)

MN 100 Market Leaders

Read this page in Pdf, Flash or Html5 edition of August 2014 Marine News Magazine

SOFTWARE cesses, inspecting components and assemblies, production planning, documenting large volume spaces or structures in 3D, surveying and construction, and reconstruction of accident sites.

The technology produces measureable ROI, such as tremendous time savings, lower labor costs, and reduced vessel downtime. To ensure customers start seeing savings within 90 days, the “Faro Check” sends out employees to assess the project and correct any issues, via more train- ing or fi xing workfl ow obstacles, etc. The company claims about 15,000 customers operating more than 30,000 in- stallations. “Most of our products are simple enough our kids can use them,” says Rob Pietsch, vice president of marketing –Americas.

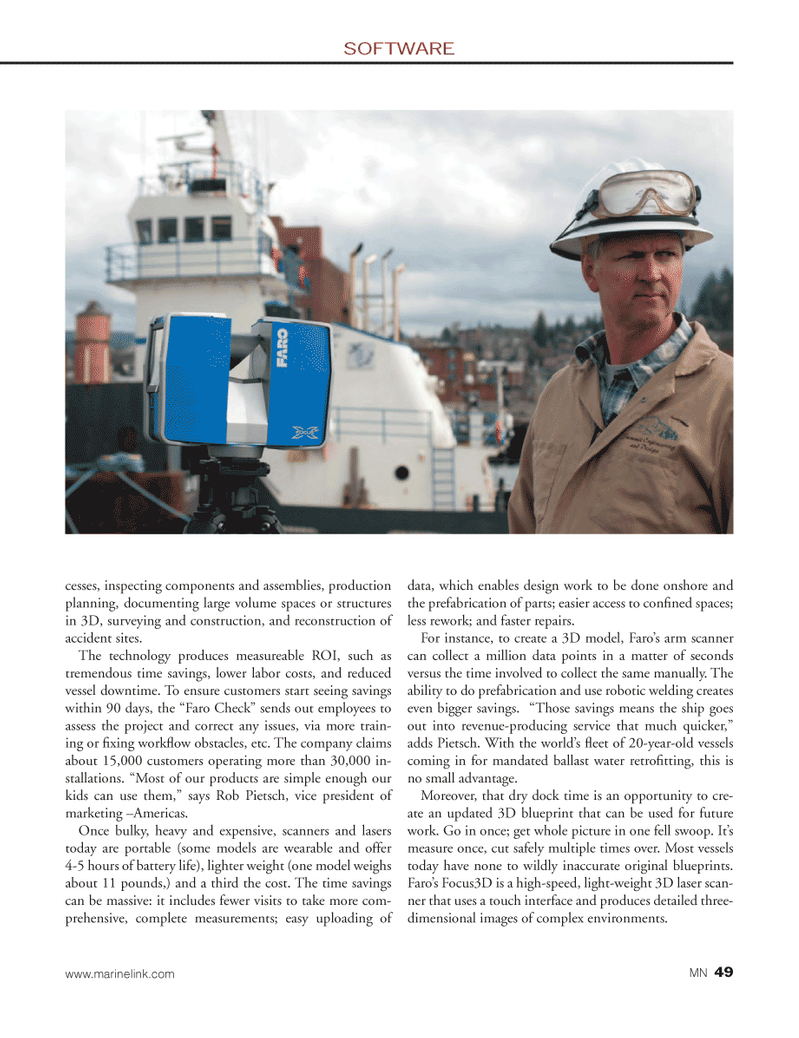

Once bulky, heavy and expensive, scanners and lasers today are portable (some models are wearable and offer 4-5 hours of battery life), lighter weight (one model weighs about 11 pounds,) and a third the cost. The time savings can be massive: it includes fewer visits to take more com- prehensive, complete measurements; easy uploading of data, which enables design work to be done onshore and the prefabrication of parts; easier access to confi ned spaces; less rework; and faster repairs.

For instance, to create a 3D model, Faro’s arm scanner can collect a million data points in a matter of seconds versus the time involved to collect the same manually. The ability to do prefabrication and use robotic welding creates even bigger savings. “Those savings means the ship goes out into revenue-producing service that much quicker,” adds Pietsch. With the world’s fl eet of 20-year-old vessels coming in for mandated ballast water retrofi tting, this is no small advantage.

Moreover, that dry dock time is an opportunity to cre- ate an updated 3D blueprint that can be used for future work. Go in once; get whole picture in one fell swoop. It’s measure once, cut safely multiple times over. Most vessels today have none to wildly inaccurate original blueprints.

Faro’s Focus3D is a high-speed, light-weight 3D laser scan- ner that uses a touch interface and produces detailed three- dimensional images of complex environments. MN 49www.marinelink.com 32-49 MN Aug14.indd 49 7/18/2014 1:37:31 PM

48

48

50

50