Page 48: of Marine News Magazine (April 2016)

Boatbuilding: Construction & Repair

Read this page in Pdf, Flash or Html5 edition of April 2016 Marine News Magazine

COATINGS

Pontoon Deck Preservation for Floating Dry Docks

Always important, anything but simple, but often overlooked.

By Bill Kraus

Courtesy: Vigor-Alaska photography ry dock pontoon deck preservation is often taken surface preparation efforts, then UHP (ultra-high pressure) for granted. In the ? ow of ever changing priorities water blasting at 35,000-40,000 psi is a modern alterna-

D for dry docks, it often gets pushed aside and/or de- tive. Designed to suck up debris and water from blasting, layed. If neglected long enough and often enough between it also leaves the surface clean and dry. preservation cycles, the thickness of the pontoon deck steel Chloride contamination needs to be removed to the plates can be compromised. Salt water with chloride con- level of 70 microsiemens of conductivity, even if it means tamination causes accelerated corrosion while impact and more than one pressure washing. Otherwise, once the coat- abrasion damage from heavy equipment also take their toll. ing has been applied, galvanic corrosion cells will develop,

For shipyards, the overall objective should be to provide causing delamination of the coating. Flash rust can be a a protective surface that will hold up over time, and that problem for coating longevity, although a slight ‘bloom’ is easy to clean. Ease of cleaning can save a lot of cost each can be tolerated by some coatings. Before the work day time after repeated dockings. All of that said; surface prep- ends and moisture appears, a primer coat should be ap- aration is the key. plied to seal the freshly blasted steel.

Coatings: Preparation is Everything Five Year Life Service

A clean sweep down of the intended surface areas should A high build coating system is best for longevity, and the be done before the subcontractor arrives on site. Pressure proper equipment will involve the use of a plural compo- washing at 3500 psi is the best way to remove chloride con- nent, heated airless spray machine capable of handling Part tamination, loose rust scale, and/or delaminated coatings. A/Part B ratios as high as 10:1. The coating system to be

Weather can be an annoying problem, but if it interferes, it is employed should include a primer coat in addition to the top better to call off work for the day than to have ? ash rust ap- coat. That’s because the typical 10-15 mil coating system em- pear, or worse, coating delamination due to excess moisture. ployed in the past is simply not suf? cient. A 40 mil system is

Shot blasting is one of the most cost effective methods of optimal, and extra millage may be required if pitting is severe. removing the old surface down to a near white metal condi- At least two days should be allowed for the coating sys- tion. A 3-4 mil anchor pro? le is preferred. Sand blasting is tem to cure; at least 24 hours for foot traf? c, 48 hours another method of surface preparation, but the containment for vehicle traf? c and submergence, a ? ve day cure. An required for sand blasting the entire pontoon deck in most anti-skid treatment on top of the ? nal coat – a 16-20 grit locales makes this approach too expensive. Nevertheless, sand aluminum oxide or equivalent – ? nishes the job.

blasting is ideal for reaching areas – wing walls, and raised steel strips along the pontoon deck – that can be dif? cult to Calculating Costs: apples to apples otherwise reach. In each case, a temporary shed can be con- The coating system itself is always the least expensive part structed using PVC pipes and plastic sheeting which moves of the pontoon deck preservation process. In fact, the coat- along with the sand blaster inside. Hand tooling should be ing applied will typically amount to only 20% of the overall kept to a minimum – it is labor intensive and expensive. job, with labor and equipment to prepare the surface and la-

If an anchor pro? le already exists on the steel from past bor and equipment to apply the coating making up the rest.

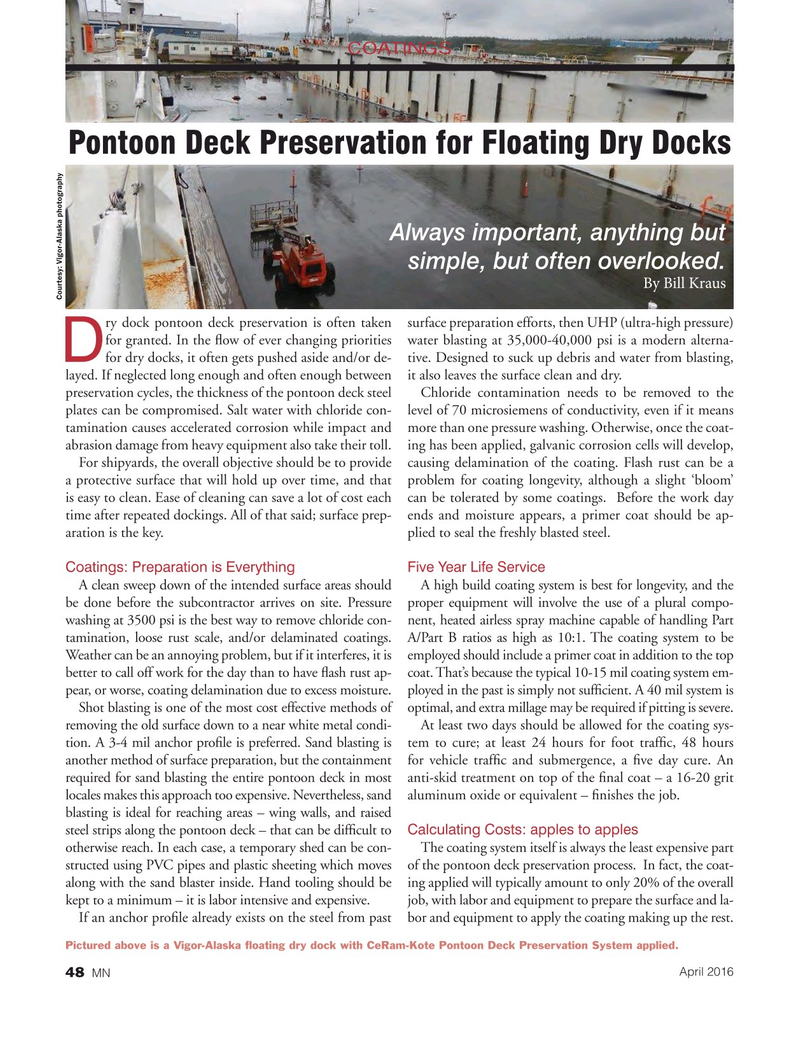

Pictured above is a Vigor-Alaska ? oating dry dock with CeRam-Kote Pontoon Deck Preservation System applied.

April 2016 48 MN

MN April16 Layout 32-49.indd 48 3/18/2016 10:41:47 AM

47

47

49

49