Page 36: of Marine News Magazine (May 2016)

Inland Waterways

Read this page in Pdf, Flash or Html5 edition of May 2016 Marine News Magazine

REGULATORY COMPLIANCE n

V o

G

P n w

C o o m

D ’ p g l

Thordon’s RiverTough prop shaft n i i a bearings eliminate headaches for r n a inland workboat operators – for the c e e bottom line, below the waterline.

B ‘

By Joseph Keefe he U.S. Environmental Protection Agency’s (EPA) bearings use the ultimate environmentally acceptable lu- new Vessel General Permit (VGP) regulations bricant (EAL) – water.

T which have come into effect impact every vessel op- Ultimately, Thordon users are unaffected by the ever- erating in U.S. waters. Indeed, there are 27 potential dis- changing regulations on environmentally acceptable lubri- charge sources identi? ed by EPA that can trip up even the cants. They also sleep better at night.

best of operators. One of those sources, of course, involves stern tubes and propeller shafts, where the use of so-called

RiverTough environmentally acceptable lubricants (EAL) is also now

Thordon’s RiverTough water lubricated tailshaft bear- required, except in the cases where OEM documentation ings, among other things, also eliminate the use of grease, speci? cally de? nes those products as infeasible. But, those another requirement of the VGP. On the water, Thordon excuses are rapidly going away, and that reality gives work- has several types of propeller shaft bearings for different boat operators plenty to worry about.

types of environments. While COMPAC bearings – prob-

On the other hand, out on North America’s brown wa- ably Thordon’s best known product – are best suited for ter estuaries, today is just another day for Thordon bearing deep draft ships operating in blue water, RiverTough prop users. Their decision to use water lubricated propeller shaft shaft bearings are best for those workboats operating in bearings ensures compliance in their oil to sea interfaces dirty, abrasive-laden waters. The size and type of bearing with the U.S. Environmental Protection Agency’s (EPA) utilized will only depend on how large of a diameter the new Vessel General Permit (VGP) regulations. That’s be- vessel requires and what is dictated by the water conditions.

cause Thordon’s RiverTough water lubricated tailshaft

The EPA’s VGP isn’t the only thing workboat operators

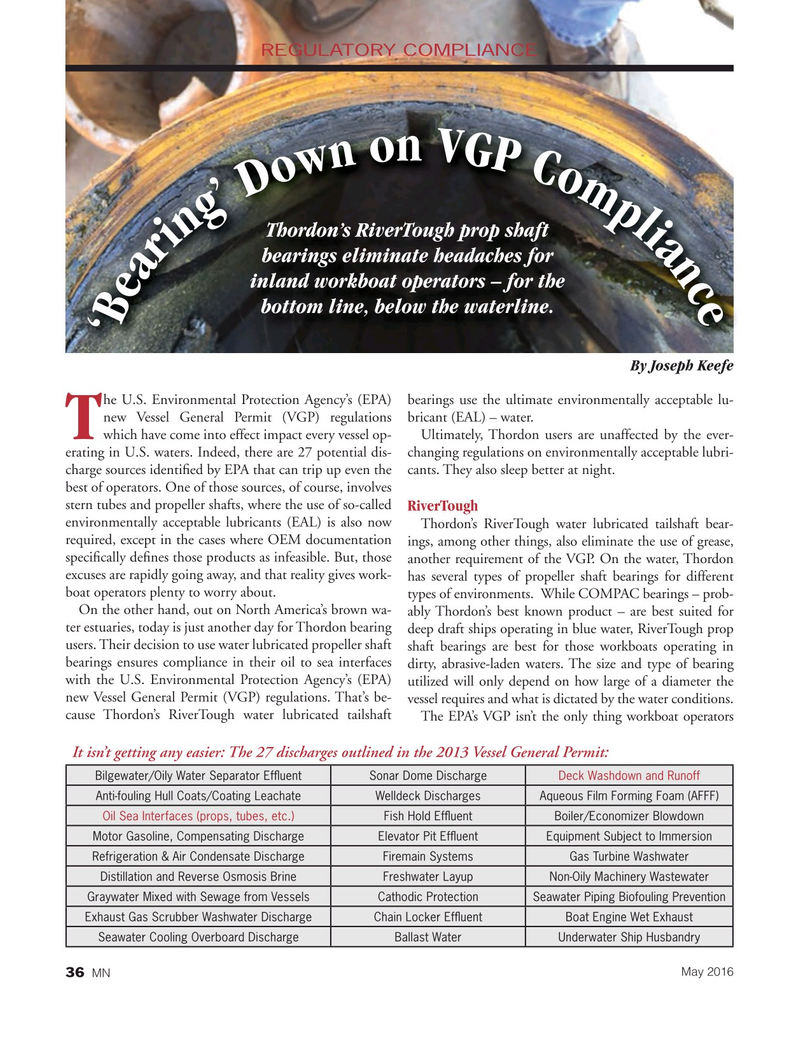

It isn’t getting any easier: The 27 discharges outlined in the 2013 Vessel General Permit:

Bilgewater/Oily Water Separator Ef? uent Sonar Dome Discharge Deck Washdown and Runoff

Anti-fouling Hull Coats/Coating Leachate Welldeck DischargesAqueous Film Forming Foam (AFFF)

Oil Sea Interfaces (props, tubes, etc.) Fish Hold Ef? uent Boiler/Economizer Blowdown

Motor Gasoline, Compensating Discharge Elevator Pit Ef? uent Equipment Subject to Immersion

Refrigeration & Air Condensate Discharge Firemain Systems Gas Turbine Washwater

Distillation and Reverse Osmosis Brine Freshwater Layup Non-Oily Machinery Wastewater

Graywater Mixed with Sewage from Vessels Cathodic ProtectionSeawater Piping Biofouling Prevention

Exhaust Gas Scrubber Washwater Discharge Chain Locker Ef? uent Boat Engine Wet Exhaust

Seawater Cooling Overboard Discharge Ballast Water Underwater Ship Husbandry

May 2016

MN 36

MN May16 Layout 34-51.indd 36 4/20/2016 11:43:27 AM

35

35

37

37