Page 28: of Marine News Magazine (July 2016)

Propulsion Technology

Read this page in Pdf, Flash or Html5 edition of July 2016 Marine News Magazine

PROPULSION: DESIGN

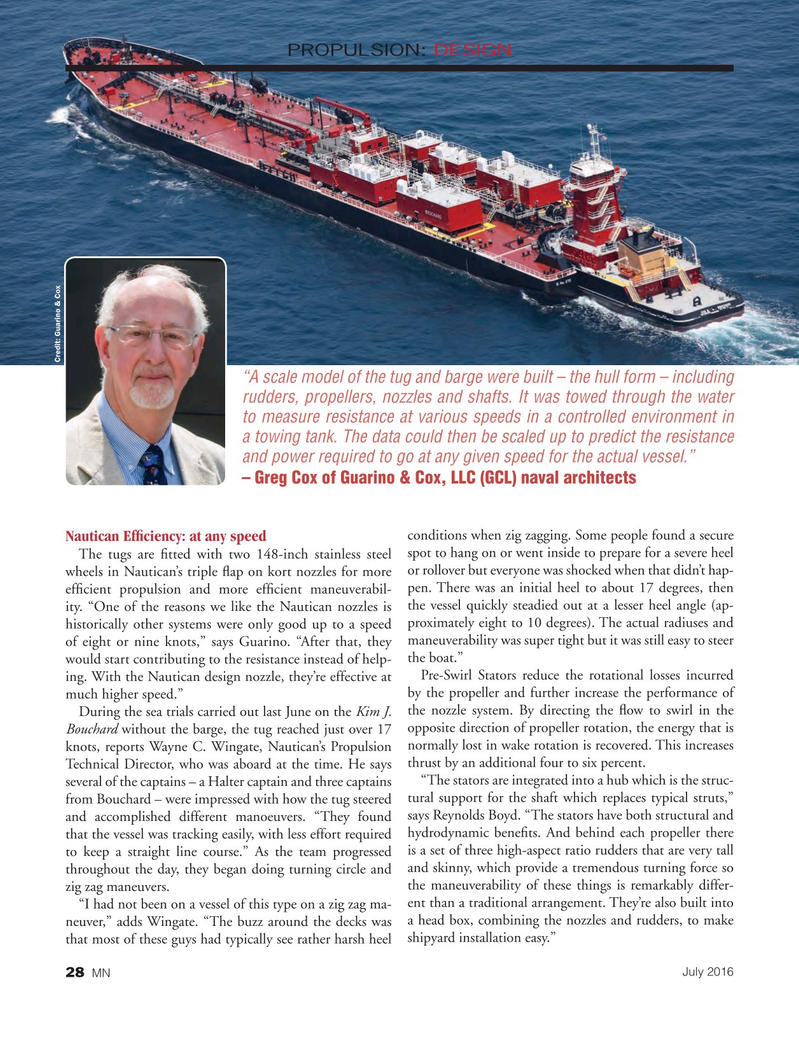

Credit: Guarino & Cox “A scale model of the tug and barge were built – the hull form – including rudders, propellers, nozzles and shafts. It was towed through the water to measure resistance at various speeds in a controlled environment in a towing tank. The data could then be scaled up to predict the resistance and power required to go at any given speed for the actual vessel.” – Greg Cox of Guarino & Cox, LLC (GCL) naval architects conditions when zig zagging. Some people found a secure

Nautican Ef? ciency: at any speed

The tugs are ? tted with two 148-inch stainless steel spot to hang on or went inside to prepare for a severe heel wheels in Nautican’s triple ? ap on kort nozzles for more or rollover but everyone was shocked when that didn’t hap- pen. There was an initial heel to about 17 degrees, then ef? cient propulsion and more ef? cient maneuverabil- ity. “One of the reasons we like the Nautican nozzles is the vessel quickly steadied out at a lesser heel angle (ap- historically other systems were only good up to a speed proximately eight to 10 degrees). The actual radiuses and of eight or nine knots,” says Guarino. “After that, they maneuverability was super tight but it was still easy to steer the boat.” would start contributing to the resistance instead of help-

Pre-Swirl Stators reduce the rotational losses incurred ing. With the Nautican design nozzle, they’re effective at by the propeller and further increase the performance of much higher speed.”

During the sea trials carried out last June on the Kim J. the nozzle system. By directing the ? ow to swirl in the

Bouchard without the barge, the tug reached just over 17 opposite direction of propeller rotation, the energy that is knots, reports Wayne C. Wingate, Nautican’s Propulsion normally lost in wake rotation is recovered. This increases

Technical Director, who was aboard at the time. He says thrust by an additional four to six percent. “The stators are integrated into a hub which is the struc- several of the captains – a Halter captain and three captains from Bouchard – were impressed with how the tug steered tural support for the shaft which replaces typical struts,” and accomplished different manoeuvers. “They found says Reynolds Boyd. “The stators have both structural and that the vessel was tracking easily, with less effort required hydrodynamic bene? ts. And behind each propeller there to keep a straight line course.” As the team progressed is a set of three high-aspect ratio rudders that are very tall throughout the day, they began doing turning circle and and skinny, which provide a tremendous turning force so the maneuverability of these things is remarkably differ- zig zag maneuvers.

ent than a traditional arrangement. They’re also built into “I had not been on a vessel of this type on a zig zag ma- neuver,” adds Wingate. “The buzz around the decks was a head box, combining the nozzles and rudders, to make that most of these guys had typically see rather harsh heel shipyard installation easy.”

July 2016

MN 28

MN July16 Layout 18-31.indd 28 6/20/2016 3:57:22 PM

27

27

29

29