Page 44: of Marine News Magazine (July 2016)

Propulsion Technology

Read this page in Pdf, Flash or Html5 edition of July 2016 Marine News Magazine

PROPULSION: EMISSIONS conomics, f? ciency

E missions

Drive Effective Choices

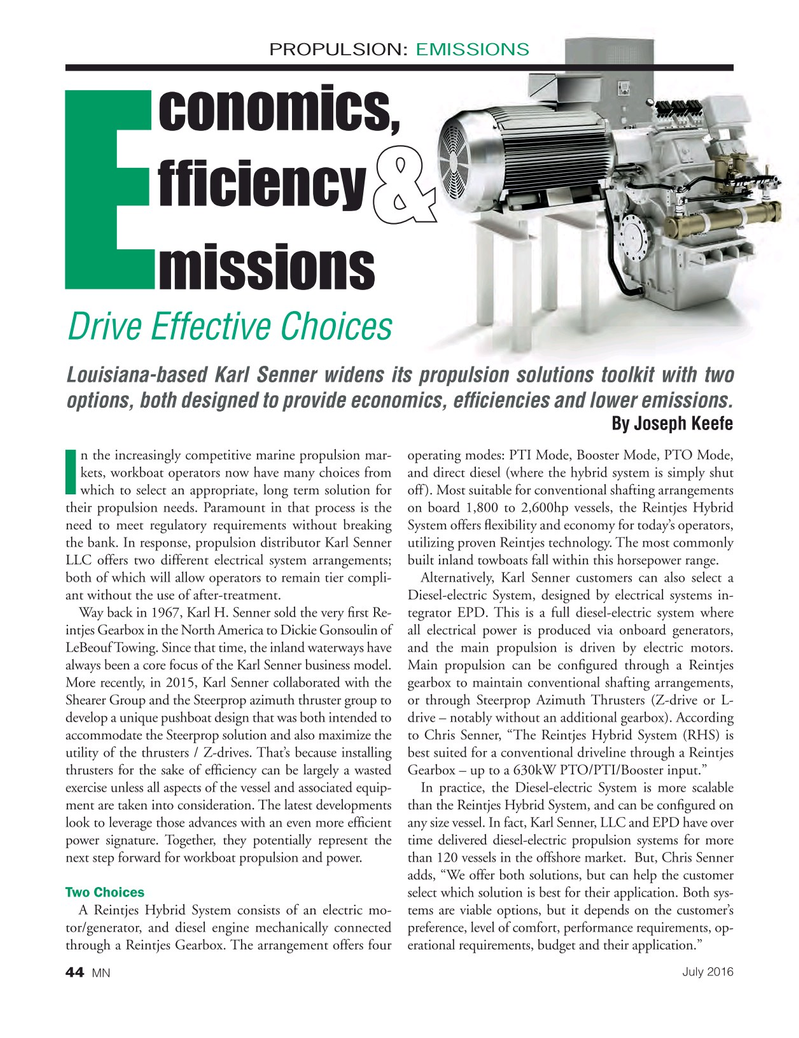

Louisiana-based Karl Senner widens its propulsion solutions toolkit with two options, both designed to provide economics, ef? ciencies and lower emissions.

By Joseph Keefe n the increasingly competitive marine propulsion mar- operating modes: PTI Mode, Booster Mode, PTO Mode, kets, workboat operators now have many choices from and direct diesel (where the hybrid system is simply shut which to select an appropriate, long term solution for off). Most suitable for conventional shafting arrangements

I their propulsion needs. Paramount in that process is the on board 1,800 to 2,600hp vessels, the Reintjes Hybrid need to meet regulatory requirements without breaking System offers ? exibility and economy for today’s operators, the bank. In response, propulsion distributor Karl Senner utilizing proven Reintjes technology. The most commonly

LLC offers two different electrical system arrangements; built inland towboats fall within this horsepower range. both of which will allow operators to remain tier compli- Alternatively, Karl Senner customers can also select a ant without the use of after-treatment. Diesel-electric System, designed by electrical systems in-

Way back in 1967, Karl H. Senner sold the very ? rst Re- tegrator EPD. This is a full diesel-electric system where intjes Gearbox in the North America to Dickie Gonsoulin of all electrical power is produced via onboard generators,

LeBeouf Towing. Since that time, the inland waterways have and the main propulsion is driven by electric motors. always been a core focus of the Karl Senner business model. Main propulsion can be con? gured through a Reintjes

More recently, in 2015, Karl Senner collaborated with the gearbox to maintain conventional shafting arrangements,

Shearer Group and the Steerprop azimuth thruster group to or through Steerprop Azimuth Thrusters (Z-drive or L- develop a unique pushboat design that was both intended to drive – notably without an additional gearbox). According accommodate the Steerprop solution and also maximize the to Chris Senner, “The Reintjes Hybrid System (RHS) is utility of the thrusters / Z-drives. That’s because installing best suited for a conventional driveline through a Reintjes thrusters for the sake of ef? ciency can be largely a wasted Gearbox – up to a 630kW PTO/PTI/Booster input.” exercise unless all aspects of the vessel and associated equip- In practice, the Diesel-electric System is more scalable ment are taken into consideration. The latest developments than the Reintjes Hybrid System, and can be con? gured on look to leverage those advances with an even more ef? cient any size vessel. In fact, Karl Senner, LLC and EPD have over power signature. Together, they potentially represent the time delivered diesel-electric propulsion systems for more next step forward for workboat propulsion and power. than 120 vessels in the offshore market. But, Chris Senner adds, “We offer both solutions, but can help the customer

Two Choices select which solution is best for their application. Both sys-

A Reintjes Hybrid System consists of an electric mo- tems are viable options, but it depends on the customer’s tor/generator, and diesel engine mechanically connected preference, level of comfort, performance requirements, op- through a Reintjes Gearbox. The arrangement offers four erational requirements, budget and their application.”

July 2016

MN 44

MN July16 Layout 32-49.indd 44 6/20/2016 4:16:33 PM

43

43

45

45