Page 99: of Marine News Magazine (November 2016)

Workboat Annual

Read this page in Pdf, Flash or Html5 edition of November 2016 Marine News Magazine

VESSELS

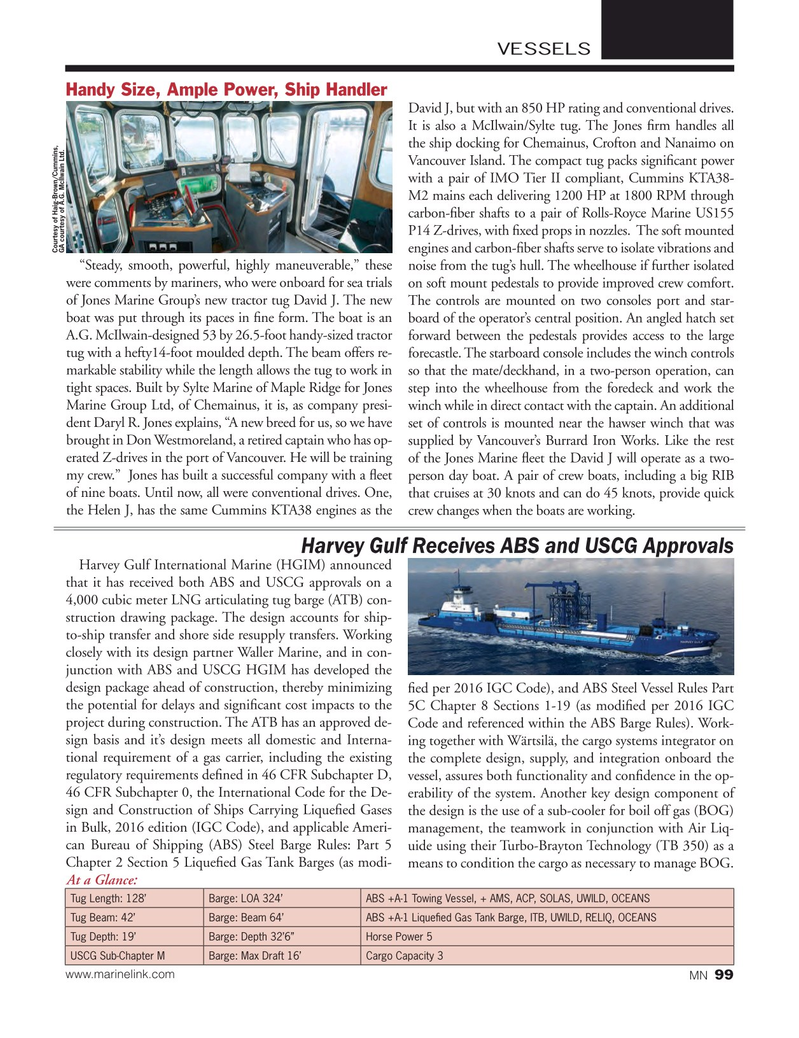

Handy Size, Ample Power, Ship Handler

David J, but with an 850 HP rating and conventional drives.

It is also a McIlwain/Sylte tug. The Jones ? rm handles all the ship docking for Chemainus, Crofton and Nanaimo on

Vancouver Island. The compact tug packs signi? cant power with a pair of IMO Tier II compliant, Cummins KTA38-

M2 mains each delivering 1200 HP at 1800 RPM through carbon-? ber shafts to a pair of Rolls-Royce Marine US155

P14 Z-drives, with ? xed props in nozzles. The soft mounted engines and carbon-? ber shafts serve to isolate vibrations and

Courtesy of Haig-Brown/Cummins,

GA courtesy of A.G. McIlwain Ltd.

“Steady, smooth, powerful, highly maneuverable,” these noise from the tug’s hull. The wheelhouse if further isolated were comments by mariners, who were onboard for sea trials on soft mount pedestals to provide improved crew comfort. of Jones Marine Group’s new tractor tug David J. The new The controls are mounted on two consoles port and star- boat was put through its paces in ? ne form. The boat is an board of the operator’s central position. An angled hatch set

A.G. McIlwain-designed 53 by 26.5-foot handy-sized tractor forward between the pedestals provides access to the large tug with a hefty14-foot moulded depth. The beam offers re- forecastle. The starboard console includes the winch controls markable stability while the length allows the tug to work in so that the mate/deckhand, in a two-person operation, can tight spaces. Built by Sylte Marine of Maple Ridge for Jones step into the wheelhouse from the foredeck and work the

Marine Group Ltd, of Chemainus, it is, as company presi- winch while in direct contact with the captain. An additional dent Daryl R. Jones explains, “A new breed for us, so we have set of controls is mounted near the hawser winch that was brought in Don Westmoreland, a retired captain who has op- supplied by Vancouver’s Burrard Iron Works. Like the rest erated Z-drives in the port of Vancouver. He will be training of the Jones Marine ? eet the David J will operate as a two- my crew.” Jones has built a successful company with a ? eet person day boat. A pair of crew boats, including a big RIB of nine boats. Until now, all were conventional drives. One, that cruises at 30 knots and can do 45 knots, provide quick the Helen J, has the same Cummins KTA38 engines as the crew changes when the boats are working.

Harvey Gulf Receives ABS and USCG Approvals

Harvey Gulf International Marine (HGIM) announced that it has received both ABS and USCG approvals on a 4,000 cubic meter LNG articulating tug barge (ATB) con- struction drawing package. The design accounts for ship- to-ship transfer and shore side resupply transfers. Working closely with its design partner Waller Marine, and in con- junction with ABS and USCG HGIM has developed the design package ahead of construction, thereby minimizing ? ed per 2016 IGC Code), and ABS Steel Vessel Rules Part the potential for delays and signi? cant cost impacts to the 5C Chapter 8 Sections 1-19 (as modi? ed per 2016 IGC project during construction. The ATB has an approved de- Code and referenced within the ABS Barge Rules). Work- sign basis and it’s design meets all domestic and Interna- ing together with Wärtsilä, the cargo systems integrator on tional requirement of a gas carrier, including the existing the complete design, supply, and integration onboard the regulatory requirements de? ned in 46 CFR Subchapter D, vessel, assures both functionality and con? dence in the op- 46 CFR Subchapter 0, the International Code for the De- erability of the system. Another key design component of sign and Construction of Ships Carrying Lique? ed Gases the design is the use of a sub-cooler for boil off gas (BOG) in Bulk, 2016 edition (IGC Code), and applicable Ameri- management, the teamwork in conjunction with Air Liq- can Bureau of Shipping (ABS) Steel Barge Rules: Part 5 uide using their Turbo-Brayton Technology (TB 350) as a

Chapter 2 Section 5 Lique? ed Gas Tank Barges (as modi- means to condition the cargo as necessary to manage BOG.

At a Glance:

Tug Length: 128’ Barge: LOA 324’ ABS +A-1 Towing Vessel, + AMS, ACP, SOLAS, UWILD, OCEANS

Tug Beam: 42’ Barge: Beam 64’ ABS +A-1 Lique? ed Gas Tank Barge, ITB, UWILD, RELIQ, OCEANS

Tug Depth: 19’ Barge: Depth 32’6” Horse Power 5

USCG Sub-Chapter MBarge: Max Draft 16’ Cargo Capacity 3 www.marinelink.com 99

MN

98

98

100

100