Page 51: of Marine News Magazine (February 2018)

Dredging & Marine Construction

Read this page in Pdf, Flash or Html5 edition of February 2018 Marine News Magazine

VESSELS

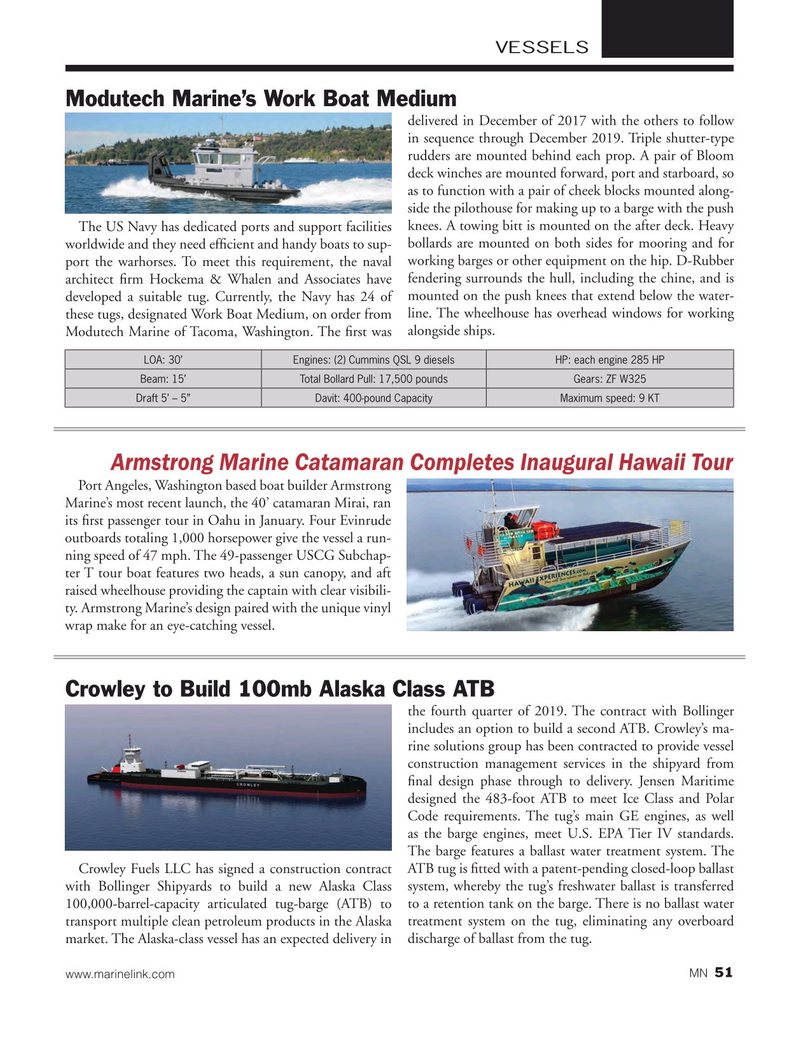

Modutech Marine’s Work Boat Medium delivered in December of 2017 with the others to follow in sequence through December 2019. Triple shutter-type rudders are mounted behind each prop. A pair of Bloom deck winches are mounted forward, port and starboard, so as to function with a pair of cheek blocks mounted along- side the pilothouse for making up to a barge with the push

The US Navy has dedicated ports and support facilities knees. A towing bitt is mounted on the after deck. Heavy worldwide and they need ef? cient and handy boats to sup- bollards are mounted on both sides for mooring and for port the warhorses. To meet this requirement, the naval working barges or other equipment on the hip. D-Rubber architect ? rm Hockema & Whalen and Associates have fendering surrounds the hull, including the chine, and is developed a suitable tug. Currently, the Navy has 24 of mounted on the push knees that extend below the water- these tugs, designated Work Boat Medium, on order from line. The wheelhouse has overhead windows for working

Modutech Marine of Tacoma, Washington. The ? rst was alongside ships.

LOA: 30’ Engines: (2) Cummins QSL 9 diesels HP: each engine 285 HP

Beam: 15’ Total Bollard Pull: 17,500 pounds Gears: ZF W325

Draft 5’ – 5” Davit: 400-pound Capacity Maximum speed: 9 KT

Armstrong Marine Catamaran Completes Inaugural Hawaii Tour

Port Angeles, Washington based boat builder Armstrong

Marine’s most recent launch, the 40’ catamaran Mirai, ran its ? rst passenger tour in Oahu in January. Four Evinrude outboards totaling 1,000 horsepower give the vessel a run- ning speed of 47 mph. The 49-passenger USCG Subchap- ter T tour boat features two heads, a sun canopy, and aft raised wheelhouse providing the captain with clear visibili- ty. Armstrong Marine’s design paired with the unique vinyl wrap make for an eye-catching vessel.

Crowley to Build 100mb Alaska Class ATB the fourth quarter of 2019. The contract with Bollinger includes an option to build a second ATB. Crowley’s ma- rine solutions group has been contracted to provide vessel construction management services in the shipyard from ? nal design phase through to delivery. Jensen Maritime designed the 483-foot ATB to meet Ice Class and Polar

Code requirements. The tug’s main GE engines, as well as the barge engines, meet U.S. EPA Tier IV standards.

The barge features a ballast water treatment system. The

Crowley Fuels LLC has signed a construction contract ATB tug is ? tted with a patent-pending closed-loop ballast with Bollinger Shipyards to build a new Alaska Class system, whereby the tug’s freshwater ballast is transferred 100,000-barrel-capacity articulated tug-barge (ATB) to to a retention tank on the barge. There is no ballast water transport multiple clean petroleum products in the Alaska treatment system on the tug, eliminating any overboard market. The Alaska-class vessel has an expected delivery in discharge of ballast from the tug.

51 www.marinelink.com MN

50

50

52

52