Page 14: of Marine News Magazine (October 2020)

Shipbuilding & Repair

Read this page in Pdf, Flash or Html5 edition of October 2020 Marine News Magazine

INSIGHTS

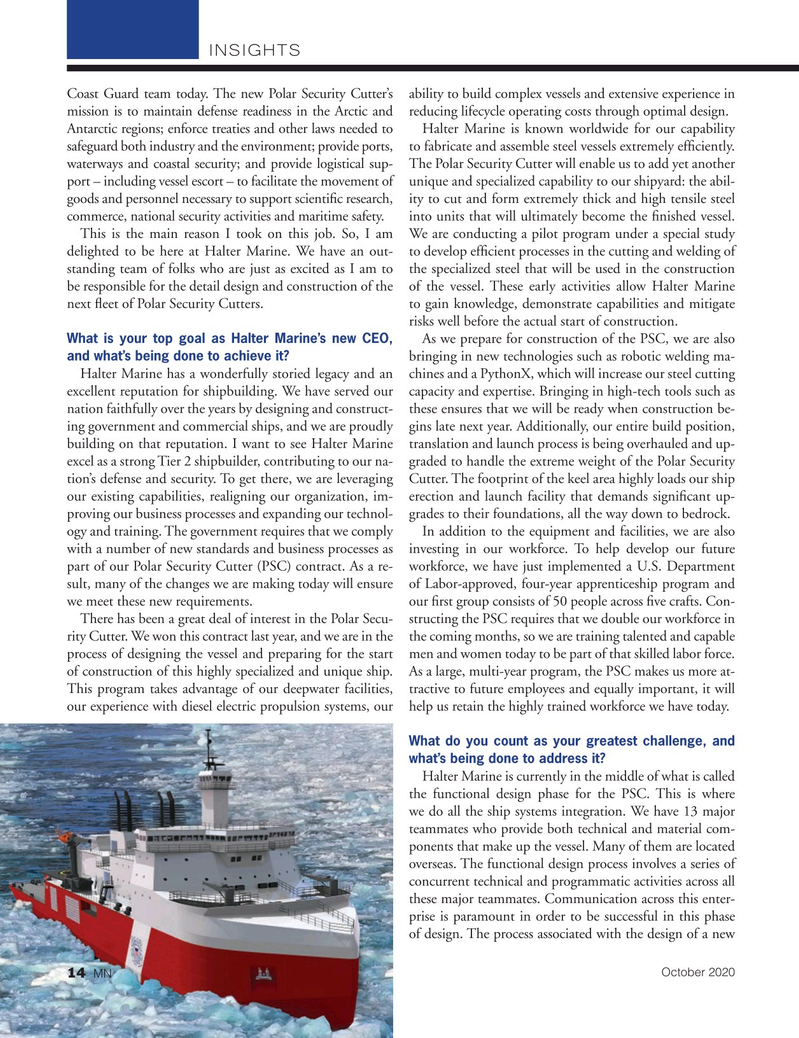

Coast Guard team today. The new Polar Security Cutter’s ability to build complex vessels and extensive experience in mission is to maintain defense readiness in the Arctic and reducing lifecycle operating costs through optimal design.

Antarctic regions; enforce treaties and other laws needed to Halter Marine is known worldwide for our capability safeguard both industry and the environment; provide ports, to fabricate and assemble steel vessels extremely ef? ciently. waterways and coastal security; and provide logistical sup- The Polar Security Cutter will enable us to add yet another port – including vessel escort – to facilitate the movement of unique and specialized capability to our shipyard: the abil- goods and personnel necessary to support scienti? c research, ity to cut and form extremely thick and high tensile steel commerce, national security activities and maritime safety. into units that will ultimately become the ? nished vessel.

This is the main reason I took on this job. So, I am We are conducting a pilot program under a special study delighted to be here at Halter Marine. We have an out- to develop ef? cient processes in the cutting and welding of standing team of folks who are just as excited as I am to the specialized steel that will be used in the construction be responsible for the detail design and construction of the of the vessel. These early activities allow Halter Marine next ? eet of Polar Security Cutters. to gain knowledge, demonstrate capabilities and mitigate risks well before the actual start of construction.

As we prepare for construction of the PSC, we are also

What is your top goal as Halter Marine’s new CEO, bringing in new technologies such as robotic welding ma- and what’s being done to achieve it?

Halter Marine has a wonderfully storied legacy and an chines and a PythonX, which will increase our steel cutting excellent reputation for shipbuilding. We have served our capacity and expertise. Bringing in high-tech tools such as nation faithfully over the years by designing and construct- these ensures that we will be ready when construction be- ing government and commercial ships, and we are proudly gins late next year. Additionally, our entire build position, building on that reputation. I want to see Halter Marine translation and launch process is being overhauled and up- excel as a strong Tier 2 shipbuilder, contributing to our na- graded to handle the extreme weight of the Polar Security tion’s defense and security. To get there, we are leveraging Cutter. The footprint of the keel area highly loads our ship our existing capabilities, realigning our organization, im- erection and launch facility that demands signi? cant up- proving our business processes and expanding our technol- grades to their foundations, all the way down to bedrock.

ogy and training. The government requires that we comply In addition to the equipment and facilities, we are also with a number of new standards and business processes as investing in our workforce. To help develop our future part of our Polar Security Cutter (PSC) contract. As a re- workforce, we have just implemented a U.S. Department sult, many of the changes we are making today will ensure of Labor-approved, four-year apprenticeship program and we meet these new requirements. our ? rst group consists of 50 people across ? ve crafts. Con-

There has been a great deal of interest in the Polar Secu- structing the PSC requires that we double our workforce in rity Cutter. We won this contract last year, and we are in the the coming months, so we are training talented and capable process of designing the vessel and preparing for the start men and women today to be part of that skilled labor force. of construction of this highly specialized and unique ship. As a large, multi-year program, the PSC makes us more at-

This program takes advantage of our deepwater facilities, tractive to future employees and equally important, it will our experience with diesel electric propulsion systems, our help us retain the highly trained workforce we have today.

What do you count as your greatest challenge, and what’s being done to address it?

Halter Marine is currently in the middle of what is called the functional design phase for the PSC. This is where we do all the ship systems integration. We have 13 major teammates who provide both technical and material com- ponents that make up the vessel. Many of them are located overseas. The functional design process involves a series of concurrent technical and programmatic activities across all these major teammates. Communication across this enter- prise is paramount in order to be successful in this phase of design. The process associated with the design of a new

October 2020 14 MN

13

13

15

15