Page 51: of Marine News Magazine (November 2024)

Read this page in Pdf, Flash or Html5 edition of November 2024 Marine News Magazine

quickly, and Walker said momentum pedestal, can extend up to 279 feet. system’s health and performance.” is building. “Since our launch, we’ve “The system is designed to connect to Walker said STAX barges adhere to mobilized multiple barges along the all ship designs without modi? cation, regulations set by the CARB and Oc-

California coast, with eight more in and with its ? exible con? gurations, cupational Safety and Health Adminis- various production stages to meet the STAX can operate even in the most tration (OSHA). “We’ve secured mul- market’s growing needs.” congested ports,” Walker said. tiple CARB Executive Orders (EO) to “We’re looking forward to the arrival “Each barge operates with two treat emissions from auxiliary engines of our third STAX barge in the Port of crewmembers onboard at all times—a on various vessel types, including con-

Hueneme in late October 2024. Two systems operator and a deckhand— tainerships (EO G-23-294) and auto more will be in service by the end of who are responsible for placing the carriers/ro-ros (EO G24-054), and the year, and we’re on track to have 25 emissions collection device, moni- we’re in the ? nal steps of securing an barges servicing the ports of California toring and adjusting the system, and EO for tankers,” he said. “As we ex- by the end of 2025,” Walker said. operating the spuds. The entire op- pand beyond California, we’ll continue “Our biggest challenge today is eration is connected online, allowing collaborating with local authorities to keeping up with the industry’s demand technology, engineering and mainte- ensure compliance with all necessary for a solution like STAX. As regula- nance teams to remotely manage the certi? cations and regulations.” tions tighten and extend to more vessel types, we’ve seen a signi? cant surge in demand. Managing our ? eet of barges across U.S. ports has become an op- erational focus,” Walker said. “We’re hiring rapidly and growing fast to keep pace, building the team needed to help solve this emissions problem at scale.”

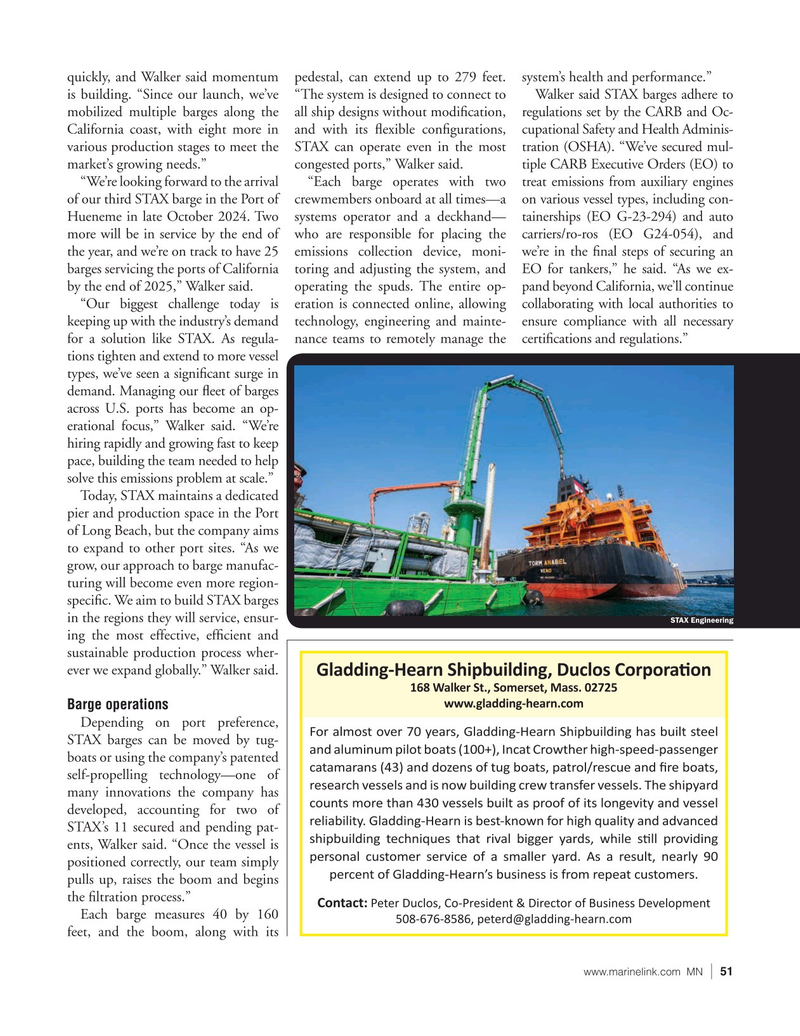

Today, STAX maintains a dedicated pier and production space in the Port of Long Beach, but the company aims to expand to other port sites. “As we grow, our approach to barge manufac- turing will become even more region- speci? c. We aim to build STAX barges in the regions they will service, ensur-

STAX Engineering ing the most effective, ef? cient and sustainable production process wher- ever we expand globally.” Walker said.

'uAEEsYO?,GA?Y^SsÐd?suEsYO??ÐuŽ?Ž?ÐŽ?AOŽY 168 Walker St., Somerset, Mass. 02725 www.gladding-hearn.com

Barge operations

Depending on port preference,

For almost over 70 years, Gladding-Hearn Shipbuilding has built steel

STAX barges can be moved by tug- and aluminum pilot boats (100+), Incat Crowther high-speed-passenger boats or using the company’s patented

ÐAlAwA?AY?;???AYEEŽ?GY?ŽIl?OdŽAl??ÐAl?Žu??G?Ð?GAYEI?GdŽAl??

self-propelling technology—one of research vessels and is now building crew transfer vessels. The shipyard many innovations the company has counts more than 430 vessels built as proof of its longevity and vessel developed, accounting for two of reliability. Gladding-Hearn is best-known for high quality and advanced

STAX’s 11 secured and pending pat- ?SsÐd?suEsYOlGÐSYs??G?lSAl?s|AudsOOG??A?E???SsuG?OuuÐ?Ž|sEsYO ents, Walker said. “Once the vessel is personal customer service of a smaller yard. As a result, nearly 90 positioned correctly, our team simply percent of Gladding-Hearn’s business is from repeat customers.

pulls up, raises the boom and begins the ? ltration process.”

Contact: Peter Duclos, Co-President & Director of Business Development

Each barge measures 40 by 160 508-676-8586, [email protected] feet, and the boom, along with its www.marinelink.com MN 51|

50

50

52

52