Page 57: of Marine News Magazine (November 2024)

Read this page in Pdf, Flash or Html5 edition of November 2024 Marine News Magazine

Top

Tech 225 builds on the success of the Marine System 200, which

Methanol-to-power has been ordered for hydrogen ferries in Norway, for example.

The Marine System 225 is suitable for a wide range of marine vessels, PowerCell said, citing “enhanced power output”, “improved operational ef? ciency” and an “indus- try-leading installation footprint”.

In September, PowerCell received approval in principle (AIP) from DNV for its new cutting-edge Methanol-to-

Power solution, which integrates the PowerCell Marine Sys- tem 225 with a methanol reformer from RIX Industries.

As the maritime sector faces mounting pressure to re- duce emissions, methanol has emerged as a viable alter- native fuel alongside hydrogen, particularly as it is readily available in many major ports worldwide. This innovative system converts methanol into hydrogen for use in a fuel

PowerCell cell, offering a clean and ef? cient energy source.

In June, Sweden-based PowerCell introduced its Marine DNV’s approval af? rms that the design meets rigorous

System 225, which it describes as powerful, yet compact and safety standards, paving the way for more sustainable op- advanced maritime power generation system. Designed with erations in the maritime sector, as both companies strive to the company’s fuel cell stack platform, the new Marine System support the industry’s transition toward decarbonization.

tem that will provide zero-carbon power to the vessel’s elec-

Ammonia-powered Tugboat Sets Sail tric motors. Ammonia, which does not emit CO2 when used as a fuel, has been gaining interest in the maritime in- dustry as stakeholders explore options to decarbonize vessel operations. Green ammonia produced with renewable en- ergy results in zero well-to-wake greenhouse gas emissions.

The demonstration sailing, performed on a tributary of the Hudson River, upstream from New York City, proves

Amogy both the viability of Amogy’s technology and marks a sig-

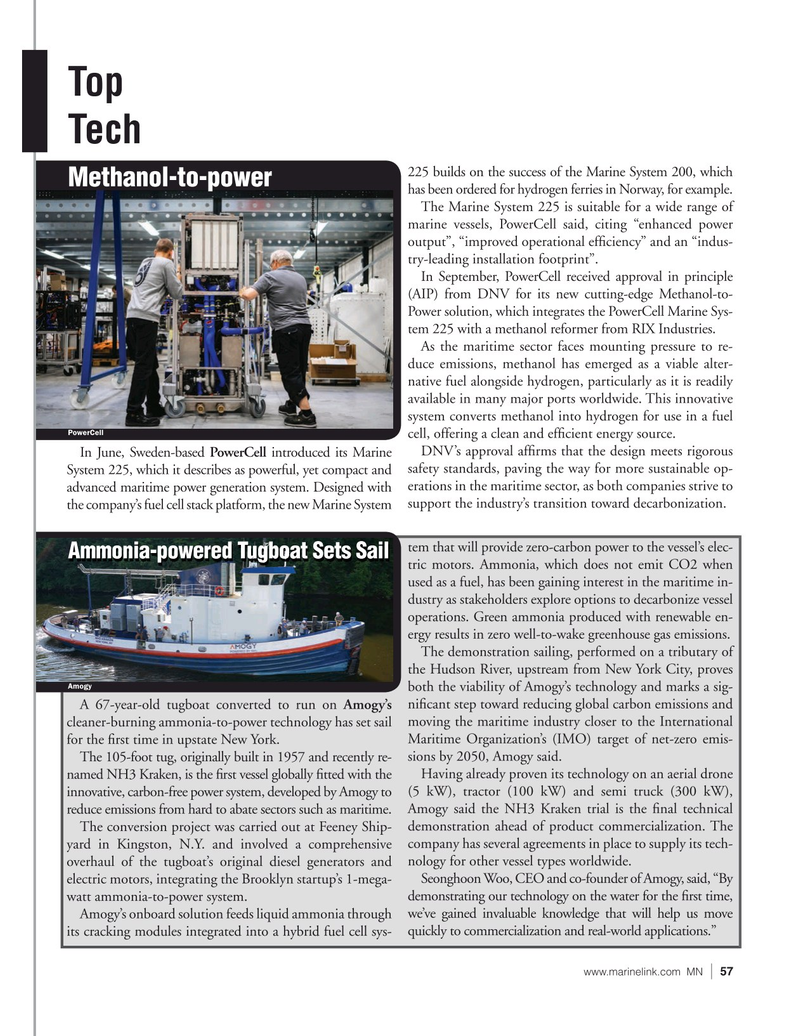

A 67-year-old tugboat converted to run on Amogy’s ni? cant step toward reducing global carbon emissions and cleaner-burning ammonia-to-power technology has set sail moving the maritime industry closer to the International for the ? rst time in upstate New York. Maritime Organization’s (IMO) target of net-zero emis-

The 105-foot tug, originally built in 1957 and recently re- sions by 2050, Amogy said. named NH3 Kraken, is the ? rst vessel globally ? tted with the Having already proven its technology on an aerial drone innovative, carbon-free power system, developed by Amogy to (5 kW), tractor (100 kW) and semi truck (300 kW), reduce emissions from hard to abate sectors such as maritime. Amogy said the NH3 Kraken trial is the ? nal technical

The conversion project was carried out at Feeney Ship- demonstration ahead of product commercialization. The yard in Kingston, N.Y. and involved a comprehensive company has several agreements in place to supply its tech- overhaul of the tugboat’s original diesel generators and nology for other vessel types worldwide.

electric motors, integrating the Brooklyn startup’s 1-mega- Seonghoon Woo, CEO and co-founder of Amogy, said, “By watt ammonia-to-power system. demonstrating our technology on the water for the ? rst time,

Amogy’s onboard solution feeds liquid ammonia through we’ve gained invaluable knowledge that will help us move its cracking modules integrated into a hybrid fuel cell sys- quickly to commercialization and real-world applications.” www.marinelink.com MN 57|

56

56

58

58