Page 37: of Marine News Magazine (July 2025)

Read this page in Pdf, Flash or Html5 edition of July 2025 Marine News Magazine

US Shipbuilding

The Trump Effect training is a challenge for smaller ? rms.” and dense machinery spaces, all built during the pandemic

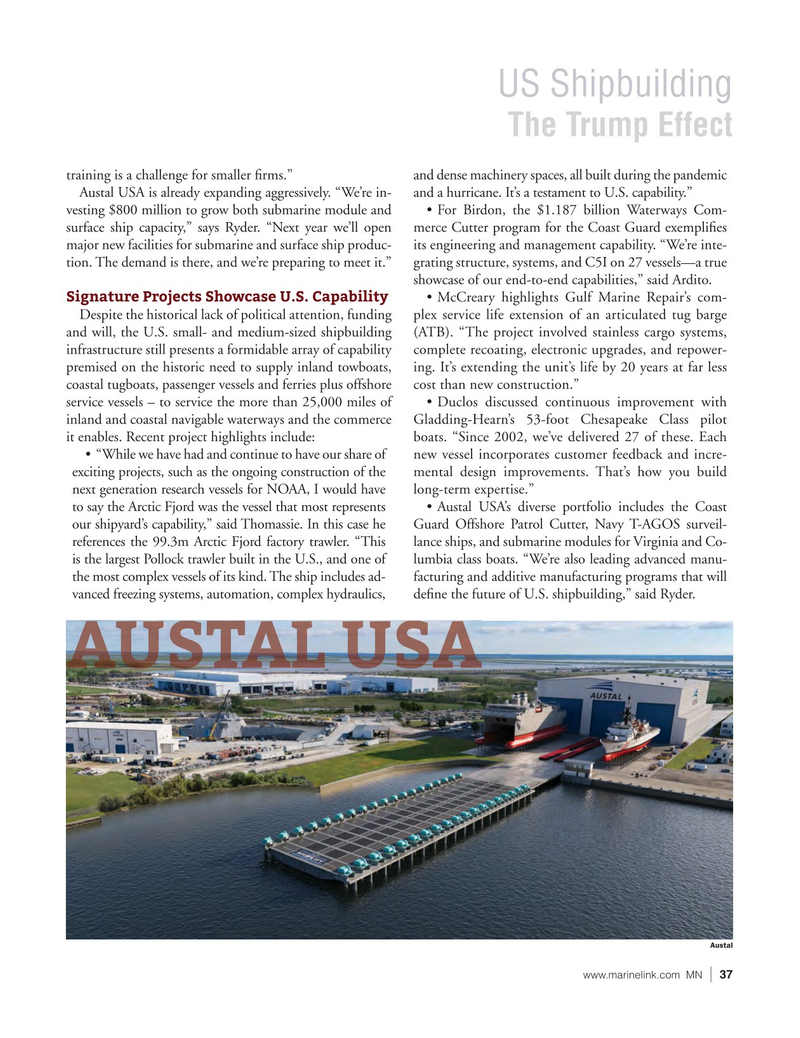

Austal USA is already expanding aggressively. “We’re in- and a hurricane. It’s a testament to U.S. capability.” vesting $800 million to grow both submarine module and • For Birdon, the $1.187 billion Waterways Com- surface ship capacity,” says Ryder. “Next year we’ll open merce Cutter program for the Coast Guard exempli? es major new facilities for submarine and surface ship produc- its engineering and management capability. “We’re inte- tion. The demand is there, and we’re preparing to meet it.” grating structure, systems, and C5I on 27 vessels—a true showcase of our end-to-end capabilities,” said Ardito.

Signature Projects Showcase U.S. Capability • McCreary highlights Gulf Marine Repair’s com-

Despite the historical lack of political attention, funding plex service life extension of an articulated tug barge and will, the U.S. small- and medium-sized shipbuilding (ATB). “The project involved stainless cargo systems, infrastructure still presents a formidable array of capability complete recoating, electronic upgrades, and repower- premised on the historic need to supply inland towboats, ing. It’s extending the unit’s life by 20 years at far less coastal tugboats, passenger vessels and ferries plus offshore cost than new construction.” service vessels – to service the more than 25,000 miles of • Duclos discussed continuous improvement with inland and coastal navigable waterways and the commerce Gladding-Hearn’s 53-foot Chesapeake Class pilot it enables. Recent project highlights include: boats. “Since 2002, we’ve delivered 27 of these. Each • “While we have had and continue to have our share of new vessel incorporates customer feedback and incre- exciting projects, such as the ongoing construction of the mental design improvements. That’s how you build next generation research vessels for NOAA, I would have long-term expertise.” to say the Arctic Fjord was the vessel that most represents • Austal USA’s diverse portfolio includes the Coast our shipyard’s capability,” said Thomassie. In this case he Guard Offshore Patrol Cutter, Navy T-AGOS surveil- references the 99.3m Arctic Fjord factory trawler. “This lance ships, and submarine modules for Virginia and Co- is the largest Pollock trawler built in the U.S., and one of lumbia class boats. “We’re also leading advanced manu- the most complex vessels of its kind. The ship includes ad- facturing and additive manufacturing programs that will vanced freezing systems, automation, complex hydraulics, de? ne the future of U.S. shipbuilding,” said Ryder.

SS

Austal www.marinelink.com MN 37|

36

36

38

38